Sealants In Concrete Pavements, Roads, Highways & Building Construction

Mr. Dinesh Chavan, Sr. Manager-R&D, Choksey Chemicals P. Ltd, Mumbai.

A sealant is a viscous material that changes state to become rubber like compound, once applied, and is used to prevent the penetration of air, gas, noise, dust or liquid from one location through a barrier into another. Typically, sealants are used to close small openings that are difficult to seal with other materials, such as concrete, drywall, etc. Desirable properties of sealants include insolubility, corrosion resistance, and adhesion. Uses of sealants vary widely and sealants are used in many industries, such as construction, automotive and aerospace.

As we know that concrete structures are provided with joints and these joints are to be sealed with an Elastomeric Sealant according to its durability.

The sealants should be in either Thermoplastic or Thermosetting in nature depending upon the specification provided.

Polysulphide sealants are the best sealants to be used for joint sealing. Moreover the performance and durability of sealant always depend on the quality of sealants or some times on the design of the joint. Proper joint design and best quality sealant are needed for obtaining longer durability.

Concrete always changes its plane due to atmospheric conditions. Carbonation may take place and the overall effect may be contraction because of its drying and shrinkage. Expansion and contraction may occur due to change in cyclic effects or change in environmental conditions like humidity and temperature or the extra load on to cracking.

Joints are provided in the concrete to prevent development of extra stresses in the concrete structures which lead to expansion and contraction due to moisture changes, temperature variation, etc or loads and vibrations.

If the contraction movements, both permanent and transient of concrete units are more than it leads to cracking. Sealant accommodates these movements in concrete without loss of integrity in concrete structure.

In building structures, to protect a gap is very important to prevent the entry of wind and rainwater in to the gaps or openings. In case of water retaining structures, e.g. tanks, dams, canals, pipes, etc. joints are required to be sealed to prevent the loss of water due to leakage.

In case of roads or bridges, which are exposed to extreme weather, the concrete itself must be protected against the damage from all the possibilities of water at the joints openings. The solid material must be prevented from falling and collecting in the open joints if so the joints cannot contract freely later. If it occurs then high stress may be generated and can damage the concrete structure.

In case of highways the joints are needed to be strengthened and sealed to prevent the damage from Heavy traffic. Hence, the function of a sealant is to restrict the entry of water, solids, gases and to protect the concrete structure from them.

The main function of sealant is to improve thermal, absorption of the vibrations and prevent unwanted matter collected in the joints. The sealant must work as its prime function when it is subjected to repeated contraction and expansions as the joint opens and closes constantly while exposed to the weather conditions.

The type of sealant available must meet the requirement of joint design and shape.

Design should be as per the appropriate standards like ASTM, BS and IS.

The source of the movements and the nature of movements for both long and short duration must be considered. The experience and the judgment play an important role in designing the joints which functions satisfactory.

The calculation of section and spacing joints is complex, because there are many factors. There are several standard methods of calculation to simplify the procedures, which appears in publications such as those of the Building Research Establishments and the British Cement Associations. The methods differs basically in the compromises or assumptions made.

The movement accommodation factor means the total movement range between the maximum compression and the maximum extension that a sealant can accommodate. It is expressed as a % of the minimum design joint width.

All construction materials changes in size as temperature changes. The amounts by which the dimensions of materials will change are calculated by using their linear coefficient of expansion in the expression.

Change = Length of span X Linear coefficient of expansion X temperature differential.

