Precast Concrete Construction Technologies for Metro Projects in India

Mahesh Tandon, Tandon Consultants Pvt. Ltd., India

The most dramatic development in the field of urban infrastructure in recent times has undoubtedly been the introduction of the metro as a public transportation system. Apart from providing the predominant mode of travel, the metro has been instrumental in reducing pollution and making a significant contribution to the improvement of quality of life for the citizens. Vehicle population in Urban India is growing at a fast rate. As clamour for more urbanization and living space takes place in a fast growing and expanding city, new residential colonies and major commercial complexes are coming up at a rapid rate, all of which require to be integrated with public transport.

For the structural engineer, metro projects have afforded great opportunities to develop their skills and to seek innovative solutions to the problems peculiar to large scale constructions in the urban milieu. Important decisions at design stages determine the success of the project in terms of speed and quality of construction, environmental impact and aesthetic appeal of the structure, as well as, cost and economic viability.

This paper discusses some of the challenges faced in the viaduct structures and how they were overcome in Metro Constructions in India through Precast Concrete Construction Technologies.

Introduction

During the last few decades, there has been a remarkable shift in the manner in which construction projects are implemented in urban India. In the past, open spaces seemed to be plentiful and not much thought was given to the consequence that such structures would have on their immediate surroundings or on the city. Now, we have to build without slowing or shutting down and build quickly [1]. Building with minimum land acquisition and without encroaching on existing road space has become a mandatory requirement. The selection of the design concept and construction methodology for Metro projects must keep in mind the following objectives:

