Polygomma: EPDM Membrane- the most preferred Single-Ply Sustainable Waterproofing Systems

Give us a brief background of Polygomma Industries Pvt. Ltd.

Polygomma is a part of the 50+ year old Vora Group of companies. Our group is manufacturing products such as anti-corrosive rubber linings, industrial valves, P.T.F.E products, and EPDM waterproofing membranes and pond liners. The group has been manufacturing EPDM waterproofing membranes for more than 20 years at our old factory in Mumbai. However, due to the increase in demand for EPDM waterproofing membranes from India as well as abroad, we have commissioned our new production facility viz Polygomma Industries Pvt. Ltd. This 50,000 sqft. production facility manufactures world-class EPDM waterproofing membranes and pond liners, in accordance with globally accepted product standards.

What are the issues and challenges confronting the waterproofing sector?

The waterproofing industry in India is at a nascent stage. Knowledge and awareness of newer technologies & products is limited and is rarely passed on to the customer. Many projects are against trying new technologies, and prefer to carry on with the age-old traditional waterproofing systems. However, with the entry of many multinationals, as well as the emergence of Indian waterproofing companies, the industry is more open to new technologies, than what it was 5 years ago. The key decision makers often use a product based on its brand value, instead of the techno-commercial benefits of the products.

Inspite of having so many waterproofing systems in India, why do you think that waterproofing is still an issue?

