Joint Sealants

Deepak Kanitkar

DGM – Technology & Business Development

Chembond Chemicals Limited, Mumbai.

All joints which are formed due to above reasons must be properly sealed, monitored and maintained. This is essential to protect the structures from ingress of foreign matter such as dirt, dust, water, chemicals and organisms. Depending on the requirement of each joint there are various types of sealing solution available in the market.

Here we will discuss some very commonly used joint sealants in civil construction. There are mainly two types Viz. Liquid applied and Pre-Formed. Varieties of polymers are used to manufacture liquid applied joint sealants. These include Polysulfide, Polyurethane, modified Polyurethanes, Silyl Terminated Polyether's, SPURs, Polymer modified Bitumen, Flexible Epoxy, Silicones and butyl rubber based materials are now being used.

Joints in Concrete

There are different types of joints in concrete. As there is always a shrinkage involved while using Cement Concrete, this factor must be considered while concrete placement. Concrete cannot poured in thick sections or longer spans, for two reasons. First reason is the heat generated in the concrete due to hydration of cement, which causes differential thermal gradient between the core and the surface. As the mass increases this gradient also increases. As per standard practices, this gradient shall be as close as or less than 20°C. This limits the placement volume. Other reason is that, most of the times continuous pours are not possible or placement may get interrupted due to unavoidable delays. Apart from this, longer and wider sections may crack due to drying, chemical, autogenous shrinkage, creep or thermal expansion and contractions. Expansion Joints, Control or Contraction Joints, Isolation Joints and Detailing joints are some of the type of joints in buildings.Expansion Joints are provided to allow movement in a structure caused by thermal or other factors such as wind loading.

Control joints are provided for expected cracking due to factors such as settlement, drying shrinkage or separation in building materials after construction. Internal control joints are typically nonmoving while in the exterior they also accommodate movement. External Control joints require more design work.

Isolation joints are placed at junctures where changes in material require isolation for any differential movement between two different materials. Typical example is window frame perimeter abutting façade materials.

Detailing joints are designed as a part of waterproofing system. They are vital to impart water tightness at structure details such as pipe penetrations and changes in planes prior to application of primary waterproofing compounds.

There are some thumb or basic rules for design of joints which are:

- Joint size no smaller than 6 mm.

- Generally limit the joint size in buildings to 25 mm

- Joint opening shall be kept at a minimum of four times anticipated movement.

- Minimum material thickness shall be 6 mm.

- Up to 12mm wide joints shall have Depth (D) = Width (W)

- Wider joints and traffic joints shall have D = W/2.

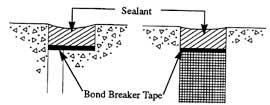

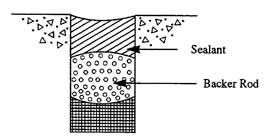

- Three-way adhesions is not allowed so use of backer Rod or Bond breaker tape is a must.

- While using PE closed foam backer rod, it shall be 25% more in diameter than the joint size.

- Porous surfaces generally require primer to avoid passage of air/impurities to sealant in wet stage and for proper adhesion.

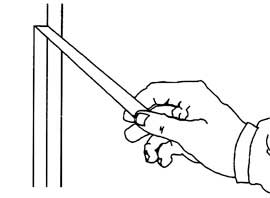

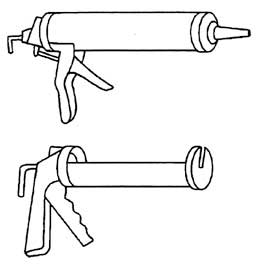

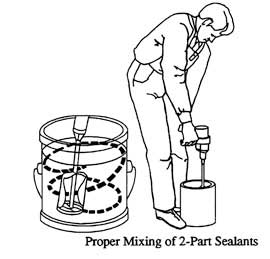

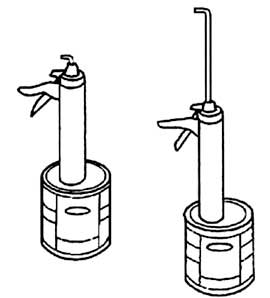

Following illustrations provide an insight into application and mixing methods.

|

|

| Use of Bond breaker tapes to avoid three way adhesion of Sealant | A section of joint showing sealant placed over a PE closed cell foam backer Rod. |

|

|

| Taping of Joint with masking tape to ensure Neatness | Sealant Gun for application of Gun Grade sealant |

|

|

| Filling of 2 part sealant in application Gun using follower plate | |

NBM&CW April 2012