The Minimum Joint Width is then calculated by,

Wt = M X 100 MAF Where M= total expected movement

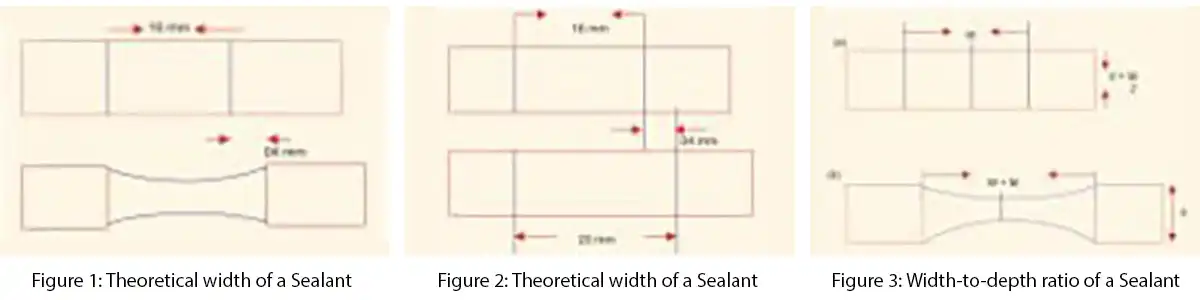

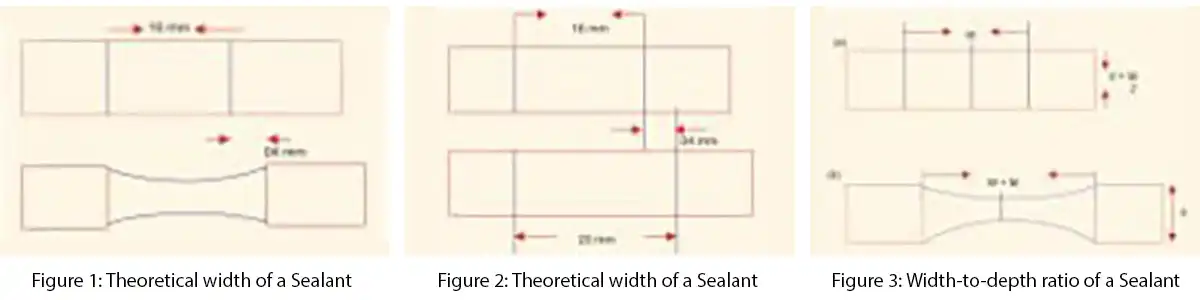

For Example (Figure 1)

M = 4mm

MAF = 25% then

Wt = 4 X 100 = 16 mm

25 Thus on the basis of this calculation, the sealant appears to be working to its maximum rated capacity of 25% if the joint is 16mm wide.

However, in practice, while the joint may have appeared on the drawing at 16mm, the joint may be sealed when thermal expansion has given rise to, for example, 2.5mm. of movement resulting in a reduction of the actual joint width from 16mm to 13.5mm. This joint could then cool and be subjected to the full 4mm movement used as a design base. Thus the joint could open from 13.5 to 17.5mm.

But the joint was sealed at a width of 13.5mm.Thus the extension to which the sealant has been subjected is not 25%

but

4 X 100 =29.6 %

13.5

On the original basis of 25% MAF, the sealant in this example has been over extended by

29.6-25/= 14.8%

25

This problem may be overcome by always calculating the joint width from the worst-case configuration, which assumes that the joint is at its minimum width. This is achieved by a modification to the equation used above. Using the same example as for Figure 1, the modification is illustrated in Figure 2

Wt = 4 X 100 + 4 = 20 mm

25

Thus if joint closes by 2.5mm before sealing and is then subjected to the full 4mm movement, the values become

Joint sealed at 17.5mm

Joint sealed at 21.5mm

Total Movement = 4 mm

The sealant has been subjected to 4mm extension on an initial sealed width of 17.5mm,therefore the % movement is calculated as

4 X 100 = 22.8%

17.5

Thus the sealant is operating within its rated MAF.

For Elastomeric sealants, a sealant depth equal to the joint width is usual to ensure an adequate volume of sealant for optimum service life.

W= Width of Joint

M = Total Expected Movement

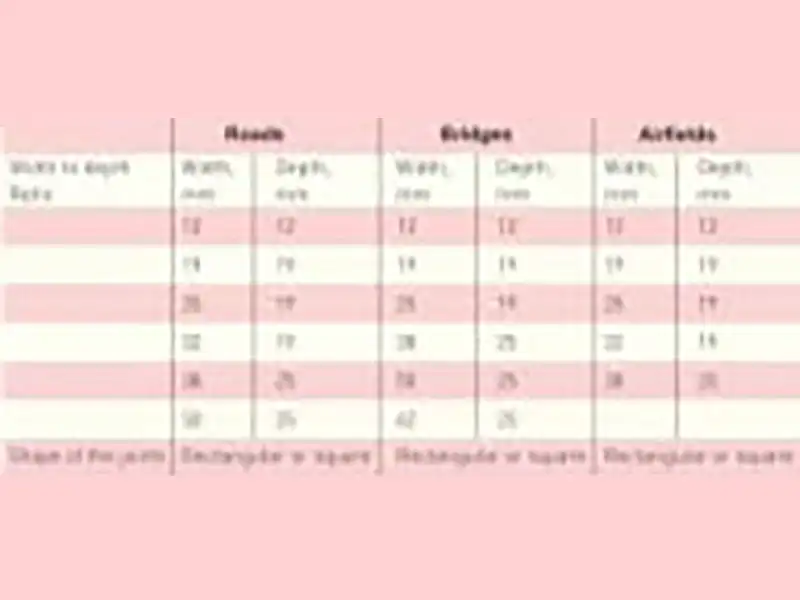

Figure 3 Width- to-depth ratio of a sealant

These typical width:depth ratios may be modified by manufactures for their sealants in particular applications, such as in trafficked joints or those subjected to sustained loading.

