Influence of Matrix Ductility and Reinforcement

Detailing on Response of Portal Frame Under Cyclic Loading

J. D. Rathod, Lecturer, and Dr. S. C. Patodi, Professor, Applied Mechanics Department,The M.S. University of Baroda, Vadodara

This paper reports the response mechanism of a composite moment resisting portal frame system with self– centering and energy dissipation capabilities under cyclic loading. The load deformation response is primarily influenced by transition mechanism of the relative flexural stiffness of beam and column members, triggered by the formation of plastic hinges in the beam. The portal frames are designed with normal and ductile reinforcement detailing as per the codal provisions and are prepared from concrete, Engineered Cementitious Composite (ECC) and 30% replacement of cement by fly ash in ECC (FAECC) matrices and their response under compressive cyclic loading is evaluated and compared with respect to strength, ductility, damage and energy absorption capability.Load-deformation and moment-curvature graphs are plotted to evaluate displacement ductility and curvature ductility respectively. The interaction of linear elastic steel reinforcement and damage tolerant deformation with ductile stress-strain behavior in tension of ECC results in non linear elastic flexural response with stable hysteretic behavior and prevents premature member failure. Compatible deformation of reinforcement and matrix lead to low interfacial bond stress and prevent composite disintegration by bond splitting and cover spalling.

Engineered Cementitious Composite (ECC) is a class of ultra ductile fiber reinforced cementitious composite developed for such kind of potential applications. Microstructure tailoring based on micromechanics can lead to extreme composite ductility of several percent in tension; a material property not seen before in discontinuous fiber reinforced cementitious composites [4]. Strain hardening property of Engineered Cementitious Composite (ECC) material in axial tension has opened a new dimension to its use in construction industry. At increasing load, the induced tensile strains in reinforcement and matrix are accommodated by further elastic deformation in steel and propagation of multiple cracking in the ECC matrix for being ductile in nature [5,6]. However, cost and sustainability of this composite are two important issues to be addressed for making it more acceptable. Replacement of cement by fly ash is the solution in this regard which has been accepted world wide over the last few decades. But this attempt requires a special attention in ECC as tensile strain is the vital issue to be addressed instead of strength.

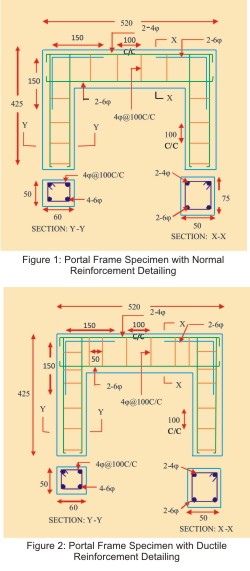

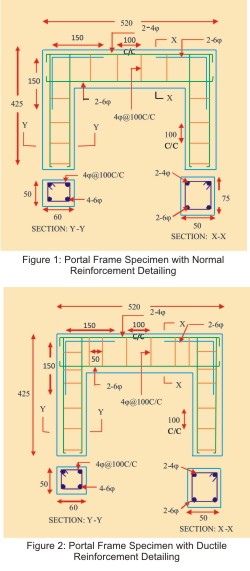

Response of portal frames made up of steel reinforced concrete and ECC matrix carrying almost same compressive strength with normal and ductile reinforcement detailing is examined in this paper under compressive cyclic loading with respect to load-deformation response, damage tolerance, energy absorption and failure mode. It is aimed to explore possibility of the use of novel material like ECC by which overall performance of the structure can be drastically enhanced. Curvature ductility and displacement ductility are evaluated. Further, 30 % cement is replaced by fly ash to examine its effect. Finally, this experimental investigation provides useful recommendations regarding reinforcement detailing with respect to use of concrete and smart material like ECC. Reinforcement detailing and dimensions of portal frame specimens are selected such that strong column/weak beam concept is satisfied. Normal reinforcement detailing is provided as per IS: 456-2000 [8] and ductile detailing is provided as per IS: 13920 [9] using 6 mm diameter bar for longitudinal reinforcement and 4 mm diameter bar for transverse reinforcement for each matrix composition as shown in Figs. 1 and 2 respectively. All the specimens are cured for 28 days normal water curing and then tested by applying cyclic compressive loading under displacement control on MTS machine. The two columns of a portal frame are fixed into the grips of a fixture which is fabricated locally. Pellets are pasted at the top and bottom of the beam portion near the beam-column connection 60 mm apart to measure the elongation. Compressive cyclic load is applied at the centre of the beam at the interval of 2000 N. The frame is loaded gradually upto 2000 N, then unloaded and reloaded to the next increment of load. This pattern of loading is continued foe each increment until failure. Curvature of the beam at connection with a column is measured at the peak load for each cycle. Average result of three specimens is presented here for discussion. In the result tables given in next section, letter N in bracket indicates normal detailing and D indicates ductile detailing in the frames prepared from concrete, ECC and FAECC.

