Partijatha Machinery

Mr. J. Ramesh, Founder, Partijatha Machinery

Apprising about the company’s other show focus he says, “We will also use this platform to get valuable feedback for our proposed fully automatic Wet cast plant which is due for commercial launch by the mid-2013 apart from collecting information about Unique Wet pressed products from our potential customers. Other than this, we are also in talks with a couple of companies from Germany and UK for jointly promoting new technologies in Precast Concrete technology, Mixing systems and related products in India.”

Commenting on their participation he informed that exhibitions like bC India is a unique opportunity for us to present our products and technologies to new potential customers. It would help us reconnect with our existing customers and personally meet them to analyze their problems if any and understand their new requirements. However, too many shows in frequent intervals have diluted the impact and enthusiasm of the visitors. Also, the quality of the visitors has improved though the total footfalls have reduced considerably. Moreover, the present subdued sentiment in Infrastructure investments in the country does not help matters.

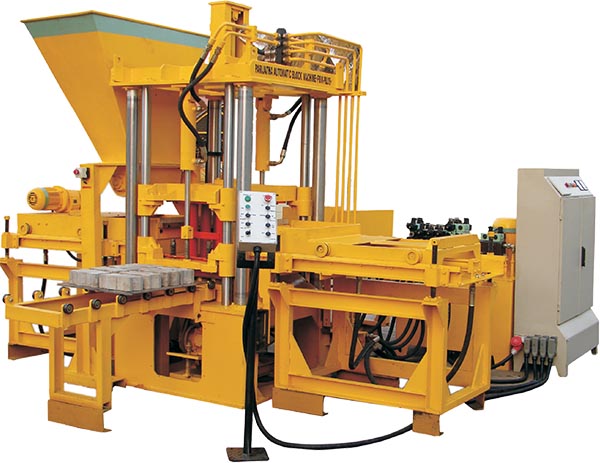

Giving an overview on company progression and achievements he stated that Parijatha is the leader in Concrete Block, Paving tile and Terrazzo tile machinery in India and growing stronger by the day. The company is well-known in every nook and corner of the country for its excellent machines designed and manufactured taking into consideration Indian working conditions and customer preferences. It has set up the most modern manufacturing facility in Bangalore which can easily match international standards. “We have always strived to understand our customers’ needs from time to time and have been quick enough to match up to their needs by innovation and agility. More importantly Parijatha designs and manufactures plants which specifically cater to the Indian customers and also relates to a few other countries where we regularly export and makes up a substantial share of sales. Incidentally, we are also the biggest exporters of Block plants and Terrazzo tile plants in India till date,” he informed.

He quipped that Parijatha always strives to introduce innovative products and technologies since its inception and is very active in understanding customers’ specific needs and quickly launches smart products which are known for their simplicity, reliability, ease of maintenance and operation. This has led to their immense popularity among all their customers who keep adding on by the day.

Expecting good year ahead for Indian construction industry he avers that it is heartening to note that the Prime Minister announced a couple of months ago about releasing a substantial amount of funds for Infrastructure development all over the country. Sadly, this has still not been converted to any kind of concrete action and results are yet to be seen. Also, repeated scams and political uncertainty had affected investor confidence in the short-term. This has led to a fairly negative sentiment and most private investors are still holding their cards close to their chest and yet to announce fresh investments. Therefore, I feel the best is yet to come for the year and look forward to some kind of activity happening after March ‘13 though not in the scale we had seen in the last few years.