Comparative Studies of Different Cements with Different Standards

S.K. Agarwal and L.P. Singh, Scientists, EST Division, Central Building Research Institute, Roorkee

The compressive strength of four cements (Three PPC and one OPC) was determined according to different international standard, BIS, BS, ASTM and Sri Lanka. The 28 days strength of one PPC is 53 MPa, the other two shows 48MPa when tested as per BIS. The 43 grade OPC also shows 50 MPa at 28 days. However, when tested as per BS & ASTM methods, the 28 days strength is approx 32.5 Mpa and 27 MPa in all the cases.

Purpose of the present study is to compare compressive strength of different cement as per different standards, so that it can be mentioned when cement is exported to other countries. Further, the study will also help in minimizing errors and time saving BIS method once accepted by BIS. A fixed value of normal consistency can be introduced like other standards. Further export of these cements will be easy once these cements have been tested as per different standards. In the present study four cements (3 Portland Pozzolana and 1 OPC) was taken. The brands of cements are not disclosed.

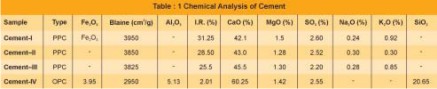

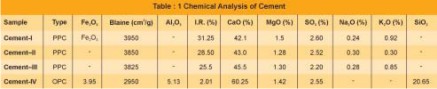

Three portland pozzolana cements and ordinary portland cement was purchased from the local market. Their physical and chemical properties are given in Table I. The results have been compared with BIS 1489-91[4].

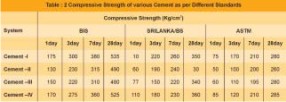

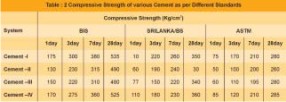

It is clear from Table 2 that Compressive Strength of all the four Cements is different at 1, 3, 7 and 28 days, when tested as per different codes of practice existing in different countries.

It is clear from Table 2 that Compressive Strength of all the four Cements is different at 1, 3, 7 and 28 days, when tested as per different codes of practice existing in different countries.

Comparing Strength data of 1, 3 and 7 day for three blended Cements, Cement-I is more than Cement 2 and 3. The higher earlier strength can be attributed to fineness of cement I. It is known that the short term activity depends on the specific surface area of the pozzolona, where as the long-term activity depends on the chemical and mineralogical composition of pozzolana. The pozzolana activity indices are highly correlated with the specific surface areas of flyashes. Further, fineness of flyashes is one of the most important physical properties affecting pozzolanic reactivity.

At early ages fineness plays an important role in the strength of mortars via a micro–filler or a cement dispersion effect or both.

In the present case, the surface area of Cement I is more compare to cement 2 and 3 showing there by higher initial strength compare to cement 2. This can be attributed to higher CaO content and less IR. However, the surface area of both the cements (2 and 3) is nearly same. The 28 days strength of C1, C2 & C3 according to BIS corresponds to 53 MPa and 48 MPa. However, when compared to BS or ASTM standards these cements are approx 32.5 MPa and 27 MPa. This is approx 35% and 40% less compare to BIS values.

The present study indicates that Indian cements are showing much lower strength, when tested as per BS/SriLanka and ASTM methods. Since blended cements especially portland pozzalana cement is available in abundance in the country with 20-30% pozzolana content. In order to ensure high performance of concrete in marine/ aggressive environment by using PPC, the proportions of cementitious materials should be much more than those generally used in blended cement in our country.

This study is important from the point of view for cement manufacturing units exporting cement as per survey by 2010, 60% cement will be blended. Their characterization will help in export.

At early ages fineness plays an important role in the strength of mortars via a micro – filler or a Cement dispersion effect or both.

In the present case, the surface area of Cement I is more compare to Cement 2 and 3. Showing there by higher initial strength compare to Cement 2.this can be other build to higher Cao Content and less IR.However, the surface area of both the cement is nearly same. The 28 day strength of C1, C2 & C3.according to BIS corresponds to 53 MPa as 43 Mpa. However, when compared to BS or ASTM standard these Cements are approx 32.5Mpa and 27 MPa. This approx 35% and 40% less compare to BIS.

The present study indicates that Indian Cements are showing much lower strength, when tested as per BS/Srilanka and ASTM method. Since blended Cements especially portland pozzalana Content. In order to ensure high performance of concrete In order to ensure high performance of concrete in marine/ aggressive environment by using PPC the proportions of cementitious materials should be much more than those generally used in blended Cement in our country.

This study is important from the point of view for Cement manufacturing units exporting Cement.

The compressive strength of four cements (Three PPC and one OPC) was determined according to different international standard, BIS, BS, ASTM and Sri Lanka. The 28 days strength of one PPC is 53 MPa, the other two shows 48MPa when tested as per BIS. The 43 grade OPC also shows 50 MPa at 28 days. However, when tested as per BS & ASTM methods, the 28 days strength is approx 32.5 Mpa and 27 MPa in all the cases.