Reinforcement detailing and dimensions of portal frame specimens are selected such that strong column/weak beam concept is satisfied. Normal reinforcement detailing is provided as per IS: 456-2000 [8] and ductile detailing is provided as per IS: 13920 [9] using 6 mm diameter bar for longitudinal reinforcement and 4 mm diameter bar for transverse reinforcement for each matrix composition as shown in Figs. 1 and 2 respectively. All the specimens are cured for 28 days normal water curing and then tested by applying cyclic compressive loading under displacement control on MTS machine. The two columns of a portal frame are fixed into the grips of a fixture which is fabricated locally. Pellets are pasted at the top and bottom of the beam portion near the beam-column connection 60 mm apart to measure the elongation. Compressive cyclic load is applied at the centre of the beam at the interval of 2000 N. The frame is loaded gradually upto 2000 N, then unloaded and reloaded to the next increment of load. This pattern of loading is continued foe each increment until failure. Curvature of the beam at connection with a column is measured at the peak load for each cycle. Average result of three specimens is presented here for discussion. In the result tables given in next section, letter N in bracket indicates normal detailing and D indicates ductile detailing in the frames prepared from concrete, ECC and FAECC.

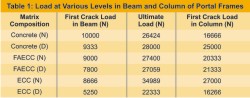

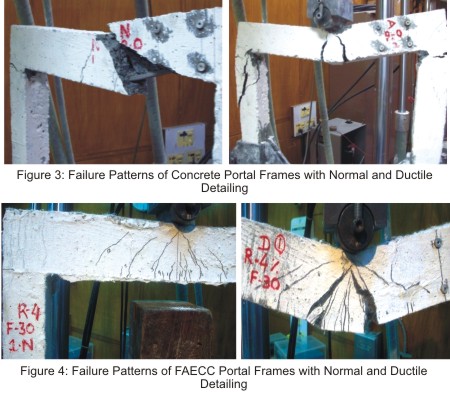

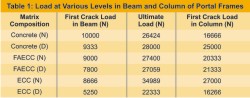

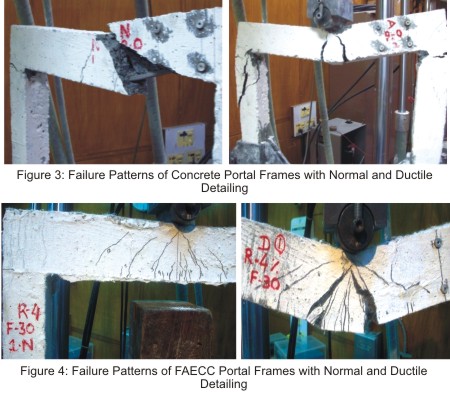

Ultimate loads resisted by concrete, FAECC and ECC frames with normal reinforcement detailing are 26424, 27400 and 34989 N respectively which indicate reverse behavior as compared to first crack. Therefore, magical role is played by ECC by interacting synergetically with reinforcement in inelastic deformation regime. ECC matrix exhibits compatible deformation with reinforcement by numerous wide spread multiple cracking which does not allow yielding of the reinforcement at one location but redistributes the stresses. Similar failure patterns are observed when portal frames are subjected to static loads [11]. All the three matrices exhibit plastic hinge in the beam prior to formation of crack in the column. First crack load in the column for Concrete, FAECC and ECC material is 16666, 20333 and 27000 N respectively along the line of beam column connection. The highest load in column is contributed by ECC due to large inelastic deformation in a beam itself and stiffness of the ECC column. Also, ECC undergoes extensive multiple cracking in the column along with plastic hinge area at center of beam which is not seen in concrete or FAECC column as depicted by failure patterns in Figs. 3 to 5. Shear failure and spalling of concrete in columns and beam are observed in concrete for both reinforcement detailed portal frames unlike FAECC and ECC. Specimens prepared from ECC exhibit numerous shear cracks in the beam column connections for normal reinforcement detailing as ECC contributes as a matrix instead of stirrups. Therefore, additional stirrups are not required when ECC or FAECC is used in the beam-column connection which minimizes placement difficulties of concrete. ECC itself is very effective shear resisting material due to which it may not require steel reinforcement in shear resistance. Therefore, ECC do not exhibit shear failure in either beam or column whereas concrete fails due to shear in spite of ductile detailing as shown in failure patterns. Pure flexure failure at the center of a beam is exhibited by ECC and FAECC. Concrete, FAECC and ECC carry first crack load of 9333, 7800 and 5250 N respectively for ductile reinforcement detailing which indicate that ductile detailing is very effective for concrete compared to FAECC and ECC. Ultimate loads recorded by concrete, FAECC and ECC with ductile reinforcement detailing are 28000, 27059 and 22333 N respectively which indicate that load carrying capacity of brittle material like concrete can be enhanced with the help of ductile detailing whereas fusion of ductile detailing and ductile matrix like ECC will not result in attractive performance. First crack load in the column is highest for concrete portal frame.

Ultimate loads resisted by concrete, FAECC and ECC frames with normal reinforcement detailing are 26424, 27400 and 34989 N respectively which indicate reverse behavior as compared to first crack. Therefore, magical role is played by ECC by interacting synergetically with reinforcement in inelastic deformation regime. ECC matrix exhibits compatible deformation with reinforcement by numerous wide spread multiple cracking which does not allow yielding of the reinforcement at one location but redistributes the stresses. Similar failure patterns are observed when portal frames are subjected to static loads [11]. All the three matrices exhibit plastic hinge in the beam prior to formation of crack in the column. First crack load in the column for Concrete, FAECC and ECC material is 16666, 20333 and 27000 N respectively along the line of beam column connection. The highest load in column is contributed by ECC due to large inelastic deformation in a beam itself and stiffness of the ECC column. Also, ECC undergoes extensive multiple cracking in the column along with plastic hinge area at center of beam which is not seen in concrete or FAECC column as depicted by failure patterns in Figs. 3 to 5. Shear failure and spalling of concrete in columns and beam are observed in concrete for both reinforcement detailed portal frames unlike FAECC and ECC. Specimens prepared from ECC exhibit numerous shear cracks in the beam column connections for normal reinforcement detailing as ECC contributes as a matrix instead of stirrups. Therefore, additional stirrups are not required when ECC or FAECC is used in the beam-column connection which minimizes placement difficulties of concrete. ECC itself is very effective shear resisting material due to which it may not require steel reinforcement in shear resistance. Therefore, ECC do not exhibit shear failure in either beam or column whereas concrete fails due to shear in spite of ductile detailing as shown in failure patterns. Pure flexure failure at the center of a beam is exhibited by ECC and FAECC. Concrete, FAECC and ECC carry first crack load of 9333, 7800 and 5250 N respectively for ductile reinforcement detailing which indicate that ductile detailing is very effective for concrete compared to FAECC and ECC. Ultimate loads recorded by concrete, FAECC and ECC with ductile reinforcement detailing are 28000, 27059 and 22333 N respectively which indicate that load carrying capacity of brittle material like concrete can be enhanced with the help of ductile detailing whereas fusion of ductile detailing and ductile matrix like ECC will not result in attractive performance. First crack load in the column is highest for concrete portal frame.

