Experimental Investigation on Flexural Behaviour of Reinforced Concrete Beams Strengthened by Ferrocement Laminates

This paper investigates the flexural behaviour of reinforced concrete beams strengthened by ferrocement laminates. Totally five beams of length 3200mm, width 150mm and depth 250mm were cast and tested. A flat ferrocement laminate 125mm wide, 25mm thick and 3000mm long was cast using cement mortar as binder and weld and woven mesh as reinforcement. The experimental study shows that the ferrocement laminate increases the flexural bahaviour of the distressed reinforced concrete beams. The aim of this project is to bond ferrocement laminates to reinforced concrete beams and strengthen it against flexure.

B.Sivagurunathan, Selection Grade Lecturer in Civil Engineering, Thiagarajar College of Engineering, Madurai. Dr.B.Vidivelli, Professor in Civil and Structural Engineering, Annamalai University, Annamalai Nagar.

In this study the methods of strengthening of reinforced concrete beams using ferrocement laminates with skeletal bar attached onto the soffit of the beams are reviewed. The methods of anchorage of the ferrocement laminates in the strengthened beams have been investigated. The methods of increasing the ultimate load of the original beams using ferrocement laminate and to control the cracking behavior of the beams as well the effect of the damage of original beams prior to repair are examined.

It is concluded that the strengthened beams have performed better in cracking behavior, reduction in mid-span deflection and increased ultimate load. Further, the pre-cracked beams prior to repair did not affect the ultimate loads of the strengthened beams tested.

Mohd Zamin Zumaat and Ashraful Alam (2006),

In this study, methods of strengthening of reinforced concrete beams using ferrocement laminates with skeletal bar attached on to the soffit of the beams are reviewed. The addition of ferrocement laminates with skeletal bar to the soffit (tension face) of the beams substantially delayed the formations of first crack, restrained the crack widths and increased the flexural stiffness and load capacities of the strengthened beams. The effects of curtailing the ferrocement laminate short of the supports were studied. In the strengthening carried out in the present work, the ferrocement laminates were extended over the supports. This however would be difficult to achieve in practice.

Vidivelli.B, et al (2001),

In this study, the damage due to overloading is considered. A total of three beams were cast and tested. One beam (control beam) was tested to ascertain the load deflection behaviour and ultimate load. The remaining two beams were damaged by overloading. After unloading the damaged beam specimens were repaired with ferrocement laminates with single layer at tension face using epoxy. Static test was conducted on all the beams to determine the load deflection behaviour and ultimate load. A comparison was made on crack width, deflection and ultimate strength at different load stages between control, damaged and repaired beams.Experimental Programme

For the beam specimen, the concrete with design compressive strength of M20 was used. The concrete mix proportions are given in Table1. 43 grade Portland Pozzalana Cement (PPC) confirming to IS: 1489 – 1991, having a specific gravity of 2.92 was used. Locally available river sand having a fineness modulus of 2.61, specific gravity of 2.65 and coarse aggregates of 20mm maximum size, having a fineness modulus of 6.97 and specific gravity of 2.9, were used. High yield strength deformed bars of Fe 415 were used as reinforcement in the concrete beam

For casting of the ferrocement laminates Portland cement mortar matrix, woven and welded meshes of size 24 gauge are tied together to act as reinforcement. Ferrocement may require chemical additives to reduce the reaction between the matrix and the reinforcement.

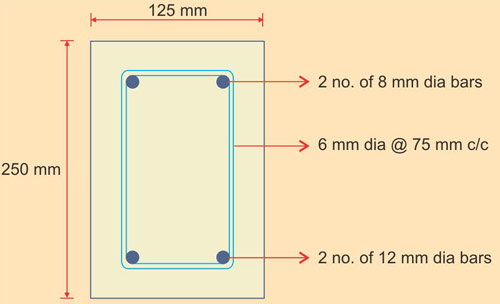

Five beams were cast for flexural test out of which one beam was control beam the second and third were tested for service load and rehabilitated and the fourth and fifth beams are retrofitted. For rehabilitation and retrofitting ferrocement laminates were used. The details of reinforcement used in the beam are as shown in the Fig.1. Wooden moulds satisfying the above specimen size were used. Before casting, machine oil was applied on the inner surfaces of moulds. Concrete was mixed using tilting type laboratory concrete mixer and was poured into the moulds in layers. Each layer of concrete was compacted well. The specimens were removed from mould after 24 hours of casting and then cured using jute bags. All specimens were moist cured for 28 days.

