How to Ensure Good Waterproofing in High-Rise Buildings

What are the waterproofing challenges in high-rise buildings?

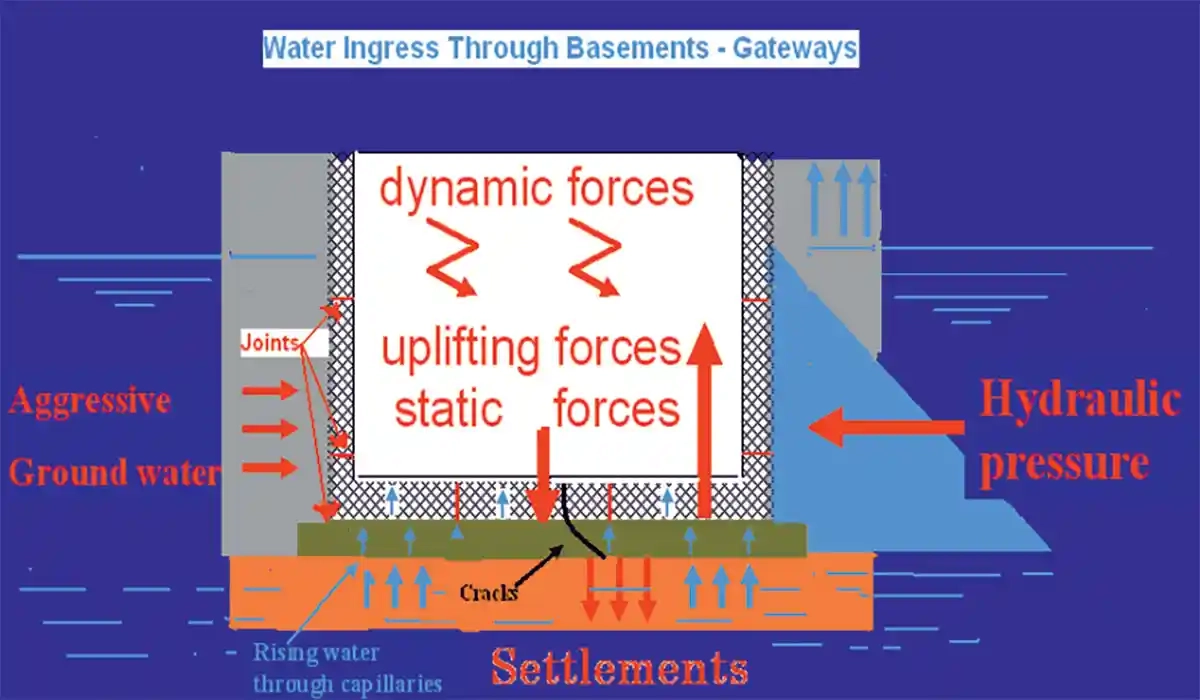

The quality of construction of high-rise buildings has to be extremely good in terms of specifications, materials etc. As buildings go higher, basements go deeper. When basements go deeper, lots of construction joints appear, and the building will undergo uplift pressure, settlements, hydrostatic pressure, seismic movements, etc.

Exposure to ground water pressure combined with quality of urban soil contamination by surrounding effluent release necessitate high quality waterproofing. One cannot afford to apply underperforming material for waterproofing or be negligent in the application quality. Specifiers need to have full information on the merits and demerits of waterproofing systems, accessories and appurtenant systems that augment high-end waterproofing materials.

Since high rise buildings have a lot of inhabitants, to reduce the carbon footprint, one must provide vegetated landscaping. This, in turn, needs the right waterproofing sealing system which can bear the brunt of the water laden soils and the fertilizers used for growing the vegetations. Waterproofing for such situations demands very durable systems which come with a higher cost. Waterbodies may be at the podium level or on the roof and thereby contained within the building. Waterproofing thus becomes a challenge in terms of the durability of the waterproofing system.

Wind-driven rain experienced in high-rises necessitates waterproofing and sealing of window perimeters and service areas. The exterior walls of high-rise buildings are also inaccessible for re-coating and maintenance, which can be problematic.

What are the main factors that contribute to waterproofing failure in high-rise concrete buildings?

Almost 99% of the failures in waterproofing happen due to the 1% of openings and transitions which are not sealed and waterproofed effectively. Before taking up waterproofing, a thorough understanding of the structural and architectural detailing are a must.

Lack of proper detailing is one of the major factors for waterproofing failures. Proposing ‘fit to purpose’ waterproofing is a way. For example, the tensile strength of waterproofing should be higher than that of the substrate’s tensile strength.