Considering an isolated segment from the tensile section of a steel reinforced flexural member, prior to formation of flexural cracking the tensile force is proportionally shared between reinforcement and matrix. At formation of an initial flexural crack, the tensile stress in the concrete matrix can not be directly transferred and is diverted into the reinforcement, resulting in tensile stress concentration and strain discontinuity between concrete and reinforcement. In contrast, initiation of flexural cracking in the steel reinforced ECC member does not result in a stress free matrix crack, but tensile stress is directly transferred across through crack. Subsequently, ECC enters the strain hardening regime and stresses are redistributed proportional to the stiffness of reinforcement and matrix at the deformation stage. Although the inelastic stiffness of ECC is significantly lower than in its uncracked state, tensile load in the matrix prior to cracking is transferred by means of fiber bridging and is not diverted into the steel reinforcement. Due to the uniform stress profile in the cracked matrix, initiation of further flexural cracking is dependent on the tensile deformation characteristics of ECC i.e. multiple cracking spacing and width and is effectively independent of interfacial bond properties. Local stress concentration in the steel reinforcement is prevented by direct tensile load transfer in the ECC matrix as well as compatible deformations between reinfor- cement and matrix, thus effectively decoupling reinforcement stress distribution and flexural crack formation from interfacial bond properties. The lack of relative slip between reinforcement and ECC in multiple cracking stages actively prevents interfacial bond deterioration and radial splitting forces.

