Effect of Fly Ash on Recycled Aggregate Concrete

Use of recycled aggregate in concrete can be useful for environmental protection and economical terms. Recycled aggregates are the materials for the future. Again fly ash is also a by product from various industries. Hence a study was needed to arrive at various combinations of both of these materials. Hence a popular concrete mix 0.5:1:1:2 was used in this study for experimental purpose. Fly ash confirming to IS 3812:2003 was used as a part replacement of cement. Fly ash was replaced by cement in % of 0%, 10%, 20%, 30% and 40%. Again natural aggregates were replaced by recycled coarse aggregates (RCA) in % of 0%, 10%, 20%, 30% 50% and 100%. Thus total thirty different trial mixes were prepared and the effects of RCA with fly ash, on fresh and hardended properties have been determined.

D. N. Parekh, Research Scholar, and

Dr. C. D. Modhera, Professor, Applied Mechanics Department; SVNIT; Surat.

Dr. C. D. Modhera, Professor, Applied Mechanics Department; SVNIT; Surat.

Introduction

Globally, the concrete industry consumes large quantities of natural resources, which are becoming insufficient to meet the increasing demands. At the same time, large number of old buildings 8 other structures have reached the end of their service life and are being demolished, resulting in generation of demolished concrete. Some of this concrete waste is used as backfill material, and much being sent to landfills. Recycling concrete by using it as replacement to new aggregate in concrete could reduce concrete waste and conserve natural sources of aggregate. In the last two decades, a variety of recycling methods for construction and demolition wastes (CDW) have been explored and are in well developed stage. It is known as recycled aggregate (RA). BS EN Standards [1,2] recommends for recycled concrete to be used in secondary structural members of relatively low grades, e.g. curbs, paving blocks and ground bearing floor slabs.

Review of Literature

Cho and Yeo (2004) [3] found that, due to the high water absorption of the recycled aggregate, a higher slump loss was observed when compared to that of natural aggregate concrete. Dhir et al. (1999) [4,5] showed that the compressive strength of concrete prepared with 100% coarse and 50% fine recycled aggregates was between 20 and 30% lower than that of the corresponding natural aggregate concrete. However, the reduction in strength can be minimized if the mixing procedure is modified (Otsuki et al. 2003; Tam et al. 2005) [6,7]. Further, Olorunsogo and Padayachee (2002) [8] found that the water absorptivity of concrete prepared with 100% recycled aggregate was higher than that of natural aggregate concrete at the curing age of 28 days. Abou-Zeid et al. (2005) [9] reported that recycled aggregate concrete exhibited higher water permeability and lower resistance to chloride ion penetration compared to conventional concrete. Salem et al. (2003) [10] showed that recycled aggregate concrete had a lower resistance to freezing and thawing compared to natural agg. concrete. Otsuki et al. (2003) [6] reported that the carbonation resistance of recycled aggregate concrete was inferior compared to that of natural aggregate concrete. Finally, the drying shrinkage and creep of recycled aggregate concrete was found to be higher than those of natural aggregate concrete (Tavakoli and Soroushian 1996; Gomez-Soberon 2003) [11, 12].

Fly ash is known to be a good pozzolanic material and has been used to increase the ultimate compressive strength and workability of fresh concrete (Mehta 1985) [13]. Naik and Ramme (1989) [14] produced concrete mixes containing large quantities of fly ash which achieved compressive strengths of 21 and 28 MPa within 28 days.

Fly ash is known to be a good pozzolanic material and has been used to increase the ultimate compressive strength and workability of fresh concrete (Mehta 1985) [13]. Naik and Ramme (1989) [14] produced concrete mixes containing large quantities of fly ash which achieved compressive strengths of 21 and 28 MPa within 28 days.

Experimental Programme

Following experimental programme was taken up on different materials as per respective Indian Standards. Utmost care was taken for preservation of materials, to the testing of samples and taking readings.

