Nanospan India Pvt Ltd

The use of Graphene with concrete has been talked about and researched ever since Graphene was invented in 2010 which grabbed its inventors a Nobel prize. Nanospan is the first company in the world to break technological and commercial barriers and bring the promise of Graphene and nano engineering to the construction industry which ultimately creates huge value addition to various modern day PRECAST PROJECTS.

Nanospan India Pvt Ltd innovates in Disruptive, Decarbonizing material technologies aimed at sustainable living for Construction Industry. Our goal is to offer the industry, the environment, and society, a choice of cutting-edge material products that can counter the challenge of climate change and carbon footprints. In addition to a unique nanoengineering approach in our product innovation, we also use sustainable methods for our product manufacturing. Our India-based supply chain combines innovation, raw materials, and economics.

SPANOCRETE™ Range:

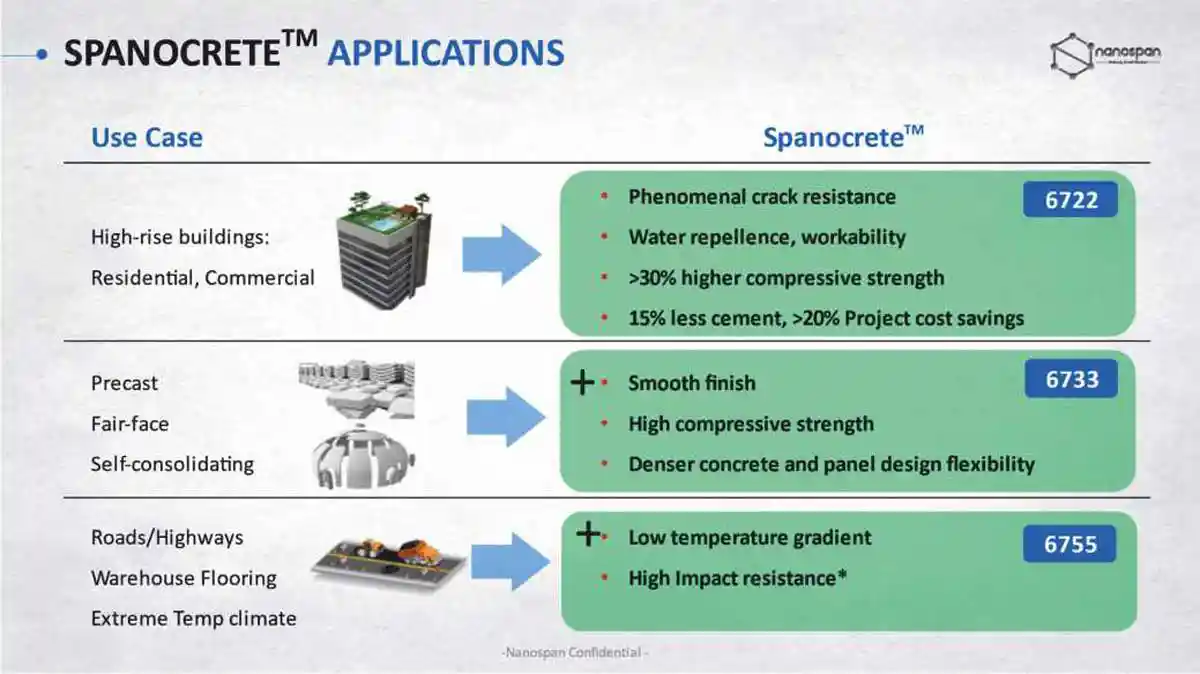

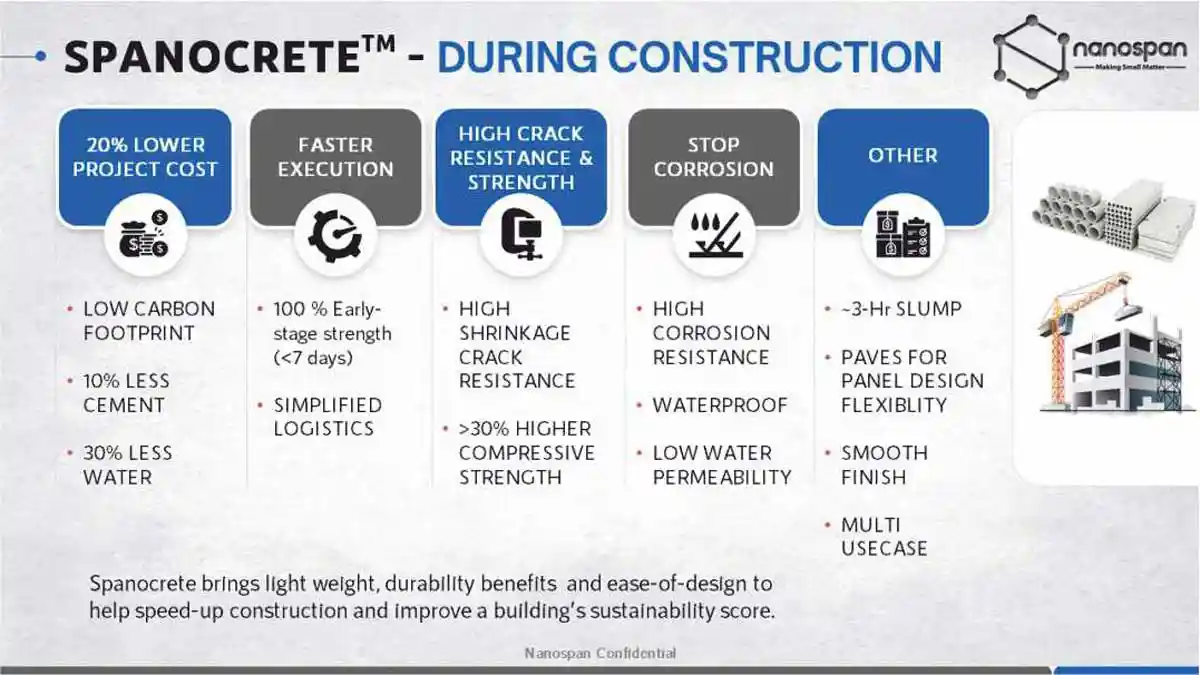

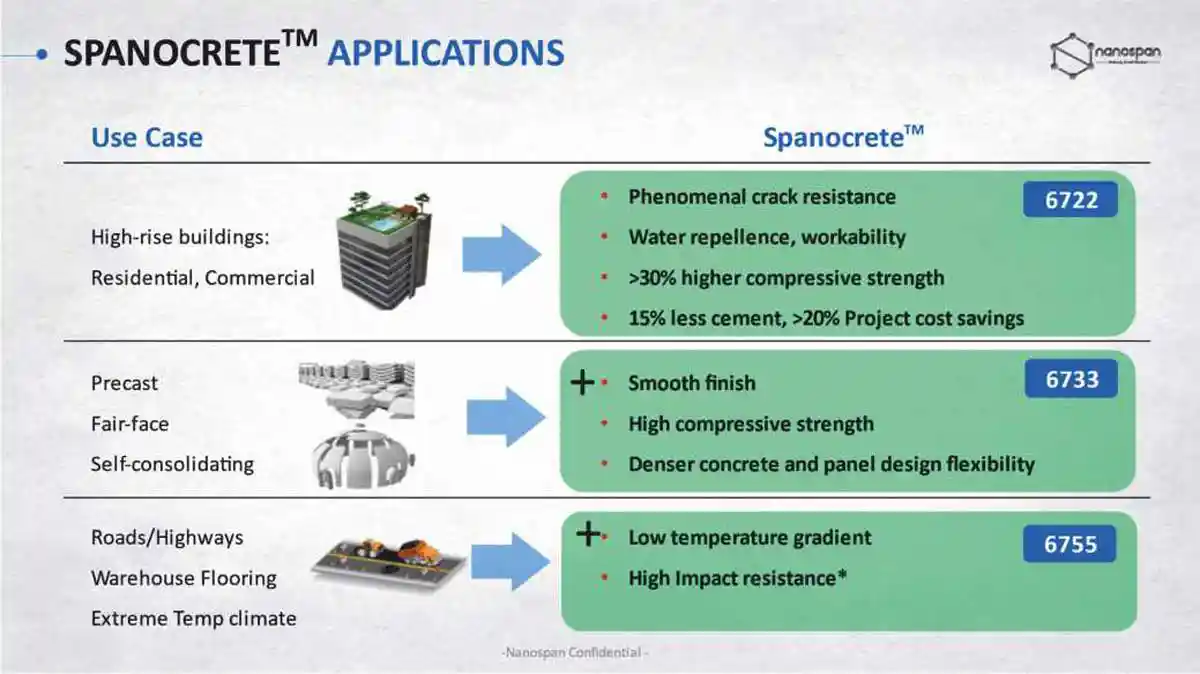

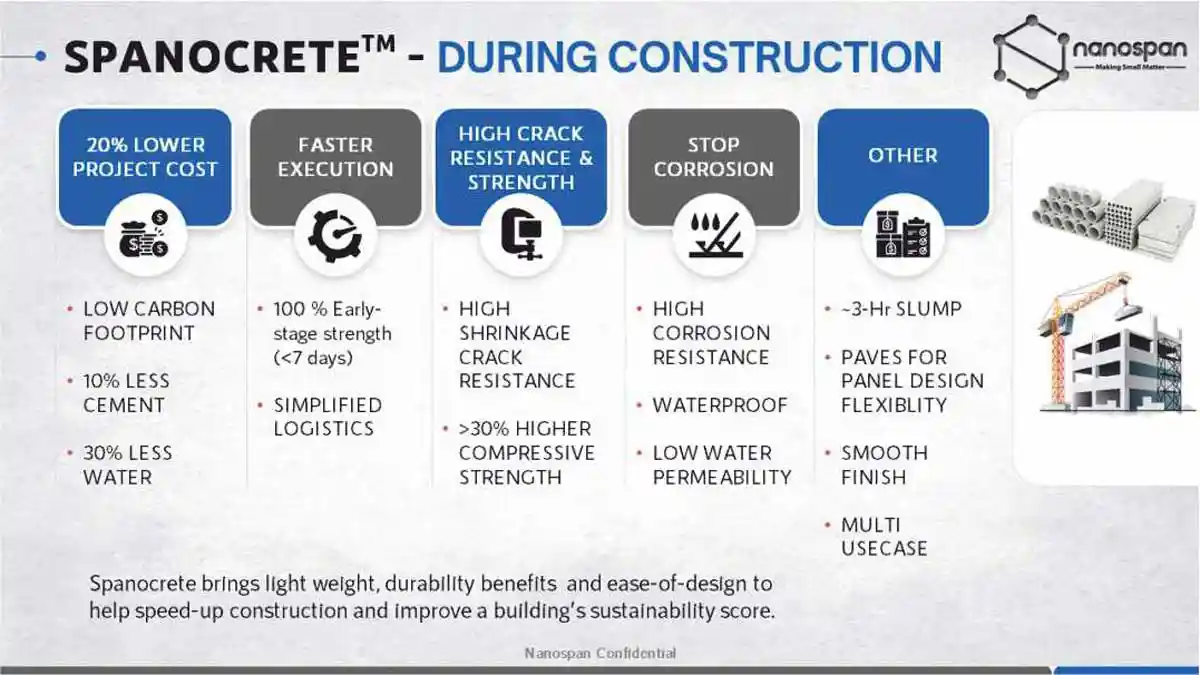

Our SPANOCRETE™ Nano concrete additive brings extended durability along with High Early & Final Compressive strengths to concrete constructions. It makes a construction resilient enough to withstand damage against water ingress and extreme temperatures along with good cost savings.