Before bonding the fabricated ferrocement laminates on the soffit (tension side) of the concrete beam, surface was made rough using sand blasting and cleaned with an air blower to remove all dirt and debris. Once the surface was prepared to the required standard, the epoxy resin was mixed in accordance with manufacturer's instructions. Mixing was carried out in a metal container with base to hardener ratio of 1:2 and was continued until the mixture obtained uniform colour. Then it was applied both on laminate and beam surface and bonded properly without any air gap.

B.Sivagurunathan, Selection Grade Lecturer in Civil Engineering, Thiagarajar College of Engineering, Madurai. Dr.B.Vidivelli, Professor in Civil and Structural Engineering, Annamalai University, Annamalai Nagar.

Introduction

Increase in service loading, environmental degradation, damage of structure due to poor quality of material and inferior design, upgrading of old structures as per new code and need of seismic retrofit leads to the need of repair and rehabilitation. Rehabilitation of deteriorated civil engineering infrastructure such as beams, girders, bridge decks, parking structures, marine structures, roads etc has been the major issue in the last decades. The need to upgrade the deteriorated civil engineering infrastructure greatly enhances with the ever increasing demands. Therefore rehabilitating existing civil engineering infrastructure has been identified as an important issue to be addressed. The strengthening of concrete structures to resist higher design loads, correct deterioration-related damage, or increased ductility has been traditionally accomplished using conventional materials and construction techniques. Externally bonded steel plates, FRP and ferro-cement laminates are some of the traditional techniques available. In the context of strengthening problem, advanced composites have the potential to prove another promising solution.Introduction to Ferrocement

Ferrocement is a form of reinforced cement mortar (micro concrete) that differs from conventional reinforced or pre-stressed concrete primarily by the manner in which the following elements are dispersed and arranged. It consists of closely placed, evenly distributed multiple layers of mesh or fine rods completely embedded in cement mortar. Widespread use of ferrocement in construction industry has occurred during the last 40 years. The main worldwide application of ferrocement construction to date has been for silos, tanks, roofs, irrigation channels, manholes & covers, and mostly boats. The construction of ferrocement can be divided in to four phases:- Fabricating the steel rods to form a skeletal (cage) framing system;

- Tying or fastening rods and mesh to the skeletal framing;

- Plastering and

- Curing.

Review of Previous Work

Ong.K.C.G, Paramasivam.P and Lim.C.T.E. (1992),In this study the methods of strengthening of reinforced concrete beams using ferrocement laminates with skeletal bar attached onto the soffit of the beams are reviewed. The methods of anchorage of the ferrocement laminates in the strengthened beams have been investigated. The methods of increasing the ultimate load of the original beams using ferrocement laminate and to control the cracking behavior of the beams as well the effect of the damage of original beams prior to repair are examined.

It is concluded that the strengthened beams have performed better in cracking behavior, reduction in mid-span deflection and increased ultimate load. Further, the pre-cracked beams prior to repair did not affect the ultimate loads of the strengthened beams tested.

Mohd Zamin Zumaat and Ashraful Alam (2006),

In this study, methods of strengthening of reinforced concrete beams using ferrocement laminates with skeletal bar attached on to the soffit of the beams are reviewed. The addition of ferrocement laminates with skeletal bar to the soffit (tension face) of the beams substantially delayed the formations of first crack, restrained the crack widths and increased the flexural stiffness and load capacities of the strengthened beams. The effects of curtailing the ferrocement laminate short of the supports were studied. In the strengthening carried out in the present work, the ferrocement laminates were extended over the supports. This however would be difficult to achieve in practice.

Vidivelli.B, et al (2001),

In this study, the damage due to overloading is considered. A total of three beams were cast and tested. One beam (control beam) was tested to ascertain the load deflection behaviour and ultimate load. The remaining two beams were damaged by overloading. After unloading the damaged beam specimens were repaired with ferrocement laminates with single layer at tension face using epoxy. Static test was conducted on all the beams to determine the load deflection behaviour and ultimate load. A comparison was made on crack width, deflection and ultimate strength at different load stages between control, damaged and repaired beams.