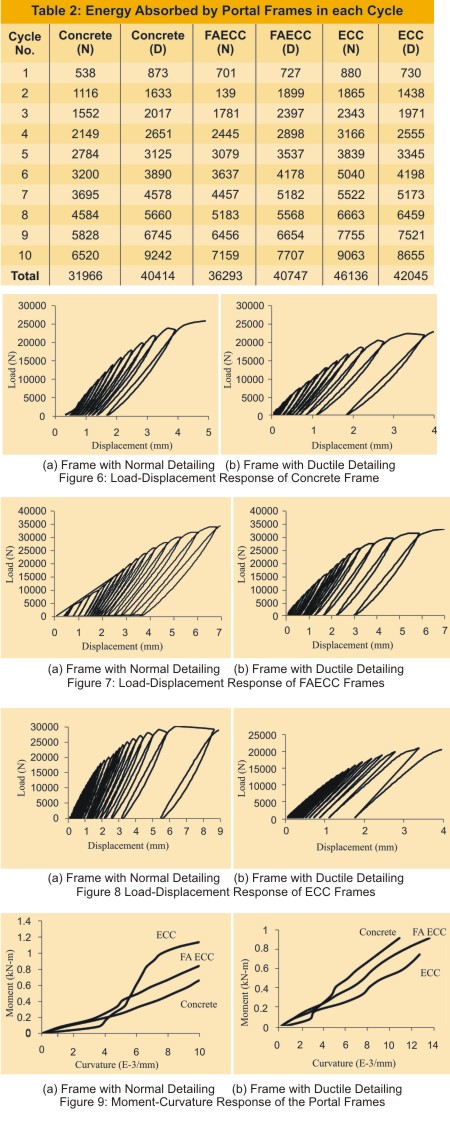

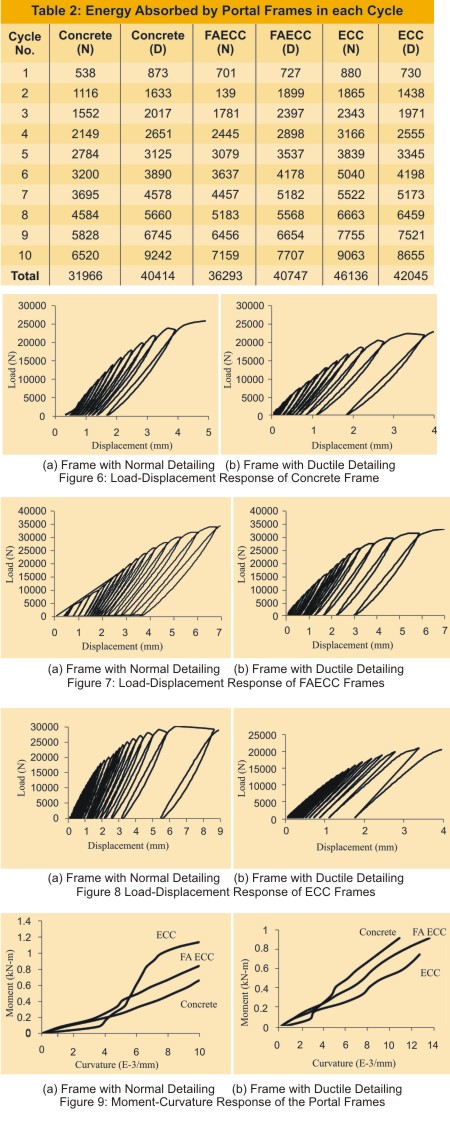

Table 2 represents energy absorbed by portal frames in each cycle and total energy absorbed in 10 cycles which are evaluated from the load-displacement graphs obtained on MTS as shown in Figs. 6, 7 and 8 with the help of NCSS software. As expected, concrete and FAECC portal frames with ductile reinforcement detailing absorb more energy compared to normal detailed frames whereas, ECC exhibits unlike behavior compared to the other two. However, amount of the energy absorbed by ECC portal frames is highest for both the reinforcement detailed portal frames. ECC frames with normal reinforcement detailing absorb maximum energy which may be beneficial in earthquake resistant structures. Thus, the major problems experienced at site of placement of concrete due to ductile detailing can be minimized and performance of the structure can be improved.

Table 2 represents energy absorbed by portal frames in each cycle and total energy absorbed in 10 cycles which are evaluated from the load-displacement graphs obtained on MTS as shown in Figs. 6, 7 and 8 with the help of NCSS software. As expected, concrete and FAECC portal frames with ductile reinforcement detailing absorb more energy compared to normal detailed frames whereas, ECC exhibits unlike behavior compared to the other two. However, amount of the energy absorbed by ECC portal frames is highest for both the reinforcement detailed portal frames. ECC frames with normal reinforcement detailing absorb maximum energy which may be beneficial in earthquake resistant structures. Thus, the major problems experienced at site of placement of concrete due to ductile detailing can be minimized and performance of the structure can be improved.

Displacement of two points in compression and tension zone of beam near column connection is measured with the help of digital vernier having 0.01 mm accuracy from which curvature is evaluated and moment versus curvature graphs are plotted as shown in Figs. 9 and 10 which indicate large inelastic deformation behavior of ECC after formation of first crack compared to FAECC and concrete with normal reinforcement detailing. Behavior of FAECC and concrete is almost same with linear and parallel lines