QGM Specializes in Designing and Manufacturing of Concrete Plants & Machinery

Automatic Block Making Machine

QGM automatic block making machines employ Germany Frequency conversional Technology. This technology guarantees the precise and parallel movement between tamper head and mould, protects the products from transfiguration and increases the production rate by improving the vibrating efficiency. It also controls the instantaneous start and stop of the motors, to protect it from over-heating caused by constant working. In addition, this technology can save the energy up to 30%.

QGM automatic block making machines have been equipped with Germany Siemens PLC control system and Siemens Touch Screen. Siemens PLC with great adaptability, guarantees the stability and reliability of the machine. It has safety logic control and troubleshooting functions, with data input and output. This PLC control system also has automatic self-locking function, avoiding mechanical accidents caused by operational mistakes. Large Siemens visualization touch screen with easy operation, is able to set up update and modify production parameters as per specific requirements. Dynamic display of the production status, automatic trouble- shooting and warning notice can be realized on the touch screen.

Recently, QGM unveiled new generation T-series automatic block making machine --T10 and T15. This series of models fully absorbing and adopting design concept and technology of German top block making machines. All the member parts of the machine meet the European Standards. T-series block making machines provide stable, fast and high-performance production. For instance, T10 is able to produce over 20,000 hollow blocks at 400x200x200mm per 8 hours.

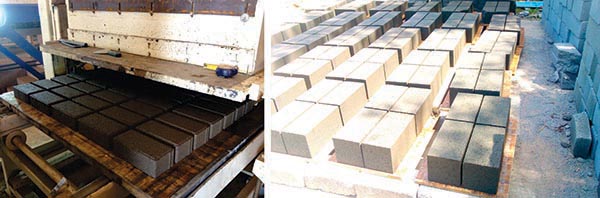

AAC Light Weight Block Production Line

QGM designs and manufactures AAC block making plant to meet the specific requirements of the market and customers. As a new building material, AAC blocks fulfill the demand of concrete industry, which requires saving the natural resources and protecting the environment. With Germany technology and own R&D, QGM provides customers state-the-art AAC block making plant.

One of the key factors affecting the quality of AAC blocks is the accuracy of weighing system. QGM AAC weighing system is equipped with Siemens PLC and electrical components, which provide extremely high accuracy of material weighing. This guarantees the quality of final AAC products. QGM also combines mature Germany Frequency Conversional Control Technology into the AAC production control system, such as cutting and transportation of AAC cakes. This technology largely improves the yield and stability of finished products.

Ready-mixed Concrete Mixing Plant

Concrete mixing plant is designed for customers who require the movement performance of concrete mixing plant. QGM takes use of international modular assembly structure, which is easily to install and the structure is compact. The plant with high automation performance can be widely used in bridge, building, irrigation and other infrastructure construction.The weighing system of the concrete mixing plant adopts special batching device, which has the fall error automatic supplement function. The aggregate, cement, water, additives are measured separately and accurately by employing Siemens PLC and electronic components. The control system uses high-performance industrial computers with double computers and double controls, one for production control and the other production management. The system has the function of real-time processing and alternative decision-makers in emergency situation, which can guarantee the reliability and stability of the control system.

Technical Support and Service

QGM offers a wide range of services in the worldwide network during the entire operating life of your QGM block making machine. There are 10 overseas offices and 25 warehouses. With specialist competence in and out of the office, the QGM service supports you in achieving your goals regarding productivity and availability of plants. QGM service does not stop with the handover of the equipment to the customer, but lasts for the life time of the machine.

NBM&CW December 2012