FAIRCRETE WW (Water Wash Admixtures)

There is a growing problem with disposal of wash water from cleaning the inside of truck mixer drums at many ready mixed concrete plants. The Landfill Tax has increased the cost of disposal and the ability to dispose of contaminated water through the drainage system has also been prohibited. One solution to this is to recycle the wash water by the use of a truck wash water admixture.

Bhavesh ShahIt is common practice in the ready-mixed concrete industry to thoroughly clean the inside of a concrete truck's drum at the end of each day using approximately 150-300 gallons of water. According to the Water Quality Act (part 116), truck wash water is a hazardous substance (it contains caustic soda and potash) and its disposal is regulated by the Environmental Protection Agency (EPA). In addition, a high pH makes truck wash water hazardous under the EPA definition of corrosivity. These regulations require concrete producers to contain truck wash water on-site and prohibit its discharge off-site

One alternative to disposal of concrete wash water in the usual way is the use of chemical stabilizing systems. The use of these admixtures circumvents the necessity to remove any wash water from concrete truck drums, and allows wash water to be reused for mixing more concrete. The admixture is added in a dosage dependent on the amount of waste water present in the drum of the concrete truck, and on the time span desired for the reuse of the water. These admixtures momentarily stop the hydration process, literally putting the cement present in a "dormant" state. Because the hydration process is interrupted, the cement in the wash water will not harden into concrete, nor will it adhere to the inside of concrete truck drums. The stabilized water is calculated into the next mix of concrete and more concrete can then be mixed in the concrete trucks.

Wash water stabilization systems are used to stabilize concrete wash water in the drum of a ready mixed truck on an overnight or over weekend basis. The washings are then incorporated in the production of the next day's initial load. This process eliminates or reduces the volume of solids/water deposited into a plant wash pit. Research has shown that the correct use of proprietary admixtures does not impart any deleterious effect on the properties of fresh concrete in respect of stiffening times, strength or other properties.

Technically, they may also be used to stabilize returned loads, which may be either downgraded to a lower specification and/or made up to new loads. However, such concretes could only be used with the agreement of the supplier, customer and regulating body. These materials function by coating the cement particles and preventing hydration taking place for a specified period of time. The time delay depends on the dosage, which is itself related to a number of other factors. With some systems, an activator may also be used to restart hydration.

Though preliminary studies have shown that concrete stabilized wash water can produce acceptable concrete, the main concern to FDOT is the state and type of admixture residues in the wash water, the effects of these residues on concrete properties, and the percentage range over which these derivatives have detrimental effect on concrete performance. Suspicion of detrimental effects on concrete durability is sufficient cause to deny use of stabilizer agents. However, if stabilized water were to be used, the benefits would include reducing the amount of water needed to clean ready-mix truck drums, reducing labor costs pertaining to washing out trucks, eliminating wash water disposal, eliminating the need for settling ponds/slurry pits and disposal costs, and reducing EPA concerns pertaining to wash water.

Following steps are to be observed while using component –A in transit.

(1) Transit shall not have any surplus concrete or balance concrete in it.

(2) Add 200 liters of water in rotating drum.

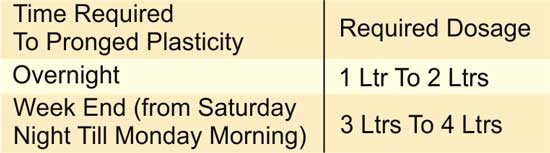

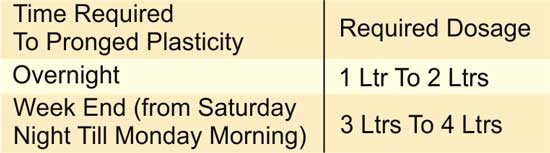

(3) Add 1 liter to 2 liters of component – A in drum and rotate the drum for 7 to 8 minutes in speed.

(4) Park the transit in parking area by recording actual quantity of water added in to it and dosage of Component – A ,after desired retention FAIRMATE WATER WASH SYSTEM (Component – B) is to be added in transit drum @ 3% to 8% by weight of binders . Rotate the drum for 7 to 8 minutes when concrete is to be restarted.

Fairmate Component – B activates the hydration process in concrete.

Fresh concrete is loaded in concrete by considering previously added water with Component – A.

Bhavesh Shah

One alternative to disposal of concrete wash water in the usual way is the use of chemical stabilizing systems. The use of these admixtures circumvents the necessity to remove any wash water from concrete truck drums, and allows wash water to be reused for mixing more concrete. The admixture is added in a dosage dependent on the amount of waste water present in the drum of the concrete truck, and on the time span desired for the reuse of the water. These admixtures momentarily stop the hydration process, literally putting the cement present in a "dormant" state. Because the hydration process is interrupted, the cement in the wash water will not harden into concrete, nor will it adhere to the inside of concrete truck drums. The stabilized water is calculated into the next mix of concrete and more concrete can then be mixed in the concrete trucks.

Wash water stabilization systems are used to stabilize concrete wash water in the drum of a ready mixed truck on an overnight or over weekend basis. The washings are then incorporated in the production of the next day's initial load. This process eliminates or reduces the volume of solids/water deposited into a plant wash pit. Research has shown that the correct use of proprietary admixtures does not impart any deleterious effect on the properties of fresh concrete in respect of stiffening times, strength or other properties.

Technically, they may also be used to stabilize returned loads, which may be either downgraded to a lower specification and/or made up to new loads. However, such concretes could only be used with the agreement of the supplier, customer and regulating body. These materials function by coating the cement particles and preventing hydration taking place for a specified period of time. The time delay depends on the dosage, which is itself related to a number of other factors. With some systems, an activator may also be used to restart hydration.

