Performance of Hybrid Fibre Reinforced Concrete Under Compression and Flexure

This paper focuses on the experimental investigation carried out on hybrid fibre reinforced concrete (combination of hooked end dramix steel fibre and a non-metallic recron‘3s - polyester fibre) up to a total fibre volume fraction of 0.5%, 1%, 1.5% and 2% which was prepared using normal mixing, compaction and curing conditions. The workability studies and the mechanical properties namely, compressive strength on cubes and cylinders, modulus of rupture, modulus of elasticity, flexural strength, the load–deflection curve and stress-strain relationships were studied for concrete prepared using different proportions of hybrid fibre combinations –hooked end dramix steel fibre and recron’ 3s fibre. Pulse velocity test is conducted at different ages to assess the quality of concrete. It is found that all concrete specimens could be classified under good quality. As a result of hybridization it has the ability to arrest cracks, increased extensibility and tensile strength, both at first crack and at ultimate, particular under flexural loading; and the fibres are able to hold the matrix together even after extensive cracking. The net result of all these is to impart to the fibre composite pronounced post – cracking ductility which is unheard of in ordinary concrete. The transformation from a brittle to a ductile type of material would increase substantially the energy absorption characteristics of the fibre composite and its ability to withstand repeatedly applied, shock or impact loading. The eûect of steel ûbers and recron’ 3s on ordinary concrete is investigated. The flexural properties were studied using two point bending tests on prism specimens as per codes recommendation. Fibre addition was seen to enhance an increase in flexural strength and ductility, respectively. Addition of hybrid fibres generally Contributed towards the energy absorbing mechanism (bridging action) whereas, the non-metallic fibres resulted in delaying the formation of micro-cracks.

Dr.A.S.S.Sekar, Asst. Prof. Dept. of Civil Department,

D.Kesavan, M.E. (Structural Engg) A.C College of Engg & Tech, Karaikudi.

D.Kesavan, M.E. (Structural Engg) A.C College of Engg & Tech, Karaikudi.

Introduction

Fibre reinforced cement and concrete materials (FRC) have been developed progressively since the early work by Romualdi and Batson in the 1960s. By the 1990s, a wide range of fibre composites and FRC products were commercially available and novel manufacturing techniques were developed for use with high fibre content. In parallel with the commercial development of FRC materials and products, an extensive research programme was undertaken to quantify the enhanced properties of FRC materials and more specifically to allow comparisons to be made between various types of fibres.

Fibre reinforced concrete (FRC) is a composite material consisting of cement, sand, coarse aggregate, water and fibres. In this composite material, short discrete fibres are randomly distributed throughout the concrete mass. The behavioral efficiency of this composite material is far superior to that of plain concrete and many other construction materials of equal cost. Due to this benefit, the use of FRC has steadily increased during the last two decades and its current field of application includes: airport and highway pavements, earthquake-resistant and explosive-resistant structures, mine and tunnel linings, bridge deck overlays, hydraulic structures, rock-slope stabilization, etc.

Extensive research work on FRC has established that addition of various types of fibres such as metallic and non-metallic fibers like (steel), glass, synthetic, and carbon, in plain concrete improves strength, toughness, ductility, post-cracking resistance, etc. These dramix hooked end steel fibres and recron’3s fibres can effectively be used for making high-strength FRC after exploring their suitability. In this investigation, therefore, an attempt has been made to study the feasibility of using two kinds of fibres for making FRC. Cementitious materials are generally quite brittle, with relatively low strength and strain capacity under tension. Hence a hand-laid steel bar reinforcement is usually necessary to increase tensile strength. For low reinforcement levels, the partial or even complete replacement of this conventional reinforcement by fibers is an advantageous alternative. For special applications, highly ductile fiber reinforced cementitious materials like ultra-high performance concrete or engineered cementitious compo- sites have been developed. Fibers may also be applied to control the detrimental effects of shrinkage. A significant reduction in crack width and crack spacing is possible, especially at early ages. They possess a high tensile strength (>500–1000 MPa) and a high elastic modulus (>200 GPa) and are available at relatively low costs. The high modulus, which is much higher than the one of concrete (30–40 GPa) or cement paste (15–20 MPa), prevents the fiber from stretching or cross contraction upon load, which hence leads to a good fiber–matrix bond and smaller crack widths. A variety of tests have been performed to determine the actual characteristics and advantages of ûbrous materials. The addition of steel fibers help in converting the brittle characteristics to ductile ones. To faster the compressive strength without sacrificing the ductility, a strategy adopted is to add discrete steel fibers as reinforcement in concrete. It is obvious that the behavior of HFRC depends on the orientations, distributions, aspect ratios, geometrical shapes and mechanical properties of fibers in concrete mixtures. The orientations and distributions of fibers affect the properties of FRC such as toughness, strength, ductility and crack width. A compromise to obtain good fresh concrete properties (including workability and reduced early-age cracking) and good toughness of hardened concrete can be obtained by adding two different fiber types, which can function individually at different scales to yield optimum performance. The addition of non-metallic fibres results in good fresh concrete properties and reduced early age cracking.

The beneficial effects of non-metallic fibres could be attributed to their high aspect ratios and increased fibre availability (because of lower density as compared to steel) at a given volume fraction. Because of their lower stiffness, these fibres are particularly effective in controlling the propagation of micro cracks in the plastic stage of concrete. The hybrid combination of metallic and non-metallic fibres can offer potential advantages in improving concrete properties as well as reducing the overall cost of concrete production. It is important to have a combination of low and high modulus fibres to arrest the micro and macro cracks, respectively. Another beneficial combination of fibres is that of long and short fibres. Once again, different lengths of fibres would control different scales of cracking. The objective of this study was to evaluate the mechanical properties of various fibre reinforced concrete systems, containing individual steel fibres and hybrid combinations of steel and non-metallic fibres. The total dosage of fibres was maintained at 0.5%, 1%, 1.5% & 2% primarily from the point of view of providing good workability. A comparative evaluation of various hybrid fibre concretes was made based on hardened concrete properties compressive, split and flexural strengths, and flexural toughness. Concrete is a quasi-brittle material with a low strain capacity. Fibers provide mechanisms that abate their unstable propagation, provide effective bridging, and impart sources of strength gain, toughness and ductility.

