An Investigation on the Strength Properties of Steel Fibre Reinforced Concrete Produced with Glass Powder as Pozzolana

Dr. K.B. Prakash, Professor, B.R. Patagundi, Asst. Professor, K.L.E.Society’s College of Engineering & Technology, Belgaum.

It has been estimated that several million tones of waste glasses are generated annually worldwide. The key sources of waste glasses are waste containers, window glasses, window screen, medicinal bottles, liquor bottles, tube lights, bulbs, electronic equipment etc. Only a part of this waste glass can be used in recycling. The remaining waste glass cannot be used for any purposes. But recently the research has shown that the waste glass can be effectively used in concrete either as glass aggregate (as fine aggregate or as coarse aggregate) or as a glass pozzolana. The waste glass when grounded to a very fine powder shows some pozzolanic properties. Therefore, the glass powder to some extent replaces the cement and contributes for the strength development. In this experimentation, an attempt has been made to study the characteristic strength properties of steel fibre reinforced concrete produced by replacing the cement by waste glass powder in various percentages like 0%, 10%, 20%, 30%, and 40%.

The concrete industry, to some extent is making use of many of these industrial wastes effectively in the production of concrete. For example the use of industrial wastes like flyash, silica fume and blast furnace slag in concrete can act as pozzolana and replace a part of cement. The pozzolanic reaction adds to the strength of concrete and also results in savings of cement. Thus nowadays the cement industries are making use of flyash, silica fume, and blast furnace slag as pozzolanas to replace a part of cement.1

It has been estimated that several million tones of waste glasses are generated annually worldwide2 The key sources of waste glasses are waste glass containers, window glasses, & glass screen, medicinal bottles, liquor bottles, tube lights, bulbs,electronic equipment etc. Only a part of this waste glass can be used in recycling. The remaining waste glass cannot be used for any purposes. But recently the research has shown that the waste glass can be effectively used in concrete either as glass aggregate (as fine aggregate or as coarse aggregate) or as a glass pozzolana.3 The waste glass when grounded to a very fine powder shows some pozzolanic properties. Therefore, the glass powder to some extent can replace the cement and also contribute for the strength development.

Post consumer and other waste glass types are a major component of the solid waste stream in many countries and most is currently landfilled.3 Alternatively, waste glass could be used as a concrete aggregate, either as a direct replacement for normal concrete aggregates (low value) or as an exposed, decorative aggregate in architectural concrete products (highvalue). Expansive alkali silica reactions (ASR) can occur between glass particles and cement paste, particularly in moist conditions and with high alkali cements. This reaction is not confined to glass aggregates but can occur when ever aggregates contain reactive silica. However, it is now fairly well accepted that by controlling the reactive silica, cement alkali level and moisture, the reaction can be reduced or totally mitigated.4,6

Finley ground glass has the appropriate chemical composition to react with alkalis in cement (pozzolanic reaction) and from cementitious products. The pozzolanic properties are likely to be derived from the high SiO2 content of glass. Powdered glass used in combination with Portland cement contributes to strength development.5 Various suppres– sants can minimize ASR of glass aggregate concrete. Pulverised fuel ash (Pfa) and metakaolin (MK) can completely eliminate ASR.2 In this experimentation, an attempt is made to study the characteristic strength properties of steel fibre reinforced concrete produced by replacing the cement by waste glass powder in various percentages like 0%, 10%, 20%,30%, and 40%.

In this experimentation, an attempt is made to study the characteristic strength properties of steel fibre reinforced concrete produced by replacing the cement by waste glass powder in various percentages like 0%, 10%, 20%,30%, and 40%.

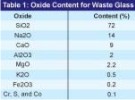

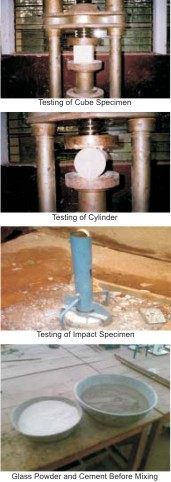

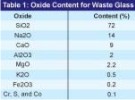

In the experimentation 43 grade OPC, locally available sand and coarse aggregates were used. The specific gravity of sand was found to be 2.61 and was Zone II sand.The specific gravity of coarse aggregate was found to be 2.92. The coarse aggregate used were of 12mm and down graded size. To impart workability, a super plasticizer Conplast SP 430 was used at the rate of 0.7% by weight of cemntitious materials. The glass powder was obtained by crushing waste glass pieces in a cone crusher mill. The glass powder passing through 600 micron was used for the experimentation. The chemical composition of glass powder is shown in Table 1. The different percentage replacement of cement by waste glass powder used in experimentation were 0%, 10%, 20%, 30%, and 40%.