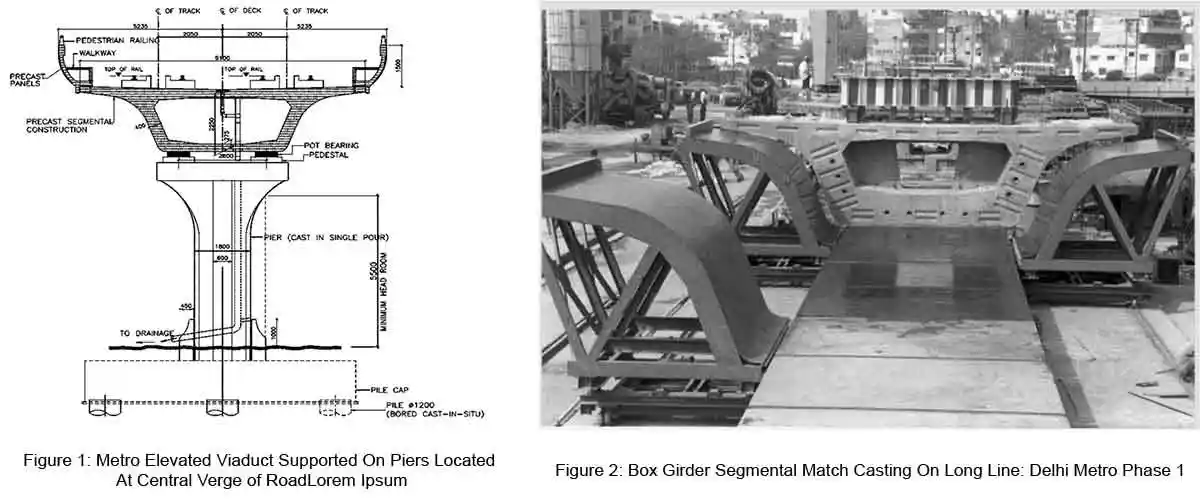

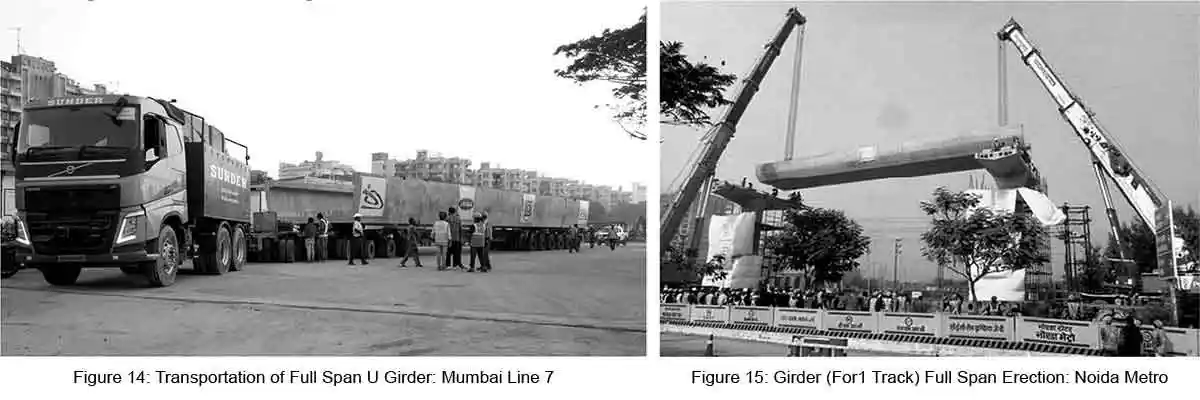

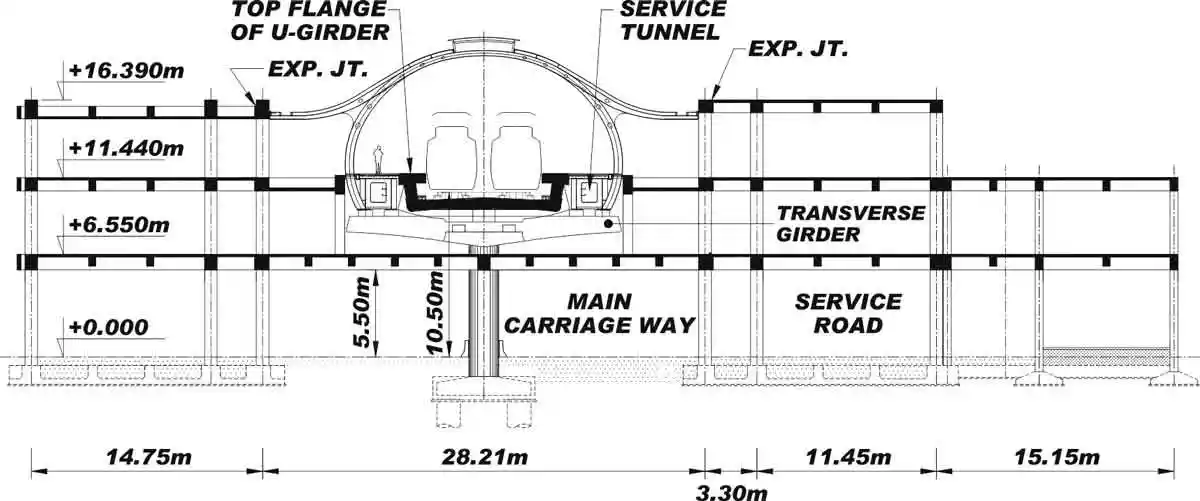

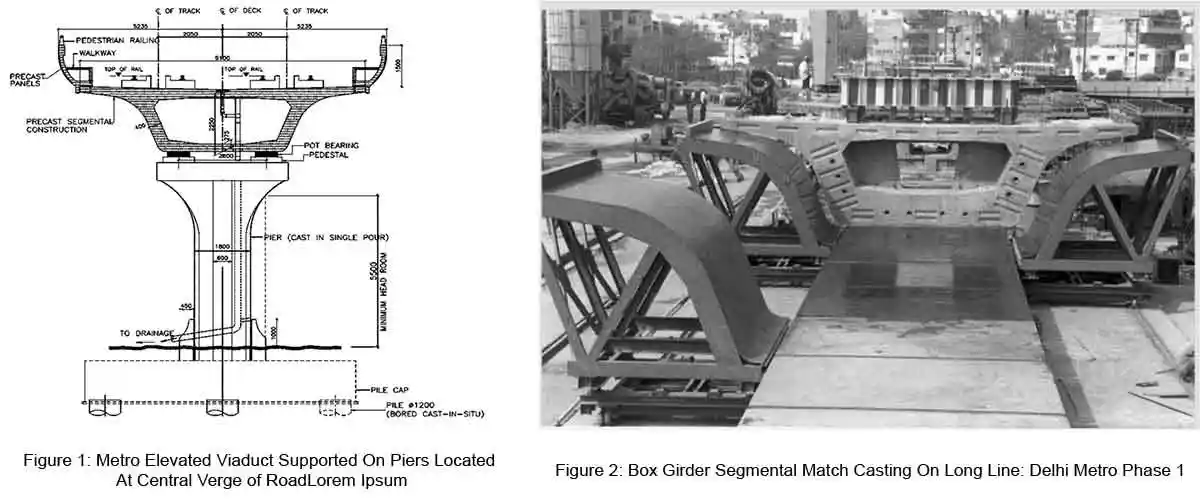

Elevated viaducts for metro structures are charachterised by long lengths and a series of ‘standard’ simply supported spans generally supported on single piers on the central verge of the roadway. (Figure 1). The superstructure is generally constructed span-by-span. The adoption of precast constructions has been instrumental in delivering the stated objectives satisfactorily. Pre-casting has been at the heart of Accelerated Bridge Construction enabling erection of several spans in a week. Pre-casting of the superstructure in the casting yard (Figure 2) concurrently with the foundations and substructures being implemented at site, brings down the project duration. Since the superstructure is precast in an ‘away’ casting yard, concreting at site is reduced and so also the air and noise pollution. Traffic diversions and disturbances are obviated to a large extent since the superstructure can be erected without ground support. High quality concrete products produced in factory-like conditions result in high durability as well as finishes.

