Crushing & Screening - Better & Faster

Mobile crawler-mounted crushing and screening plant is witnessing advancements that induce higher mobility, fuel efficiency, ease of maintenance and more productivity. NBM Media reports.

A large number of new road projects are being rolled out across the country along with road widening from 2 to 4-laning and from 4 to 6-laning, which in turn is boosting demand for mobile Crushing and Screening plants. And, given the restricted timelines, contractors want machines that give assured performance with minimum set-up time coupled with minimum downtime. Manufacturers are coming to their aid by upgrading their machines so that they deliver better and faster.

In view of the super expressways with 6 lanes and service roads, the need for aggregates requirements has increased, leading to reduced project completion time. This has led to demand for higher capacity plants of 300 to 800 tph (up from 200 tph). Also, with the restrictions being placed on use of natural sand for concrete road projects, there is increase in demand for manufactured sand plants.

Says Pai, "Especially for commercial plants that are fixed in nature, our Jaw crushers of higher capacities can be fine-tuned to meet mining requirement. We provide stockpiles between the primary jaw crusher station and the secondary cone crusher station. With stockpiles, independent operation of primary crusher, and (depending on the mining/quarrying hours) the plant owners can plan/create a stock. Further, the secondary and tertiary plant operations can be continuous, despite any breakdown or feed restriction in quarry/primary crushing with a stockpile arrangement. There would also be optimization of power consumption and flexibility in maintenance. All of this would lead to better operations from trucks for feeding to removal of finished products, power optimization etc."

He adds, "To ensure all-time availability of our plants, we have placed our service team at almost all the crushing zones and we have our experts at our branch offices across all regions and at our associates' locations. We have enhanced the capacities of our in-house foundries to take care of wear parts, and have added more stockpoints for spares."

Today, Puzzolana is certified as "Approved Training Partner of Infrastructure Equipment Skill Council" to certify operators for crushing & screening plants.

According to Jaideep Shekhar, MD, TEREX Materials Processing, India, demand for faster construction has become a major driver for customers to move towards mobility. "We have seen this trend for the last few years and it is one of the prime reasons for the growth of the tracked crushers and screeners industry in the Indian market. We have seen a similar phenomenon in the Iron Ore industry in the early 2000's when customers were opting only for Tracked Crushers and Screens to meet the strict deadlines for shipping iron ore to their export markets."

He informs that Terex Track Plants are best suited to meet the requirements in large projects that need to be completed in a relatively shorter period of time. "Terex is the market leader in Tracked Mobile Crushing and Screening market with two of our brands – Powerscreen and Terex Finlay - being the preferred choice of customers. We offer the largest selection of tracked machines that are manufactured locally to meet the price, delivery and quality requirements of Indian customers. Our range of products include Tracked Jaw Crushers and Cone Crushers, Tracked Two and Three Deck Screens and unique machines like Warriors and Tracked Conveyors. We also have an extensive range Tracked Impactors and Tracked Horizontal screens, which we import from our UK factory as per the requirements."

The company will be adding many new products to its tracked conveyor range, and will be launching the High Level Feeder Conveyor and the Low Level Feeder Conveyor in India, later this year. It is also adding its tracked 100 ft Conveyor to the 65ft and 80ft conveyors already available in the market.

Etrack a subsidiary of Keestrack, which began operations in India recently with machines imported from its parent facility in Italy, Czech Republic and China will soon begin local manufacturing at its upcoming facility in Ghiloth, Neemrana,Rajasthan. Initially, the company will manufacture 200-300 tph primary and secondary track plants, with jaw and cone with on-board screen for the Indian market, and will also consider exporting the plants to South East Asian, African and Middle East Markets.

Says Das, "Keestrack's concept of using powerful electric motors for the crusher/screener units and the necessary plant hydraulics (lifting cylinders, tracks etc) combined with several smaller e-drives for conveyors and ancillary equipment provide many other benefits in terms of safety, ease of operation and maintenance, availability and lower long-term total cost of ownership. By being able to use a significant smaller hydraulic circuit, the reduced oil volume minimizes leakage risks, optimizing the plant's environmental impact and maintenance costs. Reduced running hours of the onboard diesel when plugged in, lower rpm of engine extends service intervals and increases the resale value."

Das informs that the machines are fitted with alternator and Volvo Penta engines which ensure consistent power supply giving higher production in the long run. Another unique feature that ensures higher uptime is the ‘drop off' facility, in which, the diesel genset can be dismounted from the machine and can remotely operate through wires, if the site conditions are very dusty. Moreover, a secondary source of power can also be used to operate the plant while genset being repaired.

For the Indian market, Keestrack is considering medium and higher capacity machines, followed by smaller ones. It will economize on the machines' procurement cost with almost 90 percent localization through vendors who will develop jaw plates, cone crushers, and conclave mantles as per company standards, with a special emphasis on casting for quality. The company's target is to produce 25 units in India during the first year of its operation, and gradually increase production and expand its product portfolio.

Keestrack India is considering direct sales of its products and operational and maintenance contracts with customers. "This will help us curtail costs and enable us to have a closer liaison with our customers with a better understanding of their changing requirements and future plans," says Basu.