Fibre reinforced concrete (FRC) is a composite material consisting of cement, sand, coarse aggregate, water and fibres. In this composite material, short discrete fibres are randomly distributed throughout the concrete mass. The behavioral efficiency of this composite material is far superior to that of plain concrete and many other construction materials of equal cost. Due to this benefit, the use of FRC has steadily increased during the last two decades and its current field of application includes: airport and highway pavements, earthquake-resistant and explosive-resistant structures, mine and tunnel linings, bridge deck overlays, hydraulic structures, rock-slope stabilization, etc.

Extensive research work on FRC has established that addition of various types of fibres such as metallic and non-metallic fibers like (steel), glass, synthetic, and carbon, in plain concrete improves strength, toughness, ductility, post-cracking resistance, etc. These dramix hooked end steel fibres and recron’3s fibres can effectively be used for making high-strength FRC after exploring their suitability. In this investigation, therefore, an attempt has been made to study the feasibility of using two kinds of fibres for making FRC. Cementitious materials are generally quite brittle, with relatively low strength and strain capacity under tension. Hence a hand-laid steel bar reinforcement is usually necessary to increase tensile strength. For low reinforcement levels, the partial or even complete replacement of this conventional reinforcement by fibers is an advantageous alternative. For special applications, highly ductile fiber reinforced cementitious materials like ultra-high performance concrete or engineered cementitious compo- sites have been developed. Fibers may also be applied to control the detrimental effects of shrinkage. A significant reduction in crack width and crack spacing is possible, especially at early ages. They possess a high tensile strength (>500–1000 MPa) and a high elastic modulus (>200 GPa) and are available at relatively low costs. The high modulus, which is much higher than the one of concrete (30–40 GPa) or cement paste (15–20 MPa), prevents the fiber from stretching or cross contraction upon load, which hence leads to a good fiber–matrix bond and smaller crack widths. A variety of tests have been performed to determine the actual characteristics and advantages of ûbrous materials. The addition of steel fibers help in converting the brittle characteristics to ductile ones. To faster the compressive strength without sacrificing the ductility, a strategy adopted is to add discrete steel fibers as reinforcement in concrete. It is obvious that the behavior of HFRC depends on the orientations, distributions, aspect ratios, geometrical shapes and mechanical properties of fibers in concrete mixtures. The orientations and distributions of fibers affect the properties of FRC such as toughness, strength, ductility and crack width. A compromise to obtain good fresh concrete properties (including workability and reduced early-age cracking) and good toughness of hardened concrete can be obtained by adding two different fiber types, which can function individually at different scales to yield optimum performance. The addition of non-metallic fibres results in good fresh concrete properties and reduced early age cracking.

The beneficial effects of non-metallic fibres could be attributed to their high aspect ratios and increased fibre availability (because of lower density as compared to steel) at a given volume fraction. Because of their lower stiffness, these fibres are particularly effective in controlling the propagation of micro cracks in the plastic stage of concrete. The hybrid combination of metallic and non-metallic fibres can offer potential advantages in improving concrete properties as well as reducing the overall cost of concrete production. It is important to have a combination of low and high modulus fibres to arrest the micro and macro cracks, respectively. Another beneficial combination of fibres is that of long and short fibres. Once again, different lengths of fibres would control different scales of cracking. The objective of this study was to evaluate the mechanical properties of various fibre reinforced concrete systems, containing individual steel fibres and hybrid combinations of steel and non-metallic fibres. The total dosage of fibres was maintained at 0.5%, 1%, 1.5% & 2% primarily from the point of view of providing good workability. A comparative evaluation of various hybrid fibre concretes was made based on hardened concrete properties compressive, split and flexural strengths, and flexural toughness. Concrete is a quasi-brittle material with a low strain capacity. Fibers provide mechanisms that abate their unstable propagation, provide effective bridging, and impart sources of strength gain, toughness and ductility.

Materials & Mix Proportion

Materials

The materials used in this experimental investigation are:

1.Cement: Ultra Tech 43 grade Fly Ash based Portland pozzolana Cement (PPC) (IS 1489 PART I 1991).

2. Fine aggregate: Locally available river sand Zone II having a specific gravity of 2.43, fineness modulus of 3.425,

3. Coarse aggregate: crushed granite coarse aggregate of maximum size 20 mm and having a specific gravity of 2.99, fineness modulus of 7.54,

4. Water: water available in the college campus conforming to the Requirements of water for concreting and curing as per IS: 456 2000.

5. Fibres:

(i) Commercially available Dramix Hooked End Steel Fibre having properties of

Length : 30mm

Diameter : 0.5mm

Aspect ratio : 60

(ii) Commercially available Recron’3s Fibre

Recron 3s fibres is Polyester staple fibres having properties of

Length : 12mm

Diameter : 0.036mm

Aspect ratio : 334

Mix Proportion

Mix design as per IS Code method Concrete proportion used for the study

Grade of concrete = 20N/mm2

Water cement ratio = 0.55

The materials used in this experimental investigation are:

1.Cement: Ultra Tech 43 grade Fly Ash based Portland pozzolana Cement (PPC) (IS 1489 PART I 1991).