having same slope. ECC behaves distinctly different being ductile in nature compared to other two which strongly recommends normal reinforcement detailing for much enhanced performance. Ductile detailing doesn't make much difference in deformation capability but slope of the moment-curvature line of ECC is minimum indicating larger ductility. However, moment carrying capacity is higher for concrete portal frames.

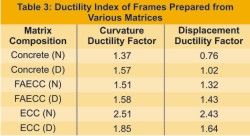

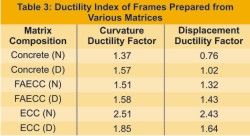

Strain in ECC, FAECC and concrete in tension is noted as 1.53 %, 0.66 % and 0.01 % respectively. Further, ECC has lower elastic modulus compared to concrete and reaches its compressive strength at a larger strain due to the lack of large aggregates. Ductility of the portal frames is evaluated by displacement and curvature ductility factors. The curvature ductility factor is evaluated as curvature at peak load divided by curvature at yield. Curvature at yield can be evaluated from yield strength and modulus of elasticity of reinforcement. Displacement ductility factor is evaluated in same manner as above with the help of displacement values of beam. ECC represents highest curvature and displacement ductility in normal reinforcement detailing. These values are more than ECC itself with ductile detailing. Displacement ductility is found to be less than curvature ductility in all cases.

Strain in ECC, FAECC and concrete in tension is noted as 1.53 %, 0.66 % and 0.01 % respectively. Further, ECC has lower elastic modulus compared to concrete and reaches its compressive strength at a larger strain due to the lack of large aggregates. Ductility of the portal frames is evaluated by displacement and curvature ductility factors. The curvature ductility factor is evaluated as curvature at peak load divided by curvature at yield. Curvature at yield can be evaluated from yield strength and modulus of elasticity of reinforcement. Displacement ductility factor is evaluated in same manner as above with the help of displacement values of beam. ECC represents highest curvature and displacement ductility in normal reinforcement detailing. These values are more than ECC itself with ductile detailing. Displacement ductility is found to be less than curvature ductility in all cases.

