Offsite Manufacturing is the Future of Construction

Nejeeb Khan, Head Design & Business Strategy, Katerra

The need for technology driven construction in retail, housing, education institutions and hospitals is rising in India owing to growing urbanization. Today, every other MNC wants a presence in India, which indicates that there will be a huge requirement for offices and tech parks across the country in the coming years. Technology driven offsite manufacturing will help in catering to this demand by reducing delivery time up to two-third, thereby speeding up the construction process.

Design and Construction Disconnect

Population explosion and rapid urbanization has increased the need for smart living across residential and commercial spaces. However, there is still a deficit of quality spaces across India’s burgeoning cities and the gap is growing every year. Today, the Indian real estate industry has been struggling with delays in completion due to lack of technology advancements, procedural and permission constraints, and delayed processes across the cycle.

A report published in April 2019 by ANAROCK Property Consultants shows that in the top seven property markets of India, a stock of 5.6 lakh units worth ₹4,51,750 crore are lying under delayed housing. A similar challenge plagues the commercial buildings (offices and malls), which are also the key growth areas of the real estate sector. This has led to a vicious spiralling downward trend economically for sectors such as banking, land acquisition and development, and further impacted the real estate sector negatively.

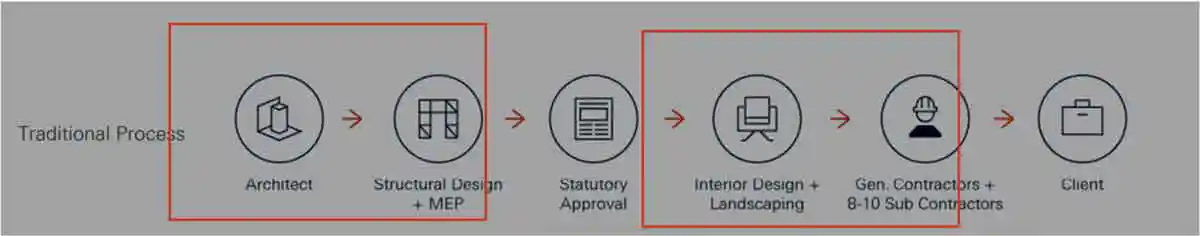

While the numbers look staggering, it is important to understand the bottlenecks that are leading to delays in project completions. In the traditional construction process, delays often occur in the design phase and in the contracting phase, and due to the disconnect between the two.

Sustainable Practices - Offsite Construction

“Productivity in construction could receive a substantial boost from standardisation, modularisation and prefabrication,” says the World Economic Forum (WEF) report on Shaping the Future of Construction. The Burj Khalifa stands testimony to this truth.

Technology today is a huge enabler for commercial, retail, and residential real estate. While we do hear about tech enabled 3D printing, we do not often realise that the applications can far exceed the end-consumer benefits. This and many other tech applications come together in the making of modular design and DFMA – Design for Manufacture Assembly.

DFMA is the combination of two methodologies - Design for Manufacture, which means the design for ease of manufacture of the parts that will form a product, and Design for Assembly, which means the design of the product for ease of assembly. This manages to address two levels of processes in a single shot, as ease of manufacture and assembly design reduce significant time and investment bottlenecks.

Companies are beginning to integrate innovations such as robotics, drones, and building information modelling (BIM) into routine construction practices. In the US, a boom in construction start-ups that develop or use such innovations attracted more than $1 billion in venture capital investments in the first half of 2018 - a 30% increase over the previous year.

A report by WEF states that constructed objects account for 25-40% of the world’s carbon emissions, and 30% of global greenhouse gas emissions are attributable to buildings. Additionally, eco-unfriendly construction techniques do not account for waste management on-site. The net effect is a disaster in the making. With time, environment-friendly norms and their implementation will become a priority for every country.

In the face of a challenge like this, offsite manufacturing solutions are enablers for organisations to become environment friendly. Achieving “zero” waste within an organisation will not only facilitate eco-friendly practices, but will also improve cost-efficiency for the developer.

Advantages of Offsite Manufacturing

Offsite manufacturing solutions bring their own advantages to the table. These include:

- Optimization and Quality: Advanced technologies used create a better-quality product (i.e. reduced tolerances, thinner sections, engineered solutions).

- Environmental: The components use less water, dust pollution is reduced, and material usage is optimized since precast concrete units can be re-used or recycled almost 100%, no matter how heavily reinforced.

- Safe, stable and durable: Offsite manufactured precast elements have better structural stability and long-term durability.

- Versatility: Factory production of concrete panels allows for a wide choice of surface finishing, colours, and unique shapes.

