Focus on Innovation in Textile Architecture

Mr. Ravi Mehta, Managing Director, Sujan Impex in an Interview with Mariya Rasheeda.

What has been Sujan Impex's guiding force towards emerging as a leading player in newer realms of an architectural and technical textiles industry?

Our focus has always been to bring the innovative concept of textile architecture to India. We have been working towards this goal single handedly since the last 10 years, and are proud to say that we are the undisputed leaders in this field today. The initial years were difficult, because of non existence of vendors having the skills to execute projects in textile architecture. However, we have worked slowly and steadily with some of our customers to build up their skills and assisted them to acquire the knowledge and the infrastructure, so that these projects can be successfully executed by Indian companies locally.

As the use of roofing fabric is not so common in India, what response the company gets from the market?

Initially we used to face a lot of skepticism from architects who were not aware of this new concept. However slowly, as the architects in India got more exposed to international trends, and with a lot of foreign architectural firms also taking up projects in India, the concept of textile architecture has gained wide acceptance. In fact today we are in a position, where we do not have enough vendors to execute projects in textile architecture as compared to the demand coming from the architects. Now people are aware that textile architecture can also be permanent architecture with life spans ranging upto 25 years and more.

Sujan is representing the France–based Ferrari Architecture & Technical Textiles in India. What are the USP of Ferrari's products?

The main advantage of Ferrari architectural textiles is our Precontraint technology. In textile architecture, the elongation of fabrics under load, must be minimal, uniform and predictable. With our patented technology which was developed by Serge Ferrari, father of Sebastien Ferrari, the current President of the company, all Ferrari fabrics are made with this technology which involves pre-stressing the woven fabric during the process of coating from all the 4 directions ensuring minimal, uniform and predictable elongation. Another advantage of Precontraint, is that the stressing of the yarns during coating make them absolutely flat, ensuring a thicker coating of PVC, which increases the longevity of the fabrics. Another USP of Ferrari is that our fabrics are 100% recyclable at the end of its life cycle, into polyester and PVC granules, which can be reused, with a special technology known as Texyloop, developed by Ferrari jointly with Solway. This technology recycles the fabrics under a closed loop process, ensuring no discharge of effluents in the process of recycling.

Please provide the details of your products and their application areas?

Permanent Roofing applications: Fluotop T2 range of fabrics with a high concentration PVDF coating, are widely used for roofing applications, like atriums, terrace coverings, entrance roofs, cafetarias, stadia roofs, etc.

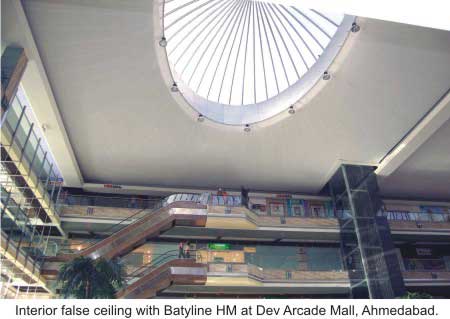

Stretched Ceilings & Partitions: Batyline range of fabrics are ideally suited for false ceilings, accoustic wall coverings etc. and can cover large stretches of area with only peripheral support systems, and are especially recommended for auditoriums and areas where sound absorption is necessary.

Solar Protection: Soltis range of fabrics are used for reducing heat and glare coming into the premises. They are used mainly for internal/external roller blinds, skylights, shade-sails, etc.

Lightweight structures like Tents, Awnings & Canopies: We have a range of fabrics for lightweight structures like awnings, canopies & tents.

Textile Facades: This is a new innovative application of fabric. A second skin of textile facade, on the exterior has a lot of advantages like extremely high reduction of heat ingress, thus reducing the airconditioning load required inside,and making the building energy efficient. The external skin can also be used as a medium of communication with digital printing of graphics, company logo, or advertising. It can also be used to renovate old buildings quickly without any major structural changes.

What is the suitability of your products keeping in mind the climatic conditions of India?

Ferrari fabrics are made to suit all kind of climatic conditions, and are used in the coldest areas of Russia and North Europe to the hottest desert areas of the Middle East. Tropical countries like Singapore, Malaysia etc. are also widely using these fabrics.

Lot of cities in India have really high temperatures in summer reaching upto 45oCelsius and above. In such conditions glass or polycarbonate transmit tremendous amount of heat and affect the Air conditioning performance adversely, contributing to extremely high energy bills. With our solar protection fabrics we can substantially reduce the heat transmission levels which would result in a better environment and reduced energy consumption.

High SPM levels in Indian cities result in a lot of dust settling of any surface, be it glass, polycarbonate or fabric. Thus maintenance is required for all surfaces, if you want to keep them good looking and clean. However our roofing fabrics have a high concentration PVDF topcoat, which makes the surface nonstick, and thus making them easily cleanable without much effort, as the dust can be just washed off with a spray of water. In a worst case scenario if no maintenance is done, at least during the monsoons the dust will be washed off naturally due to heavy rains, as the dust would not adhere to the fabric because of the non stick surface.

Another advantage is the amount and quality of natural light that comes through our roofing fabrics. The light transmission levels are just right so as to be not too high to create glare as in case of transparent materials like glass/polycarbonate. The quality of light coming through is also excellent, eliminating the need of artificial lights during daytime, also contributes to lower energy bills.

How far have architectural and technical textiles from Ferrari made its footprints in the domestic markets?

Projects have been executed with Ferrari fabrics all across the country, in all major cities, and quite a few installations are existing even in smaller cities and towns. Ferrari has become a well known name in this field across India. Some of the most prominent and visible projects are the Mumbai and Hyderabad Airports, and many shopping malls in Mumbai, Delhi, Bangalore etc. Smaller cities such as Ahmedabad, Vadodara, Lucknow, Pune, Jamnagar, etc. have also been covered under the footprint extensively. Our awning and canopy fabrics are being extensively used even in small towns, and are recognized for their highest quality and command a premium in the awning industry.

MGS Architecture September-October 2008