Production of Self–compacting Concrete Using Crusher Rock and Marble Sludge Dusts

M. Shahul Hameed, Faculty & Research Scholar, Dept. of Civil Engg., Sethu Institute of Technology, Kariapatti; P. Kathirvel, Faculty & Research Scholar, Dept. of Civil Engg., KLN College of Engg., Madurai, and Dr. A.S.S. Sekar, Asst. Professor, Dept. of Civil Engg., Alagappa Chettiyar College of Engg. & Tech., Karaikudi

For many decades, concrete has largely been used as a construction material, whether in moderate aggressive environment, or in strong aggressive environment. By volume alone, concrete is the world's most important construction material. Self–compacting Concrete (SCC) as the name implies that the concrete requiring a very little or no vibration to fill the form homogeneously. SCC is defined by two primary properties: Ability to flow or deform under its own weight (with or without obstructions) and the ability to remain homogeneous while doing so. The study explores the use of marble sludge dust (MSD) and crusher rock dusts (CRD) to increase the amount of fines and hence achieve self-compactibility in an economical way, suitable for Indian construction industry. The study focuses on comparison of fresh properties of SCC containing varying amounts of MSD and CRD with that containing commercially available viscosity modifying admixture. The comparison is done at different dosages of superplasticizer keeping cement, water, coarse aggregate, and fine aggregate contents constant. Test results substantiate the feasibility to develop low cost SCC using MSD and CRD.

The self-compacting concrete differs from conventional concrete in the following three characteristic features, namely, (i) appropriate flowability, (ii) non-segregation, and (iii) no blocking tendency. An increase in the flowability of concrete is known to increase the risk of segregation. Therefore, it is essential to have a proper mix design. This paper reports the results of an investigation into the development of low-bleeding self-compacting concrete. V-Funnel test is used to assess the flowability and segregation resistance of the self-compacted concrete.

Ordinary Portland Cement (43 Grade) with 28% normal consistency with specific surface 3300 cm2/g Conforming to IS: 8112-1989 was used.

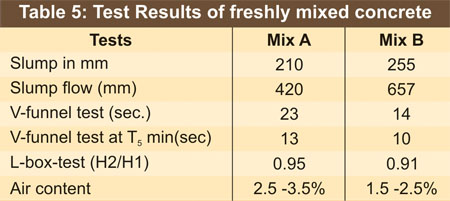

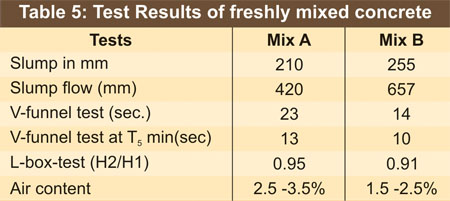

Properties of freshly mixed concrete were tested for qualifying within the specified EFNARC range of SCC [3] and given in Table 5. The slump flow of Mix B was 657 mm within the EFNARC range of SCC. The results of slump flow show that the flow increased with the increase in the quantity of fine particle. As far as filling ability of the Mix B, results of V - funnel tests remained more towards the minimum range or even lesser. This showed more filling ability but less viscous mix. Due to the very low w/b-ratio and the very high fineness of Marble sludge dust and crusher rock dust the viscosity of the SCC is obviously higher than that of conventional concrete. The air content is therefore somewhat higher than in conventional concrete. While testing the concrete for passing ability, majority of the mixes passed through the bars very easily and without any blockage. The results of L-box test show that the ratio of L-box increased with the increase of marble sludge dust. V - Funnel at T5 minutes test shows the potential to segregation resistance. V - funnel at T5minutes test results for Mix A and Mix B are 13 sec and 10 sec respectively. The results of this test remained very encouraging and within the EFNARC range.

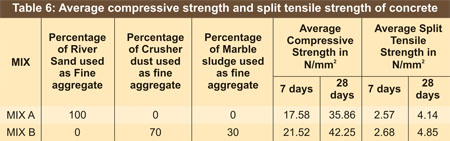

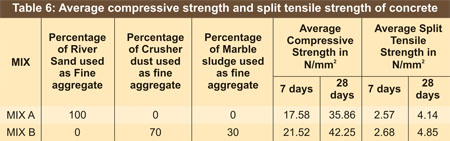

The 7 days and 28 days compressive strength of SCC is increasing up to 21.52 N/mm2 and 42.25 N/mm2 respectively. Whereas, the conventional concrete, the 7 days and 28 days compressive strength is 17.58 N/mm2 and 35.86 N/mm2 respectively. The test results of 7 days and 28 days compressive strength is given in Table 6. CRD and MSP reduce the pore structure of concrete results improve the strength of concrete. The crusher rock particles have greater rough surface than river sand. The rough surface improves the bond strength. Hence, a SCC concrete specimen made with crusher rock dust gives greater compressive strength.