In such cases, sealant depth may be increased to provide a greater bonding with concrete surface. Reference should made to individual manufacturers literature in such cases,

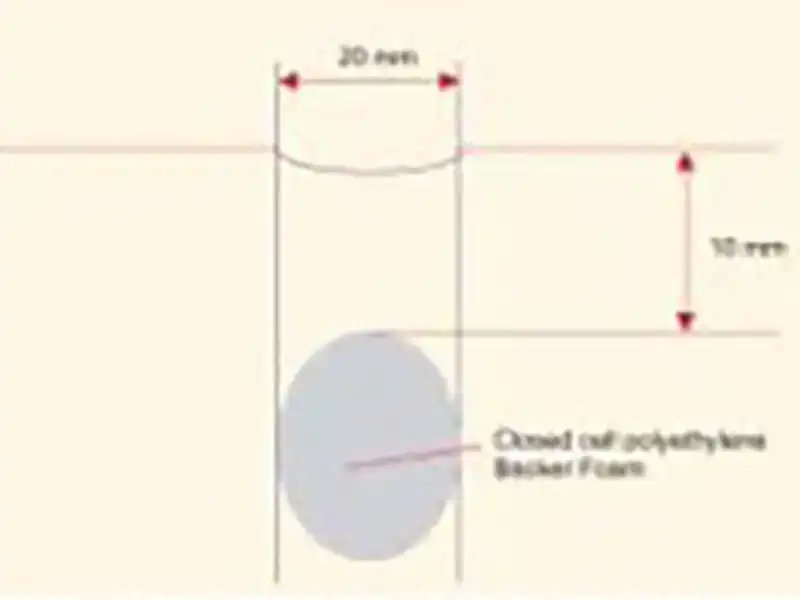

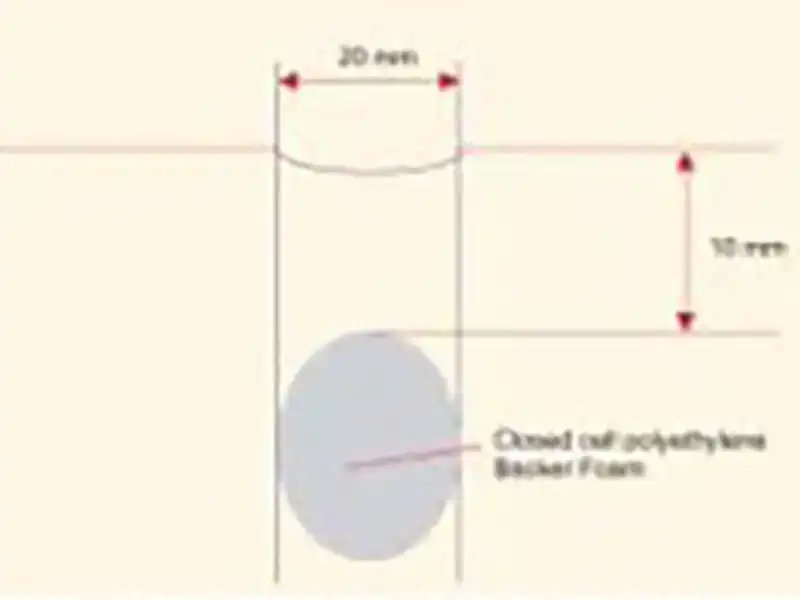

The use of circular section (see Figure 4) back-up strips can modify the sealant profile from square or rectangular to one with a concave shape at the backup interface. The depth of the sealant in such a case should be considered to be that at the center of the curved face where sealant depth is least.

The use of circular section (see Figure 4) back-up strips can modify the sealant profile from square or rectangular to one with a concave shape at the backup interface. The depth of the sealant in such a case should be considered to be that at the center of the curved face where sealant depth is least.