2. Fine aggregate: Locally available river sand Zone II having a specific gravity of 2.43, fineness modulus of 3.425,

3. Coarse aggregate: crushed granite coarse aggregate of maximum size 20 mm and having a specific gravity of 2.99, fineness modulus of 7.54,

4. Water: water available in the college campus conforming to the Requirements of water for concreting and curing as per IS: 456 2000.

5. Fibres:

(i) Commercially available Dramix Hooked End Steel Fibre having properties of

Length : 30mm

Diameter : 0.5mm

Aspect ratio : 60

(ii) Commercially available Recron’3s Fibre

Recron 3s fibres is Polyester staple fibres having properties of

Length : 12mm

Diameter : 0.036mm

Aspect ratio : 334

Mix Proportion

Mix design as per IS Code method Concrete proportion used for the study

| MATERIALS | Cement | Fine aggregate | Coarse aggregate | Water |

| Kg/m3 | 348.33 | 551.27 | 1316.22 | 191.6 |

| Ratio | 1 | 1.584 | 3.782 | 0.55(w/c) |

Grade of concrete = 20N/mm2

Water cement ratio = 0.55

Experimental Program

Specimens

In this experimental work, concrete specimens were cast with and without fibres. The specimens considered in this study consisted of 51 numbers of 150mm size cubes, 150 mm diameter and 300 mm long cylinders and 100 mm × 100 mm × 500 mm size prisms. The nominal mix proportion used for casting the specimens was 1: 1.58: 3.78: 0.55 (cement: sand: coarse aggregate: water-cement ratio).

Fresh concrete was cast in steel moulds with hand compaction.

i) 150 mm cubes (for compressive strength as per IS 516-1959 (Reaffirmed 1999);

(ii) 150 mm x300 mm cylinders

(iii) 100 x 100 x 500 mm beam (prism) specimens (for flexural Test) as per IS 516-1959 (Reaffirmed 1999) and also as per ASTM test method.

Three specimens each were tested in the case of compressive strength, flexural strength and modulus of elasticity experiments. In the case of flexural tests three beam specimens were used, and the average of these tests is reported in the load–deflection plot, and used for calculating the various parameters. The specimens were demoulded after 24 h, and placed inside a water tank until the age of testing.

In this experimental work, concrete specimens were cast with and without fibres. The specimens considered in this study consisted of 51 numbers of 150mm size cubes, 150 mm diameter and 300 mm long cylinders and 100 mm × 100 mm × 500 mm size prisms. The nominal mix proportion used for casting the specimens was 1: 1.58: 3.78: 0.55 (cement: sand: coarse aggregate: water-cement ratio).

|

|

|

| Photo 1: Steel & Recron’3s Fibres | Photo 2: Dramix Steel Fibre | Photo 3: Dramix Steel Fibre (Collated & Loose State) |

|

|

| Photo 4: Recron’3s Fibre | Photo 5: Mixture of Steel & Recron Fibres with Concrete |

Fresh concrete was cast in steel moulds with hand compaction.

i) 150 mm cubes (for compressive strength as per IS 516-1959 (Reaffirmed 1999);

(ii) 150 mm x300 mm cylinders

(iii) 100 x 100 x 500 mm beam (prism) specimens (for flexural Test) as per IS 516-1959 (Reaffirmed 1999) and also as per ASTM test method.

Three specimens each were tested in the case of compressive strength, flexural strength and modulus of elasticity experiments. In the case of flexural tests three beam specimens were used, and the average of these tests is reported in the load–deflection plot, and used for calculating the various parameters. The specimens were demoulded after 24 h, and placed inside a water tank until the age of testing.

Mixing, Casting & Curing Details

All ingredients are weighed separately as per the mix details. The uniformity of concrete and proper distribution of fibres mainly depends on the mixing procedure. Cement and aggregates are mixed thoroughly by using rotary mixer machine and then fibres are added manually. The total fibre volume fraction used for casting is 0.5%, 1%, 1.5% & 2%.

In this total fibre volume fraction the proportion of steel and recron’3s fibre fraction is as follows

Recron 3s fibres are Polyester staple fibres for mixing in concrete and mortar for improving certain properties of the concrete and mortar. Fibres have special triangular shape for better anchoring with other ingredients of the mix. The fibres are made from polyemerisation of pure teraphthalic acid and Mono Ethylene Glycol using catalyst. Recron 3s fibres are available in 6mm and 12mm length.

While the mixing operation is in progress, 80% of water is added first and mixed for about 5 min then the remaining water is added and mixed thoroughly. For each mix, a total of 3 cubes of 150 x 150 x 150 mm, 150x300mm cylinders and 100x100x500mm prisms casted. After 24 HRS the specimens are demoulded, immersed in potable water (available in college campus) all mixes are tested for workability in terms of slump, compacting factor (CF) and flow table test as per Indian Standard IS: 1199—1959. The main purpose of these tests is to check the consistency and the uniformity of concrete from batch to batch. Slump values are not so consistent indicating the fact, that this is not a good measure of workability for HFRC. It is in general noticed that conventionally popular tests like slump and compacting factor tests are not as appropriate and accurate in determination of workability of fibre reinforced concrete as they are for plain concrete this is essentially because of interlocking of fibres there by affecting normal workability due to concrete ingredients. Still upon vibration the fibre reinforced concretes exhibited the needed workability for placement. However, the concrete is compacted easily by means of hand compaction.

In this total fibre volume fraction the proportion of steel and recron’3s fibre fraction is as follows

| Steel % | Recron’3s % |

| 100 | 0 |

| 80 | 20 |

| 70 | 30 |

| 60 | 40 |

Recron 3s fibres are Polyester staple fibres for mixing in concrete and mortar for improving certain properties of the concrete and mortar. Fibres have special triangular shape for better anchoring with other ingredients of the mix. The fibres are made from polyemerisation of pure teraphthalic acid and Mono Ethylene Glycol using catalyst. Recron 3s fibres are available in 6mm and 12mm length.