Though preliminary studies have shown that concrete stabilized wash water can produce acceptable concrete, the main concern to FDOT is the state and type of admixture residues in the wash water, the effects of these residues on concrete properties, and the percentage range over which these derivatives have detrimental effect on concrete performance. Suspicion of detrimental effects on concrete durability is sufficient cause to deny use of stabilizer agents. However, if stabilized water were to be used, the benefits would include reducing the amount of water needed to clean ready-mix truck drums, reducing labor costs pertaining to washing out trucks, eliminating wash water disposal, eliminating the need for settling ponds/slurry pits and disposal costs, and reducing EPA concerns pertaining to wash water.

Mechanism

The chemicals used have the ability to stop the hydration of the main phases of the Portland cement; especially the tri-calcium silicate, even after initial hydration has started and to prevent nucleation of the calcium hydroxide from solution. Further hydration is suspended until an activator is added or the system is flooded with an excess of fresh hydration product when a new batch of concrete is added.Benefits:

- Eco-friendly

- Saves wash out water.

- Reduces the time of work as no cleaning of pumps and pipers requires.

- Protect the environment.

- Eliminates the wash out pits.

- Reduces clean-up time.

- Reutilization of concrete residue which eliminates the concrete wash water disposal.

- Superior set retardation.

- Acts as a cleansing agent to reduce the buildup on fins.

- Improveds profitability for the ready- mix producer.

- Reduces water requirements.

Advantages

- Concrete treated with these admixtures will produce normal setting characteristics and improved ultimate compressive strength performance over conventional concrete.

- Provides a quality, profitable, and reliable method to treat returned concrete for reuse or hold (for a few hours) and then reuse on the same day.

- Reduces expensive disposal costs associated with returned concrete.

- Allows reuse of concrete wash water overnight or over a weekend in many situations.

- Reduces concrete wash water disposal.

- Reduces amount of concrete wash water needed and truck mixer washout.

- Reduces expensive disposal costs associated with concrete wash water.

- Permits long haul applications for extended haul times without slump loss.

- Provides extended truck discharge times.

- Controls peak temperature rise in the concrete.

- Reduces central mixer washout and washout water.

Specifications Conform:

ASTM C 494 Types B and D.Application

Primary Application- Stabilize wash out water

- Concrete requiring water reducing and set retardation

- Concrete requiring extended slump life

Dosage

Dosage varies between manufacturers depending on the materials used and the period before fresh concrete is to be mixed but is typically between 1 and 3 liters for a 6m3 trucks.

Following steps are to be observed while using component –A in transit.

(1) Transit shall not have any surplus concrete or balance concrete in it.

(2) Add 200 liters of water in rotating drum.

(3) Add 1 liter to 2 liters of component – A in drum and rotate the drum for 7 to 8 minutes in speed.

(4) Park the transit in parking area by recording actual quantity of water added in to it and dosage of Component – A ,after desired retention FAIRMATE WATER WASH SYSTEM (Component – B) is to be added in transit drum @ 3% to 8% by weight of binders . Rotate the drum for 7 to 8 minutes when concrete is to be restarted.

Fairmate Component – B activates the hydration process in concrete.

Fresh concrete is loaded in concrete by considering previously added water with Component – A.

Dispensing

The product should be dispensed through a calibrated, automatic dispenser. This should include a system that allows full traceability of the use, i.e. as part of the Quality System.Overdose

Overdosing can lead to retardation with most types of concrete.Operation

- The ready-mix truck should be emptied of all returned concrete except tailings coating the drum.

- The correct dosage is added, either via a dispenser for liquid products or via "no of sachets" for powder products.

- Then two methods of cleaning can be used:M

Water Wash

- The driver then operates a lance that discharges the admixture and water at high pressure to wash the residue to the bottom of the drum.

- The dispenser is programmed to deliver exactly 200 liters of water into the drum.

- The drum may now be left static until the next day (or over a weekend if appropriately dosed).

- The only alteration to the next mix is to reduce the water by 200 liters.

Stoning

- This uses 2 tones of coarse aggregate plus 200 liters of water

- This mixture including the admixture are turned in the drum then brought up and down the blades three times. The drum is stopped on the third cycle whilst the mixture is at the top.

- The drum is then left to stand.

- The next mix added should be adjusted for the coarse aggregate and water.

Use with other admixtures

Wash water admixtures are compatible with air entrainers, normal and superplasticing admixtures. The manufacturer's advice should be sought regarding other types of admixture.Effects on properties of concrete Strength

The compressive strength of concrete is not significantly affected by the use of wash water admixtures provided the product is used according to the manufacturer's instructions. In many cases the strength of the concrete has been shown to increase.Workability

The workability of the concrete is not affected by the use of wash water admixtures.Setting time

The setting time of the concrete is not significantly affected by the use of wash water admixtures.Other fresh concrete properties

Air entrainment, bleed and temperature rise are similar to those of a control concrete containing no wash water admixture.Other hardened concrete properties

Creep and drying shrinkage are not altered from that of plain concrete and durability is unchanged.Precaution / Limitation

- Wear protective goggles and gloves when handling FAIRMATE WATER WASH ADMIXTURE

- Add to mix independent of other admixtures.

- Care should be taken to maintain admixtures above freezing; however, freezing and subsequent thawing will not harm the material if thoroughly agitated.

- Do not agitate with air

NBM&CW February 2013