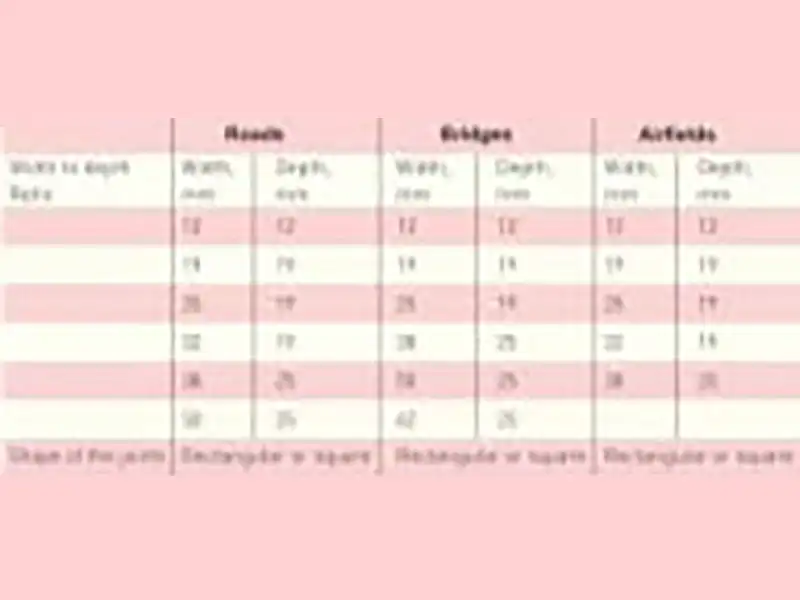

Joint depth should also be considered, from the point of view of sealant selection and the curing characteristics, as well as the requirements of the preferred joint profile. The suggested width to depth ratios of sealants in roads, bridges and airfields.

Figure 4: Depth of a Sealant with a Circular Back up

These are the materials which form a surface skin after application, thereby protecting the main body of material underneath. They are commonly referred as mastics.

Figure 4: Depth of a Sealant with a Circular Back up

These are the materials which form a surface skin after application, thereby protecting the main body of material underneath. They are commonly referred as mastics.

These are useful in the joints where very little movements are expected.

2) Bitumen and Rubber/Bitumen-based Sealants

These are Thermoplastic in nature and retain the degree of flexibility. Typical application are in roofing, water-retaining structures, and areas where compatibility with bitumen materials are desirable.

3) Acrylic Sealants

Basically two types of acrylic resin sealants are in common usage. Solvent base and water base. Solvent-based material is thermoplastic in nature. They are used externally. Water based sealants are widely used on corners of windows, doors, internally.

4) Flexible Epoxide Sealants

They are based on Epoxy resins, and varying degrees of flexibility are available by addition of other polymers or extenders.

These are normally available in multi-component products, when mixed together, it cures at ambient temperature though they have good degree of flexibility, becomes rigid at low temperature.

5) Polysulphide Sealants

These are available in one or two component systems.

These are available in one or two component systems.

The single part materials cure on exposure to moisture. Slow cure is generally expected for these sealants. They are elastic-plastic in nature’s BS 5215 refers to these materials.

Two part Polysulphide requires on site mixing and cures chemically. These are available in Gun grade BS 4254 and pouring grade BS5212. Polysulphide are widely used in construction/expansion joints of pavements and buildings.

6) Polyurethane Sealants

This is also available in one or two component system. Available in both Gun and Pouring grade.

One part is moisture curing and used in building constructions. Two part sealants are chemically cured and can be used in trafficked joints (BS5212). Pitch or tar modified polyurethane sealants are also available.

7) Silicone Sealants

Available in one-component system follows BS5889.Can be used for interior purpose.

Two component silicone sealants are used for glass insulation.

8) Hot-poured Sealants

These comprise bitumen, rubber/bitumen and pitch/polymer combinations. They are primarily used in road pavement joints, subways and water retaining structures.

Concrete Road/Highways, BS 5212 (1990) Bridges, BS 4254 (1983) Airfields, BS 5212 (1990)

Normal Civil construction, BS 4254 (BS1983)

Back up materials shall be compatible with sealants. It must be resilient in nature. Materials impregnated with oil or bitumen shall not be used.

Back up materials shall be compatible with sealants. It must be resilient in nature. Materials impregnated with oil or bitumen shall not be used.

Polyethylene-closed cell foam, polyurethane-closed cellfoam, sponge rubber-closed cell, neoprene foamed rod, pre-formed gasket. The back up material shall be used in the joints to adjust width to depth ratio as recommended.

Machine Mixed sealants

Supplied in Part I and Part II. Each pack is packed in proportionate ratio of mixing.

Mixing should be done as per the ratio suggested by the manufacturer. Mixing can be done by spatula/ rod/ wooden bat. For proper and homogeneous mixing efficient mixing can be accomplished by means of hand held power drill motor at RPM around 150 to provide adequate shearing action.