While the mixing operation is in progress, 80% of water is added first and mixed for about 5 min then the remaining water is added and mixed thoroughly. For each mix, a total of 3 cubes of 150 x 150 x 150 mm, 150x300mm cylinders and 100x100x500mm prisms casted. After 24 HRS the specimens are demoulded, immersed in potable water (available in college campus) all mixes are tested for workability in terms of slump, compacting factor (CF) and flow table test as per Indian Standard IS: 1199—1959. The main purpose of these tests is to check the consistency and the uniformity of concrete from batch to batch. Slump values are not so consistent indicating the fact, that this is not a good measure of workability for HFRC. It is in general noticed that conventionally popular tests like slump and compacting factor tests are not as appropriate and accurate in determination of workability of fibre reinforced concrete as they are for plain concrete this is essentially because of interlocking of fibres there by affecting normal workability due to concrete ingredients. Still upon vibration the fibre reinforced concretes exhibited the needed workability for placement. However, the concrete is compacted easily by means of hand compaction.

Testing Methodology

The specimens were taken out from the curing tank just prior to the test.

1. To determine compressive strength (fck)

The tests for compressive strengths of cube specimens at 28 days from casting were conducted using a 2000 KN compression testing machine

2. To determine stress-strain relation ship (Youngs modulus of elasticity) (EC)

The tests for compressive strengths of cylindrical specimens at 28 days from casting to determine stress-strain relationship using compressometer (Longitudinal strain) & extensometer (lateral strain) arrangement were conducted using a 2000 kN compression testing machine.

Using stress- strain curve

i) Youngs modulus of hybrid fibre reinforced concrete was derived.

ii) Equivalent energy at yield & at ultimate was derived.

iii) Deflection ductility & Energy ductility were derived.

a) Deflection = Deflection at Ultimate load

Ductility Deflection at Yield load

b) Energy = Energy at Ultimate load

Ductility Energy at Yield load

To determine flexural strength (modulus of rupture) ( fcr)

The test for modulus of rupture (two point loading) was conducted using a 100 KN universal testing machine. The net deflections at the centre were recorded on to a deflectometer. Load – deflection curves were drawn.

These tests were conducted as per the relevant. IS: 516 – 1959 (reaffirmed 1999) Indian Standard specifications and other codal specifications.

To determine the pulse velocity

The non-destructive testing (NDT) that is ultrasonic pulse velocity testing were conducted to determine quality of concrete.

1. To determine compressive strength (fck)

The tests for compressive strengths of cube specimens at 28 days from casting were conducted using a 2000 KN compression testing machine

2. To determine stress-strain relation ship (Youngs modulus of elasticity) (EC)

The tests for compressive strengths of cylindrical specimens at 28 days from casting to determine stress-strain relationship using compressometer (Longitudinal strain) & extensometer (lateral strain) arrangement were conducted using a 2000 kN compression testing machine.

Using stress- strain curve

i) Youngs modulus of hybrid fibre reinforced concrete was derived.

ii) Equivalent energy at yield & at ultimate was derived.

iii) Deflection ductility & Energy ductility were derived.

a) Deflection = Deflection at Ultimate load

Ductility Deflection at Yield load

b) Energy = Energy at Ultimate load

Ductility Energy at Yield load

To determine flexural strength (modulus of rupture) ( fcr)

The test for modulus of rupture (two point loading) was conducted using a 100 KN universal testing machine. The net deflections at the centre were recorded on to a deflectometer. Load – deflection curves were drawn.

| Type of concrete |

Steel- recron’3s (%) |

Compressive Strength (N/mm2) |

Modulus of rupture (N/mm2) | Compressive Strength Increases in percent |

Modulus of rupture Increases in percent |

| Plain concrete | 0 | 28.88 | 0.72 | 0 | 0 |

| 0.5% | 100-0 | 31.44 | 0.84 | 8.86 | 16.66 |

| 0.5% | 80-20 | 33 | 0.96 | 14.26 | 33.33 |

| 0.5% | 70-30 | 31 | 1.08 | 7.34 | 50 |

| 0.5% | 60-40 | 32.27 | 1.12 | 11.73 | 55.55 |

| 1% | 100-0 | 44.44 | 1.64 | 53.87 | 127.77 |

| 1% | 80-20 | 46.44 | 1.78 | 60.8 | 147.22 |

| 1% | 70-30 | 36.66 | 1.8 | 26.93 | 150 |

| 1% | 60-40 | 34.34 | 1.84 | 18.90 | 155.55 |

| 1.5% | 100-0 | 46.55 | 1.76 | 61.18 | 144.44 |

| 1.5% | 80-20 | 48 | 1.88 | 66.20 | 161.11 |

| 1.5% | 70-30 | 41.66 | 1.92 | 44.25 | 166.67 |

| 1.5% | 60-40 | 33.34 | 1.84 | 15.44 | 155.55 |

| 2% | 100-0 | 48.88 | 1.92 | 69.23 | 166.67 |

| 2% | 80-20 | 50 | 2 | 73.13 | 177.77 |

| 2% | 70-30 | 42.55 | 2.16 | 47.33 | 200 |

| 2% | 60-40 | 38.88 | 1.88 | 34.62 | 161.11 |

These tests were conducted as per the relevant. IS: 516 – 1959 (reaffirmed 1999) Indian Standard specifications and other codal specifications.

To determine the pulse velocity

The non-destructive testing (NDT) that is ultrasonic pulse velocity testing were conducted to determine quality of concrete.

