Prensoland Offers Innovative, Cost-effective and Customized Precast Solution

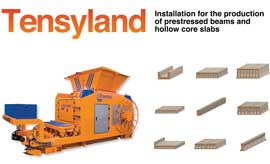

Prensoland with over fifty years of experience in manufacturing machinery for Precast Concrete elements has supplied more than 1000 installations all over the world for producing Precast Concrete Elements. The company manufactures two types of machines COMPACTA and TENSYLAND where the first one is used for making Concrete Blocks and Pavers, whereas the second one is used for making Pre-stressed Hollow Core Slabs and Beams of Concrete.

COMPACTA MACHINES are available in different capacities of production and can be installed in different formats from Semi-automatic to fully-automatic whereas TENSYLAND machines are the most versatile, economical to run & maintain and fastest casting machines in the world. One machine can manufacture every possible pre-stressed Concrete profile at the change of a mould.

India's biggest installed capacity for manufacturing Pre-stressed Hollow Core Slabs and Beams of Concrete was set up by Preca Solutions Pvt Ltd in Hyderabad, wherein the entire installation has been supplied by Prensoland. Preca is now constructing a 15-storey building in Hyderabad using these Precast elements. They are capable of manufacturing Pre-stressed Hollow Core Slabs, Solid Slabs, Wall Panels, Pre-stressed Beams, Hollow Beams, Stadium Seat Panels, and many more Pre-stressed Concrete profiles.

Not only this but also country's biggest installed capacity for making Blocks and Pavers of Concrete is also being installed by Prensoland for a customer in Punjab (India). A fully automatic Vibrocompacta machine being installed there is capable of moulding up to 100 tons of Concrete products per hour and manufacturing Hollow & Solid Concrete Blocks, High strength pavers (Dual Layer), Fly Ash Blocks, Insulated Blocks, Retaining wall blocks, Façade Blocks, and many more PCC Concrete profiles.

The non-availability of good quality high strength pavers is posing a big threat to the quality of paving work of Road shoulders and Municipal areas in the urban as well as rural areas of the country. The prohibition on use of Red bricks in many parts of the country gives the opportunity to introduce and use, good quality Concrete Hollow Blocks for making walls as they are economical, better engineered and a green-product. Every consumer is waiting and willing to use good construction product, hence current period is the most opportune time for companies and entrepreneurs to make such products using COMPACTA MACHINES, to lead and succeed in the Indian market.

Prensoland has presence and offices, around the world for providing high value innovative solutions to its customers, which includes consultation, planning, installation, implementation, maintenance, and training of workers. In India, the Prensoland operations are based out of the capital city of New Delhi and it provides the most Cost-effective solution to its customers for their Precast Concrete production facilities customised to their needs.

COMPACTA MACHINES are available in different capacities of production and can be installed in different formats from Semi-automatic to fully-automatic whereas TENSYLAND machines are the most versatile, economical to run & maintain and fastest casting machines in the world. One machine can manufacture every possible pre-stressed Concrete profile at the change of a mould.

India's biggest installed capacity for manufacturing Pre-stressed Hollow Core Slabs and Beams of Concrete was set up by Preca Solutions Pvt Ltd in Hyderabad, wherein the entire installation has been supplied by Prensoland. Preca is now constructing a 15-storey building in Hyderabad using these Precast elements. They are capable of manufacturing Pre-stressed Hollow Core Slabs, Solid Slabs, Wall Panels, Pre-stressed Beams, Hollow Beams, Stadium Seat Panels, and many more Pre-stressed Concrete profiles.

Not only this but also country's biggest installed capacity for making Blocks and Pavers of Concrete is also being installed by Prensoland for a customer in Punjab (India). A fully automatic Vibrocompacta machine being installed there is capable of moulding up to 100 tons of Concrete products per hour and manufacturing Hollow & Solid Concrete Blocks, High strength pavers (Dual Layer), Fly Ash Blocks, Insulated Blocks, Retaining wall blocks, Façade Blocks, and many more PCC Concrete profiles.

The non-availability of good quality high strength pavers is posing a big threat to the quality of paving work of Road shoulders and Municipal areas in the urban as well as rural areas of the country. The prohibition on use of Red bricks in many parts of the country gives the opportunity to introduce and use, good quality Concrete Hollow Blocks for making walls as they are economical, better engineered and a green-product. Every consumer is waiting and willing to use good construction product, hence current period is the most opportune time for companies and entrepreneurs to make such products using COMPACTA MACHINES, to lead and succeed in the Indian market.

|

|

Prensoland has presence and offices, around the world for providing high value innovative solutions to its customers, which includes consultation, planning, installation, implementation, maintenance, and training of workers. In India, the Prensoland operations are based out of the capital city of New Delhi and it provides the most Cost-effective solution to its customers for their Precast Concrete production facilities customised to their needs.

NBM&CW February 2013