Effect of High Temperature on the Addition of Three Industrial Wastes as Pozzolanas and Rubber Latex on the Properties of Concrete

Dr. K. B. Prakash, Professor of Civil Engineering, B.S.Krishnamurthy, Professor of Civil Engineering, K.L. Society’s, Gogte Institute of Technology, Belgaum

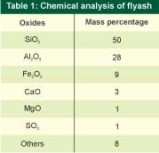

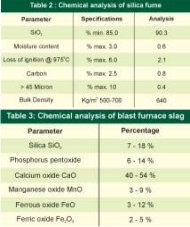

Extensive research work for decades is in progress throughout the globe in concrete technology in finding alternative materials which can partially or fully replace ordinary Portland cement (OPC) and which can also meet the requirements of strength and durability aspects. Amongst the many alternatives materials tried as partial cement replacement materials, the strength, workability and durability performance of industrial by products like flyash, blast furnace slag, silica fume, metakaoline, rice husk ash, etc., now termed as supplementary cementitious materials (SCM) are quite promising. Subsequently, these have led to the development of binary, ternary and tertiary blended concretes depending on the number of SCM and their combinations used as partial cement replacement materials. Binary blends contain one SCM, ternary blends contain combination of any two SCM and tertiary blends contain combination of any three SCM respectively. In this paper, an experimental investigation is carried out to assess the compressive strength of rubber latex modified tertiary blended concretes subjected to elevated temperatures of 1000C and 2000C for 24 hours duration. From the experimental investigation, it can be concluded that rubber latex modified tertiary blended concretes subjected to 1000C or 2000C with 30% replacement of cement by tertiary blends (FA+SF+BFS) in proportions of (10+10+10) show a better resistance to temperature.

Introduction

Human safety in case of fire is one of the major considerations in the design of buildings. It is extremely necessary to have a complete knowledge about the behavior of all construction materials before using them in the structural elements[1]. Concrete is a non-homogeneous material consisting of hardened cement paste and aggregates. With an increase in temperature, cracking is initiated due to thermal incompatibilities between the aggregates and the hardened cement paste[2].Developments in 1990s have seen a marked increase in the number of structures involving the first time heating of concrete. These include nuclear reactor pressure vessels, storage tanks for hot crude oil and hot water, coal gasification and liquefaction vessels which are subjected to elevated temperatures of up to 2500C. The extensive use of concrete as a structural material in all the above mentioned structures necessitated the need to study the behavior of concrete at high temperature and its durability for the required needs.[3]

A number of research workers in various countries have investigated the effect of elevated temperature on the residual strength of concrete. In most of these investigations the main variable, as far as heating regime is concerned, has been the maximum level of temperature to which the concrete is subjected, the value generally ranging from 1000C–9000C[3]. Research work has also been carried out to evaluate the performance at elevated temperature on blended cement concretes containing supplementary cementitious materials (SCM) as partial replacement to ordinary Portland cement. These SCM include industrial by products like flyash [4], silica fume [5], ground granulated blast furnace slag [6], metakaoline[7] etc.

Research works have indicated that the fire resistance of concrete is highly dependent on its constituent materials, particularly the pozzolanas. Experimental investigations also indicate that the addition of silica fume highly densifies the pore structure of concrete, which can result in explosive spalling due to the build up of pore pressure by steam. It is also investigated that the addition of flyash or ground granulated blast furnace slag enhances the fire resistance of concrete. It is reported that the compressive strength of flyash concrete retained higher strengths than the pure OPC concrete at higher temperature upto 6500C[1]. Research work has been carried out on three high strength concrete mixes incorporating silica fume, flyash and ground granulated blast furnace slag independently subjecting to a maximum temperature of 9000C and tested under loaded conditions. It is observed that ground granulated blast furnace slag concrete showed the best performance followed by flyash and silica fume concretes. Similarly, research work has also been carried out to evaluate the performance of metakaoline concrete at elevated temperature upto 8000C. The research findings has indicated that after an increase in compressive strength at 2000C, the metakaoline concrete suffered a more severe loss of compressive strength and permeability related durability than the corresponding silica fume, flyash and OPC concretes at higher temperatures.

Research Significance

Not much published research work is available on tertiary blended concretes containing rubber latex and subjected to elevated temperature. Hence this experimental investigation was carried out to investigate the performance of rubber latex modified tertiary blended concretes subjected to elevated temperature of 1000C and 200 C.Experimental Programme

The mix design was carried out for M25 grade concrete as per IS: 10262 -1982[8] which yielded a proportion of 1:1.23:2.41 with a w/ c ratio of 0.45.