Replacement of cement by fly ash in ECC increases compressive strength but it reduces ductility and energy absorbing capacity. Normal or ductile reinforcement detailing does not make much difference and hence overall economy of a structure can be achieved by replacing 30 % cement by fly ash in ECC and providing normal reinforcement detailing. Shear failure in column or beam and matrix spalling is not observed in ECC and FAECC frames unlike concrete frames.

This paper reports the response mechanism of a composite moment resisting portal frame system with self– centering and energy dissipation capabilities under cyclic loading. The load deformation response is primarily influenced by transition mechanism of the relative flexural stiffness of beam and column members, triggered by the formation of plastic hinges in the beam. The portal frames are designed with normal and ductile reinforcement detailing as per the codal provisions and are prepared from concrete, Engineered Cementitious Composite (ECC) and 30% replacement of cement by fly ash in ECC (FAECC) matrices and their response under compressive cyclic loading is evaluated and compared with respect to strength, ductility, damage and energy absorption capability.Load-deformation and moment-curvature graphs are plotted to evaluate displacement ductility and curvature ductility respectively. The interaction of linear elastic steel reinforcement and damage tolerant deformation with ductile stress-strain behavior in tension of ECC results in non linear elastic flexural response with stable hysteretic behavior and prevents premature member failure. Compatible deformation of reinforcement and matrix lead to low interfacial bond stress and prevent composite disintegration by bond splitting and cover spalling.

Introduction

In most structural applications of steel reinforced concrete, a large flexural stiffness is desirable in order to limit member deflections under service load conditions for which the elastic deflection limit can be small and must not be exceeded. In seismic resistant structures, however, inelastic deformations at particular locations of the structural system are intended to dissipate large energy, thereby reducing the effects of seismic excitation on the structure. In particular, moment resisting frames designed according to the strong column/weak beam concept are expected to undergo inelastic deformations by formation of plastic hinges in the beam members, while the columns remain elastic in order to maintain vertical load carrying capacity and prevent possible collapse. Expected plastic hinge regions must be properly detailed to provide confinement, shear resistance and protection against buckling of longitudinal reinforcement [1]. Particular flexural members in seismic structures such as beams and first story columns may be required to undergo relatively large flexural deformations while maintaining their load carrying capacity. In steel reinforced concrete members, these deformations are likely to exceed the elastic deflection limit, which accommodates the need for energy dissipation; however, it also implies relatively large residual deformations after unloading [2]. Generally, the beam column joints of a RC frame structure subjected to cyclic load experience large internal forces. Consequently, the ductile behavior of RC structures dominantly depends on the reinforcement detailing of the beam column joints. Because of placement difficulties, however, reinforcement detailing of the beam column joints is not easy to handle and sometimes it is difficult to carry out the same according to the design drawings [3].Engineered Cementitious Composite (ECC) is a class of ultra ductile fiber reinforced cementitious composite developed for such kind of potential applications. Microstructure tailoring based on micromechanics can lead to extreme composite ductility of several percent in tension; a material property not seen before in discontinuous fiber reinforced cementitious composites [4]. Strain hardening property of Engineered Cementitious Composite (ECC) material in axial tension has opened a new dimension to its use in construction industry. At increasing load, the induced tensile strains in reinforcement and matrix are accommodated by further elastic deformation in steel and propagation of multiple cracking in the ECC matrix for being ductile in nature [5,6]. However, cost and sustainability of this composite are two important issues to be addressed for making it more acceptable. Replacement of cement by fly ash is the solution in this regard which has been accepted world wide over the last few decades. But this attempt requires a special attention in ECC as tensile strain is the vital issue to be addressed instead of strength.