A sealant is a viscous material that changes state to become rubber like compound, once applied, and is used to prevent the penetration of air, gas, noise, dust or liquid from one location through a barrier into another. Typically, sealants are used to close small openings that are difficult to seal with other materials, such as concrete, drywall, etc. Desirable properties of sealants include insolubility, corrosion resistance, and adhesion. Uses of sealants vary widely and sealants are used in many industries, such as construction, automotive and aerospace.

As we know that concrete structures are provided with joints and these joints are to be sealed with an Elastomeric Sealant according to its durability.

The sealants should be in either Thermoplastic or Thermosetting in nature depending upon the specification provided.

Polysulphide sealants are the best sealants to be used for joint sealing. Moreover the performance and durability of sealant always depend on the quality of sealants or some times on the design of the joint. Proper joint design and best quality sealant are needed for obtaining longer durability.

Why Joints are Required or Needed?

Concrete is a rigid material in nature with low flexural strength made up of inorganic binder cement, sand, gravel and water.Concrete always changes its plane due to atmospheric conditions. Carbonation may take place and the overall effect may be contraction because of its drying and shrinkage. Expansion and contraction may occur due to change in cyclic effects or change in environmental conditions like humidity and temperature or the extra load on to cracking.

Joints are provided in the concrete to prevent development of extra stresses in the concrete structures which lead to expansion and contraction due to moisture changes, temperature variation, etc or loads and vibrations.

If the contraction movements, both permanent and transient of concrete units are more than it leads to cracking. Sealant accommodates these movements in concrete without loss of integrity in concrete structure.

Why Joint Sealing is Needed?

Considering the possibility of expansion and contraction & construction joints in the concrete structure, gap (expansion joints), which is usually to be sealed in order to prevent passage of gases, liquids, solids or other undesired substances in to the gap or through them.In building structures, to protect a gap is very important to prevent the entry of wind and rainwater in to the gaps or openings. In case of water retaining structures, e.g. tanks, dams, canals, pipes, etc. joints are required to be sealed to prevent the loss of water due to leakage.

In case of roads or bridges, which are exposed to extreme weather, the concrete itself must be protected against the damage from all the possibilities of water at the joints openings. The solid material must be prevented from falling and collecting in the open joints if so the joints cannot contract freely later. If it occurs then high stress may be generated and can damage the concrete structure.

In case of highways the joints are needed to be strengthened and sealed to prevent the damage from Heavy traffic. Hence, the function of a sealant is to restrict the entry of water, solids, gases and to protect the concrete structure from them.

The main function of sealant is to improve thermal, absorption of the vibrations and prevent unwanted matter collected in the joints. The sealant must work as its prime function when it is subjected to repeated contraction and expansions as the joint opens and closes constantly while exposed to the weather conditions.

How to Design the Joint and the Types of Joints?

The working of the joint sealants depends on the movement to be accommodated at the joint, on the shape of the joint and the physical properties of the sealant. The location and the width of the joints that requires the sealing can only be specified when a sealant is available which will take the required movements and joint shape, or the concrete structure must be redesigned to reduce the movements at the joints.The type of sealant available must meet the requirement of joint design and shape.

Design should be as per the appropriate standards like ASTM, BS and IS.

The source of the movements and the nature of movements for both long and short duration must be considered. The experience and the judgment play an important role in designing the joints which functions satisfactory.

Factors to be considered while Designing Joints

- The joints between two concrete units may take the total movements of both units.

- The movement of the end of a unit depends on its effective length

- The actual service temperature of the material being joined.

- When different types of material are joined together and having different surface temperature then the appropriate Linear coefficient thermal expansion of each material must be considered while calculating the joint movements.

- In case of butt joints the movements to which sealant can properly respond is at correct angle to the joint faces. The joint must be taken into account where such comparisons and deflection occurring is very large.

- The movement capability factor of a particular sealant must be taken for calculation. The sealant manufacturer can provide the movement capability factor for a particular sealant.

Movement Calculation

Calculation of section and spacing of jointsThe calculation of section and spacing joints is complex, because there are many factors. There are several standard methods of calculation to simplify the procedures, which appears in publications such as those of the Building Research Establishments and the British Cement Associations. The methods differs basically in the compromises or assumptions made.

Summary of the Joint Design Procedure

- Calculate the Maximum potential movement in the structure from all causes.

- Decide the location of the movement joint.

- Calculate the maximum movement at each joint.

- Select a possible sealant, and, from its MAF, calculate minimum theoretical joint width.