All materials, i.e. fly ash, cement, aggregates etc were tested as per respective IS. Both the normal and recycled aggregates used in this study were in an air-dried state. A constant effective water/binder ratio (w/b) was maintained at 0.5 (or effective water of 266.7 kg/m3) for all concrete mixtures. Since the recycled aggregates had greater water absorption than normal aggregates, they required more water to maintain the slump of fresh concrete from 50 to 100 mm.

Now, Mix type i. e. Mix A prepared with constant proportions of 0.5:1:1:2. Cement content in this mix has been replaced by fly ash in 10%, 20%, 30% and 40%. Natural aggregates (NA) were replaced by Recycled Aggregate (RA) of 0%, 10%, 20%, 30%, 50%, and 100%. Detail proportions with mix designations are given below in Table 1.

These mixes were prepared tested in laboratory for fresh and hardended properties of RAC. Comparisons for the different results are prepared with graphs.

All materials, i.e. fly ash, cement, aggregates etc were tested as per respective IS. Both the normal and recycled aggregates used in this study were in an air-dried state. A constant effective water/binder ratio (w/b) was maintained at 0.5 (or effective water of 266.7 kg/m3) for all concrete mixtures. Since the recycled aggregates had greater water absorption than normal aggregates, they required more water to maintain the slump of fresh concrete from 50 to 100 mm.

Now, Mix type i. e. Mix A prepared with constant proportions of 0.5:1:1:2. Cement content in this mix has been replaced by fly ash in 10%, 20%, 30% and 40%. Natural aggregates (NA) were replaced by Recycled Aggregate (RA) of 0%, 10%, 20%, 30%, 50%, and 100%. Detail proportions with mix designations are given below in Table 1.

