SPAX International: A Quality Manufacturer of Screw

We are getting a good response from the Indian markets and we have just started our operations and are focusing site demonstrations in the beginning." says Mr. Ajay Khashu, Regional Sales Manager (Indian Operation), Spax India International in an interview with MGS Architecture.

Please tell us something about SPAX global operations, its manufacturing facilities and their locations, and products turned out.

At SPAX, craftsmanship and high-tech combine. Engineers, tool manufacturing and production staff all work in perfect harmony. The result is a branded product of the highest quality. Most of all, we focus on the individual needs of the customer. That's why SPAX produces countless product variations, all tailored to the differing requirements of our customers in industry, trade and DIY. Doing it yourself all specially manufactured and packaged. Our approach to optimum customer service insists on constant availability for delivery and comprehensive product information. The high level of customer satisfaction proves us right.

What are areas of applications of SPAX products?

Is it possible to enumerate one or two success stories, where SPAX products have been used in challenging conditions outside India?

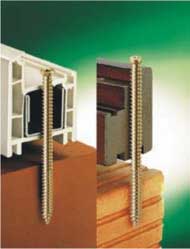

As in the case of the Heide Park Soltau, construction is being carried out by Messrs Ingenieur Holzbau Cordes in co-operation with Merk Holzbau & Intamin Swiss with the engineering consultants Stengel Munich providing the design and structural analysis. SPAX 8X300mm full threaded screws with the general construction approval Z-9.1-519 are being used for the 1sttime to create the so called transverse reinforcement. Unavoidable cracks and splitting of the timber at the round press in plug locations can lead to a drop in load capacity. To counteract this eventuality the screws reinforce the timber vertical to the direction of grain flow i.e. in the direction in which the timber displays its weakest tensile properties. By adopting this approach, it is generally expected that numerous small cracks will appear and not the large one, a factor that has a favorable effect on load bearing capacity.

Where does India fit in Spax International market strategy?

Of the extensive products range, is it possible to give example of new innovative materials suitable to Indian conditions?

What has been the response of Indian market towards products marketed by Spax International so far?

We are getting a positive response from the market of India. We have just started our operations and are focusing on site demonstrations in the beginning.

What are the plans at hand to promote these products aggressively in Indian market?

Uncompromised quality and absolute customer orientation are at the heart of both the company philosophy and its formula for success. It all starts with the development of the innovative machinery and complex systems used for screw manufacturing by ABC's group of companies itself. This, and years of experience, give the company its insurmountable competitive edge over competitors and imitators. Qualifications and further training measures for employees are very much central to the company's strategy. After all, a good product can only be manufactured by qualified and satisfied employees. That's why we employ long-standing, well-trained staff, who have learned their trade inside-out so as to keep pace with rapid technological development. At SPAX, craftsmanship and high-tech combine. Engineers, tool manufacturing and production staff all work in perfect harmony. The result is a branded product of the highest quality. Most of all, we focus on the individual needs of the customer. That's why SPAX produces countless product variations, all tailored to the differing requirements of our customers in industry, trade and DIY, all specially manufactured and packaged. Our approach to optimum customer service insists on constant availability for delivery and comprehensive product information. The high level of customer satisfaction proves us right.

MGS Architecture March April 2009