Elaborating on the safety aspects of the plants, Palagiri adds, "For the Kleemann EVO plants, there is greater safety as its operation is via a mobile control panel that can be attached at three different points on the plant. This guarantees the best viewing positions of the plant functions. All plant functions are started automatically – without each side discharge conveyor having to be activated individually. Data on machine operation can also be read off at the control panel. Plant movement is without jolts thanks to the proportionally activated hydraulic valves. The plants operate particularly efficiently and produce a high output when interlinked with crushing plants of the EVO series, whose size and output are tuned to the EVO screening plants. A further bonus for safe plant operation is the emergency-off function, which, in the case of an interlinked combination of plants, works across all screening and crushing stages."

He further adds, "Our pan India reach and quick availability of service engineers on site, help customers further in preventive maintenance thereby minimizing equipment downtime. Operational intelligence on plant performance provided by TIL also enables customers to optimize their production plans, to meet their business requirement."

TIL is focused on timely availability of parts, lowering of operating costs, enhancing equipment availability. Says Shrivastsv, "Our plants are robustly designed keeping in mind the operating environment. The design also provides our customers the flexibility to adapt to the changing demands for products in the market."

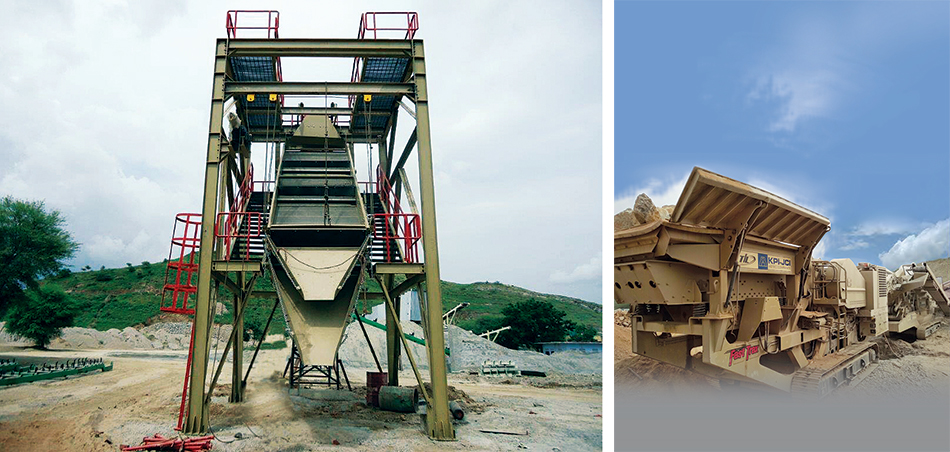

TIL is in partnership with Telsmith Inc., Kolberg Pioneer Inc. (KPI), Johnson Crushers International (JCI) and Astec Mobile Screens (AMS), all of which belong to Astec Aggregate & Mining Group (AAMG). This co-operation results in the design, manufacture, marketing and service support of a range of world-class Track Mobile Plants, Wheeled Portable Plants, Stationery Plants, Unit Equipment manufactured at TIL's Kharagpur Works in West Bengal (viz. Jaw Crushers, Cone Crushers, Vertical Shaft Impactors, Vibrating Screens & Vibrating Grizzly Feeders) and High Frequency Screens for mining and quarry operations in India. TIL offers aggregate crushing plants up to 500 TPH from Astec Aggregate & Mining Group (a part of Astec Industries, Inc. US).

Bringing significant utility and value to earthmoving machines, of any brand or model, MB Crusher is offering the widest range of attachments in the industry. Products include Crusher Machines, Screening Machines, Drum Cutters, Demolition and Sorting Grapples and its newest product Shaft Screeners (officially launched at Bauma Munich this year).

He informs that except for the large units, most of the stone crushing units either buy stone from nearby mines or are situated close to the small mines. The smaller units mostly use a combination of local explosives, mechanical and manual stone breaking methods. The mined stones are then transported to the crusher sites by tractor trolleys or pay-loaders. This not only consumes valuable time but also adds significant logistical costs. Considering the tough geographical terrains in some parts of India, transportation cost impacts the price of the raw materials and more time is taken to reach the construction site.

He adds, "MB products can be attached to any brand and model of excavator/backhoe loader, which means that crushing operations can be carried out directly at construction sites, helping contractors become independent from third party suppliers, and from delays and inflated costs, beyond their control. One of our esteemed customers has been quoted as saying: ‘Thanks to MB, we are getting more job orders because we are doing work which our competitors cannot, and are generating more revenue’."

As regards aftersales and aftermarket support Piero Guizzetti informs, "As a global market leader with an installed base spread across 150 countries, we try to imbibe the best global practices which are most pertinent to the Indian market, as aftersales support is of utmost importance here. When we came to India, we designed a very sustainable, flexible and dynamic service structure. We undertake scheduled visits to customer sites to ensure that our machines are being properly utilized, adequately maintained and operated by a trained person. We have warehouses spread across our network for prompt delivery of spares, and we maintain adequate stock for minimum 12 months. We have been in India for over 5 years now and will continue to invest in after-sales and service. This is because we hope to see India as one of our top 3 markets for the next 20 years."

MB provides operator training, engages on a regular basis with its sales and service partners, holds capacity building sessions, shares product knowledge and solutions to help its team members to provide the best product support and service.

NBM&CW July 2019