| Table 1 Mix Proportions A with fly ash | ||||||

| Designation | Water | Cement | Fly Ash | Fine Aggregate | Coarse Aggregate | |

| Recycled | Natural | |||||

| AF00R00 | 0.5 | 1 | 0 | 1 | 0 | 2 |

| AF00R10 | 0.5 | 1 | 0 | 1 | 0.2 | 1.8 |

| AF00R20 | 0.5 | 1 | 0 | 1 | 0.4 | 1.6 |

| AF00R30 | 0.5 | 1 | 0 | 1 | 0.6 | 1.4 |

| AF00R50 | 0.5 | 1 | 0 | 1 | 1 | 1 |

| AF00R100 | 0.5 | 1 | 0 | 1 | 2 | 0 |

| AF10R00 | 0.5 | 0.9 | 0.1 | 1 | 0 | 2 |

| AF10R10 | 0.5 | 0.9 | 0.1 | 1 | 0.2 | 1.8 |

| AF10R20 | 0.5 | 0.9 | 0.1 | 1 | 0.4 | 1.6 |

| AF10R30 | 0.5 | 0.9 | 0.1 | 1 | 0.6 | 1.4 |

| AF10R50 | 0.5 | 0.9 | 0.1 | 1 | 1 | 1 |

| AF10R100 | 0.5 | 0.9 | 0.1 | 1 | 2 | 0 |

| AF20R00 | 0.5 | 0.8 | 0.2 | 1 | 0 | 2 |

| AF20R10 | 0.5 | 0.8 | 0.2 | 1 | 0.2 | 1.8 |

| AF20R20 | 0.5 | 0.8 | 0.2 | 1 | 0.4 | 1.6 |

| AF20R30 | 0.5 | 0.8 | 0.2 | 1 | 0.6 | 1.4 |

| AF20R50 | 0.5 | 0.8 | 0.2 | 1 | 1 | 1 |

| AF20R100 | 0.5 | 0.8 | 0.2 | 1 | 2 | 0 |

| AF30R00 | 0.5 | 0.7 | 0.3 | 1 | 0 | 2 |

| AF30R10 | 0.5 | 0.7 | 0.3 | 1 | 0.2 | 1.8 |

| AF30R20 | 0.5 | 0.7 | 0.3 | 1 | 0.4 | 1.6 |

| AF30R30 | 0.5 | 0.7 | 0.3 | 1 | 0.6 | 1.4 |

| AF30R50 | 0.5 | 0.7 | 0.3 | 1 | 1 | 1 |

| AF30R100 | 0.5 | 0.7 | 0.3 | 1 | 2 | 0 |

| AF40R00 | 0.5 | 0.6 | 0.4 | 1 | 0 | 2 |

| AF40R10 | 0.5 | 0.6 | 0.4 | 1 | 0.2 | 1.8 |

| AF40R20 | 0.5 | 0.6 | 0.4 | 1 | 0.4 | 1.6 |

| AF40R30 | 0.5 | 0.6 | 0.4 | 1 | 0.6 | 1.4 |

| AF40R50 | 0.5 | 0.6 | 0.4 | 1 | 1 | 1 |

| AF40R100 | 0.5 | 0.6 | 0.4 | 1 | 2 | 0 |

These mixes were prepared tested in laboratory for fresh and hardended properties of RAC. Comparisons for the different results are prepared with graphs.

Materials Testing

Fly ash and Cement

The fly ash used here was in accordance with its IS 3812 (Part 1): 2003 [15]. Chemical requirem- ents and physical requirements of fly ash were in accordance with table 1 and table 2 of IS 3812 (Part 1): 2003 [15] respectively.

An OPC 53 grade conforming to IS 12269 – 1987 [16] was used throughout the study for concrete production. The samples of cement were taken in accordance with the requirements of standard IS: 3535-1986[17] and tested by using the relevant specification of IS [18-27]. All results were shown in Table 2 with their respective IS requirements for comparisons.

Fine and Coarse Aggregates

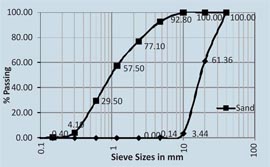

Local river sand with a fineness modulus of 3.04 was used as a fine aggregate. Crushed limestone with a maximum size of 20 mm was used as coarse aggregate. Jaw crusher was used for preparation of recycled aggregates and opening for size has been decided by considering the Fineness Modulus (FM) of NCA. In this study, NCA and RCA were used with same FM to overcome aggregate size effect in concrete. Samples for any testing of aggregate were prepared in accordance with IS: 2430 – 1995[22]. Sieve Analysis and other testes of aggregates were carried out as per the guidelines given by respective IS [18] and detail grading chart is shown below in Fig 1.

Elongation and flakiness index tests were carried out in accordance with IS: 2386 (PART I) – 1997[19], while specific gravity, apparent specific gravity, water absorption and bulk density were determined using IS: 2386 (PART III) – 1997[20]. Results were shown in Table 3.

Mechanical properties of aggregates were determined by using IS: 2386 (Part IV) – 1997[21] and shown in table 4 below. It shows that all aggregates results were within prescribed IS limits.

Concrete Testing

Sampling and analysis of concrete have been carried out as per IS: 1199 – 1959[18]. The quantities of cement, fly ash, silica fume, each size of aggregate, and water for each batch was determined by weight, to an accuracy of 0.1 percent of the total weight of the batch. Fresh properties of concrete (i.e. workability) was measured with help of slump cone test and test was carried out in accordance with IS:1199 – 1959[18]. The cubical moulds were used 150x150x150 mm while cylindrical mould was of 150 mm diameter and 300 mm height and both conforming to IS: 10086-1982[32]. All strength tests were carried out in accordance with IS: 516 – 1963 [33], while split tensile strength of concrete was measured in accordance with IS: 5816 – 1999[30].

The fly ash used here was in accordance with its IS 3812 (Part 1): 2003 [15]. Chemical requirem- ents and physical requirements of fly ash were in accordance with table 1 and table 2 of IS 3812 (Part 1): 2003 [15] respectively.