Experimental Programme

Material Used

For the beam specimen, the concrete with design compressive strength of M20 was used. The concrete mix proportions are given in Table1. 43 grade Portland Pozzalana Cement (PPC) confirming to IS: 1489 – 1991, having a specific gravity of 2.92 was used. Locally available river sand having a fineness modulus of 2.61, specific gravity of 2.65 and coarse aggregates of 20mm maximum size, having a fineness modulus of 6.97 and specific gravity of 2.9, were used. High yield strength deformed bars of Fe 415 were used as reinforcement in the concrete beam

|

| Figure 1: Cross section and reinforcement details of RC Beams |

For casting of the ferrocement laminates Portland cement mortar matrix, woven and welded meshes of size 24 gauge are tied together to act as reinforcement. Ferrocement may require chemical additives to reduce the reaction between the matrix and the reinforcement.

Details of Test Specimen

|

| Figure 2: Preparation of distressed beam surface |

|

| Figure 3: Ferrocement laminate |

Five beams were cast for flexural test out of which one beam was control beam the second and third were tested for service load and rehabilitated and the fourth and fifth beams are retrofitted. For rehabilitation and retrofitting ferrocement laminates were used. The details of reinforcement used in the beam are as shown in the Fig.1. Wooden moulds satisfying the above specimen size were used. Before casting, machine oil was applied on the inner surfaces of moulds. Concrete was mixed using tilting type laboratory concrete mixer and was poured into the moulds in layers. Each layer of concrete was compacted well. The specimens were removed from mould after 24 hours of casting and then cured using jute bags. All specimens were moist cured for 28 days.

Bonding of Ferrocement laminate to beam

|

| Figure 4: Bonding of laminnates to the beam |

|

| Figure 5: Experimental setup |

Before bonding the fabricated ferrocement laminates on the soffit (tension side) of the concrete beam, surface was made rough using sand blasting and cleaned with an air blower to remove all dirt and debris. Once the surface was prepared to the required standard, the epoxy resin was mixed in accordance with manufacturer's instructions. Mixing was carried out in a metal container with base to hardener ratio of 1:2 and was continued until the mixture obtained uniform colour. Then it was applied both on laminate and beam surface and bonded properly without any air gap.

Experimental set-up

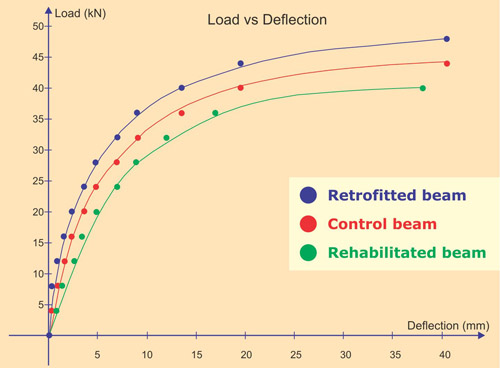

Two-point loading system was adopted for the tests. At the end of each load increment, deflection and ultimate load were carefully observed and recorded. The ultimate load for the control beam was found out. Then the other two beams (S) were tested for service load and rehabilitated with ferrocement laminates. The other two beams (R) were retrofitted with ferrocement laminates. The rehabilitated and retrofitted beams were again tested by two point loads and at the end of each load increment; the deflection was carefully observed and recorded. The recorded values are graphically represented and are shown in Fig.6. |

| Figure 6: Load vs Deflection |

Results and Discussions

From the test results summarized in Fig.6, it can be concluded that the rehabilitated beam with ferrocement laminates 12% lesser load than the controlled beam. The retrofitted beam carries 18% more load than that of control and 24% of rehabilitated beam. Fig.6 shows the ultimate load carrying capacity of the beams with different configuration.Acknowledgements

The experimental work was carried out in the Structural Engineering Laboratory of Thiagarajar College of Engineering, Madurai and Tamilnadu. We would like to thank the faculty members of Structural engineering Department, AnnamalaiUniversity, Annamalai nagar.References

- Mohammad taghi kazemi and Reza morshed (2005), "Seismic shear strengthening of RC columns with ferrocement jacket", Journal of structural Engineering, Vol.1.

- Ong, K.C.G, Paramasivam. P and Lim, C.T.E (1992), "Flexural strengthening of Reinforced concrete beams using ferrocement laminates", Journal of Ferrocement, Vol.22, No.4, PP. 331 - 342.

- Vidivelli.B, Antony Jeyasehar.C, Srividya P.R. (2001),"Repair and Rehabilitation of Reinforced concrete beams by Ferrocement," In proceedings of the Seventh International conference on ferrocement, Singapore, PP. 465 – 470.

NBM&CW March 2011