Waterproofing of Bridge Decks The Latest Technique and Material

Pratap Singh Rautela, Nile Waterproofing Materials, Co. S.A.E. company Noida.

Bridges are important infrastructure facilities connecting different areas and allowing smooth movement of men, material and machinery from one place to another. Roads have no purpose unless bridges are provided for crossing rivers. Railway lines (ROB), highways (Flyovers) etc. Early deterioration of cement concrete bridge structures resulting into weakness or even part collapses disturb the movement of traffic and has serious impact over social and financial status of the local society. Minor causes like leakage and seepage of water or deicing salt solution into even the slightly permeable deck concrete surface result into corrosion of reinforcing steel which result into spalling, cracking and loss of section of structure.

The problem can be solved to a great extent if concrete surface is protected against ingress of moisture and salts. In other words, if a protection layer is introduced over the bridge deck concrete surface in form of a dependable water proofing system.

Bridge Decks: Waterproofing Choice

It represents the first line of defense and prevents the ingress of water, road de-icing salts, and aggressive chemicals which would corrode the steel reinforcing bars in the concrete causing severe structural damages.

Some countries with mainly warm weather and dry climates choose not to waterproof their bridge decks but, a recent analysis in the USA showed that 200,000 Bridge decks are seriously suffering from corrosion resulting in direct cost of $2 billion for replacement and refurbishment.

Concrete will always have some degree of porosity and allied with surface wear and hair line cracking, will allow water and corrosive materials to penetrate and attack the steel reinforcement. The primary defense against such destructive agents is good dense concrete, along with a proven waterproofing system installed by a qualified contractor.

Bridge Deck Waterproofing Systems

Two types of Bridge deck waterproofing systems are available for use:- Sheet Systems These are Polymer Modified Bituminous sheets bonded to the bridge deck, using torch application, hot mopping asphalt, or through self-adhesion. Manufacturers have developed various systems that would satisfy the enhanced requirements of the bridge deck waterproofing market.

- Liquid (Sprayed) Systems These systems largely fall into acrylics and Polyurethanes and normally consist of three elements. Primer, Membrane applied in one or two coats and tack coat specially developed to enhance the bond of the membrane to the surfacing mix.

Performance Requirements for the System

Independent of the bridge deck waterproofing system choice, certain performance criteria has to be met in order to avoid potential concerns regarding leakage, poor bonding, embrittlement or softening of the membrane in service.Such performance criteria are:

- Impermeability to water under all conditions

- Good adhesion to deck

- Good adhesion to surfacing.

- Capable of bridging shrinkage cracks in concrete

- High mechanical properties to handle traffic loads including shear forces in curves and during braking and accelerating

- Tolerant of deck texture and details

- Tough to withstand site damage and operation

- Safe to apply

- Able to withstand elevated surface temperatures

- Can be applied over a wide range o f ambient conditions

- Nonegradable

Proper Site Practice the key Success

The success of bridge deck waterproofing operation is often reliant on site procedures, workmanship and weather conditions.- Professional preparation is as important as the properties of material or system to be used. Before the work commences at site the following major issues need be addressed:

- Availability of properly trained workforce and qualified supervisors

- Site engineer must have design detailing and construction records accessible

- Provision of adequate strong area for material to be used

- A Safe access to bridge deck must be secured for personnel, equipment and materials

- Established method of statement, and execution program discussed and approved by all parties

- Review of weather conditions likely to affect the waterproofing operation

- Preparation of concrete deck to meet strict surface finish requirements (Sound, even, uncontaminated, dry, dust free). Thereby offering optimum opportunity for a strong bond to waterproofing membrane.

- Use of an appropriate primer

- Choice and application of a waterproofing system approved and in compliance with Highway Agency Standards.

- Adequate protection of the waterproofing membrane prior to the application of the asphalt road surfacing

- Use of approved asphalt road surfacing with low void content mix design

Bitunil Bridge Deck Waterproofing System

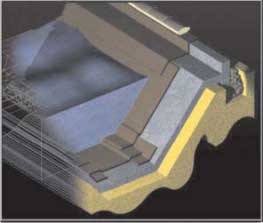

BITUNIL Bridge Deck Waterproofing System consists of two layers of fully torch welded heavy duty APP modified bitumen membranes with composite polyester reinforcement, applied on a primed substrate.System Application:

- Concrete surface must have a minimum acceptable gradient to ensure water drainage on the surface of the asphalt pavement.

- A primer coat must be applied to concrete deck to seal the voids, promote W.P. adhesion, and assure against blister formation.

- Prior to membrane application, a reinforcing MBM strip shall be applied to cover all intersections with edge beams.

- Waterproofing Membrane shall be applied fully bonded to bridge deck, parallel to down slope direction. Side laps and end laps shall be 8-12 cm, and 12-15 cm respectively.

- Second waterproofing layer shall be applied fully bonded onto the first layer, at the same direction of rolls length, with shifting the side laps 0.5 meter in order to secure the membrane waterproofing system with maximum overlaps.

- Flashings must extend min. of 10 cm up against the edge beams.

- Waterproofing must be protected against sunlight until asphalt layers, of drainage, protective and wear courses are applied. It is recommended to apply the asphalt layers as soon as possible.

- Thickness and mix design of asphalt courses are as per consultant and project specifications.

- Bridge deck joints must be filled up (Grouted) and covered with 200 mm

- MBM cover strip prior to membrane application.

- Bitunil System recommendation is for two layers of MBM fully torch welded onto deck surface however, for bridges with low daily traffic (ADT<2000), without significant importance to local and regional traffic, and without frequent breaking and turning traffic, a single layer system is adequately sufficient.

Bitunil manufactures and market large types of waterproofing systems to suit different requirements of Engineering industry to mention few of those are BITUBOND–4, BITUBOND 4/E, NILOBIT-PM, NILOBIT-PM-MINERAL NILOBIT-F, BITY FLEX 4 & 4E, BITUPLAST 4 & 4/E, BITUGARDEN 4- 4E & M BITUTER 4 & 4E, BITUGUM MINERAL, NILOBIT-PN, NILOBIT-PM.

The company has achieved great reputation for its products and services it offers to its clients. The products are being used in almost all corners of the world due to their high quality, reliability, uniformity in Quality and successful performance.

Bridge Joints: Selection and Water Management

Based on the predicted movement related to imposed design loads, and temperature variation ranges, the bridge designer specifies the appropriate bridge joints. Selection can vary from a wide range of pre-fabricated expansion joints, to cast in place Asphaltic plug joints. The drainage system for the joint should ideally overlap the deck waterproofing system used. Combined subsurface drainage outlets serve to discharge water and prevent build-up behind the joint. Regular inspection of surfacing and joints is necessary to maintain satisfactory performance throughout bridge service life. Early fault detection, such as blocked drainage or damaged surfacing, is necessary to avoid major remedial work. Inspection and maintenance should be scheduled to coincide with other bridge maintenance work to reduce disruption and consequential costs.

NBM&CW January 2008