An OPC 53 grade conforming to IS 12269 – 1987 [16] was used throughout the study for concrete production. The samples of cement were taken in accordance with the requirements of standard IS: 3535-1986[17] and tested by using the relevant specification of IS [18-27]. All results were shown in Table 2 with their respective IS requirements for comparisons.

| Table 2 : Results of Cement | |||

| No | Type of Test | Results | IS - Limits |

| 1. | Type of Cement | OPC 53 Grade | - |

| 2. | Fineness Test | 8% | <10% |

| 3. | Normal Consistency | 29% | - |

| 4. | Soundness Test. | 4.9 mm | < 10 mm |

| 5. | Initial Setting time | 85 Minutes | >30 min |

| 6. | Final Setting time. |

198 Minutes |

|

|

7. |

Compressive Strength Test | 27.87MPa (3 – Days) | >27 MPa |

| 37.66MPa (7 – Days) | >37 MPa | ||

| 54.73MPa (28 – Days) | >53 MPa | ||

Fine and Coarse Aggregates

|

| Figure 1: Grading Curve of Fine and Coarse Aggregate |

Elongation and flakiness index tests were carried out in accordance with IS: 2386 (PART I) – 1997[19], while specific gravity, apparent specific gravity, water absorption and bulk density were determined using IS: 2386 (PART III) – 1997[20]. Results were shown in Table 3.

| Table 3 :Basic properties of aggregates | |||

| NCA | RA | NFA | |

| Specific Gravity | 2.84 | 2.35 | 2.70 |

| Apparent Sp. Gravity | 2.77 | 2.31 | 2. 67 |

| Water Absorption | 0.89% | 7.57% | 0.80% |

| Bulk Density (kg/m3) | 1490 | 1290 | 1480 |

| Apparent Density (kg/m3) | 2820 | 2510 | 2680 |

| Flakiness Value (%) | 14.4 % | 25.33 % | - |

| Elongation Value (%) | 16.45 % | 21.50 % | - |

| Table 4 : Mechanical properties of Aggregates | ||

| NCA | RA | |

| Impact Value (%) | 8.88 % | 15.03 % |

| Crushing Value (%) | 14.04 % | 25.52 % |

| Abrasion Value (%) | 15.58 % | 26.70 % |

| IS Limit (For Road) (%) |

30.00 % |

|

| IS Limit (For Buildings) (%) |

|

|

| Table 5 : Workability for Mix A with different % of FA and RCA (in slump value) | ||||||

| Fly ash mix | Different % of RA | |||||

| 0 | 10 | 20 | 30 | 50 | 100 | |

| AF00 | 135 | 125 | 110 | 85 | 75 | 60 |

| AF10 | 135 | 130 | 115 | 90 | 85 | 75 |

| AF20 | 140 | 135 | 120 | 95 | 85 | 80 |

| AF30 | 145 | 135 | 120 | 100 | 90 | 80 |

| AF40 | 155 | 145 | 125 | 105 | 100 | 90 |

Mechanical properties of aggregates were determined by using IS: 2386 (Part IV) – 1997[21] and shown in table 4 below. It shows that all aggregates results were within prescribed IS limits.

Concrete Testing

Sampling and analysis of concrete have been carried out as per IS: 1199 – 1959[18]. The quantities of cement, fly ash, silica fume, each size of aggregate, and water for each batch was determined by weight, to an accuracy of 0.1 percent of the total weight of the batch. Fresh properties of concrete (i.e. workability) was measured with help of slump cone test and test was carried out in accordance with IS:1199 – 1959[18]. The cubical moulds were used 150x150x150 mm while cylindrical mould was of 150 mm diameter and 300 mm height and both conforming to IS: 10086-1982[32]. All strength tests were carried out in accordance with IS: 516 – 1963 [33], while split tensile strength of concrete was measured in accordance with IS: 5816 – 1999[30].

Results and Discussions

Fresh Properties of Concrete

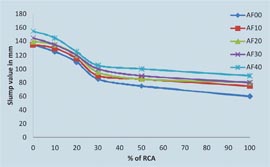

Fly ash is spherical, and when used in concrete typically increases slump or reduces the required mixing water. However, results in figure 2 indicates that the slump of fresh concretes containing recycled aggregates and fly ash increased slightly with increased fly ash replacement. For example, AF00, AF10, AF20, AF30 and AF40 with 100% replacement of recycled aggregate had initial slumps of 60, 75, 80, 80 and 90 mm respectively. The slightly greater slump of fresh concrete containing greater fly ash replacement could have been caused by a greater volume of paste (ground fly ash had a much lower specific gravity than Portland cement), leading to reduced aggregate particle interference and enhanced concrete workability. In addition, perhaps not all of the fly ash particles were ground and sufficient spherical particles exist to help lubricate the mixture. This result was similar to Ravina (1984)[34] who found that fly ash can reduce slump loss when it is partially used to replace cement.