Discussion on Experimental Results from Compressive and Flexural Strength Tests

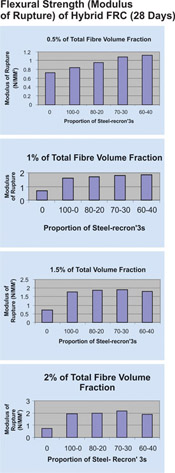

Experimental results given in the above Table1 indicates that Compressive Strength and Flexural Strength (modulus of rupture) was observed in the case of plain Concrete increase with addition of steel and recron’3s fibre, Compared to steel fibre concrete, hybrid fibre concretes showed better compressive strength, flexural strength & crack control features. The total crack area reduced with increased addition of non-metallic fibres i.e. recron’3s fibre,

When compared with the plain control concrete this hybrid fibre reinforced concrete gives good results on both compressive and flexural strength.

The reduction in crack width using hybrid fibre combinations significantly contributed to the reduction of the overall crack area. The improved performance of hybrid fibre combinations can be attributed to the increase in fibre availability compared to the steel fibre concrete, since all non-metallic recron ‘3s (polyester fibre) fibre had considerably lower specific gravity than steel. The increase in fibre availability reduces the fibre spacing and also the propensity for crack origination. However, the performance is not linked only to the fibre availability amongst the hybrid fibre concretes; the performance was further affected by the length and stiffness of the non-metallic fibres.

From the above experimental investigation Discussion of Compressive and Flexural Strength Test Results by comparing with ordinary plain control concrete

When compared with the plain control concrete this hybrid fibre reinforced concrete gives good results on both compressive and flexural strength.

The reduction in crack width using hybrid fibre combinations significantly contributed to the reduction of the overall crack area. The improved performance of hybrid fibre combinations can be attributed to the increase in fibre availability compared to the steel fibre concrete, since all non-metallic recron ‘3s (polyester fibre) fibre had considerably lower specific gravity than steel. The increase in fibre availability reduces the fibre spacing and also the propensity for crack origination. However, the performance is not linked only to the fibre availability amongst the hybrid fibre concretes; the performance was further affected by the length and stiffness of the non-metallic fibres.

From the above experimental investigation Discussion of Compressive and Flexural Strength Test Results by comparing with ordinary plain control concrete

- When total fibre content – 0.5% Compressive strength increases from 7.34% to 14.26%. But it gives good results on 80%-20% combination of steel-recron’3s fibre fraction. Flexural strength increases from 16.66% to 55.55%. But it gives good results on 60%-40% combination of steel- recron’3s fibre fraction.

- When total fibre content – 1% Compressive strength increases from 18.90% to 60.8%. But it gives good results on 80%-20% combination of steel-recron’3s fibre fraction. Flexural strength increases from 127.77% to 155.55% But it gives good results on 60%-40% combination of steel- recron’3s fibre fraction.

|

| Photo 6: Compressive Strength Test Set Up |

- When total fibre content – 1.5 % Compressive strength increases from 15.44% to 66.20% but it gives good results on 80%-20% combination of steel-recron’3s fibre fraction. Flexural strength increases from 144.44 % to 166.67%. But it gives good results on 70%-30% combination of steel- recron’3s fibre fraction.

- When total fibres content – 2 % Compressive strength increases from 34.62% to 73.13%. But it gives good results on 80%-20% combination of steel-recron’3s fibre fraction. Flexural strength increases from 161.11 % to 200% But it gives good results on 70%-30% combination of steel- recron’3s fibre fraction

|

| Photo 7: View of Failed Hybrid Specimens – 2% -all |

If the recron’3s fibre content increases then compressive and flexural strength increases upto optimum. When proportion of recron fibre increases from 30% to 40% in total fibre content then modulus of rupture increases and crack formation is decreases with increases in recron 3s fibre content.

Stress – Strain Relationship

Behaviour of Cylinder Under Compression

Youngs Modulus of Elasticity is derived from the experimental set up of cylinder under compression using compressometer (longitudinal strain) and extensometer (lateral strain) arrangement.

Computation of Ductility

Deflection Ductility & Energy Ductility

a) Deflection = Deflection at Ultimate load

Ductility Deflection at Yield load

b) Energy = Energy at Ultimate load

Ductility Energy at Yield load

From the above experimental investigation Discussion of modulus of elasticity of concrete (Ec), Equivalent Energy at Yield & Ultimate Point and Deflection Ductility & Energy Ductility Results, by comparing with ordinary plain control concrete

|

|

|

|

|

| Photo 8: Flexural Strength Test Set up | Photo 9: View of Failed Hybrid Specimens |

Stress – Strain Relationship

Behaviour of Cylinder Under Compression

Youngs Modulus of Elasticity is derived from the experimental set up of cylinder under compression using compressometer (longitudinal strain) and extensometer (lateral strain) arrangement.