In the current scenario, for a concrete mix to support all the key functional requirements of various clients, distinct materials are added separately at various stages of construction. The overall cost & execution time of the project increases drastically as the number of raw materials increase. This is where, Nanospan has an edge & provides a one-stop comprehensive multifunctional concrete additive SPANOCRETE™ that can replace many existing “a la carte” admixtures & chemical agents.

SPANOCRETE™ based nano concrete has already been deployed in the construction of multiple high-rise buildings in southern India with exceptionally good results. It has been extensively tested by leading third-party authorized testing labs, customers and in our own R&D labs in Hyderabad. Additionally, SPANOCRETE™ has been put to trial with various concrete mix designs under different climatic conditions umpteen number of times. It established its performance for a few prestigious tunnel projects which earned a very good appreciation. With a manufacturing plant in place now, it is ready to be deployed in high profile infrastructure projects across India.

Precast Problem Statements are Typically Framed Based on Below Points.

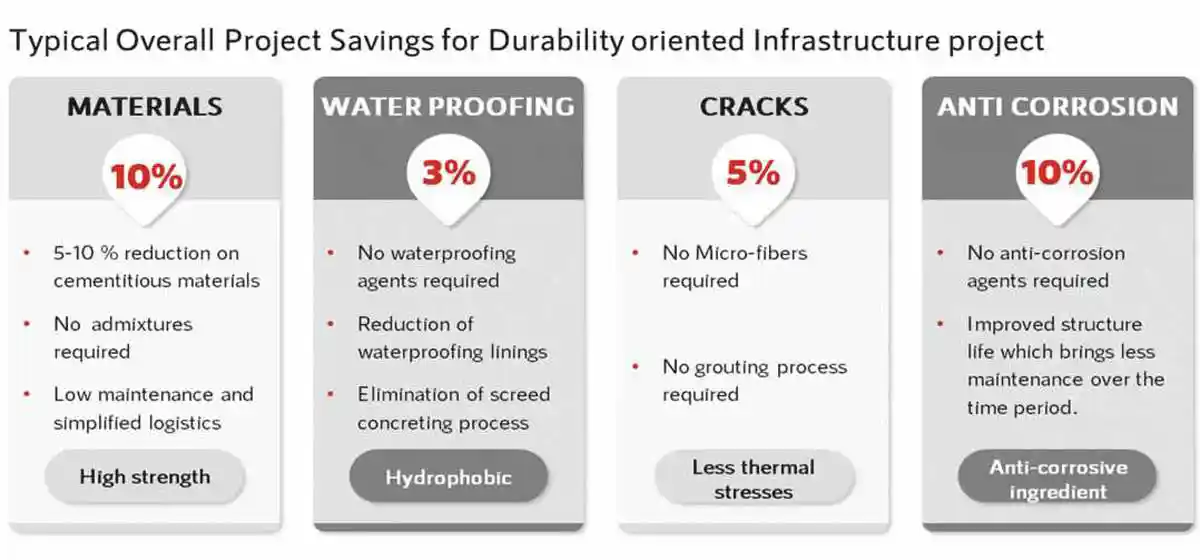

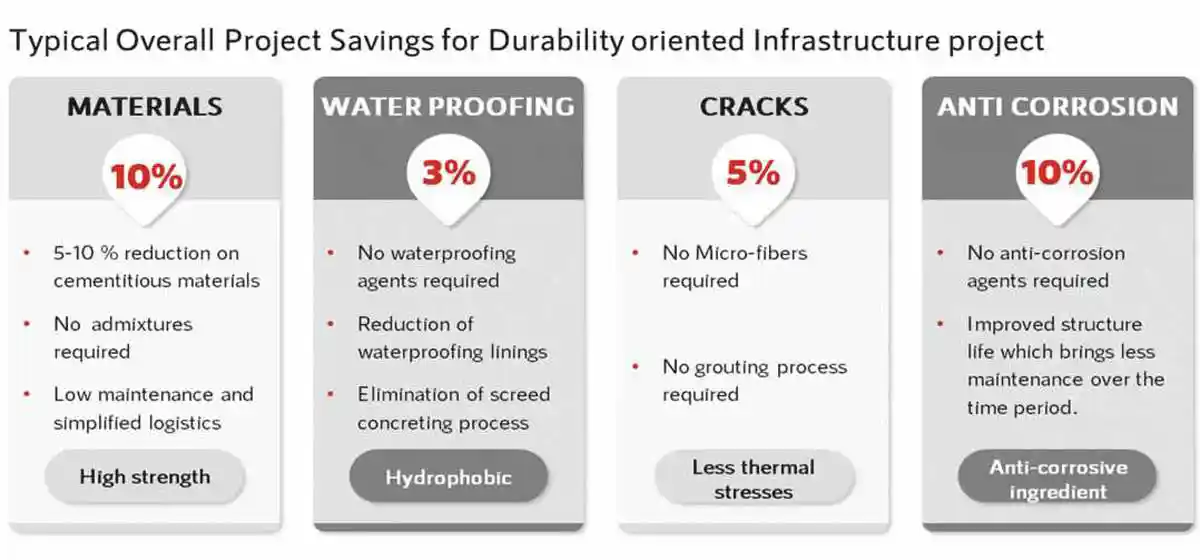

The above savings were derived based on our comprehensive trials for a prestigious Underground Infrastructure Project. For a Precast Project, it can be even higher.

Nanospan's products & IP compete on a global scale. They place India on the global map of nanomaterial innovations which could ultimately boost “Make In India” products for the rest of world.

Nanospan India Pvt Ltd innovates in Disruptive, Decarbonizing material technologies aimed at sustainable living for Construction Industry. Our goal is to offer the industry, the environment, and society, a choice of cutting-edge material products that can counter the challenge of climate change and carbon footprints. In addition to a unique nanoengineering approach in our product innovation, we also use sustainable methods for our product manufacturing. Our India-based supply chain combines innovation, raw materials, and economics.

SPANOCRETE™ Range:

Our SPANOCRETE™ Nano concrete additive brings extended durability along with High Early & Final Compressive strengths to concrete constructions. It makes a construction resilient enough to withstand damage against water ingress and extreme temperatures along with good cost savings.

In the current scenario, for a concrete mix to support all the key functional requirements of various clients, distinct materials are added separately at various stages of construction. The overall cost & execution time of the project increases drastically as the number of raw materials increase. This is where, Nanospan has an edge & provides a one-stop comprehensive multifunctional concrete additive SPANOCRETE™ that can replace many existing “a la carte” admixtures & chemical agents.

SPANOCRETE™ based nano concrete has already been deployed in the construction of multiple high-rise buildings in southern India with exceptionally good results. It has been extensively tested by leading third-party authorized testing labs, customers and in our own R&D labs in Hyderabad. Additionally, SPANOCRETE™ has been put to trial with various concrete mix designs under different climatic conditions umpteen number of times. It established its performance for a few prestigious tunnel projects which earned a very good appreciation. With a manufacturing plant in place now, it is ready to be deployed in high profile infrastructure projects across India.

Precast Problem Statements are Typically Framed Based on Below Points.

- Chloride-induced corrosion for precast concrete (PC) structures.

- Requirement of high early strength structural elements.

- Requirement of smooth finish (Fair Face grade).

- Ability to bring in higher strength for thinner & curved elements without the need to add fibres which paves way for design & shape flexibility.

- Overall cost of precast concrete project & its completion time.

The above savings were derived based on our comprehensive trials for a prestigious Underground Infrastructure Project. For a Precast Project, it can be even higher.

Nanospan's products & IP compete on a global scale. They place India on the global map of nanomaterial innovations which could ultimately boost “Make In India” products for the rest of world.

Concrete Construction April - May 2022