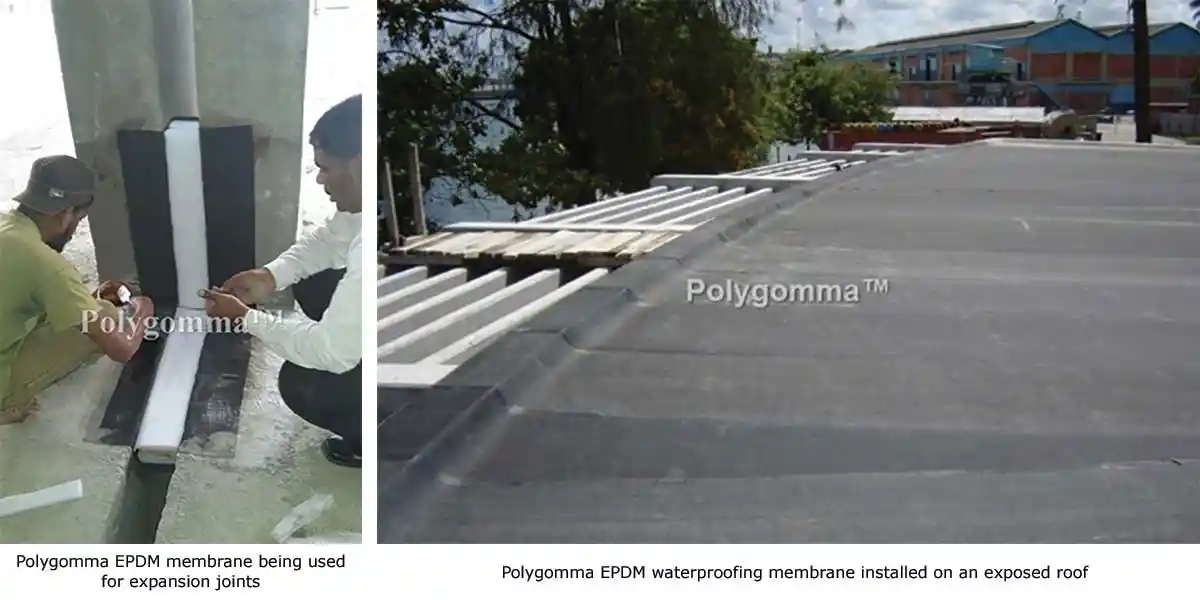

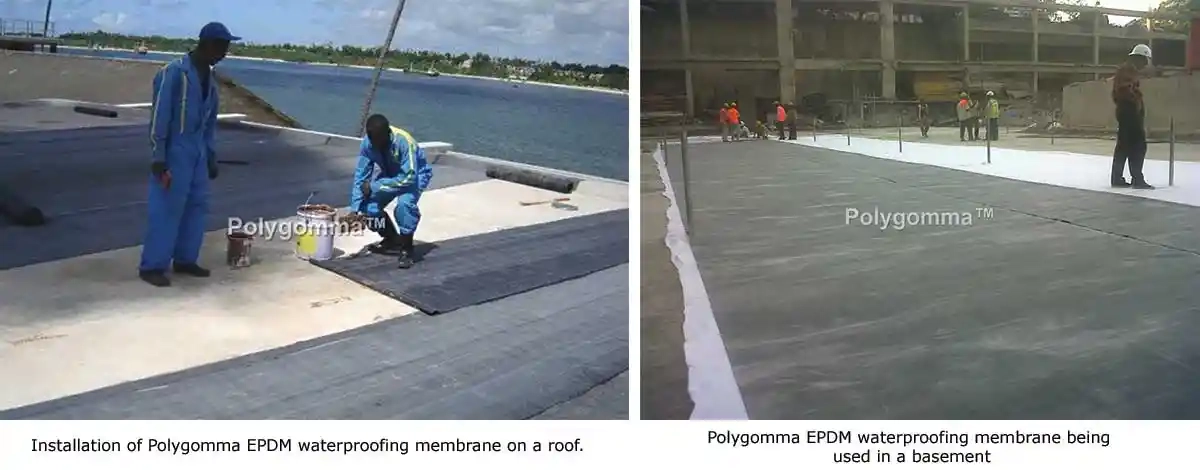

There are two types of waterproofing systems used in India: traditional systems and non-traditional systems. Traditional ones would include brick bat coba, box type waterproofing, various coatings, bitumen-based membranes, etc. The non-traditional would include all other types of waterproofing systems such as advanced crystalline materials, TPO membranes, PVC membranes, etc, including EPDM membranes. Generally, projects use multiple types of waterproofing. The basic chemistry of the material on which the selected waterproofing system is based, is completely ignored. For example, the tiles used for box type waterproofing systems in basements are brittle in nature, and tend to crack upon building settlement. This gives rise to server leakage. Other systems such as brick bat coba, bitumen-based membranes or waterproofing coatings, either add tremendous load on the structure, or they are made out of unsaturated materials, which react with the chemical environment and tend to degrade over a period of time. The EPDM rubber used to manufacture our waterproofing membranes is a saturated polymer. There are no reactive bonds available. This is why EPDM membranes are known to have a life of more than 40 years even in exposed conditions. Globally, EPDM membranes are the most preferred single-ply waterproofing systems for over 4 decades. Besides our EPDM, membranes can be used to waterproof almost all areas of a building such as basements, podiums/landscape areas, terraces/roofs, swimming pools, expansion joints, etc. A single system for the entire project is much better than multiple systems.

With a life expectancy of over 40 years, EPDM membranes are the most preferred single-ply waterproofing systems. They are not only easy, quick and safer to use but also eco-friendly, recyclable and resistant to UV, ozone and chemicals.

What are the advantages that your products have over the traditionally used waterproofing materials or systems in India?

The Polygomma EPDM waterproofing membranes are UV & ozone-resistant. They can perform as required for over 40 years even in exposed conditions. The EPDM waterproofing membranes are single ply. Hence, the performance and the thickness across the cross section are uniform. This is not true for most bitumen-based waterproofing membranes, and waterproofing coatings. The bitumen-based membranes are multi-ply, and have a risk of inter-ply de-bonding and blisters. The various waterproofing coatings are generally applied by a brush or a spray gun. It is very difficult to get a uniform thickness across the entire area where it is applied. There are no torches or flames required during the application of our EPDM membranes. This makes the application process safe and quick. Most importantly, our EPDM waterproofing membranes are chemical-resistant. The rain water is mostly acidic (pH<7). Our membranes perform well even in acidic and corrosive environments. This probably is the reason why many waterproofing systems fail. We also manufacture EPDM membranes of 6 meters of width and length of 30 meters with factory seams. This makes installation of large areas such as basements quick and easy.

Our products have the quality certification of various global markets such as CE, GOST-R, etc. We have tied up with applicator companies in each zone of India offering their services or guidance to the projects using our products.

Our EPDM membranes are also used as pond liners, where water is stored 24X7, for a year. When a product can serve well in such service conditions, it is bound to do well in waterproofing of a building, where it will come in contact with water, probably during the monsoons.

With the advent of modern and greener construction techniques and practices, more advanced waterproofing solutions are making their way into the country. Please highlight the applications and features of your innovative products in terms of sustainability, energy-efficiency, environment and user-friendly, and so forth.

We, at Polygomma, truly believe that we need to provide products that are eco-friendly. The technology at our new factory enables us to manufacture EPDM membranes without emitting any pollution. No air or water is polluted during the entire manufacturing process. This makes our EPDM membranes a lot more eco-friendly than other waterproofing systems. Also, the EPDM membranes can be recycled at the end of its use, causing almost zero waste during its lifetime.

Besides waterproofing, what are the other uses of your products?

We manufacture two grades of EPDM products, the EPDM waterproofing membranes, which are used for waterproofing of buildings, and EPDM pond liners. The Polygomma EPDM pond liners can be used in artificial lakes, golf courses, ponds, water storage pits, canals, etc. Our pond liners are aquatic-friendly, so they can also be used for pond used for fish farming or in ponds used to breed aquatic animals. The life expectancy of the EPDM pond liners is much higher than the conventional pond liners which are made using plastics such as HDPE, etc.

Tell us about your company's focus on research & development, quality control systems, and applicator training program.

Our R&D department is continuously working to make our products better. We strive to make such products that will give us an advantage over other global manufacturers of EPDM membranes and pond liners. In fact, within almost a year of commissioning of our new production facility, our products already have an advantage over other global manufacturers in more ways than one. To ensure the quality of our products, they are manufactured strictly as per their relevant ASTM and EN product standards. Our products also have the quality certification of various global markets where we sell, such as CE, GOST-R, etc. We have tied up with applicator companies in each zone of India offering their services or guidance to the projects using our products.

NBM&CW February 2017