- Increase the value obtained in step 4 by applying manufacturing and erection deviation and arrive thereby at the minimum design joint width. Allow for an appropriate depth of sealant, and for back up material.

- If the result of step 5 gives a joint width which is too wide for aesthetic, economic or technical reasons, go back to step 4 and recalculate with an alternative sealant of higher MAF.

- If the problem still appears insoluble, go back to step 2 and recalculate on the basis of installing more joints at smaller intervals.

- Ensure the final result is consistent with nature and quality of the joint surface likely to be produced in the given building materials.

Movement Accommodation Factor (MAF)

Most of the sealant manufactures assign a movement accommodation factor (MAF) to each of their products to provide a value for the calculation of joint dimensions. But so far there is no universal definition for this factor.The movement accommodation factor means the total movement range between the maximum compression and the maximum extension that a sealant can accommodate. It is expressed as a % of the minimum design joint width.

All construction materials changes in size as temperature changes. The amounts by which the dimensions of materials will change are calculated by using their linear coefficient of expansion in the expression.

Change = Length of span X Linear coefficient of expansion X temperature differential.

The Minimum Joint Width is then calculated by,

Wt = M X 100 MAF Where M= total expected movement

For Example (Figure 1)

M = 4mm

MAF = 25% then

Wt = 4 X 100 = 16 mm

25 Thus on the basis of this calculation, the sealant appears to be working to its maximum rated capacity of 25% if the joint is 16mm wide.

However, in practice, while the joint may have appeared on the drawing at 16mm, the joint may be sealed when thermal expansion has given rise to, for example, 2.5mm. of movement resulting in a reduction of the actual joint width from 16mm to 13.5mm. This joint could then cool and be subjected to the full 4mm movement used as a design base. Thus the joint could open from 13.5 to 17.5mm.

But the joint was sealed at a width of 13.5mm.Thus the extension to which the sealant has been subjected is not 25%

but

4 X 100 =29.6 %

13.5

On the original basis of 25% MAF, the sealant in this example has been over extended by

29.6-25/= 14.8%

25

This problem may be overcome by always calculating the joint width from the worst-case configuration, which assumes that the joint is at its minimum width. This is achieved by a modification to the equation used above. Using the same example as for Figure 1, the modification is illustrated in Figure 2

Wt = 4 X 100 + 4 = 20 mm

25

Thus if joint closes by 2.5mm before sealing and is then subjected to the full 4mm movement, the values become

Joint sealed at 17.5mm

Joint sealed at 21.5mm

Total Movement = 4 mm

The sealant has been subjected to 4mm extension on an initial sealed width of 17.5mm,therefore the % movement is calculated as

4 X 100 = 22.8%

17.5

Thus the sealant is operating within its rated MAF.

Joint Depth Considerations

For most applications of sealants in butt movement joints, 5mm is considered to be the practical minimum sealant depth. For Elastomeric sealants the depth should be approximately half the joint width. This ratio is a rectangular section, and it represents apractical compromise between sealant depth and adequate bond area to the substrate to give minimum stress to the sealant resulting from the movement.For Elastomeric sealants, a sealant depth equal to the joint width is usual to ensure an adequate volume of sealant for optimum service life.

W= Width of Joint

M = Total Expected Movement

Figure 3 Width- to-depth ratio of a sealant

These typical width:depth ratios may be modified by manufactures for their sealants in particular applications, such as in trafficked joints or those subjected to sustained loading.

In such cases, sealant depth may be increased to provide a greater bonding with concrete surface. Reference should made to individual manufacturers literature in such cases,

Joint depth should also be considered, from the point of view of sealant selection and the curing characteristics, as well as the requirements of the preferred joint profile. The suggested width to depth ratios of sealants in roads, bridges and airfields.

Selection of a Proper Sealant

If the sealants are to be performed well in the joints then it should have the following properties:- It must be an impermeable material.

- It must accommodate the movement and the degree of movements occurring at the joint by deformation.

- It should be capable of accommodating the movement for cyclic changes like temperature, moisture, vibrations etc.

- It should have strong adhesion with the joint faces and there should not be any peeling at the corners when there is a deflection of joints.

- Should have a good impact without cohesion failure, must resist the load, stress due to compression, tension and impact.

- Must resist flow due to gravity.

- Should have a good flexibility at all service temperatures.

- It should be durable. It should not adversely affected by aging, weathering, freezing of water, light, water vapor, growth of the fungus and human damage.

- It should have good fire resistance and fuel resistance.

- Should have a partial reparability.

- Low maintenance cost.