For many decades, concrete has largely been used as a construction material, whether in moderate aggressive environment, or in strong aggressive environment. By volume alone, concrete is the world's most important construction material. Self–compacting Concrete (SCC) as the name implies that the concrete requiring a very little or no vibration to fill the form homogeneously. SCC is defined by two primary properties: Ability to flow or deform under its own weight (with or without obstructions) and the ability to remain homogeneous while doing so. The study explores the use of marble sludge dust (MSD) and crusher rock dusts (CRD) to increase the amount of fines and hence achieve self-compactibility in an economical way, suitable for Indian construction industry. The study focuses on comparison of fresh properties of SCC containing varying amounts of MSD and CRD with that containing commercially available viscosity modifying admixture. The comparison is done at different dosages of superplasticizer keeping cement, water, coarse aggregate, and fine aggregate contents constant. Test results substantiate the feasibility to develop low cost SCC using MSD and CRD.

Introduction

Owing to all its properties, use of SCC is constantly increasing all over the world. But the adoption has not been as fast as it should have been due to its higher cost of production. In India, SCC is used in limited owing to lack of awareness and the higher costs associated with its production. SCC is defined by two primary properties: Deformability and Segregation resistance. Deformability or flowability is the ability of SCC to flow or deform under its own weight (with or without obstructions). Segregation resistance or stability is the ability to remain homogeneous while doing so. High range water reducing admixtures are utilized to develop sufficient deformability. At the same time, segregation resistance is ensured, which is accomplished either by introducing a chemical VMA or by increasing the amount of fines in the concrete. These viscosity modifying admixtures are very expensive and the main cause of increase in the cost of SCC. Self-compacting Concrete is considered to be the most promising building material for the expected revolutionary changes at the job sites as well as on the desk of designers and civil engineers. However, the basic principles of this material are substantially based on those of flowing, cohesive, and superplasticized concretes developed in the mid of 1970's. The necessary ingredients for manufacturing SCC are superplasticizers and powder materials (including cement, fly ash, ground fillers or other mineral additions even in the form of fine recycled aggregate) at an adequate content (> 400 kg/m3 of cement and filler), with some limits in the maximum size of the coarse aggregate (< 25 mm).The self-compacting concrete differs from conventional concrete in the following three characteristic features, namely, (i) appropriate flowability, (ii) non-segregation, and (iii) no blocking tendency. An increase in the flowability of concrete is known to increase the risk of segregation. Therefore, it is essential to have a proper mix design. This paper reports the results of an investigation into the development of low-bleeding self-compacting concrete. V-Funnel test is used to assess the flowability and segregation resistance of the self-compacted concrete.

Self-compacting High Performance Concrete

The prototype of SCC was first completed in 1988 using materials already on the market. The prototype performed satisfactorily with regard to drying and hardening shrinkage, heat of hydration, denseness after hardening, and other properties and was named "High Performance Concrete." Since then, the term high performance concrete has been used around the world to refer to high durability concrete. Therefore, Okamura [1] has changed the term for the proposed concrete to "Self-compacting High Performance Concrete" (SCHPC) and this was defined as follows at the three stages of concrete:- Fresh : Self–compactable.

- Early age : avoidance of initial defects.

- After hardening : Protection against external factors.

- High strength

- Minimum shrinkage and creep

- High durability

- Easy to cast

- Cost effective.

The Role of Superplasticizers and Powder Materials

With the advent of superplasticizers, flowing concretes with slump level up to 250 mm were manufactured with no or negligible bleeding, provided that an adequate cement factor was used [3]. The slump was increased by increasing the amount of mixing water. When the slump is over 175 mm the bleeding increases too much and this was the reason why ACI in 1973 did not recommend slump higher than 175 mm [4]. The most important basic principle for flowing and cohesive concretes including SCCs is the use of superplasticizer combined with a relatively high content of powder materials in terms of portland cement, mineral additions, ground filler and/or very fine sand.Characterisation of Wastes Marble Sludge Powder and Quarry Rock Dust