Loading

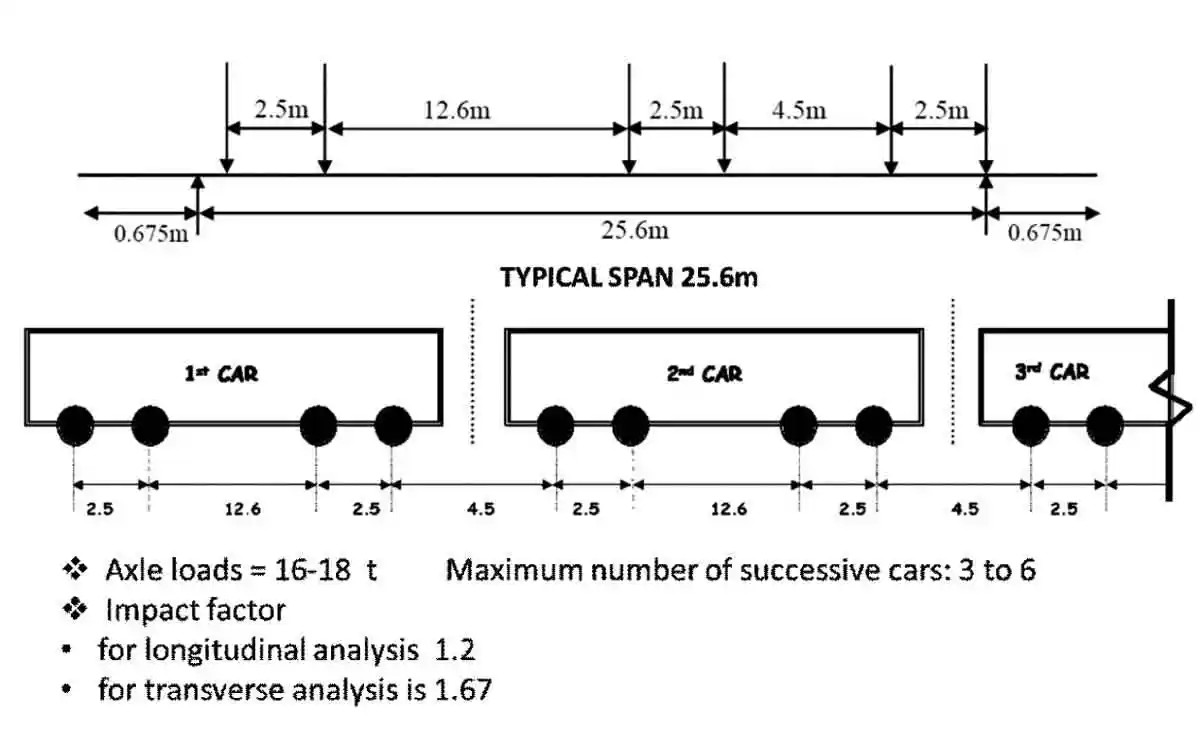

Figure 3: Rolling Stock Loading

Figure 3: Rolling Stock Loading

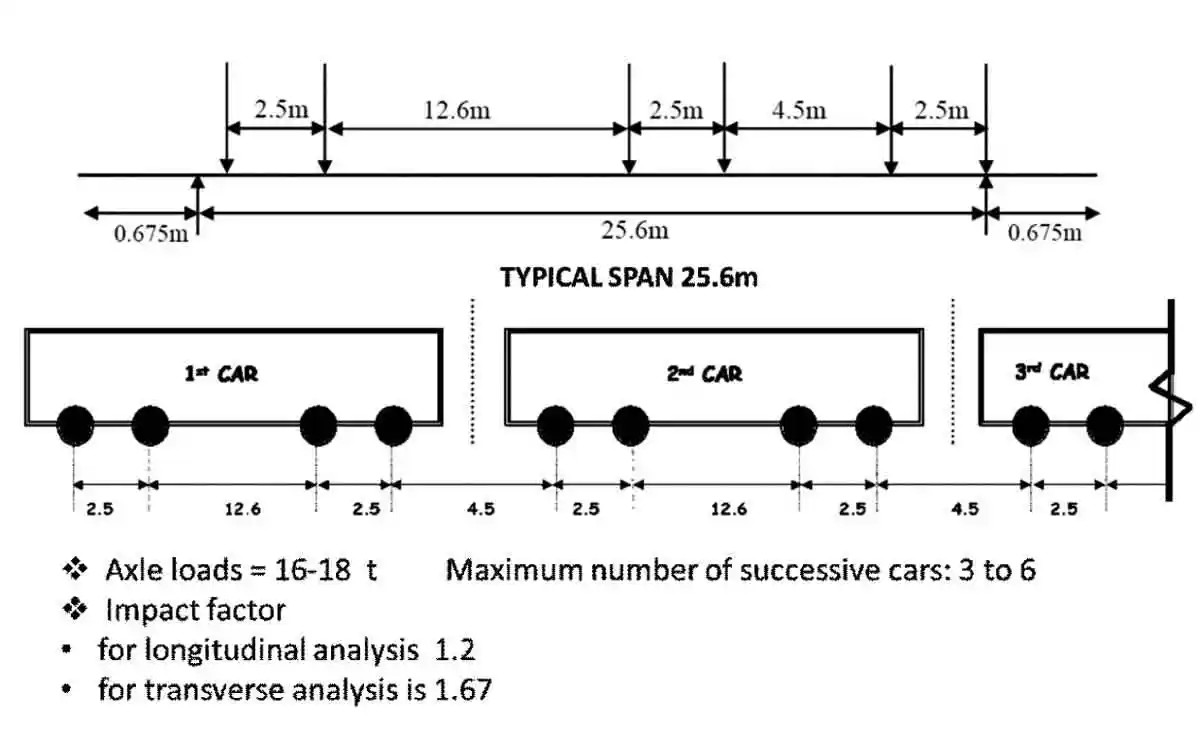

The loading due to the rolling stock is much higher than in a highway bridge (Figure 3). The axle loads vary between 16-18t depending on the coach width (2.9 to 3.2m) in the concerned metro system. The design is carried out essentially by codes developed for the Indian Railways.

The Impact Factor is different for the longitudinal and transverse direction due to the difference in the relevant span length.

Concept Stage

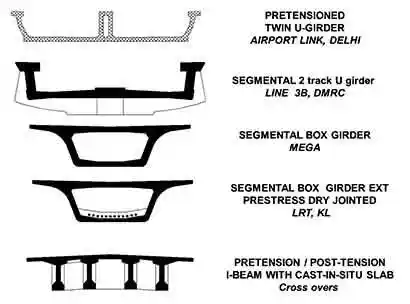

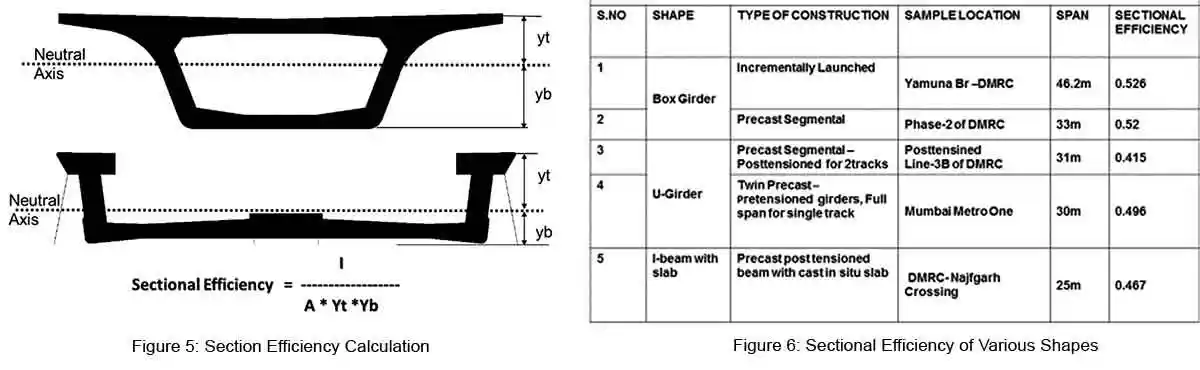

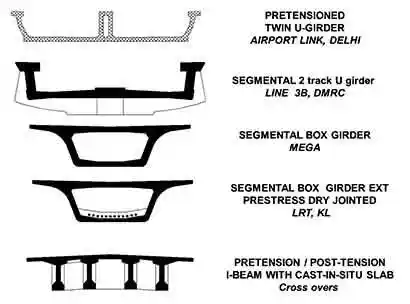

Figure 4: Standard Span Superstructure Concepts

The major decisions to be taken at the concept stage for the precast superstructure depend on the evaluation of the most suitable systems in relation to the following:

Figure 4: Standard Span Superstructure Concepts

The major decisions to be taken at the concept stage for the precast superstructure depend on the evaluation of the most suitable systems in relation to the following:

As in all jobs heavily dependent on large scale pre-casting of elements, standardization of moulds in the casting facility is the key feature which determines the cost and speed of construction. A constant depth of section and a fixed profile on the outer surface of the precast superstructure is important. The variations in structural thicknesses are effected on the internal side.