Types of Sealants

1) Butyl Sealants Figure 4: Depth of a Sealant with a Circular Back up

Figure 4: Depth of a Sealant with a Circular Back upThese are useful in the joints where very little movements are expected.

2) Bitumen and Rubber/Bitumen-based Sealants

These are Thermoplastic in nature and retain the degree of flexibility. Typical application are in roofing, water-retaining structures, and areas where compatibility with bitumen materials are desirable.

3) Acrylic Sealants

Basically two types of acrylic resin sealants are in common usage. Solvent base and water base. Solvent-based material is thermoplastic in nature. They are used externally. Water based sealants are widely used on corners of windows, doors, internally.

4) Flexible Epoxide Sealants

They are based on Epoxy resins, and varying degrees of flexibility are available by addition of other polymers or extenders.

These are normally available in multi-component products, when mixed together, it cures at ambient temperature though they have good degree of flexibility, becomes rigid at low temperature.

5) Polysulphide Sealants

The single part materials cure on exposure to moisture. Slow cure is generally expected for these sealants. They are elastic-plastic in nature’s BS 5215 refers to these materials.

Two part Polysulphide requires on site mixing and cures chemically. These are available in Gun grade BS 4254 and pouring grade BS5212. Polysulphide are widely used in construction/expansion joints of pavements and buildings.

6) Polyurethane Sealants

This is also available in one or two component system. Available in both Gun and Pouring grade.

One part is moisture curing and used in building constructions. Two part sealants are chemically cured and can be used in trafficked joints (BS5212). Pitch or tar modified polyurethane sealants are also available.

7) Silicone Sealants

Available in one-component system follows BS5889.Can be used for interior purpose.

Two component silicone sealants are used for glass insulation.

8) Hot-poured Sealants

These comprise bitumen, rubber/bitumen and pitch/polymer combinations. They are primarily used in road pavement joints, subways and water retaining structures.

Requirements to Seal the Joints

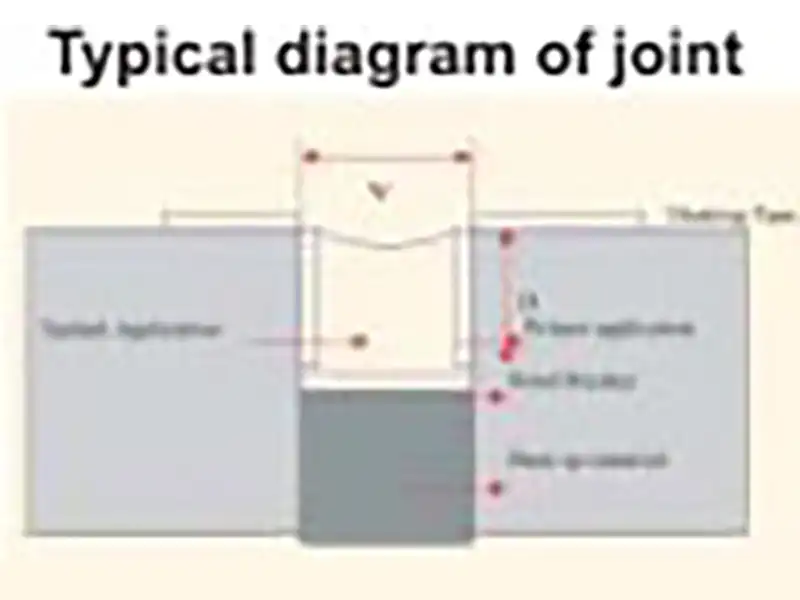

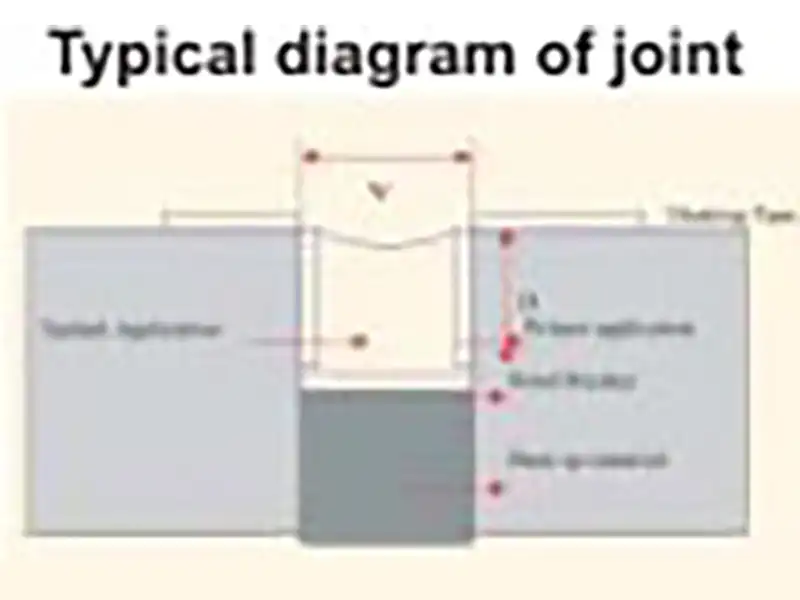

For effective sealants field performance, the following points are very important.- Selection of correct sealant

- Calculation of correct width to depth ratio.