Introduction

In the last two decades, the quality of cement has improved considerably, due to improvement in the cement manufacturing technology. Cement conforming to 43 grade or 53 grade are giving much higher compressive strength as recommended in respective BIS codes 8112 and 12269 [1,2]. Different countries have their own standards for testing cement. Different international standards have fixed consistency (Srilanka=0.40, BS-12=0.400, ASTM =0.485). However, according to BIS normal consistency varies 0.27 to 0.33 depending upon the fineness of cement. In BIS method normal consistency has to be determined on daily bases. One study involving 53 grade OPC has been done [3].Purpose of the present study is to compare compressive strength of different cement as per different standards, so that it can be mentioned when cement is exported to other countries. Further, the study will also help in minimizing errors and time saving BIS method once accepted by BIS. A fixed value of normal consistency can be introduced like other standards. Further export of these cements will be easy once these cements have been tested as per different standards. In the present study four cements (3 Portland Pozzolana and 1 OPC) was taken. The brands of cements are not disclosed.

Materials

Cement

Three portland pozzolana cements and ordinary portland cement was purchased from the local market. Their physical and chemical properties are given in Table I. The results have been compared with BIS 1489-91[4].

Consistency

Normal consistencies of all the four cements were determined as per BIS [5].Casting of Cubes

70 mm cubes were cast as per BIS. After 24 hours, cubes were demolded and kept in water at 27+20C. Cubes were also cast at 0.400 and 0.485 normal consistencies according to BS and ASTM methods.Compressive Strength

Compressive Strength of cube was determined at 1, 3, 7 and 28 days as per BIS methods [6]. The results are summarized in Table 2.Result and Discussion

Comparing Strength data of 1, 3 and 7 day for three blended Cements, Cement-I is more than Cement 2 and 3. The higher earlier strength can be attributed to fineness of cement I. It is known that the short term activity depends on the specific surface area of the pozzolona, where as the long-term activity depends on the chemical and mineralogical composition of pozzolana. The pozzolana activity indices are highly correlated with the specific surface areas of flyashes. Further, fineness of flyashes is one of the most important physical properties affecting pozzolanic reactivity.

At early ages fineness plays an important role in the strength of mortars via a micro–filler or a cement dispersion effect or both.

In the present case, the surface area of Cement I is more compare to cement 2 and 3 showing there by higher initial strength compare to cement 2. This can be attributed to higher CaO content and less IR. However, the surface area of both the cements (2 and 3) is nearly same. The 28 days strength of C1, C2 & C3 according to BIS corresponds to 53 MPa and 48 MPa. However, when compared to BS or ASTM standards these cements are approx 32.5 MPa and 27 MPa. This is approx 35% and 40% less compare to BIS values.

The present study indicates that Indian cements are showing much lower strength, when tested as per BS/SriLanka and ASTM methods. Since blended cements especially portland pozzalana cement is available in abundance in the country with 20-30% pozzolana content. In order to ensure high performance of concrete in marine/ aggressive environment by using PPC, the proportions of cementitious materials should be much more than those generally used in blended cement in our country.

This study is important from the point of view for cement manufacturing units exporting cement as per survey by 2010, 60% cement will be blended. Their characterization will help in export.

At early ages fineness plays an important role in the strength of mortars via a micro – filler or a Cement dispersion effect or both.

In the present case, the surface area of Cement I is more compare to Cement 2 and 3. Showing there by higher initial strength compare to Cement 2.this can be other build to higher Cao Content and less IR.However, the surface area of both the cement is nearly same. The 28 day strength of C1, C2 & C3.according to BIS corresponds to 53 MPa as 43 Mpa. However, when compared to BS or ASTM standard these Cements are approx 32.5Mpa and 27 MPa. This approx 35% and 40% less compare to BIS.

The present study indicates that Indian Cements are showing much lower strength, when tested as per BS/Srilanka and ASTM method. Since blended Cements especially portland pozzalana Content. In order to ensure high performance of concrete In order to ensure high performance of concrete in marine/ aggressive environment by using PPC the proportions of cementitious materials should be much more than those generally used in blended Cement in our country.

This study is important from the point of view for Cement manufacturing units exporting Cement.

Conclusion

It is concluded from the present study that Cement claming 53 Mpa strength for PPC according to BIS are showing approx 32.5 and 27 Mpa when tested as per BS/ASTM method.Acknowledgment

This paper is part of ongoing R&D work in Central Building Research Institute and is published with the permission of Director, CBRI, Roorkee, India.References

- Specification for 43 grade Ordinary Portland Cement BIS 8112 (2005). Manak Bhavan New Delhi.

- Specification for 53 grade Ordinary Portland Cement BIS 8112 (2005). Manak Bhavan New Delhi.

- Dordi, C.M., Concrete for the Millennium Advance in Cement Technology Ed. S.N. Ghosh Tech Books International p.421 (2002).

- Specification for Portland Pozzolana Cement, BIS 1489 (Part I) Feb 2004, Manak Bhavan New Delhi

- Specification for physical test for hydraulic Cement BIS 4031 (Part 4); Determination of consistency of standard Cement Paste. (2005), Manak Bhavan, New Delhi.

- Specification for Physical Test for hydraulic Cement BIS 4031 (Part 6)–Determination of Compressive Strength (2005). Manak Bhavan, New Delhi.

NBM&CW October 2008