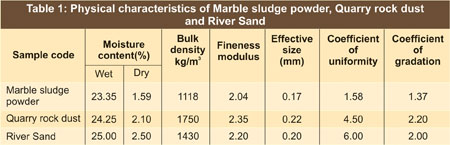

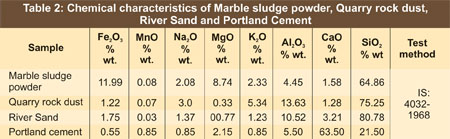

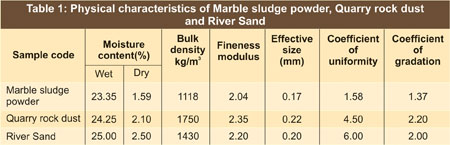

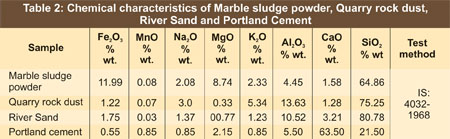

The physical characteristics of the waste are furnished in Table 1. The fineness modulus of marble sludge powder and quarry rock dust is comparable to that of fine sand of F.M. 2.2 to 2.6. The coefficient of uniformity for fine sand generally should be less than 6. Similarly the coefficient of gradation should be between 1 and 3 for fine sand. The chemical characteristics of the River sand, Marble sludge powder and Quarry rock dust are furnished in Table 2. The chemical characteristics are compared with the oxide composition of ordinary Portland cement.

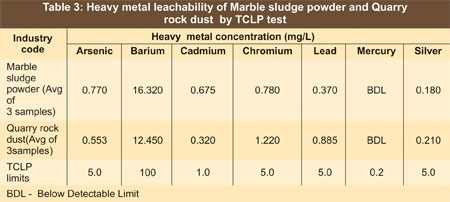

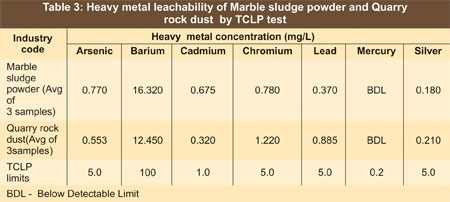

Heavy Metal Leachability of the Waste

The waste is of inorganic type with heavy metal concentration in the TCLP extract of the marble sludge powder and quarry rock dust are as shown in Table 3. The heavy metals concentration of As, Ba, Cd, Cr, Hg, Pb and Ag are within the acceptable limits as specified by USEPA. The results indicate that there won't be any impact on the leachability of waste.

Raw Materials and Test Methods

Cement

Ordinary Portland Cement (43 Grade) with 28% normal consistency with specific surface 3300 cm2/g Conforming to IS: 8112-1989 was used.

Marble Sludge Powder

Marble sludge powder was obtained in wet form directly from deposits of Marble factories. Wet Marble sludge powder must be dried before the sample preparation. Marble dust was sieved from 1mm sieve. The high content of CaO confirmed that the original stones were Marble and limestone. The dust was also tested (NP 85) to identify the absence of organic matter, thus confirming that it could be used in concrete mixtures.Quarry Rock Dust

The quarry rock dust was obtained from a local crusher at Kariapatti, in District Virudunagar. The specific gravity of the quarry rock dust used was 2.677. Moisture content and bulk density of waste are less than the sand properties.Fine Aggregate

Medium size sand from Madurai Vaigai river with a modulus of fineness = 2.20; Specific gravity 2.677, normal grading with the silt content 0.8%.Coarse Aggregate

Crushed stone from Madurai district with a size of 5-20 mm and normal continuous grading was used. The content of flaky and elongated particles is < 3%, the crushing index d"6% and the specific gravity 2.738.Water

Tap water available in the concrete laboratory was used in manufacturing the concrete. The qualities of water samples are uniform and potable.Super Plasticizer

A superplasticizer based on refined lingo Sulphonates, 'Roff Superplast 320' was used to get and preserve the designed workability.Mix Proportion of Concrete

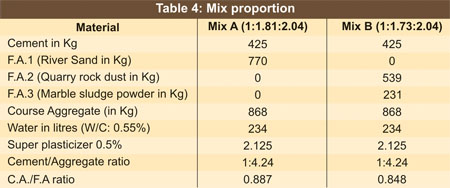

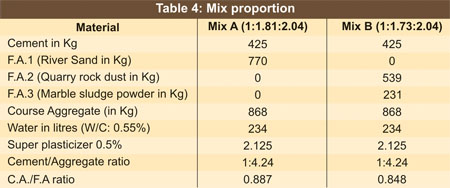

For Durability Studies the Indian Standard mix Proportion (by weight) used in the mixes of Conventional Concrete and green concrete were fixed as 1:1.81:2.04, 1:1.73:2.04 after several trials. Based on properties of raw materials, two different mix proportions are taken and given in Table 4. Mix A is the controlled concrete using river sand and Mix B is the green concrete using Industrial waste (50% quarry rock dust and 50% marble sludge powder) as fine aggregate. The water/cement ratio for both the mixes was 0.55% by weight. Water reducing admixture was used to improve the workability and its dose was fixed as 250 m1/50kg of cement.