- Proper cleaning of the joint faces.

- Through details on the joints.

- Suitable primer depending upon the surface.

- Use of non-impregnated backup material.

- Provision of Bond breaker

- Suitable application equipment and techniques.

- Qualified applicator

- Adequate field inspection.

Specification of Sealants

A quality sealant must comply with international standards. Only British STDs are mentioned.Concrete Road/Highways, BS 5212 (1990) Bridges, BS 4254 (1983) Airfields, BS 5212 (1990)

Normal Civil construction, BS 4254 (BS1983)

Back up Materials

Polyethylene-closed cell foam, polyurethane-closed cellfoam, sponge rubber-closed cell, neoprene foamed rod, pre-formed gasket. The back up material shall be used in the joints to adjust width to depth ratio as recommended.

Bond Breaker

Bond breaker can be a polyethylene tape. The bond breaker tape shall be placed over the back up material. It is to avoid third surface bonding of the sealants.Primer

The primer to be used as per the manufacturers recommendations. Primer for porous and Non-porous substrate should be separate. It is to be applied in two coats.Masking Tape

It should be self-adhesive polyethylene. Tape is to be applied on the joint surfaces to protect joint edges from being spoilt by sealants material while application. Tape must be removed after application of sealant.Solvents

Solvents are used for equipment cleaning. Generally Xylene, toluene are used for cleaning immediately after the use.Storage of Material

Store the material as per the supplier’s recommendations.Methods of Applications of Sealants

Hand Mixed SealantsMachine Mixed sealants

Hand Mixed Sealant Mixing

Hands mixed sealants are supplied in two parts that consist of base component and another is hardener that is curing agent.Supplied in Part I and Part II. Each pack is packed in proportionate ratio of mixing.

Mixing should be done as per the ratio suggested by the manufacturer. Mixing can be done by spatula/ rod/ wooden bat. For proper and homogeneous mixing efficient mixing can be accomplished by means of hand held power drill motor at RPM around 150 to provide adequate shearing action.

Mechanised Sealant Mixing

It is an automatic machine used for application of high volume. The equipment is designed to deliver the two fluid component materials in proportionate a portable mixer head through suitable flexible hoses by means of a positive displacement. The mixed material flows at a fixed pressure into the joints and self levels itself.Application- sealing of the joints

- Examination of the Joints The contractor should examine the joint size and condition of all joints and should reports all technical/practical difficulties which are not acceptable to the main contractors. The joints shall not be wet.

- Cleaning of Joints Faces The joint faces should be cleaned by wire brush and dust to be removed thoroughly. If there is oil then it has to be cleaned by xylene or toluene.

- Installation of Back Up Material and Bond Breaker The back up material and bond breaker shall be placed in the joints to allow the placement of the sealant to the desired depth, the surface of which should be recessed by not less than 3mm below the pavement surface.

- Priming Apply primer in two coats as recommended by the manufacturers. Avoid brushing on the bond breaker tape. Allow the primer to dry as per the specification.

- Apply the masking tape on the edges of the both the joint faces. Tape shall be removed immediately after the tooling.

- Sealant Pouring Fill the sealant in the ready joint by hand or machine. Use spatula for filling in to joints Fill some extra material and then do the tooling by a knife blade and pull down the level of sealant surface. After tooling remove the masking tape. The material will self leveled.

- Curing of Sealant Allow the sealant to cure as per the manufacturers recommended specification before starting the any other operation.

- Cleaning of Tools Clean the tools and equipment immediately after the application by solvents such as xylene or toluene.

References

- British Standard Institution–specification for cold poured joint sealants for concrete pavements BS 5212: 1990

- British standard Institution–Guide to selection of constructional sealants BS 6213:1982

- British standard Institution–Code of practice of joints and jointing in building construction BS 6093:1981

- British standard Institution–Specification for two part Polysulphide sealants BS 4254:1983

NBM&CW November 2007