| MODULUS OF ELASTICITY OF CONCRETE (EC) | ||||

| TABLE 2 Modulus of Elasticity of Concrete (Ec) | ||||

| Type of concrete (Total fibre volume fraction) |

Steel-recron’3s (%) |

Modulus of elasticity (Ec) (N/MM2) |

Modulus of Elasticity (Ec) Increases in percent |

|

| Plain concrete | 0 | 16980 | 0 | |

| 0.5% | 100-0 | 20590 | 21.26 | |

| 0.5% | 80-20 | 22323 | 31.46 | |

| 0.5% | 70-30 | 24810 | 46.11 | |

| 0.5% | 60-40 | 20893 | 23.04 | |

| 1% | 100-0 | 22740 | 33.92 | |

| 1% | 80-20 | 26570 | 56.47 | |

| 1% | 70-30 | 29600 | 74.32 | |

| 1% | 60-40 | 22620 | 33.21 | |

| 1.5% | 100-0 | 23763 | 39.94 | |

| 1.5% | 80-20 | 28463 | 67.62 | |

| 1.5% | 70-30 | 30631 | 80.39 | |

| 1.5% | 60-40 | 23370 | 37.63 | |

| 2% | 100-0 | 24834 | 46.25 | |

| 2% | 80-20 | 29762 | 75.27 | |

| 2% | 70-30 | 32500 | 91.40 | |

| 2% | 60-40 | 23214 | 36.71 | |

| EQUIVALENT ENERGY CALCULATION AT YIELD & ULTIMATE POINT | |||

| Table 3 Equivalent Energy Calculations at Yield & Ultimate Point | |||

| TOTAL FIBRE VOLUME (%) |

STEEL-RECRON’3S (%) | Equivalent Energy at Yield (Nmm) |

Equivalent Energy at Ultimate (Nmm) |

| 0 | 0 | 181.67 | 228.90 |

| 0.5 | 100-0 | 326.67 | 571.67 |

| 0.5 | 80-20 | 363.34 | 788.44 |

| 0.5 | 70-30 | 520.23 | 1238.14 |

| 0.5 | 60-40 | 420 | 961.8 |

| 1 | 100-0 | 620 | 1407.4 |

| 1 | 80-20 | 730 | 1773.90 |

| 1 | 70-30 | 760 | 2021.6 |

| 1 | 60-40 | 720 | 1627.20 |

| 1.5 | 100-0 | 638.34 | 1480.94 |

| 1.5 | 80-20 | 768.34 | 1920.85 |

| 1.5 | 70-30 | 634 | 1642.06 |

| 1.5 | 60-40 | 1145 | 2599.15 |

| 2 | 100-0 | 1006.66 | 2456.25 |

| 2 | 80-20 | 1026.70 | 2669.42 |

| 2 | 70-30 | 1330 | 3617.66 |

| 2 | 60-40 | 1181.66 | 2776.90 |

| Table 4 Deflection Ductility & Energy Ductility | |||||

| Type of concrete (Total fibre volume fraction) |

Steel-recron’3s (%) |

Deflection Ductility |

Energy Ductility |

Deflection Ductility increases in Percent |

Energy Ductility Increases in Percent |

| Plain concrete | 0 | 1.2 | 1.26 | 0 | 0 |

| 0.5% | 100-0 | 1.52 | 1.75 | 26.66 | 38.88 |

| 0.5% | 80-20 | 2 | 2.17 | 66.66 | 72.22 |

| 0.5% | 70-30 | 1.75 | 2.38 | 45.83 | 88.88 |

| 0.5% | 60-40 | 2 | 2.29 | 66.66 | 81.74 |

| 1% | 100-0 | 2.1 | 2.27 | 75 | 80.15 |

| 1% | 80-20 | 2.4 | 2.43 | 100 | 92.85 |

| 1% | 70-30 | 1.88 | 2.66 | 56.66 | 111.11 |

| 1% | 60-40 | 1.70 | 2.26 | 41.66 | 79.36 |

| 1.5% | 100-0 | 2.15 | 2.32 | 79.16 | 84.12 |

| 1.5% | 80-20 | 2.72 | 2.50 | 126.67 | 98.41 |

| 1.5% | 70-30 | 2.30 | 2.59 | 91.66 | 105.55 |

| 1.5% | 60-40 | 1.818 | 2.27 | 51.50 | 80.15 |

| 2% | 100-0 | 2.125 | 2.44 | 77.08 | 93.65 |

| 2% | 80-20 | 2.42 | 2.60 | 101.66 | 106.34 |

| 2% | 70-30 | 2.20 | 2.72 | 83.33 | 115.87 |

| 2% | 60-40 | 1.9 | 2.35 | 58.33 | 86.50 |

Computation of Ductility

Deflection Ductility & Energy Ductility

a) Deflection = Deflection at Ultimate load

Ductility Deflection at Yield load

b) Energy = Energy at Ultimate load

Ductility Energy at Yield load

From the above experimental investigation Discussion of modulus of elasticity of concrete (Ec), Equivalent Energy at Yield & Ultimate Point and Deflection Ductility & Energy Ductility Results, by comparing with ordinary plain control concrete

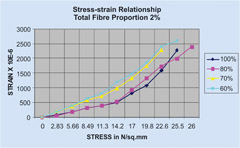

|

| Above Graph Shows Stress-Strain Relation For 2% of Total Fibre Volume Fraction |

- When total fibre content – 0.5% Modulus of elasticity of concrete (Ec) increases from 21.26% to 46.11% Deflection Ductility increases from 26.66% to 66.66% & Energy Ductility increases from 38.87% to 81.74%

- When total fibre content – 1% Modulus of elasticity of concrete (Ec) increases from 33.21% to 74.32% Deflection Ductility increases from 41.66% to 100% & Energy Ductility increases from 79.36% to 111.11%

|

| Photo 10: Compressive Strength Test Set Up (Stress- Srain Relationship Test Arrangement) |

- When total fibre content – 1.5 % Modulus of elasticity of concrete (Ec) increases from 37.63% to 80.39% Deflection Ductility increases from 51.50% to 126.67% & Energy Ductility increases from 80.15% to 105.55%

- When total fibre content – 2 % Modulus of elasticity of concrete (Ec) increases from 36.71% to 91.40% Deflection Ductility increases from 58.33% to 101.66% & Energy Ductility increases from 86.50% to 115.87%

But Modulus of elasticity of concrete (Ec) increases in each total fibre fraction good results at 70%-30% combination of steel-recron’3s fibre fraction

And it gives good results on Deflection Ductility & Energy Ductility increases in each total fibre fraction good results at 80%-20% & 70%-30% combination of steel- recron’3s fibre fraction