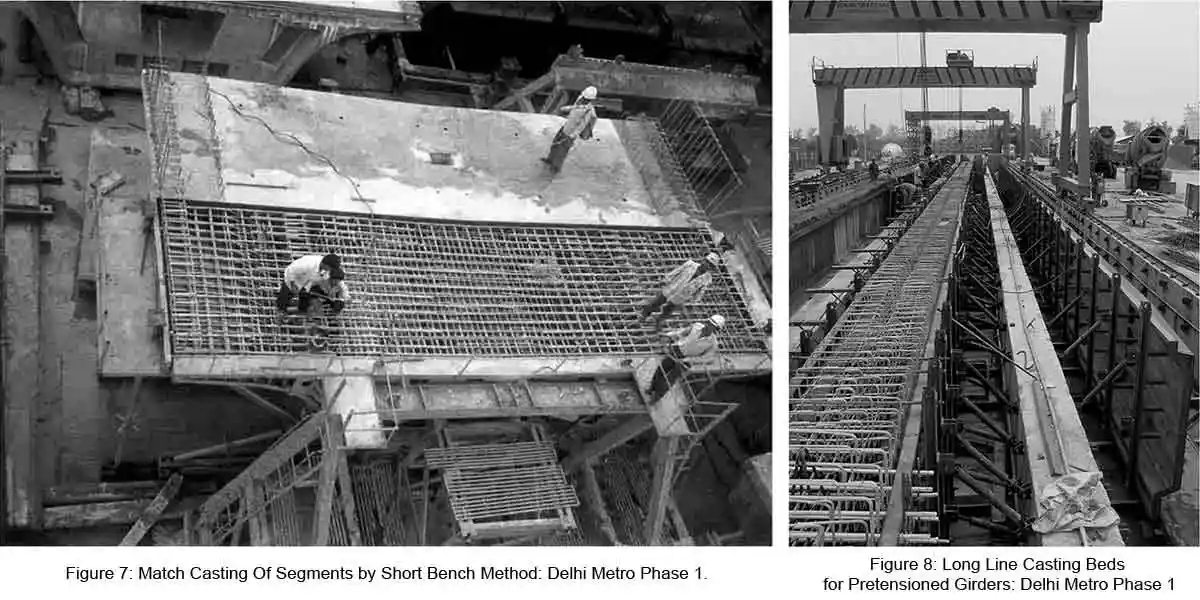

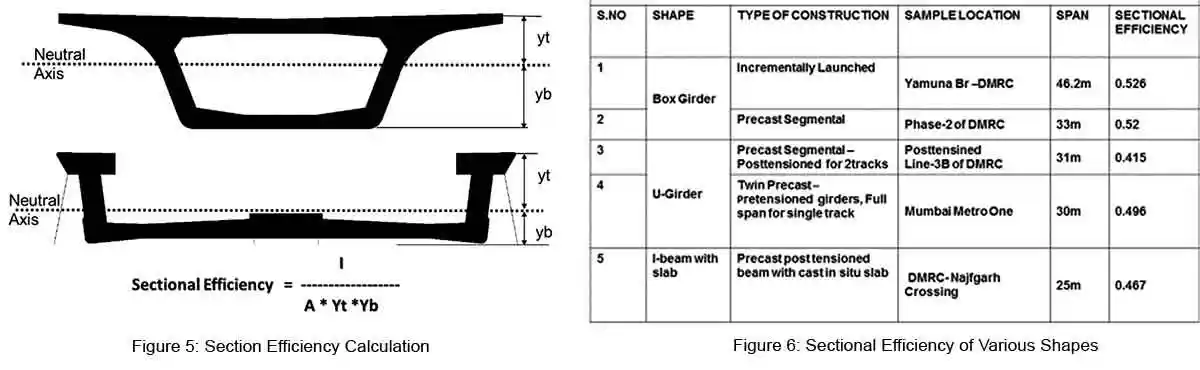

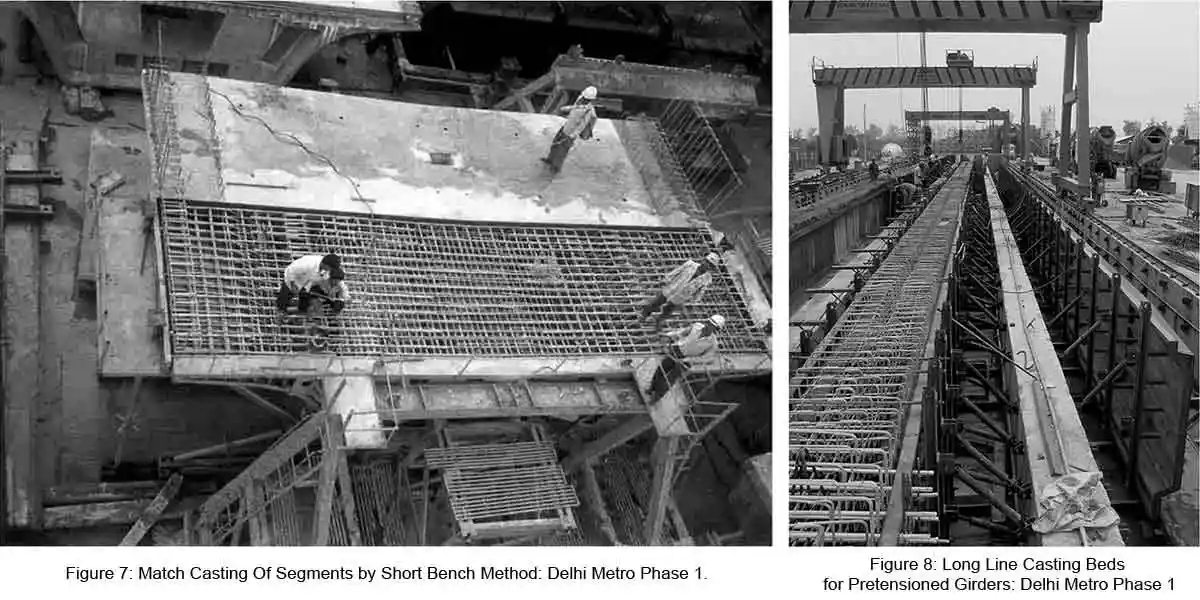

The required size and shape of the casting yard is dependent on the type of pr-ecasting facility visualized for the project. The long line methodology (Figure 2) requires a “longish” rectangle whole the short bench (Figure 7) requires a “squarish” configuration. The long line methodology is particularly suited to pre-tensioning (Figure 8).

The alignment is often characterized by tight curvatures as it snakes through the crowded areas of the city. It has several breaks at the location of stations which have a totally different architectural character as compared to the viaduct and often implemented under a separate contract. The superstructure used in the viaduct may or may not be suitable for adoption in the station structure.

Precast Segmental Metro Viaduct

Precast segmental technique when employed in India uses traditional internal post-tensioning tendons with epoxy bonded joints. The tendons are threaded through preformed ducts before tensioning in situ. Being a span-by-span erection, post-tensioning of cables can be effected from the free end only.