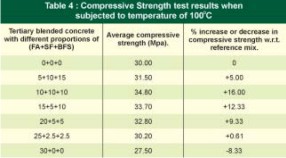

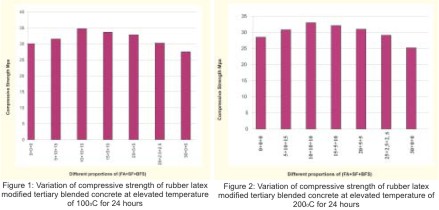

The cement, sand and coarse aggregates were weighed according to the proportion of 1:1.23:2.41 and dry mixed. Before mixing, 30% of cement was replaced by (flyash + silica fume + blast furnace slag), according to the proportions such as (0+0+0), (5+10+15), (10+10+10), (15+5+10), (20+5+5), (25+2.5+2.5), and (30+0+0) respectively. The required amount of water was added to this dry mix and intimately mixed. The calculated quantity of superplasticizer was now added and mixed thoroughly. After this, 2% rubber latex (by weight of cement) was added to the mix and the entire concrete was agitated thoroughly to get a homogeneous mix. Then the mix was placed layer by layer in the moulds to cast the specimens. The specimens were prepared both by hand compaction as well by imparting vibrations through vibrating Table. The specimens were finished smooth and kept under wet gunny bags for 24 hours after which they were cured for 28 days. After 28 days curing, the specimens were placed in the heating chambers.

Experimental Results

Observations and Discussions

It is observed that the rubber latex modified tertiary blended concrete with (10+10+10) proportions of (FA+SF+BFS) subjected to elevated temperature of 1000C show a higher compressive strength as compared with reference mix subjected to elevated temperatures of 1000C. The percentage increase the compressive strength as compared to reference mix is about 16.00%.It is also observed that the rubber latex modified tertiary blended concrete with (10+10+10) proportions of (FA+SF+BFS) and subjected to elevated temperature of 2000C show a higher compressive strength as compared to reference mix subjected to elevated temperatures of 2000C. The percentage increase in the compressive strength as compared to reference mix is about 15.79%.

The increase in the compressive strength may be due to the fact that the rubber latex modified tertiary blended concrete with (10+10+10) proportion of (FA+SF+BFS), changes the morphological structure of concrete which can resist the temperature in a better way. The flyash and blast furnace slag added in concrete may accommodate the pressure created by temperature rise with minute air bubbles and silica fume added imparting the strength.

Conclusion

It can be concluded that 30% replacement of cement by (10+10+10) proportions of (FA+SF+BFS) in rubber latex modified tertiary blended concrete subjected to elevated temperature of 1000C or 2000C for 24 hours show a better resistance to temperature as compared to other proportions.Acknowledgment

The authors would like to express their deep sense of gratitude and sincere thanks to the Board of Management and Principals of both the engineering colleges for all the encouragement and cooperation given in conducting the experimental investigation. The authors also sincerely thank all the research contributors whose research publications have been referred in the preparation of this paper.References

- Chi-Sun Poon, Salman Azar, Mike Anson, Yuk-Lung Wong, “Performance of metakaolin concrete at elevated temperature,” Cement & Concrete Composites 25(2003) pp.83-89.

- Xu Y, Wong Y.L, Poon C.S and Anson M. “Influence of PFA on cracking of concrete and cement paste after exposure to high temperature,” Cement and Concrete Research, 33(2003) pp. 2009-2016.

- Potha Raju M, Janaki Rao A, “Effect of temperature on residual compressive strength of flyash concrete,” The Indian Concrete Journal, May 2001, pp.347-350.

- Potha Raju M, Shobha M and Rambabu K. “Flexural strength of flyash concrete under elevated temperature,” Magazine of Concrete Research, 2004, 56. No.2, March, pp.83-88.

- Saad M, Abo-El-Enein S.A, Hanna G.B and Kotkata M.F. “Effect of Temperature on Physical and Mechanical Properties of Concrete containing Silica Fume,” Cement and Concrete Research, Vol.26, No.5, 1996, pp.669-675.

- Ramlochan T, Thomas M.D.A and Hooton R.D. “The effect of pozzolans and slag on the expansion of mortars cured at elevated temperatures,” Cement and Concrete Research, 34(2004),pp. 1341-1356.

- Bai J, Wild S. “Investigation of the temperature change and heat evolution of mortar containing PFA and metakaolin,” Cement and Concrete Composites, 24(2002), pp.201-209.

- IS:10262-1980: “Recommended guide lines for mix design.”

- IS:519-1959: “ Method of testing for concrete strength.”

NBM&CW October 2008