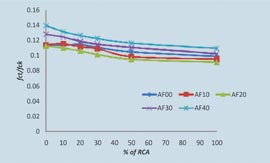

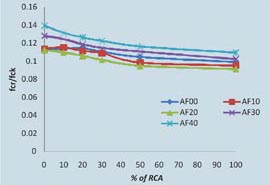

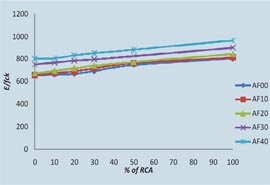

Ratio of different quantities i.e. fct/fck , fcr/fck or E/fck gives clear idea regarding relationship of both quantities with % of recycled coarse aggregates. Again similar pattern of results were observed for all graphs.

Fly ash is spherical, and when used in concrete typically increases slump or reduces the required mixing water. However, results in figure 2 indicates that the slump of fresh concretes containing recycled aggregates and fly ash increased slightly with increased fly ash replacement. For example, AF00, AF10, AF20, AF30 and AF40 with 100% replacement of recycled aggregate had initial slumps of 60, 75, 80, 80 and 90 mm respectively. The slightly greater slump of fresh concrete containing greater fly ash replacement could have been caused by a greater volume of paste (ground fly ash had a much lower specific gravity than Portland cement), leading to reduced aggregate particle interference and enhanced concrete workability. In addition, perhaps not all of the fly ash particles were ground and sufficient spherical particles exist to help lubricate the mixture. This result was similar to Ravina (1984)[34] who found that fly ash can reduce slump loss when it is partially used to replace cement.

Ratio of different quantities i.e. fct/fck , fcr/fck or E/fck gives clear idea regarding relationship of both quantities with % of recycled coarse aggregates. Again similar pattern of results were observed for all graphs.

|

|

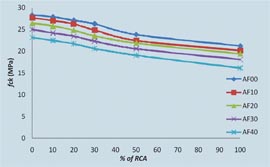

| Figure 2: Workability for Mix A with different % of FA and RCA | Figure 3: fck7 for Mix A with different % of FA and RCA (MPa) |

|

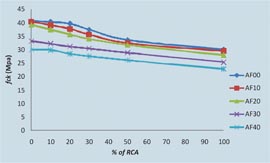

|

| Figure 4: fck for Mix A with different % of FA and RCA (MPa) | Figure 5: Ratio of fct/fck for Mix A with different % of FA and RCA |

|

|

| Figure 6: Ratio of fcr/fck for Mix A with different % of FA and RCA | Figure 7: Ratio of E/fck for Mix A with different % of FA and RCA |