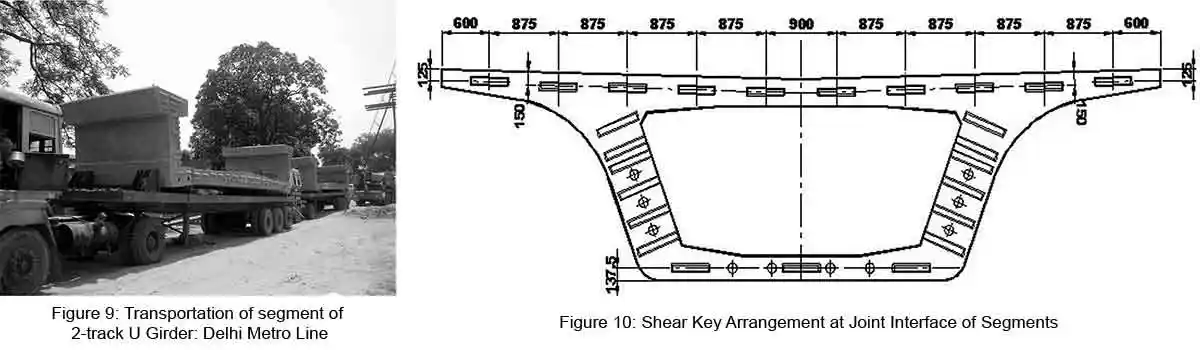

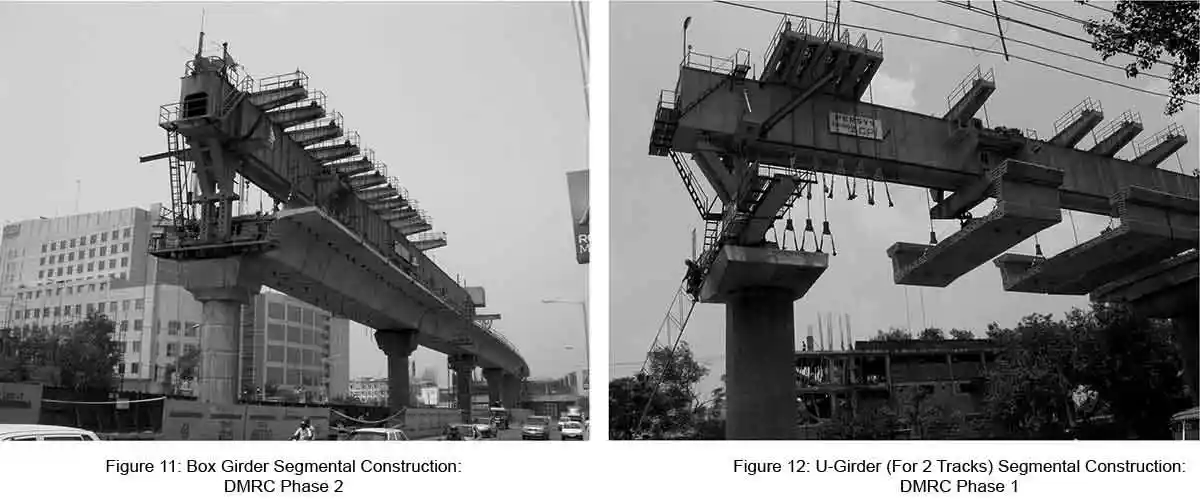

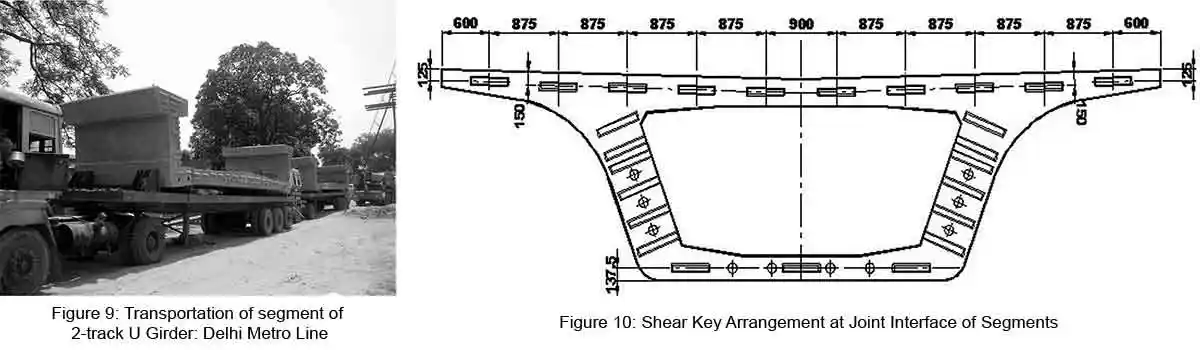

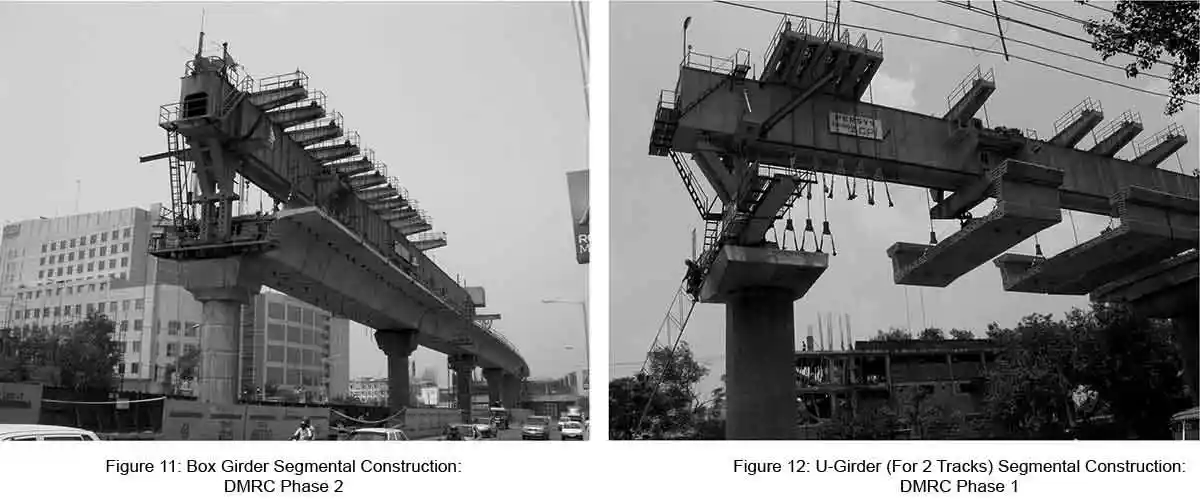

The match-cast segments are produced in a centralized casting yard and transported to site, (Figure 9). The process of ‘match casting’ where the adjoining segment is cast against the previous one is pivotal to the formation of shear keys (Figures 2, 9, 10) that enable shear transfer across the joints of the segments. Assembly-cum-Launching trusses, (Figures 11, 12) have been used almost without exception for the erection and assembly of the precast segments, which are typically 3.0m long and weigh 40-50t each.

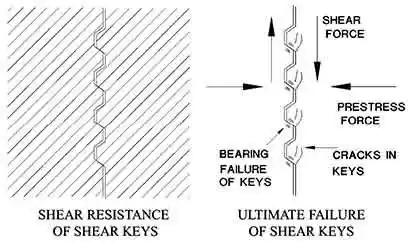

Figure 13: Segmental Construction: Structural Action at Shear Keys

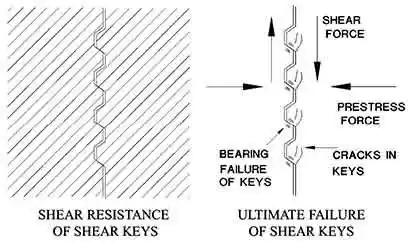

After dry matching of segments of the concerned span at the assembly truss, epoxy is applied and temporary prestressing done using short high tensile steel bars. An axial stress of 0.3 MPa is required to be imparted on the glued area (across the epoxy joint) during curing to enable a watertight joint. The shear resistance of the match cast joints of the segments is derived from the structural action of the geometry of shear keys combined with the prestressing force acting normal to the surface (Figure 13).

Figure 13: Segmental Construction: Structural Action at Shear Keys

After dry matching of segments of the concerned span at the assembly truss, epoxy is applied and temporary prestressing done using short high tensile steel bars. An axial stress of 0.3 MPa is required to be imparted on the glued area (across the epoxy joint) during curing to enable a watertight joint. The shear resistance of the match cast joints of the segments is derived from the structural action of the geometry of shear keys combined with the prestressing force acting normal to the surface (Figure 13).

The major purpose of epoxy used at segment joints can be summarized as follows:

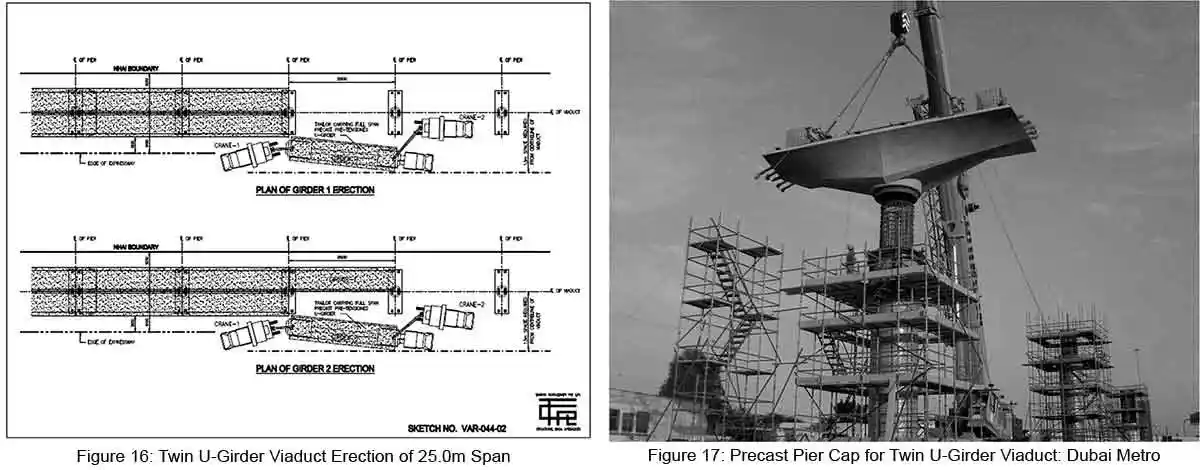

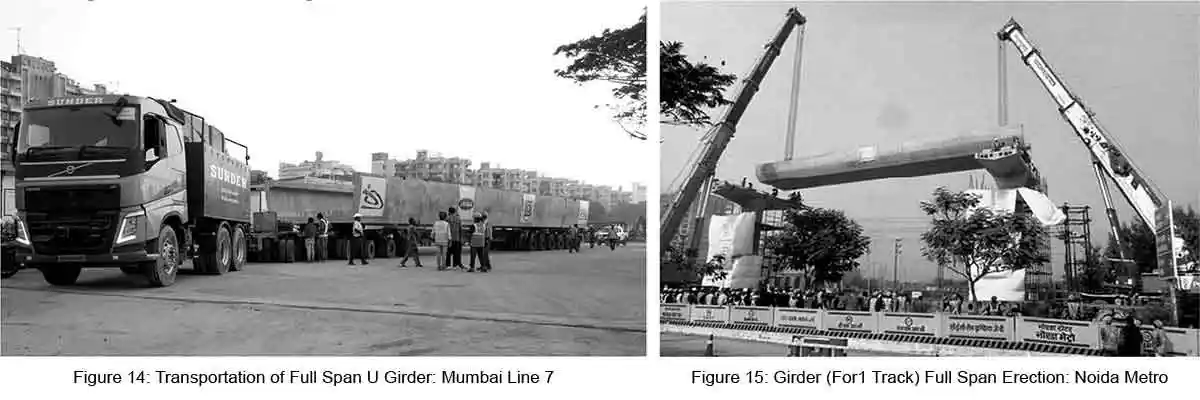

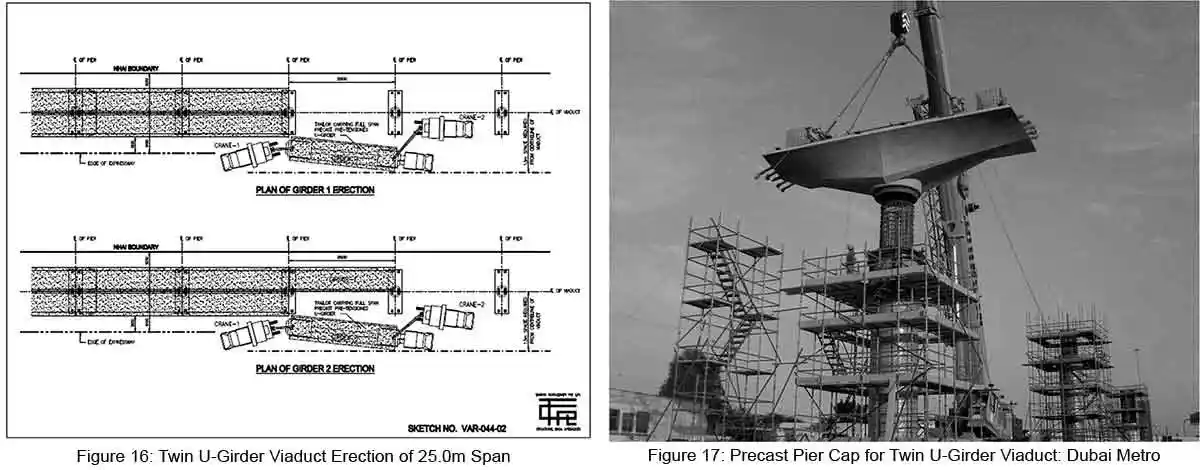

The twin U-Girder concept requires wide pier caps in the transverse direction to accommodate the supporting bearings of the girders (Figure 15). Employment of pre-casting and special erection techniques for the pier caps has become the usual practice (Figure 17).

Metro Elevated Stations

Figure 18 Stations: Employment of Precast Elements: DMRC Phase 1

Elevated Stations which are located along the Metro alignment every kilometer or so have a completely different character in comparison to the viaduct. They have to be designed architecturally to house entries and exit points, platforms, ticketing and technical rooms and services for handling of passengers and for facilitation for movement of rolling stock. The sizing of the stations require design considerations like estimation of passenger traffic, frequency and length of trains and whether any property development is to be incorporated in the building.

Figure 18 Stations: Employment of Precast Elements: DMRC Phase 1

Elevated Stations which are located along the Metro alignment every kilometer or so have a completely different character in comparison to the viaduct. They have to be designed architecturally to house entries and exit points, platforms, ticketing and technical rooms and services for handling of passengers and for facilitation for movement of rolling stock. The sizing of the stations require design considerations like estimation of passenger traffic, frequency and length of trains and whether any property development is to be incorporated in the building.

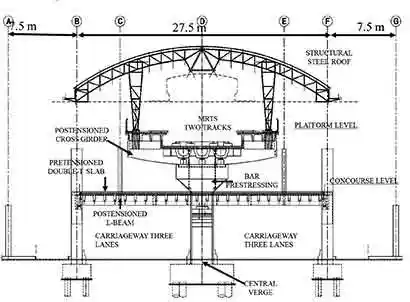

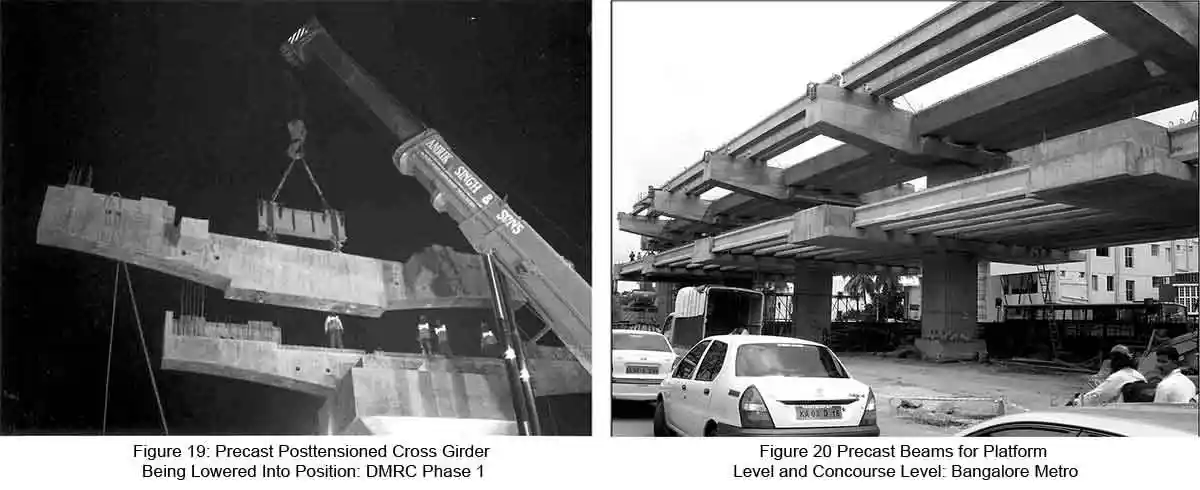

The simplest and common type of stations may have three levels (entry at ground level, concourse level for ticketing and entry into paid areas, and, platform level for boarding the trains). Invariably, a roof is required above the platform level for the comfort and safety of the travelling public. A typical station using precast structural components is shown in Figure 18. A variety of precast elements were adopted for the design brief of limiting the max weight as 50t and max length of individual element as 15m. The types of precast elements used and their weights were:

