ZENTRIFIX KMH

Mineral-based corrosion protection and bonding coat used in concrete repair

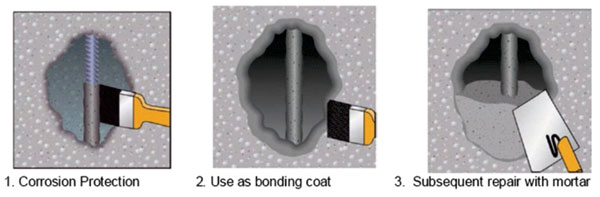

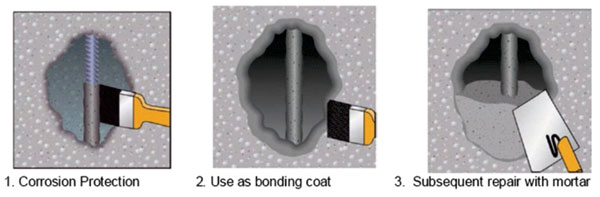

Zentrifx KMH is a ready to use mineral based one component corrosion in hinitor and a bond coat. In addition to use as corrosion protection, the use of Zentrifix KMH improves the adhesion of the coarse repair mortar. In addition, it is also a solvent-free product.

Before application of Zentrifix KMH, the surface must be moistened. It should be damp, but not saturated with water. Zentrifix KMH is a one-component product, which must be mixed with water. Zentrifix KMH is slowly added to the water while stirring continuously, until a homogenous lump free mixture is achieved. Mixing takes about 5 minutes. Slowly rotating mixers are particularly suitable. The Ratio of Zentrifix KMH to water is as mentioned below:

100 pbw Zentrifix KMH

20 –25 pbw water

As with other cementitious materials, the added water may be varied slightly depending upon consistency required.

Zentrifix KMH can be applied by brush. As corrosion protection, the homogeneously mixed material is applied to the prepared reinforcing steel with suitable brushes in two coats. Care must be taken that binding wires and also the areas between reinforcement and concrete are fully coated to ensure sufficient coat thicknesses. As bonding Coat, the homogeneously mixed material is carefully brushed into the pre-wetted surface. Short bristle brushes are recommended. The coarse repair mortar is then applied onto this fresh bond coat. Only so many surfaces should be prepared as can be worked "fresh-on-fresh".

MC-Bauchemie (India) Pvt. Ltd. Manufactures these products along with a host of other Construction Chemicals in technical and financial collaboration with MC-Bauchemie, Germany. MC-Bauchemie (India) Pvt. Ltd. is an ISO 9001: 2008 certified Company.

Zentrifx KMH is a ready to use mineral based one component corrosion in hinitor and a bond coat. In addition to use as corrosion protection, the use of Zentrifix KMH improves the adhesion of the coarse repair mortar. In addition, it is also a solvent-free product.

Before application of Zentrifix KMH, the surface must be moistened. It should be damp, but not saturated with water. Zentrifix KMH is a one-component product, which must be mixed with water. Zentrifix KMH is slowly added to the water while stirring continuously, until a homogenous lump free mixture is achieved. Mixing takes about 5 minutes. Slowly rotating mixers are particularly suitable. The Ratio of Zentrifix KMH to water is as mentioned below:

100 pbw Zentrifix KMH

20 –25 pbw water

As with other cementitious materials, the added water may be varied slightly depending upon consistency required.

Zentrifix KMH can be applied by brush. As corrosion protection, the homogeneously mixed material is applied to the prepared reinforcing steel with suitable brushes in two coats. Care must be taken that binding wires and also the areas between reinforcement and concrete are fully coated to ensure sufficient coat thicknesses. As bonding Coat, the homogeneously mixed material is carefully brushed into the pre-wetted surface. Short bristle brushes are recommended. The coarse repair mortar is then applied onto this fresh bond coat. Only so many surfaces should be prepared as can be worked "fresh-on-fresh".

MC-Bauchemie (India) Pvt. Ltd. Manufactures these products along with a host of other Construction Chemicals in technical and financial collaboration with MC-Bauchemie, Germany. MC-Bauchemie (India) Pvt. Ltd. is an ISO 9001: 2008 certified Company.

NBM&CW July 2016