The mix design was carried out for M20 grade of concrete by IS 10262:19827, which yielded a mix proportion of 1:1.29:3.11 with a water cement ratio of 0.44.

The specimens were prepared according to the mix proportion and by replacing cement by glass powder in different proportion. The entire mix was dry mixed by adding1% steel fibres (by volume fraction) and then water was added (w/c = 0.44) along with super plasticizer at a dosage of 0.7% (by weight of cement). The entire mix was homogeneously mixed and specimens were cast.

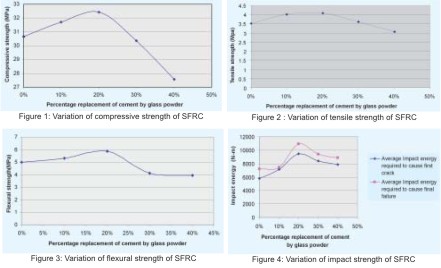

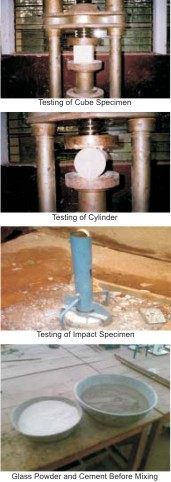

To find out the compressive strength, specimens of dimensions 150X150X150mm were cast and Tested under compressive testing machine of capacity 2000 KN as per IS 516:19598. To find out tensile strength, the cylindrical specimens of dimensions 150mm diameter and 300mm length were cast. Split tensile strength was obtained by testing the specimens on CTM of capacity 2000 KN as per IS 5816:19999. To find out the flexural strength, the specimens of dimensions 100mm x 100mm x 500mm were cast. Two point loading was adopted on an effective span of 400mm and tested as per IS 516:19598. For impact strength test, the specimens were of dimension 150 mm dia and 60 mm height. Drop weight test was adopted for testing impact specimen. They were kept in Shrudder’s impact testing machine and the hammer weighing 4.54 kg was dropped from a height of 457 mm. Number of blows required tocause first crack and final crack were noted down. Impact energy is calculated by the following formula.

To find out the compressive strength, specimens of dimensions 150X150X150mm were cast and Tested under compressive testing machine of capacity 2000 KN as per IS 516:19598. To find out tensile strength, the cylindrical specimens of dimensions 150mm diameter and 300mm length were cast. Split tensile strength was obtained by testing the specimens on CTM of capacity 2000 KN as per IS 5816:19999. To find out the flexural strength, the specimens of dimensions 100mm x 100mm x 500mm were cast. Two point loading was adopted on an effective span of 400mm and tested as per IS 516:19598. For impact strength test, the specimens were of dimension 150 mm dia and 60 mm height. Drop weight test was adopted for testing impact specimen. They were kept in Shrudder’s impact testing machine and the hammer weighing 4.54 kg was dropped from a height of 457 mm. Number of blows required tocause first crack and final crack were noted down. Impact energy is calculated by the following formula.

Impact energy = WhN (N-m)

Where,

W=Weight of ball in N = 45.4N

h=Height of fall in metres = 0.457m

N= Number of blows required to cause first crack or final failure as the case may be.

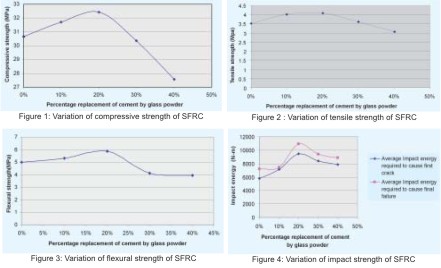

It has been observed that the higher compressive strength for SFRC can be obtained when 20% cement is replaced by glass powder. The percentage increase in compressive strength for 20% replacement by waste glass powder is found to be 5.77%. It is observed that the compressive strength of SFRCincreases linearly from 0% replacement to 20% replacement of cement by waste glass powder and thereafter it decreases continuously. At 30% and 40% replacement of cement by waste glass powder, it is observed that the compressive strength strikes lower than the reference mix.