Track girders (pretensioned), 25t

Double-T girders constituting the platform level (pretensioned), 22t

Double-T girders constituting the concourse level (pretensioned), 20t

L-beams at concourse level (posttensioned), 25t

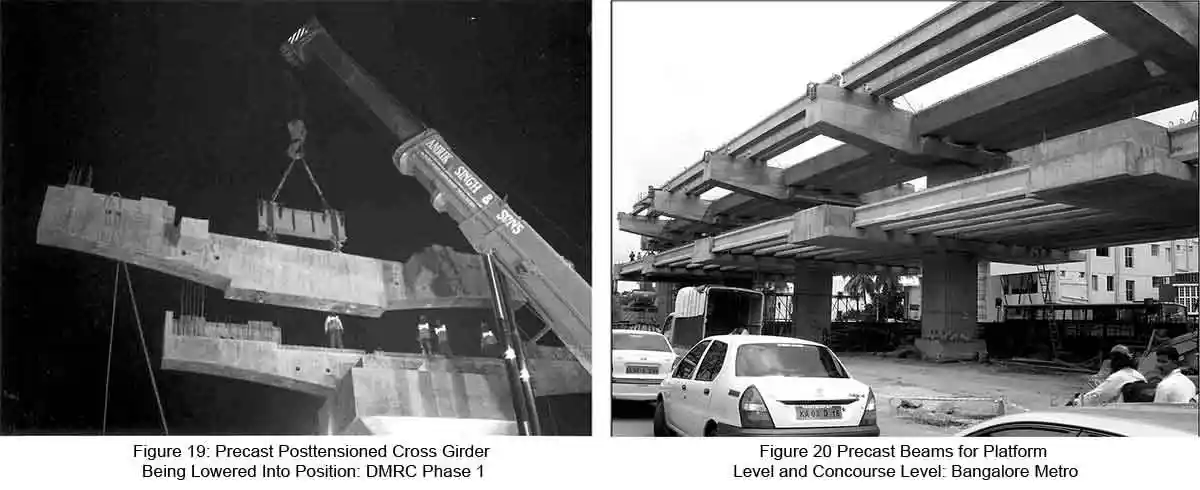

Cross Girders (posttensioned), 45t

The heaviest precast element, the post-tensioned cross girder, can be seen being lowered into position in Figure 19.

Figure 21: Erection of Precast Elements of Station: Hyderabad Metro

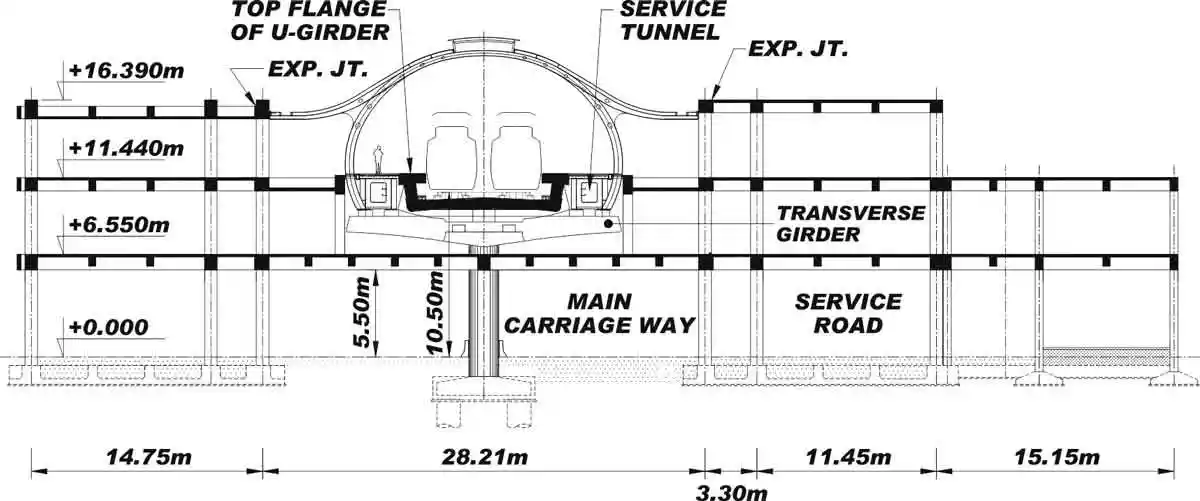

Figures 20, 21, 22 show the erection stage of same other concepts for Metro Stations using precast elements.

Figure 21: Erection of Precast Elements of Station: Hyderabad Metro

Figures 20, 21, 22 show the erection stage of same other concepts for Metro Stations using precast elements.

Property development for commercial purposes to augment the earnings of the Metro projects is becoming increasingly more common. The resulting complexity of the architectural requirements affords a good scope for innovation in deciding the type of precast structural components. At Interchange Stations where passengers can transfer from one corridor to another corridor or corridors can involve labyrinthine paths which create challenges in planning, design and erection.

Concluding Remarks

People still prefer personal vehicle due to lack of adequate public transport infrastructure in Urban India. Motor vehicle population in some of the major cities doubles every 10 years. Due to scarcity of land, the expansion of road network at ground level is not feasible. Environmental pollution and degradation is an obvious fall-out of this scenario. With the ongoing Metro constructions across major cities in India, citizens see a ray of hope that the quality of life will improve in the near future.

Given the character of the Metro projects, the use of Precast Concrete technologies is the obvious answer. In the urban situation, pre-casting of the concrete elements is usually carried out in an ‘away’ casting yard and limiting the dimensions and weights of the individual precast elements become important considerations in design. The methodology and standardization of manufacture, handling, transportation and erection of these elements are the major points of review and reflection during the planning stages of the project. The elevated viaduct superstructure and the structure of the stations can be constituted entirely from precast concrete elements.

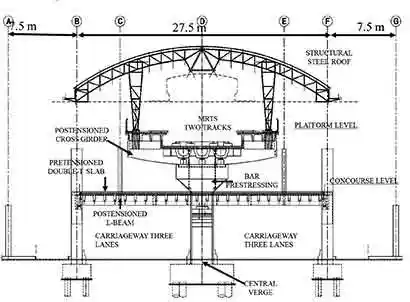

Figure 22: Section through Station for U Girder (2 tacks) Concept: DMRC Phase 1

Figure 22: Section through Station for U Girder (2 tacks) Concept: DMRC Phase 1

Acknowledgments

The Metro projects are completed or underway in a large number of cities in India [2].

The Figures in the paper mention the names of the project to which they relate to and are hereby acknowledged.

References

The most dramatic development in the field of urban infrastructure in recent times has undoubtedly been the introduction of the metro as a public transportation system. Apart from providing the predominant mode of travel, the metro has been instrumental in reducing pollution and making a significant contribution to the improvement of quality of life for the citizens. Vehicle population in Urban India is growing at a fast rate. As clamour for more urbanization and living space takes place in a fast growing and expanding city, new residential colonies and major commercial complexes are coming up at a rapid rate, all of which require to be integrated with public transport.

For the structural engineer, metro projects have afforded great opportunities to develop their skills and to seek innovative solutions to the problems peculiar to large scale constructions in the urban milieu. Important decisions at design stages determine the success of the project in terms of speed and quality of construction, environmental impact and aesthetic appeal of the structure, as well as, cost and economic viability.

This paper discusses some of the challenges faced in the viaduct structures and how they were overcome in Metro Constructions in India through Precast Concrete Construction Technologies.