Testing of Specimens

For each mix, slump flow, L-box and V-funnel test were carried out. Brief explanation and illustration of Slump flow, L-Box and V-funnel test is given below.Slump Flow Test

It is the most commonly used test and gives a good assessment of filling ability. At first, the inside of slump cone and the smooth leveled surface of floor on which the slump cone is to be placed are moistened. The slump cone is held down firmly. The cone is then filled with concrete. No tamping is done. Any surplus concrete is removed from around the base of the concrete. After this, the cone is raised vertically and the concrete is allowed to flow out freely. The diameter of the concrete in two perpendicular directions is measured. The average of the two measured diameters is calculated. This is the slump flow in mm. The higher the slump flow value, the greater its ability to fill formwork under its own weight. As per EFNARC guide, the range is from 650 mm to 800 mm [5].

|

|

L Box Test Method

It assesses filling and passing ability of SCC. The vertical section is filled with concrete, and then gate lifted to let the concrete flow into the horizontal section. When the flow has stopped, the heights 'H1' and 'H2' are measured. Closer to unity value of ratio 'H2/H1' indicates better flow of concrete [5].

|

|

V-funnel Test And V-funnel At T=5 Min

The test measures flowability and segregation resistance of concrete. At first, the test assembly is set firmly on the ground and the inside surfaces are moistened. The trap door is closed and a bucket is placed underneath. Then the apparatus is completely filled with concrete without compacting. After filling the concrete, the trap door is opened and the time for the discharge is recorded. This is taken to be when light is seen from above through the funnel. To measure the flow time at T–5minutes, the trap door is closed and V-funnel is refilled immediately. The trap door is opened after 5 minutes and the time for the discharge is recorded. This is the flow time at T–5minutes. Shorter flow time indicate greater flowability [5].

|

|

Compressive Strength Test

Compressive strength test usually gives an overall picture of the quality of concrete because strength is directly related to the structure of the hydrated cement paste. The compression test is an important concrete test to determine the strength development of the concrete specimens. Compressive strength tests (BS 1881: Part 103: 1983) were performed on the cube specimens at the ages of 7, 28 and 90 days.

|

|

Split Tensile Strength Test

The indirect method of applying tension in the form of splitting was conducted to evaluate the effect of MSP and CRD on tensile properties of concrete. The split tensile strength is a more reliable technique to evaluate tensile strength of concrete (lower coefficient of variation) compared to other methods. The split tensile strength of 150 mm diameter and 300 mm high concrete cylindrical specimens was determined to assess the effect of CRD and MSP on the tensile properties of the concrete.

|

|

Test Results and Discussions

Fresh Flow Property

Properties of freshly mixed concrete were tested for qualifying within the specified EFNARC range of SCC [3] and given in Table 5. The slump flow of Mix B was 657 mm within the EFNARC range of SCC. The results of slump flow show that the flow increased with the increase in the quantity of fine particle. As far as filling ability of the Mix B, results of V - funnel tests remained more towards the minimum range or even lesser. This showed more filling ability but less viscous mix. Due to the very low w/b-ratio and the very high fineness of Marble sludge dust and crusher rock dust the viscosity of the SCC is obviously higher than that of conventional concrete. The air content is therefore somewhat higher than in conventional concrete. While testing the concrete for passing ability, majority of the mixes passed through the bars very easily and without any blockage. The results of L-box test show that the ratio of L-box increased with the increase of marble sludge dust. V - Funnel at T5 minutes test shows the potential to segregation resistance. V - funnel at T5minutes test results for Mix A and Mix B are 13 sec and 10 sec respectively. The results of this test remained very encouraging and within the EFNARC range.

Hardened Mixture Properties

Compressive Strength Test

The 7 days and 28 days compressive strength of SCC is increasing up to 21.52 N/mm2 and 42.25 N/mm2 respectively. Whereas, the conventional concrete, the 7 days and 28 days compressive strength is 17.58 N/mm2 and 35.86 N/mm2 respectively. The test results of 7 days and 28 days compressive strength is given in Table 6. CRD and MSP reduce the pore structure of concrete results improve the strength of concrete. The crusher rock particles have greater rough surface than river sand. The rough surface improves the bond strength. Hence, a SCC concrete specimen made with crusher rock dust gives greater compressive strength.