It has been observed that the higher compressive strength for SFRC can be obtained when 20% cement is replaced by glass powder. The percentage increase in compressive strength for 20% replacement by waste glass powder is found to be 5.77%. It is observed that the compressive strength of SFRCincreases linearly from 0% replacement to 20% replacement of cement by waste glass powder and thereafter it decreases continuously. At 30% and 40% replacement of cement by waste glass powder, it is observed that the compressive strength strikes lower than the reference mix.

Similar trends are observed for tensile strength, flexural strength and impact strength. The percentage increase in tensile strength, flexural strength and impact strength for 20% replacement of cement by waste glass powder are found to be 15.95%, 17.37%, and 51.59% respectively.

This may be due to the fact that 20% replacement of cement by glass powder may give rise to maximum pozzolanic reaction and it may act as strong filler material, thus contributing towards more strength.

It has been estimated that several million tones of waste glasses are generated annually worldwide. The key sources of waste glasses are waste containers, window glasses, window screen, medicinal bottles, liquor bottles, tube lights, bulbs, electronic equipment etc. Only a part of this waste glass can be used in recycling. The remaining waste glass cannot be used for any purposes. But recently the research has shown that the waste glass can be effectively used in concrete either as glass aggregate (as fine aggregate or as coarse aggregate) or as a glass pozzolana. The waste glass when grounded to a very fine powder shows some pozzolanic properties. Therefore, the glass powder to some extent replaces the cement and contributes for the strength development. In this experimentation, an attempt has been made to study the characteristic strength properties of steel fibre reinforced concrete produced by replacing the cement by waste glass powder in various percentages like 0%, 10%, 20%, 30%, and 40%.

Introduction

Almost every industry produce waste irrespective of the nature of their products. The effective disposal of these wastes is a challenging task ahead. In olden days, such wastes were used as land fill materials for the low-lying areas. Waste generation and its disposal in landfill sites are unsustainable. The industrial wastes like flyash, silica fume, blast furnace slag etc. and other wastes like solid waste, waste plastics, waste glass, waste tiles and other agricultural wastes are causing the environmental pollution in one or the other way. The efficient safe disposal or efficient recycling is one of the challenging tasks ahead of engineers.The concrete industry, to some extent is making use of many of these industrial wastes effectively in the production of concrete. For example the use of industrial wastes like flyash, silica fume and blast furnace slag in concrete can act as pozzolana and replace a part of cement. The pozzolanic reaction adds to the strength of concrete and also results in savings of cement. Thus nowadays the cement industries are making use of flyash, silica fume, and blast furnace slag as pozzolanas to replace a part of cement.1

It has been estimated that several million tones of waste glasses are generated annually worldwide2 The key sources of waste glasses are waste glass containers, window glasses, & glass screen, medicinal bottles, liquor bottles, tube lights, bulbs,electronic equipment etc. Only a part of this waste glass can be used in recycling. The remaining waste glass cannot be used for any purposes. But recently the research has shown that the waste glass can be effectively used in concrete either as glass aggregate (as fine aggregate or as coarse aggregate) or as a glass pozzolana.3 The waste glass when grounded to a very fine powder shows some pozzolanic properties. Therefore, the glass powder to some extent can replace the cement and also contribute for the strength development.

Post consumer and other waste glass types are a major component of the solid waste stream in many countries and most is currently landfilled.3 Alternatively, waste glass could be used as a concrete aggregate, either as a direct replacement for normal concrete aggregates (low value) or as an exposed, decorative aggregate in architectural concrete products (highvalue). Expansive alkali silica reactions (ASR) can occur between glass particles and cement paste, particularly in moist conditions and with high alkali cements. This reaction is not confined to glass aggregates but can occur when ever aggregates contain reactive silica. However, it is now fairly well accepted that by controlling the reactive silica, cement alkali level and moisture, the reaction can be reduced or totally mitigated.4,6

