Elgi’s Compressors – Driving Concrete Batching Plants to Deliver Right Quality Concrete Mix

In the construction industry, producing high quality concrete in the right amount and delivering it on time is a challenging task. The right quality of concrete, produced by the concrete batching plants, increases the durability and sustainability of construction. It is the Compressed Air that drives the concrete batching plant operation to deliver the right quality of concrete and on time.

Usage of Compressed Air in Concrete Batching Plant

Concrete batching plant is an equipment in which aggregates (sand, gravel, crushed stone, slag, etc) are batched, mixed with water, cement and other additives homogeneously to obtain concrete of the desired strength and quality.

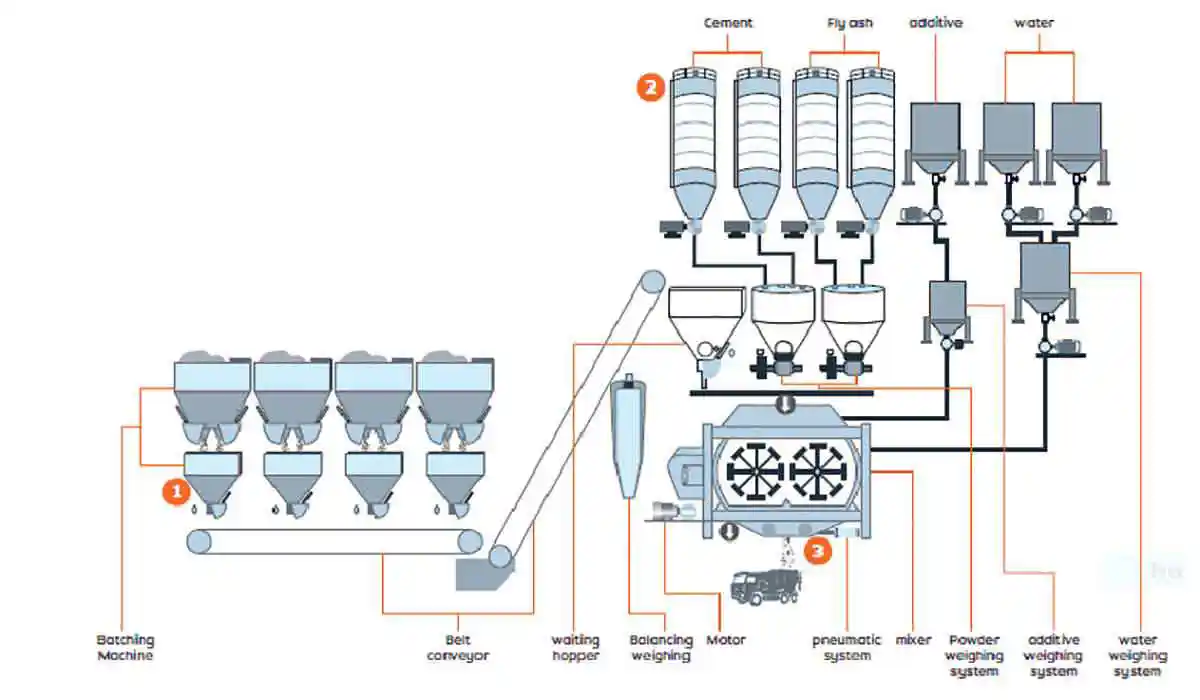

Layout of a Concrete Batching Plant

- Aggregate bins: contain sand, gravel, and other aggregates

- Cement silo: container used for storage of bulk cement onsite

- Mixer: the heart of a batching plant where ingredients are mixed together to form concrete

Charging: A cyclic process of continuously feeding all ingredients to the mixer, ensuring the mixer is not idle and proportion of all ingredients is precise.

Mixing: This is the complete blending of materials required for production of a homogeneous concrete.

Discharging: After mixing, the concrete mixture is evacuated from the mixing chamber to the RMC (Ready Made Concrete) truck via a discharge chute.

Why Compressed Air is Critical in a Concrete Batching Plant

Compressed air is used in the control system tyically during charging and discharging cycles to actuate pneumatic valves in the aggregate bins and the mixer. As charging, mixing and discharging is a continuous operation in a concrete batching plant, the compressor must be up and running to ensure seamless operation. Compressed air is also used to clean the silos so that the right proportion of cement and flyash is charged, thereby ensuring the desired output quality.

In Aggregate Bins, valves are controlled by load sensing cells and PLC. Compressed Air is required for opening these valves based on the signals from load cells for discharging aggregates to the hopper/ conveyer belt.

In the Mixer, Compressed Air is used for operating the pneumatic delivery valves which aids in unloading mixed concrete onto the ready-mix concrete (RMC) truck. Concrete typically sets in 30 to 40 minutes. If it is not delivered on time from the mixer, the concrete will set inside the mixer with no other option than to replace the entire mixer.

Compressed Air is utilised for cleaning the silos and for dusting the deposits in the silo walls/lining during operation. If silos are not cleaned at regular intervals, the holding capacity of silos will be reduced due to accumulated residue, resulting in decreased output quantity.

Compressed Air is used as an alternate for water for cleaning the silos. If water is used for cleaning, the silo must be dried before loading, which takes ample time, thereby reducing productivity.

How Compressed Air is Driving Productivity in a Batching Plant

Productivity is key for a batching plant and as Compressed Air plays a critical role in this, choosing the right partner for the compressor is imperative. ELGi offers application-specific compressors that are robust and reliable, and are backed by efficient customer support.

ELGi’s offers a wide range of 3 to 15HP Single Stage and Two Stage reciprocating compressors fitted with oil bath air filters as standard, specifically for batching plant applications. The compressors have proven to be the right product for batching plants that work in dusty environments. The oil bath air filters are designed to offer an excellent degree of filtration, besides the capacity for prolonged use, and minimum maintenance, ensuring seamless compressor performance in any external environment.

ELGi has a dealer network in 100+ locations across India and 600+ sales/service professionals on ground to support varied industries, especially batching plants installed in different locations across the country.

NBM&CW March 2021