Response of portal frames made up of steel reinforced concrete and ECC matrix carrying almost same compressive strength with normal and ductile reinforcement detailing is examined in this paper under compressive cyclic loading with respect to load-deformation response, damage tolerance, energy absorption and failure mode. It is aimed to explore possibility of the use of novel material like ECC by which overall performance of the structure can be drastically enhanced. Curvature ductility and displacement ductility are evaluated. Further, 30 % cement is replaced by fly ash to examine its effect. Finally, this experimental investigation provides useful recommendations regarding reinforcement detailing with respect to use of concrete and smart material like ECC.

Matrix Composition

Recron 3S brand synthetic fibers of substantial triangular cross section produced by Reliance Industries Ltd. are used in 4% volume fraction. Kamal brand 53 grade OPC, 300m passing silica sand, 2% dose of high performance concrete super plasticizer of Glenium 51 brand, w/c ratio of 0.35, sand/cement ratio of 0.5 are used in ECC matrix composition for the preparation of frames in the present experimental investigation. Mix proportion for concrete frame is adopted as 1:1.295:2.407 with Kamal brand 53 grade of OPC, silica sand confirming to zone II, 12.5 mm size coarse aggregate, w/c ratio of 0.35 and 0.5% dose of super plasticizer of SP430 brand. 30% fly ash used in the ECC composition is a processed siliceous pulverized ash confirming to IS 3812 (Part 1): 2003 [7]. Plain mild steel reinforcement of 6 mm diameter for longitudinal and 4 mm diameter for transverse direction having yield strength of 250N/mm2 is used in the preparation of specimens with normal and ductile detailing.Specimen Details and Test Set Up

Discussion of Test Results

Compressive strength of ECC, FAECC and concrete is reported as 36.77 N/mm2, 39.84 N/mm2 and 40.23 N/mm2 [10] respectively which indicates that concrete is the strongest construction material in compression out of the three. Total number of compressive load cycles resisted by each portal frame upto failure is different but overall observation indicates that repairable integrity of all the three matrices is almost lost after 10 cycles; therefore three matrices are compared with each other for first 10 cycles. Table 1 represents load carrying capacity of frames at first crack and ultimate. Frames prepared from concrete, FAECC and ECC indicatec first crack load of 10,000, 9000 and 8666 N respectively for normal reinforcement detailing which indicate that a material which is stronger in compression has higher modulus of rupture indicating truly a matrix property. But after formation of first crack, interaction of matrix with steel reinforcement comes into picture and as a result of which formation of other cracks takes place in inelastic deformation regime.

Considering an isolated segment from the tensile section of a steel reinforced flexural member, prior to formation of flexural cracking the tensile force is proportionally shared between reinforcement and matrix. At formation of an initial flexural crack, the tensile stress in the concrete matrix can not be directly transferred and is diverted into the reinforcement, resulting in tensile stress concentration and strain discontinuity between concrete and reinforcement. In contrast, initiation of flexural cracking in the steel reinforced ECC member does not result in a stress free matrix crack, but tensile stress is directly transferred across through crack. Subsequently, ECC enters the strain hardening regime and stresses are redistributed proportional to the stiffness of reinforcement and matrix at the deformation stage. Although the inelastic stiffness of ECC is significantly lower than in its uncracked state, tensile load in the matrix prior to cracking is transferred by means of fiber bridging and is not diverted into the steel reinforcement. Due to the uniform stress profile in the cracked matrix, initiation of further flexural cracking is dependent on the tensile deformation characteristics of ECC i.e. multiple cracking spacing and width and is effectively independent of interfacial bond properties. Local stress concentration in the steel reinforcement is prevented by direct tensile load transfer in the ECC matrix as well as compatible deformations between reinfor- cement and matrix, thus effectively decoupling reinforcement stress distribution and flexural crack formation from interfacial bond properties. The lack of relative slip between reinforcement and ECC in multiple cracking stages actively prevents interfacial bond deterioration and radial splitting forces.