Other causes of failure are improper selection of waterproofing system, not carrying out proper preparatory work, use of incompatible materials, design flaws, co-ordination issues (applicator & product owner become the responsible persons for waterproofing execution), incorrect diagnosis of leakage problems, faulty external plastering, and lack of effective monitoring post the application.

Please give examples of the different types of waterproofing systems being applied in concrete buildings and structures.

In every structure, depending on the exposure conditions and serviceability requirements, and in every part of the building, different kinds of waterproofing systems are specified, as shown in the table Table 1:

| Table 1 | ||||

| Areas | Types / Category (Exposure) | Area of application | Product / System suggested | |

| SUBGROUND | PILES / PILE CAPS | WET & DRY | Pile Top | Epoxy grout |

| WET & DRY | Reprofiling of pile | Factory Controlled Repair Mortars | ||

| FOOTINGS, FOUNDATIONS in RCC | WET | Below footings | Pressure sensitive HDPE membrane | |

| Footings perimeters | Self-adhesive HDPE / SBS membranes / PU coatings protected with boards from backfills | |||

| RAFT | WET | Below RAFT | Pressure sensitive HDPE membrane | |

| Confined Retaining wall | WET | On shore piles | Sacrificial shuttering and cell mesh bonded to a blended polyethylene membrane (mechanically bonded) |

|

| Sacrificial shuttering and Pressure sensitive HDPE membrane | ||||

| Un-Confined Retaining wall | WET | Membrane | Self-adhesive HDPE/SBS membranes | |

| Liquid applied | Pure Polyurea/Polyurethane coating | |||

| Podiums | Driveways | Wet & Dry | Liquid applied | PU coating |

| Land scape areas | Wet | Liquid applied | Hybrid PU/ Polyurea | |

| Swimming pool | Floors and walls | Wet | Liquid applied | Cementitious with negative pressure resistance / PU coating overlaid with Glass tiles or ceramic tiles and gaps filled with UV resistant resinous tile grout |

| Roofs | Dry | Liquid applied/membrane | Hybrid polyurea / TPO membranes | |

| Landscaped | Liquid applied | Hybrid polyurea | ||

| Bathrooms | All types | Always wet | Liquid – Brush applied | Cementitious coating with good tensile and elongation |

Roofs of high-rise buildings: Remedial waterproofing in roofs is by far the most complicated. Roofs are usually crowded due to installed units for air conditioning, plumbing pipes fixed onto the roof surface and parapet walls, etc. Sometimes, steel fabricated over-bridges are erected over roof areas, where large sized pipes run over the roof surface. All these need to be relocated and lifted well above the roofing surface or parapet before one can start surface preparations. In domestic situations, the relocation may be far easier, which the waterproofing contractor can take up as a part of his remedial job.

Loose plasters and cracks in surface of the roof need to be exposed with mechanical means along with high pressure water jetting, etc. Once the bare surfaces of the walls and roofing surface are exposed, there could be signs of corrosion seen.

Generally re-roofing requires quite a bit of civil work, which sometimes may be outside the scope of the waterproofing job per se.

In short, there is no straight answer for recommendation of the waterproofing materials, as it is always subjective. A tailored solution needs to be worked out to see that the remedial waterproofing is effective and long lasting.

Wet areas and bathrooms: Here, a superficial remedy must not be done. It is essential to remove tiles. The basic waterproofing must be done by way of brush applied cementitious coatings after repair of plumbing and sanitary fittings. In most situations, old, corroded GI plumbing has to be replaced and relocated in the bathroom. This can include doing up the bathroom interiors with more modern fittings.

In case a bathroom’s base is leaking into the neighbour’s bathroom below, PU Injections may be the most effective solution.

Basement walls: Good materials are available to arrest mild dampness in the interior side of concrete basement walls. Once a dry surface is achieved, it will be safe to coat these walls with decorative paints.

Leaking podiums: The entire area on top of a leaking podium has to be removed and put back in place after the surface preparation, examination, and repair of the deteriorated areas. After this, based on the kind of hard scaping or wet scaping design, appropriate membranes such as pure polyurea or hybrid polyurea can be suggested. The existing expansion joint profiles need to be repaired and re-treated, and then filled with a low modulus high MAF sealant. The sealant all along the podium surface will need to be covered with an aluminum channel cover riveted over, to protect the sealant from the landscaping and soil overburdens.

Please tell us about Fosroc and its areas of expertise.

Fosroc has been manufacturing construction chemicals since 80 years. A UK-based company, it has a strong hold in the Indian subcontinent since the past 40 years with manufacturing and marketing. Fosroc provides all kinds of assistance right from concrete admixtures and surface treatments to waterproofing and industrial flooring. Products include anchors, grouts, protective coatings, adhesives, joint sealants, and cement grinding aids.

NBM ICCT, November-December 2022