- Speed: Offsite manufactured buildings are built 50% faster than traditional construction.

Katerra, a leading design and technology driven global construction company, is introducing many new and innovative solutions in India, which need to be adapted to cater to the country’s growing demand for infra development. India has a tremendous potential for replicating some of the global construction models and for building beautiful structures in both commercial and residential sectors.

With Katerra’s cutting-edge technology, the end products are more durable, sustainable, and better designed, and they enable speed and precision during construction. Committed to follow sustainable practices, Katerra consumes 30% less water and materials across all its projects. Onsite manufacturing and assembly ensure minimal dust pollution and wastage. Katerra also provides end-to-end building services such as complete 3D rooms, walls, beams, columns, hollow core slabs, double walls, modular MEPs, and plug-and-play bathroom pods.

Plans for India

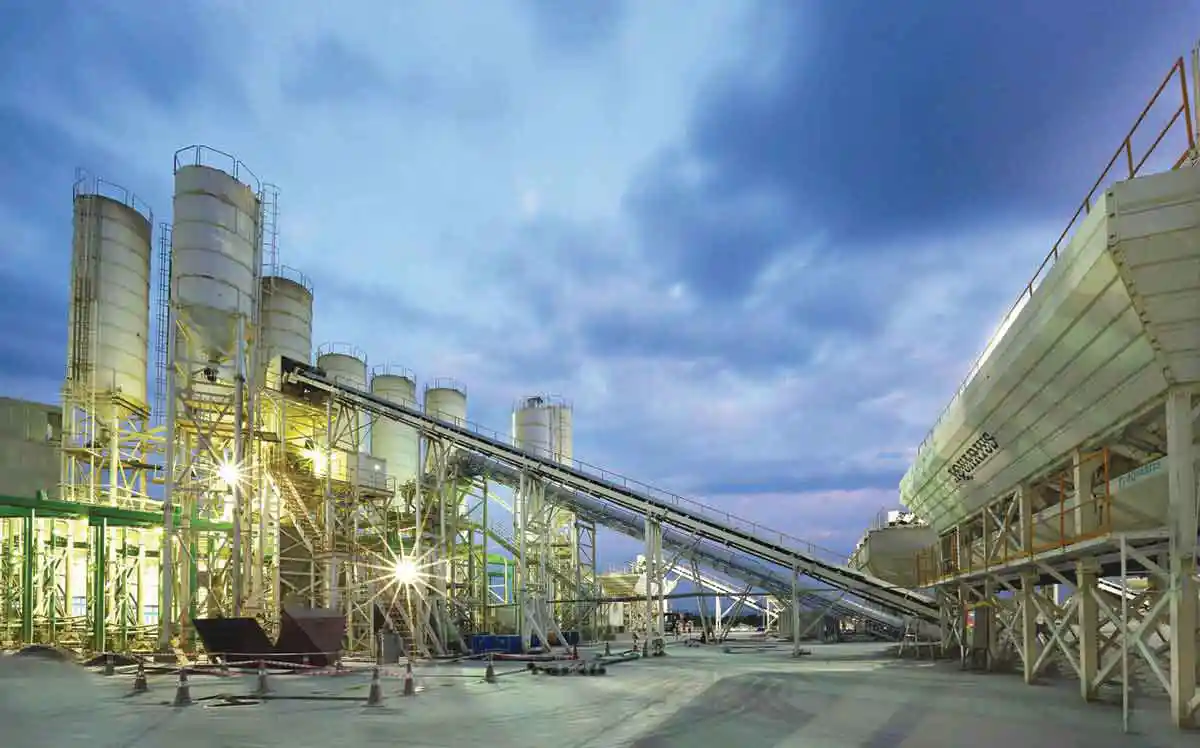

Apart from the company’s factory at Krishnagiri near Bangalore, Katerra now has a factory in Hyderabad to service clients in the southern part of India. Going forward, plans are afoot to set up factories in the Mumbai-Pune region in the latter part of the year, followed by a plant in NCR to cater to the northern market.

Katerra is poised to create over 1,000 factory jobs and over 7,000 additional jobs in Hyderabad across various jobsite and auxiliary services. Katerra also plans to set up vocational training centres to upskill the workforce and provide technical training to help them build long-term careers.

Katerra plans to expand its operations in the Indian market and revolutionize the construction sector by introducing advanced global practices. With the rapid demographic, climatic and social changes, and quick advancements in technology, the real estate sector will have to adapt and accept the whirlwind of changes facing them. Developers who adapt to the changes sooner than later will have the first-mover advantage.

NBM&CW September 2019