| Table 6 : fck7 for Mix A with different % of FA and RCA (MPa) | ||||||

| Fly ash mixes | Different % of RCA | |||||

| 0 | 10 | 20 | 30 | 50 | 100 | |

| AF00 | 28.4 | 27.95 | 27.17 | 26.34 | 23.87 | 21.25 |

| AF10 | 27.75 | 27.1 | 26.33 | 24.9 | 22.5 | 20.2 |

| AF20 | 26.5 | 25.85 | 24.88 | 23.56 | 21.89 | 19.41 |

| AF30 | 25.07 | 24.25 | 23.5 | 22.33 | 20.6 | 18.12 |

| AF40 | 23.2 | 22.5 | 21.75 | 20.66 | 19.1 | 16.15 |

| Table 7 : fck for Mix A with different % of FA and RCA (MPa) | ||||||

| Fly ash mixes | Different % of RCA | |||||

| 0 | 10 | 20 | 30 | 50 | 100 | |

| AF00 | 40.71 | 40.33 | 39.67 | 37.5 | 33.6 | 30 |

| AF10 | 40.41 | 39.16 | 37.75 | 35.67 | 32.46 | 29.5 |

| AF20 | 39.23 | 37.5 | 35.67 | 34.02 | 31.81 | 27.95 |

| AF30 | 33.2 | 32.21 | 31.14 | 30.46 | 28.88 | 25.37 |

| AF40 | 30.1 | 29.89 | 28.49 | 27.58 | 26.11 | 22.83 |

| Table 8 : fct for Mix A with different % of FA and RCA (MPa) | ||||||

| Fly ash mixes | Different % of RCA | |||||

| 0 | 10 | 20 | 30 | 50 | 100 | |

| AF00 | 4.62 | 4.59 | 4.54 | 4.15 | 3.52 | 2.97 |

| AF10 | 4.61 | 4.52 | 4.21 | 3.89 | 3.2 | 2.81 |

| AF20 | 4.41 | 4.12 | 3.78 | 3.45 | 3.02 | 2.55 |

| AF30 | 4.25 | 4.01 | 3.7 | 3.5 | 3.2 | 2.6 |

| AF40 | 4.2 | 3.93 | 3.6 | 3.38 | 3.04 | 2.5 |

| Table 9 : fcr for Mix A with different % of FA and RCA (MPa) | ||||||

| Fly ash mixes | Different % of RCA | |||||

| 0 | 10 | 20 | 30 | 50 | 100 | |

| AF00 | 4.62 | 4.59 | 4.54 | 4.15 | 3.52 | 2.97 |

| AF10 | 4.61 | 4.52 | 4.21 | 3.89 | 3.2 | 2.81 |

| AF20 | 4.41 | 4.12 | 3.78 | 3.45 | 3.02 | 2.55 |

| AF30 | 4.25 | 4.01 | 3.7 | 3.5 | 3.2 | 2.6 |

| AF40 | 4.2 | 3.93 | 3.6 | 3.38 | 3.04 | 2.5 |

| Table 10 : E for Mix A with different % of FA and RCA (MPa) | ||||||

| Fly ash mixes | Different % of RCA | |||||

| 0 | 10 | 20 | 30 | 50 | 100 | |

| AF00 | 26729 | 26646 | 26500 | 26007 | 25073 | 24143 |

| AF10 | 26664 | 26386 | 26065 | 25577 | 24786 | 24008 |

| AF20 | 26401 | 26007 | 25577 | 25177 | 24619 | 23580 |

| AF30 | 24973 | 24722 | 24445 | 24266 | 23839 | 22831 |

| AF40 | 24170 | 24114 | 23731 | 23476 | 23051 | 22042 |

Conclusions

Following conclusions are drawn.

- 10% of RA and 10% of fly ash is giving the same results as that of 100% NA and 0% fly ash.

- Workability for fresh concrete was increased with increase of incorporation of fly ash. Though due to incorporation of RA workability is going on decreasing with increase of % of RA

- Compressive strength of mix A prepared with 100% RA and 40% fly ash are lower than 100% NA and 0% fly ash concrete, by nearly 44%.

- Ratio of fct/fck or fcr/fck is giving clear idea regarding change of values for 40% fly ash incorporation.

It can be generally concluded that 10% of RA with 10% of fly ash might give better result than 10% RA and 0% fly ash for workability point of view.

Acknowledgement

Research reported in this research was supported by Gujarat Council of Science and Technology (GujCOST), Department of Science and Technology; Govt of India. This support is greatly acknowledged.

References

- BS 8500-1 Concrete. Complementary British standard to BS EN 206-1. Method of specifying and guidance for the specifier. BSI; 2006.

- BS 8500-2 Concrete. Complementary British standard to BS EN 206-1. Specification for constituent materials and concrete. BSI; 2006.

- Cho, Y. H., and Yeo, S. H. (2004). "Appli- cation of recycled waste aggregate to lean concrete subbase in highway pavement." Can. J. Civ. Eng.,31(6), 1101–1108.

- Dhir, R. K., Limbachiya, M. C., and Leelawat, T. (1999). "Suitability of recycled concrete aggregate for use in BS 5328 designated mixes." Proc. Inst. Civ. Eng., Struct. Build., 134(4), 257–274.