Split Tensile Strength Test

The 7 days and 28 days split tensile strength is increasing up to 2.68 N/mm2 and 4.85 N/mm2 respectively for SCC. The split tensile strength for conventional concrete is 2.57 N/mm2 and 4.14 N/mm2. The test results of 7 days and 28 days compressive strength and split tensile strength is given in table 6.When comparing the SCC with normal concrete there is much improvement in split tensile strength value. MSP improves the flow property value. But, when MSP percentage increases beyond 15%, the strength reduced.Cost Analysis

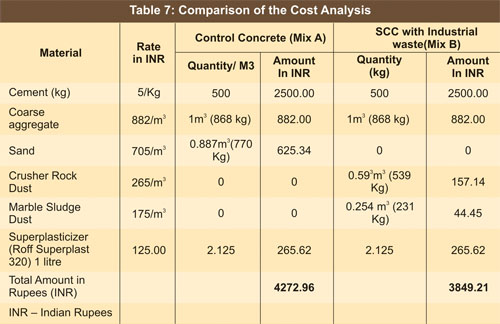

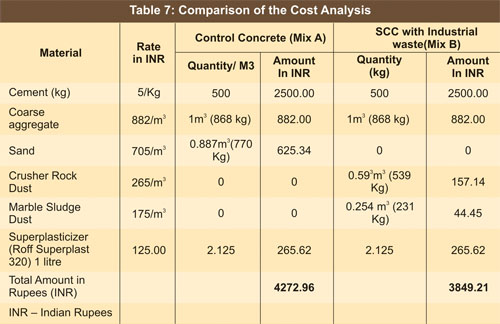

Cost analysis of the materials used, has been analyzed as per the purchased price from the market (as on June 2009). The mixes selected for calculation and analysis were those which could pass maximum properties of freshly mixed concrete. The detailed calculations are summarized in Table 7. It is clear that the cost of ingredients of specific SCC containing MSD and CRD is Rs.3849.10 only, which is 9.91% less than the control concrete.

Conclusion

Throughout the world, the waste disposal costs have escalated greatly. At the same time, the concrete construction industry has realized that Marble Sludge Dust and Crusher Rock Dust are relatively inexpensive and widely available by-product that can be used for sand replacement to achieve excellent workability in fresh concrete mixtures. These materials can be used in the manufacturing of economical SCC in different ways. When the crusher rock dust and marble sludge dust were used as replacement of sand, the requirements of expensive chemicals such as HRWRA and viscosity modifying agent (VMA) decreased. Based on field experience and laboratory tests, the properties of SCC, when compared to conventional portland cement concrete, can be summarized as follows:- The possibility of developing low cost SCC using crusher rock and marble sludge dusts is feasible. Low cost SCC can be made, by incorporating these industrial waste by replacing the river sand.

- The utilization of MSD and CRD in SCC solves the problem of its disposal thus keeping the environment free from pollution and enhance the resource productivity of the concrete construction industry.

- The chemical compositions of Crusher dust and Marble sludge such as Fe2O3, MnO, Na2O, MgO, K2O, Al2O3, CaO, and SiO2 are comparable with that of cement.

- The replacement of fine aggregate with 30% marble sludge and 70% Crusher dust (Mix B) gives an excellent result in strength aspect and quality aspect. It induced higher compressive strength, higher splitting tensile strength

- The results showed that the substitution of 70% of the crusher and 30% of marble sludge induced easier flowability, pumpability, and compactability.

- Early-strength up to 7 days, which can be accelerated with suitable changes in the mix design when earlier removal of formwork or early structural loading is desired.

- In fresh state, some of the mix results values were out of the EFNARC range and therefore before casting the concrete, the properties of freshly mixed concrete must be checked for SCC.

References

- Okamura, H. and Ouchi, M., (1999). "Self-compacting concrete- development, present and future", Proceedings of the First International RILEM symposium on Self-Compacting Concrete, pp.3-14.

- Zhu W., Gibbs C J., and Bartos P J M., (2001). "Uniformity of in situ properties of self compacting concrete in full-scale structural elements," Cement & Concrete Composites, Vol. 23, pp. 57-64.

- M. Collepardi, "Assessment of the "Rheoplasticity" of Concretes," Cement and Concrete Research, (1976) pp. 401-408.

- ACI Manual of Concrete Practice, «Recommended Practice for Selecting Proportions for Normal Weight Concrete», 1ACI 211.1-70, Part 1, (1973) pp.211-214, ACI Publications.

- EFNARC. (2002). "Specifications and Guidelines for Self Compacting Concrete." Available online at: www.efnarc.org

NBM&CW October 2010