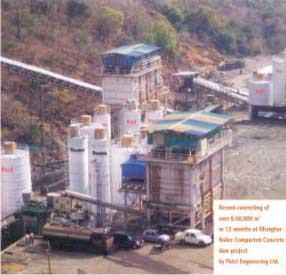

Record Concreting of over 6,50,000 m3 by Patel Engineering Ltd.

Two Schwing Stetter Concrete Batching and Mixing plants–Models HN 3.0 (120 m3/hr) and one HN 4.0 (160 m3/hr) were installed aggregating to 400 m3/hr batching capacity. The plants had twin shaft mixers and the control system was Stetter MCI 300 system.

Ghatghar Pumped Storage Scheme is a hydropower generation project constructed by Irrigation Department Govt. of Maharashtra. Total 250 MW power will be produced from this hydro power plant. Three dams Saddle Dam No. 1, 2, and Upper Dam, build up the upper reservoir. Lower dam builds up the lower reservoir. Water conductor system consists of inclined underground pressure shaft and the underground powerhouse, which has two units of 125 MW turbines. These turbines act as reversible pumps. In nonpeak hours the water from the Lower Dam reservoir, which will be filled with water, and stored after power generation, will be pumped back to Upper Reservoir. Saddle Dam No. 1, Upper Dam and Lower Dam are built in Roller Compacted Concrete.

This is a premium article available exclusively for our subscribers.

If you are already a subscriber, please Login

If not, subscribe now and get access to well researched articles & reports on infrastructure construction, equipment & machinery, innovations & technology, project reports, case studies, and more. All this by simply paying just ₹200/- for a month of complete portal access, or a discounted rate of ₹1000/- for a full year of access.

NBM&CW May 2007

Model Lighthouse Housing Projects

The six Lighthouse Housing Projects (LHPs) promoted by the Union Ministry of Housing & Urban Affairs (MoHUA) are playing a crucial role in mainstreaming cutting-edge housing technologies. Being built as part of the Global Housing Technology

Healthy Planet School in Noida Receives ‘Outstanding Concrete Structure’ Award from ICI, Ghaziabad Centre

Healthy Planet School is one of a kind pre-school with the best state-of-the-art facilities. The project, conceptualized as a cocoon, is built over an area of 37,025 sqft, and is surrounded by lush green trees. The school encourages children to interact socially

Incorporating Laser Tech for Creation of Heavy-Duty Warehouse Flooring

India is fast becoming a digital economy with smartphones and the internet reaching even the most remote areas. There is a boom in online shopping, which is driving the need for upscaling the logistics industry and increasing the need

Tackling Challenging Strata in Building Sardar Sarovar Dam One of the Largest Dams in the World

Deep Foundations Institute of India (DFI of India) held a webinar under its Groundwork program on “Foundation Treatment for Concrete Gravity Dam: A Case Study of Sardar Sarovar Dam” on 18 January 2022. It covered topics like

CONTAKT Smart Solution for Planning, Monitoring and Documentation

With the sensor-based CONTAKT construction site software, Doka offers a digital solution that brings the construction project planned in BIM to life on the construction site. The new Fröschl office building is an

Shiva Statue at Nathdwara, Rajasthan

Nathdwara near Udaipur in Rajasthan is famous for the Shrinathji Temple. This holy town now boasts a 351 feet (107m) tall statue of the trident-wielding, stoic, and compassionate Lord Shiva - the largest Shiva statue

Exposed Reckli Finish Retaining Wall

The Reckli Finish Exposed Retaining Wall at Sabarmati Riverfront in Ahmedabad, using a 9m high Exposed Retaining Wall with a textured finish, and outer face using Formliner Formwork (known as Reckli), has grabbed the eyes of the world. Besides

Delhi Metro Terminal 1 IGI Airport Terminal

One of the great benefits of Delhi Metro Phase 3 is that the domestic terminals of the Indira Gandhi Intl’ Airport have got Metro connectivity - a boon to the city’s domestic air passengers. While the Airport Express Link provides

Simulating oversize and heavy vehicle manoeuvres using AutoTURN® from Transoft Solutions

Narrow mountain roads, steep hills and challenging ‘S’ curves are just part of the landscape in the ‘toe’ of Southern Italy, where wind farms are becoming a common part of the countryside. With green technology like wind

Atlas Copco XA316 and XAT266 portable air compressors for Mumbai underground metro line

Atlas Copco portable air compressors have been deployed for the first underground metro line in Mumbai, and they are not just under the supervision of Mumbai Metro Rail Corporation Limited (MMRCL) but also under

Cranes in Full Force at - India's Major Road Project

The 135-km, 11,000 crores Eastern Peripheral Expressway-2 which was inaugurated recently by the Prime Minister, connects towns of UP and Haryana and act as an outer ring road for the capital. It is the country's

Indira Paryavaran Bhawan - First On-site Zero Net Energy Building of India

A zero-energy or a net zero building is a building with zero net energy consumption from outside source, which means that the total amount of energy used by the building on an annual basis is almost equal to

Making of a Green Data Centre

Data centres make up 3% of global energy consumption. The main reason behind data centres being major energy guzzlers is the IT processing power, which has increased substantially to meet the growing

Apollo ValueTec Plant Gives Competitive Edge to Rana Builders

Dhaka-based Rana Builders (Pvt.) Ltd. specialises in construction of roads, bridges and buildings. When purchasing a new asphalt-mixing plant, it wanted a product that would help meet its objective of on-time delivery

BHAI concrete batch mix plant working at Asia’s largest waste-water treatment plant

Delhi Jal Board is setting up a 318 MLD (70 MGD) wastewater treatment plant at GT Karnal Road on the outskirts of Delhi. The ₹414.78 crore project, said to be the largest in Asia, is being constructed by EPC contractor-Larsen & Toubro

The Fast Lane to Growth

When the National Highways Authority of India (NHAI) last widened the Vijayawada-Chilakaluripet Highway in the early 2000s, the country was at the beginning of its exponential economic growth. Since then, the nation’s GDP

Sany cranes deployed at Suzlon India's wind power project

Project developers are deploying new cranes and advanced transportation to enable faster and safer completion of their projects. Suzlon India's wind power project at Agar in Madhya Pradesh, is one such site

Insitu Investigation of Cinder Mound For Building Construction - A Case Study

Cinder is a waste generated as coal residues from the blast furnace of thermal power plant. It was accumulated over a long periods near railway station, Jamshedpur, Jharkhand, India. This dumping

SoilTech Mk. III - 3rd Generation nano-polymer stabilization

Golfshire is a super-premium residential project in Bangalore, comprising luxury villas, a 18-hole PGA standard golf course, a large convention centre with seating capacity of 5000, and a 5-star hotel. The project is