Displacement of two points in compression and tension zone of beam near column connection is measured with the help of digital vernier having 0.01 mm accuracy from which curvature is evaluated and moment versus curvature graphs are plotted as shown in Figs. 9 and 10 which indicate large inelastic deformation behavior of ECC after formation of first crack compared to FAECC and concrete with normal reinforcement detailing. Behavior of FAECC and concrete is almost same with linear and parallel lines having same slope. ECC behaves distinctly different being ductile in nature compared to other two which strongly recommends normal reinforcement detailing for much enhanced performance. Ductile detailing doesn't make much difference in deformation capability but slope of the moment-curvature line of ECC is minimum indicating larger ductility. However, moment carrying capacity is higher for concrete portal frames.

Conclusions

Ductile detailing is introduced in the code with the intention of improving the seismic performance of the structure. But this provision itself limits good concrete placement in many cases at site and thus does not fulfill the desired purpose. ECC is one of the best solutions in such cases as it does not contain coarse aggregates which minimize the placing problem and ductile detailing may not be necessary with ECC being ductile in nature. Therefore, ECC can be used in such fuse zones where large inelastic energy is expected to be absorbed. This investigation provides enough evidence that higher compressive strength may not improve overall seismic performance of the structure but rather ductile composite like ECC can result in a better performance.Replacement of cement by fly ash in ECC increases compressive strength but it reduces ductility and energy absorbing capacity. Normal or ductile reinforcement detailing does not make much difference and hence overall economy of a structure can be achieved by replacing 30 % cement by fly ash in ECC and providing normal reinforcement detailing. Shear failure in column or beam and matrix spalling is not observed in ECC and FAECC frames unlike concrete frames.

References

- Li V. C. and Fisher G., "Intrinsic Response Control of Moment-Resisting Frames Utilizing Advanced Composite Materials and Structural Elements" ACI Structural Journal, Vol. 100, No. 2, pp. 166-176, March-April 2003.

- Li V. C. and Fisher G., "Deformation Behavior of Fiber-Reinforced Polymer Reinforced Engineered Cementitiuos Composite (ECC) Flexural Members under Reversed Cyclic Conditions," ACI Structural Journal, Vol. 100, No. 1, pp. 25-35, Jan.-Feb. 2003.

- Gencoglu M. and Ilhan E., "An Experimental Study on the Effect of Steel Fiber Reinforced Concrete on the Behavior of the Exterior Beam-Column Joints Subjected to Reversal Cyclic Loading," Turkish Journal of Engineering and Environmental Science, pp. 493-501, Feb. 2002.

- Li V. C., "Engineered Cementitious Composites- Tailored Composites through Micromechanical Modeling", Proceedings of Fiber Reinforced Concrete: Present and the Future, Canadian Society of Civil Engineering, Montreal, Canada, pp. 64-97.

- Li V. C. and Fisher G., "Influence of Matrix Ductility on the Tension Stiffening Behavior of Steel Reinforced Engineered Cementitious Composites (ECC)," ACI Structural Journal, Vol. 99, No. 1, pp. 104-111, Jan.-Feb. 2002.

- Li V. C. and Fisher G., "Effect of Matrix Ductility on Deformation Behavior of Steel Reinforced ECC Flexural Members under Reversed Cyclic Loading Conditions," ACI Structural Journal, Vol. 99, pp. 781-790, No. 6, Nov.-Dec. 2002.

- IS 3813 (Part 1): 2003, "Pulverized Fuel Ash – Specification," Part 1 for use as Pozzolana in Cement, Cement Mortar and Concrete, Bureau of Indian Standard, New Delhi, 2003.

- IS 456: 2000, "Code of Practice for Plain and Reinforced Concrete," Bureau of Indian Standard, New Delhi, 2000.

- IS 13920: 1993, "Code of Practice for Ductile Detailing of Reinforced Concrete Structures Subjected to Seismic Forces," Bureau of Indian Standard, New Delhi, 1993.

- Rathod J. D. and Patodi S. C., "Effect of Cement: Sand Ratio on Shear Strength of ECC in 1D and 2D Fiber Orientationm," Civil Engineering and Construction Review Journal, Vol. 21, No. 5, pp. 86-96, May 2008.

- Rathod J. D. and Patodi S. C., "Response of Engineered Cementitious Composites with Steel Reinforcement and Concrete in Moment Resisting Frames," New Building Materials and Construction World Journal, Vol. 13, No. 12, pp. 232-243, June 2008.

NBM&CW June 2009