And it gives good results on Deflection Ductility & Energy Ductility increases in each total fibre fraction good results at 80%-20% & 70%-30% combination of steel- recron’3s fibre fraction

Ultrasonic Pulse Velocity Test Results

|

| Photo 11: View of Failed Hybrid Specimens |

| TOTAL FIBRE VOLUME (%) |

STEEL-RECRON’3S | PULSE VELOCITY (M/Sec) |

CLASSIFICA - TION (QUALITY) |

| 0 | 0 | 4350 | Good |

| 0.5 | 100-0 | 4466.88 | Good |

| 0.5 | 80-20 | 4656 | Excellent |

| 0.5 | 70-30 | 4418.03 | Good |

| 0.5 | 60-20 | 4680 | Excellent |

| 1 | 100-0 | 4983.38 | Excellent |

| 1 | 80-20 | 5172.41 | Excellent |

| 1 | 70-30 | 4823.15 | Excellent |

| 1 | 60-40 | 5000 | Excellent |

| 1.5 | 100-0 | 4918.03 | Excellent |

| 1.5 | 80-20 | 4918.03 | Excellent |

| 1.5 | 70-30 | 4672.89 | Excellent |

| 1.5 | 60-40 | 4918 | Excellent |

| 2 | 100-0 | 5172.41 | Excellent |

| 2 | 80-20 | 4807.69 | Excellent |

| 2 | 70-30 | 4983.38 | Excellent |

| 2 | 60-40 | 4411.76 | Good |

Conclusion

The primary objective of this study was to evaluate the action of hybrid fibres at different volume fractions to obtain a good high strength concrete.

The above mentioned investigations allow the two different fibre influences to be distinguished for green concrete and for hardened concrete.

The experimental results of this study have led to the following conclusions:

The above mentioned investigations allow the two different fibre influences to be distinguished for green concrete and for hardened concrete.

The experimental results of this study have led to the following conclusions:

- It is possible to produce fibre concrete composites using polyester fibres in combination with steel fibres to performance high strength plain concrete.

- The addition of steel fibres aids in converting the properties of brittle concrete to a ductile material but addition of steel fibres with recron‘3s fibre makes the results better than that and generally it improving the compressive strength and flexural strength of plain control concrete; but the improvement in strength does not always increase with a larger dosage of fibres.

- Compressive Strength of hybrid fibre reinforced concrete (HFRC) increases in each total fibre volume fraction 0.5% to 2%. but in each total fibre volume fraction it gives good results on 80%-20% combination of steel- recron’3s fibre fraction.

- Flexural Strength of hybrid fibre reinforced concrete (HFRC) increases in each total fibre volume fraction 0.5% to 2%. but in each total fibre volume fraction it gives good results on 70%-30% combination of steel- recron’3s fibre fraction.

- From the stress-strain curve shows Modulus of elasticity of concrete (Ec) increases in each total fibre fraction it gives good results at 70%-30% combination of steel-recron’3s fibre fraction

- From the stress-strain curve results, it is evident that the ductility of fibre reinforced concrete depends primarily on the fibres ability to bridge the cracks at high levels of strain. Thus, stiffer fibres would provide better crack bridging; this makes the good performance of steel fibres with recron‘3s polyester fibre.

Deflection Ductility & Energy Ductility increases in each total fibre fraction and it gives good results at 80%-20% &70%-30% Combination of steel-recron’3s fibre fraction.

Addition of hybrid fibres generally Contributed towards the energy absorbing mechanism (bridging action) whereas, the non-metallic fibres recron’ 3s (polyester) resulted in delaying the formation of micro-cracks. - The pulse velocity for HFRC varies depending on the volume fraction of the fibres. The quality of concrete is excellent, since pulse velocity is greater than about 4575 m/s at 28 days in all the cases.

- Hybrid fibres were more effective in crack reduction compared to individual steel fibres. The percentage of cracks of different sizes indicates the degree of cracking. The percentage of crack widths greater than 2 mm was found to be more than 90% in the case of controlled concrete and 60% in the case of steel fibre concrete and almost zero in the case of hybrid fibre concretes.

These secondary cracks were thinner than the main crack the total area of secondary cracks was calculated to be always less than of main cracks. The main crack was neither continuous nor distinctive. - Increased fibre availability in hybrid fibre systems (due to the lower densities of non-metallic fibres), in addition to the ability of non-metallic recron‘3s fibres (polyester) in bridging smaller micro-cracks, could be the reasons for the enhancement in strength and flexural properties.

- For all fibre concrete mixtures, there was a corresponding increase in the modulus of elasticity compared to the control concrete. It can be seen, however, that the difference in performance of the steel fibre concrete and the hybrid fibres concretes with respect to compressive strength and modulus of elasticity is significant.

- A major significance of these findings is that steel fibres in concrete could be replaced to a small extent with nonmetallic recron‘3s fibres (mainly polyester) to provide similar ductility properties to steel fibre concrete.

Thus, hybrid fibre composites combining steel and polyester fibres have the potential for large scale use in concrete construction. - Addition of recron’3s fibres does not significantly increase the ultimate flexural strength of SFRC. However, it improves the energy absorption capacity of concrete. The energy absorption of concrete with total fibre volume fraction of 0.5% to 2% was about 5.46 to15 times that of plain concrete.

In cubes, prisms and cylinders with low fibre volume the resisting load after cracking was relatively small. The rate of improvement in energy absorption increased with increase in fibre content. 13. It is recommended to use fibre volumetric percentages in the range of longer fibres (i.e., fibres with higher aspect ratio) provided higher energy absorption. The energy absorption of hybrid fibres was about 1.4 to 2.16 times that of steel fibre reinforced concrete.