Introduction

During the last few decades, there has been a remarkable shift in the manner in which construction projects are implemented in urban India. In the past, open spaces seemed to be plentiful and not much thought was given to the consequence that such structures would have on their immediate surroundings or on the city. Now, we have to build without slowing or shutting down and build quickly [1]. Building with minimum land acquisition and without encroaching on existing road space has become a mandatory requirement. The selection of the design concept and construction methodology for Metro projects must keep in mind the following objectives:

- Accelerated construction

- Reduced environmental pollution

- Minimum disturbance to traffic

- Durability of structural components

- High quality of finishes and close tolerances

- Aesthetic quality.

Elevated viaducts for metro structures are charachterised by long lengths and a series of ‘standard’ simply supported spans generally supported on single piers on the central verge of the roadway. (Figure 1). The superstructure is generally constructed span-by-span. The adoption of precast constructions has been instrumental in delivering the stated objectives satisfactorily. Pre-casting has been at the heart of Accelerated Bridge Construction enabling erection of several spans in a week. Pre-casting of the superstructure in the casting yard (Figure 2) concurrently with the foundations and substructures being implemented at site, brings down the project duration. Since the superstructure is precast in an ‘away’ casting yard, concreting at site is reduced and so also the air and noise pollution. Traffic diversions and disturbances are obviated to a large extent since the superstructure can be erected without ground support. High quality concrete products produced in factory-like conditions result in high durability as well as finishes.

Loading

Figure 3: Rolling Stock Loading

Figure 3: Rolling Stock LoadingThe loading due to the rolling stock is much higher than in a highway bridge (Figure 3). The axle loads vary between 16-18t depending on the coach width (2.9 to 3.2m) in the concerned metro system. The design is carried out essentially by codes developed for the Indian Railways.

The Impact Factor is different for the longitudinal and transverse direction due to the difference in the relevant span length.

Concept Stage

Figure 4: Standard Span Superstructure Concepts

Figure 4: Standard Span Superstructure Concepts- Feasibility of the transportation of precast elements over existing road network.

- Type of Pre-casting Facility (Long line / Short Bench).

- Prestressing (Pre-tensioning/ Post-tensioning).

- Construction Methodology (Segmental / Full Span).

- Section of Girder (Box Girder/ U-Girder for 2 tracks/ Twin U-Girder/ I-Girder).

As in all jobs heavily dependent on large scale pre-casting of elements, standardization of moulds in the casting facility is the key feature which determines the cost and speed of construction. A constant depth of section and a fixed profile on the outer surface of the precast superstructure is important. The variations in structural thicknesses are effected on the internal side.

The required size and shape of the casting yard is dependent on the type of pr-ecasting facility visualized for the project. The long line methodology (Figure 2) requires a “longish” rectangle whole the short bench (Figure 7) requires a “squarish” configuration. The long line methodology is particularly suited to pre-tensioning (Figure 8).

The alignment is often characterized by tight curvatures as it snakes through the crowded areas of the city. It has several breaks at the location of stations which have a totally different architectural character as compared to the viaduct and often implemented under a separate contract. The superstructure used in the viaduct may or may not be suitable for adoption in the station structure.

Precast Segmental Metro Viaduct

Precast segmental technique when employed in India uses traditional internal post-tensioning tendons with epoxy bonded joints. The tendons are threaded through preformed ducts before tensioning in situ. Being a span-by-span erection, post-tensioning of cables can be effected from the free end only.

The match-cast segments are produced in a centralized casting yard and transported to site, (Figure 9). The process of ‘match casting’ where the adjoining segment is cast against the previous one is pivotal to the formation of shear keys (Figures 2, 9, 10) that enable shear transfer across the joints of the segments. Assembly-cum-Launching trusses, (Figures 11, 12) have been used almost without exception for the erection and assembly of the precast segments, which are typically 3.0m long and weigh 40-50t each.

Figure 13: Segmental Construction: Structural Action at Shear Keys

Figure 13: Segmental Construction: Structural Action at Shear KeysThe major purpose of epoxy used at segment joints can be summarized as follows:

- To lubricate the shear key surfaces of adjoining shear key surfaces of the segments to facilitate erection

- To accurately match the adjoining segments

- To provide water tightness and durability at the joints in service

The twin U-Girder concept requires wide pier caps in the transverse direction to accommodate the supporting bearings of the girders (Figure 15). Employment of pre-casting and special erection techniques for the pier caps has become the usual practice (Figure 17).

Metro Elevated Stations

Figure 18 Stations: Employment of Precast Elements: DMRC Phase 1

Figure 18 Stations: Employment of Precast Elements: DMRC Phase 1The simplest and common type of stations may have three levels (entry at ground level, concourse level for ticketing and entry into paid areas, and, platform level for boarding the trains). Invariably, a roof is required above the platform level for the comfort and safety of the travelling public. A typical station using precast structural components is shown in Figure 18. A variety of precast elements were adopted for the design brief of limiting the max weight as 50t and max length of individual element as 15m. The types of precast elements used and their weights were:

Track girders (pretensioned), 25t

Double-T girders constituting the platform level (pretensioned), 22t

Double-T girders constituting the concourse level (pretensioned), 20t

L-beams at concourse level (posttensioned), 25t

Cross Girders (posttensioned), 45t

The heaviest precast element, the post-tensioned cross girder, can be seen being lowered into position in Figure 19.

Figure 21: Erection of Precast Elements of Station: Hyderabad Metro

Figure 21: Erection of Precast Elements of Station: Hyderabad MetroProperty development for commercial purposes to augment the earnings of the Metro projects is becoming increasingly more common. The resulting complexity of the architectural requirements affords a good scope for innovation in deciding the type of precast structural components. At Interchange Stations where passengers can transfer from one corridor to another corridor or corridors can involve labyrinthine paths which create challenges in planning, design and erection.

Concluding Remarks

People still prefer personal vehicle due to lack of adequate public transport infrastructure in Urban India. Motor vehicle population in some of the major cities doubles every 10 years. Due to scarcity of land, the expansion of road network at ground level is not feasible. Environmental pollution and degradation is an obvious fall-out of this scenario. With the ongoing Metro constructions across major cities in India, citizens see a ray of hope that the quality of life will improve in the near future.

Given the character of the Metro projects, the use of Precast Concrete technologies is the obvious answer. In the urban situation, pre-casting of the concrete elements is usually carried out in an ‘away’ casting yard and limiting the dimensions and weights of the individual precast elements become important considerations in design. The methodology and standardization of manufacture, handling, transportation and erection of these elements are the major points of review and reflection during the planning stages of the project. The elevated viaduct superstructure and the structure of the stations can be constituted entirely from precast concrete elements.

Figure 22: Section through Station for U Girder (2 tacks) Concept: DMRC Phase 1

Figure 22: Section through Station for U Girder (2 tacks) Concept: DMRC Phase 1Acknowledgments

The Metro projects are completed or underway in a large number of cities in India [2].

The Figures in the paper mention the names of the project to which they relate to and are hereby acknowledged.

References

- TANDON MAHESH, Metro Projects- Structural Engineering Challenges. Special Paper National Seminar on Metro Rail Projects, Indian association of Structural Engineers, New Delhi, Nov 2011.

- INDIAN RAILWAYS website http://indianrailways.gov.in/railwayboard/view_section.jsp?lang=0&id=0,1,304, 366,1496,1500

NBM&CW August 2019