Finley ground glass has the appropriate chemical composition to react with alkalis in cement (pozzolanic reaction) and from cementitious products. The pozzolanic properties are likely to be derived from the high SiO2 content of glass. Powdered glass used in combination with Portland cement contributes to strength development.5 Various suppres– sants can minimize ASR of glass aggregate concrete. Pulverised fuel ash (Pfa) and metakaolin (MK) can completely eliminate ASR.2

Experimental Programe

In the experimentation 43 grade OPC, locally available sand and coarse aggregates were used. The specific gravity of sand was found to be 2.61 and was Zone II sand.The specific gravity of coarse aggregate was found to be 2.92. The coarse aggregate used were of 12mm and down graded size. To impart workability, a super plasticizer Conplast SP 430 was used at the rate of 0.7% by weight of cemntitious materials. The glass powder was obtained by crushing waste glass pieces in a cone crusher mill. The glass powder passing through 600 micron was used for the experimentation. The chemical composition of glass powder is shown in Table 1. The different percentage replacement of cement by waste glass powder used in experimentation were 0%, 10%, 20%, 30%, and 40%.

The mix design was carried out for M20 grade of concrete by IS 10262:19827, which yielded a mix proportion of 1:1.29:3.11 with a water cement ratio of 0.44.

The specimens were prepared according to the mix proportion and by replacing cement by glass powder in different proportion. The entire mix was dry mixed by adding1% steel fibres (by volume fraction) and then water was added (w/c = 0.44) along with super plasticizer at a dosage of 0.7% (by weight of cement). The entire mix was homogeneously mixed and specimens were cast.

Impact energy = WhN (N-m)

Where,

W=Weight of ball in N = 45.4N

h=Height of fall in metres = 0.457m

N= Number of blows required to cause first crack or final failure as the case may be.

Test Results

Tables 2, 3, 4, 5 and Fig 1, 2, 3, 4 show respectively the compressive strength, tensile strength, flexural strength and impact strength test results of steel fibre reinforced concrete when the cement is replaced by waste glass powder in different proportions.Discussions on Test Results

Similar trends are observed for tensile strength, flexural strength and impact strength. The percentage increase in tensile strength, flexural strength and impact strength for 20% replacement of cement by waste glass powder are found to be 15.95%, 17.37%, and 51.59% respectively.

This may be due to the fact that 20% replacement of cement by glass powder may give rise to maximum pozzolanic reaction and it may act as strong filler material, thus contributing towards more strength.

Conclusions

The following conclusions may be drawn based on experimental observations.- Steel fibre reinforced concrete produced by replacing 20% cement by waste glass powder gives higher compressive strength, tensile strength, flexural strength and impact strength.

- In general, waste glass powder can be used effectively as pozzolana in steel fibre reinforced concrete tosave the consumption of cement.

Acknowledgment

The authors would like to thank the management authorities of KLES’s College of Engineering and Technology, Belgaum for their kindsupport. The authors also thank Principal Dr. S.C. Pilli and HOD, Civil Engineering Department Dr.V.V.Karajinnifor giving all the encouragement needed which kept the enthusiasmalive.References

- Suryawanshi C.S., “Use of industrial and domestic waste in concrete”, Civil Engineering & Construction Review, Feb 1999.

- Byars E. A, Morales B and Zhu H. Y., “Waste glass as concrete aggregate and pozzolana – laboratory and industrial projects”, Concrete, Vol.38, No.1, January 2004, pp 41-44.

- Byars E A, Morales B and Zhu H Y, “Conglasscrete I”, www.wrap.org.uk.

- Baxter S. Jin W and Meyer C, “Glasscrete–concrete with glass aggregate” ACI Materials Journal, Mar -April, 2000, pp 208-213.

- Albert Tang, Ravindra Dhir, Tom Dyer, and Yongjun, “Towards maximizing the value andsustainable use of glass”,Concrete Journal, Volume 38, January 2004, pp.38-40.

- Byars E A, Morales B, and Zhu H Y, “Conglasscrete II”, www.wrap.org.uk.

- IS 10262:1982, “Recommended guidelines of concrete mix design”.

- IS 516:1959, “Method of tests for strength of concrete”.

- IS 5816:1999, “Splitting tensile strength of concrete method of test.”

NBM&CW August 2008