It increase in strength of hybrid fibre reinforced concrete enhances the energy absorption capacity. - Among hybrid fibre combinations, the steel and polyester fibres combination performed better in all respects compared to the mono-steel fibre concrete and ordinary concrete.

- Non-metallic Recron’3s fibres (polyester) reduced the number of cracks and width of cracks at comparable load levels. It doesn’t allow concrete to break and fall down at failure as it holds at the bottom, so which can be used in strengthening the beams of seismic prone zones.

Rather ductile fiber reinforced concrete can be produced, suited for an application in earth quake regions for instance.

Acknowledgment

The above project work is financially supported by the Tamilnadu State Council For Science And Technology, Chennai.

The authors are very much thankful to the Member Secretary of the above council for his constant support and continuous encouragement.

The authors are very much thankful to the Member Secretary of the above council for his constant support and continuous encouragement.

References

- Perumalsamy N. Balaguru, Sarendra P. Shah, Fiber reinforced cement composites, Mc Graw Hill International Editions 1992.

- D.J. Hannant. Fibre-reinforced concrete. Advanced Concrete Technology Set,2003, Pages 1-17. Elsevier Science Ltd .

- M. K. Lee and B. I. G. Barr. Strength and fracture properties of industrially prepared steel fibre reinforced concrete. Cement and Concrete Composites Volume 25, Issue 3, April 2003, Pages 321-332 Elsevier Science Ltd.

- Josef Kaufmann, Jo¨rn Lu¨bben, Eugen Schwitter. Mechanical reinforcement of concrete with bi-component fibers 23 May 2007 Composites

- A. Sivakumar and Manu Santhanam. Mechanical properties of high strength concrete reinforced with metallic and non-metallic fibres. Cement and Concrete Composites,Volume 29, Issue 8,September 2007, Pages 603-608 Elsevier Science Ltd.

- Steffen Grünewald and Joost C. Walraven.Parameter-study on the influence of steel fibers and coarse aggregate content on the fresh properties of self-compacting concrete Cement and Concrete Research,Volume 31, Issue 12,December 2001, Pages 1793-1798 Elsevier Science Ltd

- Josef Kaufmann, Jörn Lübben and Eugen Schwitter. Mechanical reinforcement of concrete with bi-component fibers Composites Part A: Applied Science and Manufacturing Volume 38, Issue 9, September 2007, Pages 1975-1984 Elsevier Science Ltd.

- M.C. Nataraja, T.S. Nagaraj and S.B. Basavaraja. Reproportioning of steel fibre reinforced concrete mixes and their impact resistance

- Cement and Concrete Research,Volume 35, Issue 12,December 2005, Pages 2350-2359Elsevier Science Ltd

- Ali R. Khaloo and Majid Afshari. Flexural behaviour of small steel fibre reinforced concrete slabs Cement and Concrete Composites,Volume 27, Issue 1,January 2005, Pages 141-149 Elsevier Science Ltd.

- Yining Ding and Wolfgang Kusterle Compressive stress–strain relationship of steel fibre-reinforced concrete at early age. Cement and Concrete Research Volume 30, Issue 10, October 2000, Pages 1573-1579 Elsevier Science Ltd

- Sofren Leo Suhaendi and Takashi Horiguchi Effect of short fibers on residual permeability and mechanical properties of hybrid fibre reinforced high strength concrete after heat exposition Cement and Concrete Research Volume 36, September 2006, Pages 1672-1678 Elsevier Science Ltd

- S. Mindess and A.J. Boyd High performance fibre reinforced concrete Advances in Building Technology,2002, Pages 873-880 Elsevier Science Ltd

- O. Kayali, M. N. Haque and B. Zhu Some characteristics of high strength fiber reinforced lightweight aggregate concrete Cement and Concrete Composites,Volume 25, Issue 2,February 2003, Pages 207-213 Elsevier Science Ltd

- N. Banthia and M. Sappakittipakorn . Toughness enhancement in steel fiber reinforced concrete through fiber hybridization Cem ConRes,Volume 37, Issue 9,Sept 2007, Pages 1366-1372 Elsevier Science Ltd.

- Qian CX, Stroeven P. Development of hybrid polypropylene–steel fibre-reinforced concrete. Cem Concr Res 2000;30:63–8.

- Yao W, Lib J, Wu K. Mechanical properties of hybrid fiber reinforced concrete at low fiber volume fraction. Cem Concr Res 2003;33:27–30.

- Banthia N, Nandakumar N. Crack growth resistance of hybrid fibre reinforced cement composites. Cem Concr Compos 2003;25:3–9.

- Indian Standard Designation, IS516-1999, Methods of tests for strength of concrete. New Delhi, India: Bureau of Indian Standards.

- N. Banthia, M. Sappakittipakorn .Toughness enhancement in steel fiber reinforced concrete through fiber hybridization. 23 May 2007.

- A. Sivakumar, Manu Santhanam. A quantitative study on the plastic shrinkage cracking in high strength hybrid fibre reinforced concrete 27 March 2007. Cement & concrete composite.

- Yining Ding, Wolfgang Kusterle Compressive stress strain relationship of steel fibre-reinforced concrete at early age. 26 June 2000. Cement & concrete research

- Sofren 'Leo Suhaendi, Takashi Horiguchi' Effect of short fibers on residual permeability and mechanical properties of hybrid fibre reinforced high strength concrete after heat exposition. 16 May 2006 cement & concrete research.

- M.C. Nataraja,' T.S. Nagaraj, S.B. Basavaraja' Reproportioning of steel fibre reinforced concretemixes and their impact resistance. 15 June 2005 Cement & concrete research

- Singh s.p, mohammadi y., madan S.K. Flexural fatigue strength of steel fibrous concrete containing mixed steel fibres.Mar.20,2006

NBM&CW December 2011