- Dhir, R. K., Munday, J. G. L., and Ong, L. T. (1986). "Investigations of the engineering properties of OPC/pulverized-fuel ash concrete: De- formation properties." Struct. Eng., 64B (2), 36–42.

- Otsuki, N., Miyazat, S., and Yodsudjai,W. (2003). "Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration, and carbonation of concrete." J. Mater. Civ. Eng., 15(5), 443–451.

- Ravindrajah R S, Loo Y H and Tam C T. (2005) Strength evaluation of recycled aggregate concrete by in-situ tests. Mat Stru; 21(4):289–95.

- Olorunsogo, F. T., and Padayachee, N. (2002). "Performance of recycled aggregate concrete monitored by durability indexes." Cem. Concr. Res.,32(2), 179–185.

- Abou-Zeid, M. N., Shenouda, M. N., McCabe, S., and El-Tawil F. A. (2005). "Reincarnation of concrete." Conc. Int.,27 (2), 53–59.

- Salem, R. M., Burdette, E. G., and Jack- son, N. M. (2003). "Resistance to freezing and thawing of recycled aggregate con- crete." ACI Mater. J., 100 (3), 216–221.

- Tavakoli, M., and Soroushian, P. (1996). "Drying shrinkage behavior of recycled aggregate concrete." Conc. Int., 18 (11), 58–61.

- Gomez-Soberon, J. M. V. (2003). "Relation- ship between gas absorption and the shrinkage and creep of recycled aggregate concrete." Cem Conc Res,25(2), 42–48.

- Mehta, P. K. (1985). "Influence of fly ash characteristics on the strength of Portland-fly ash mixture." Cem. Concr. Res.,15 (4), 669–674.

- Naik, T. R., and Ramme, B. W. (1989). "High-strength concrete containing large quantities of fly ash." ACI Mater. J.,86 (2), 111–116.

- IS 3812 (Part 1): 2003 Pulverized fuel ash – Specification (Part 1) For use as pozzolana in cement, cement mortar and concrete.

- IS: 12269 – 1987 Specifications for 53 – grade ordinary Portland cement.

- IS: 3535 – 1986 Method of Sampling hydraulic cements – First Revision.

- IS: 1199 – 1959 Methods of Sampling and Analysis of Concrete.

- IS: 2386 – 1997 (PART I) Method of Test for Aggregate for Concrete – Particle Size and Shape.

- IS: 2386 – 1997 (PART III) Method of Test for Aggregate for Concrete – Specific Gravity, Density, Voids, Absorption and Bulking.

- IS: 2386 – 1997 (PART IV) Method of Test for Aggregate for Concrete – Mechanical Properties.

- IS: 2430 – 1995 Methods for Sampling of Aggregates for Concrete.

- IS: 4031 – 1996 (Part – 1) Method of Physical Tests for Hydraulic Cement – Determination of Fineness by Dry Sieving.

- IS: 4031 – 1988 (Part – 3) Method of Physical Tests for Hydraulic Cement – Determination of Soundness.

- IS: 4031 – 1988 (Part – 4) Methods of physical tests for hydraulic cement – Determination of consistency of standard cement paste (First Revision)

- IS: 4031 - 1988 (Part-5) Methods of physical tests for hydraulic cement - Determination of Initial and Final Setting Times (First Revision)

- IS: 4031 – 1988 (Part – 6) Method of Physical Tests for Hydraulic Cement - Determination of Compressive Strength of hydraulic cement other than masonry cement.

- IS: 5513 - l976 Specification for Vicat Apparatus.

- IS: 5514 – 196 Specification for apparatus used in Le-Chatelier test.

- IS: 5816 – 1999 Splitting tensile strength of concrete – Method of Test.

- IS: 10080 – 1982 Specification for vibrating machine for casting standard cement mortar cubes.

- IS: 10086 – 1982 Specification for moulds for use in tests of cement and concrete.

- IS: 516 – 1999 Method of Test for Strength of Concrete.

- Ravina, D. (1984). "Slump loss of fly ash concrete." Concr. Int.,6(4), 35–39.

NBM&CW August 2012