Offsite Construction

Srinidhi Anantharaman explores offsite building construction in a holistic manner and provides an overview of the entire design and construction lifecycle of such buildings, along with the compulsions of architectural, structural and services, design decisions and their impacts on off-site and on-site constraints.

Concrete buildings are ubiquitous in India whereas the western world had adapted to steel and composite buildings a century ago. India did have some steel buildings in the early to mid-19th century but was overwhelmed by concrete subsequently.

When there is an apparent abundance of low-cost labour, concrete and brick & mortar buildings, they appear to be economical; however, in the present environment of low productivity, high maintenance workforce, and demand for high quality facilities, there is a clear business case to move to industrialized production of buildings using fewer high-skilled workers.

Steel-composite and precast concrete building technologies are the front runners in this scenario as they exploit off-site manufacturing. While both have their pros and cons, there is now a realization that the final answer lies in an appropriate mix of steel, precast, composite, and concrete technologies, along with traditional on-site technologies for certain building elements.

Conventional ‘On-site’ concrete intensive buildings have been slow and lumbering to build but suited some sectors that depended on slow sales revenues to fund the project. It is however not suited for any investment-based project as the cost of time is not factored in traditional construction. The other issue in conventional construction was its dependence on apparently cheap and abundant ‘migrant’ labour, which is neither cheap not freely available.

Off-site construction technologies cover both Steel-Concrete Composite & Precast technologies. Both these technologies have been prevalent and popular in the west and they respect time value of money.

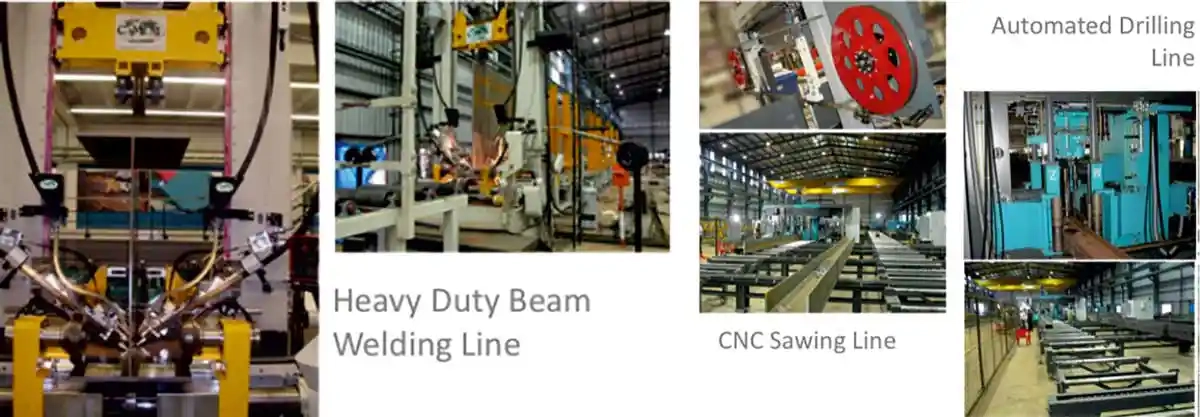

Steel prefabrication leads to light, fast to erect and precise buildings with just ‘low-skill’ rigging workforce onsite. The ‘high-skill’ workforce offsite is utilized more efficiently due to the industrialized production possibilities.

Typical Work Breakdown

Offsite refers to any work done away from its final position. Logistically, steel works may be fabricated on site or concrete may be precast on site but not in-situ.

While RCC is also a steel-concrete composite with steel rebar embedded in concrete, the term is now referred specifically to structural steel and RCC behaving as a single integral structural system.

Projects have multiple stakeholders and teamwork is the main ingredient for a successful project. The various stakeholders have been broadly identified in the following chart.

Work Breakdown Structure (WBS) is based on a classification hierarchy starting with the project level spatial features and ending with the single- part production item or the raw material / bought- out item.

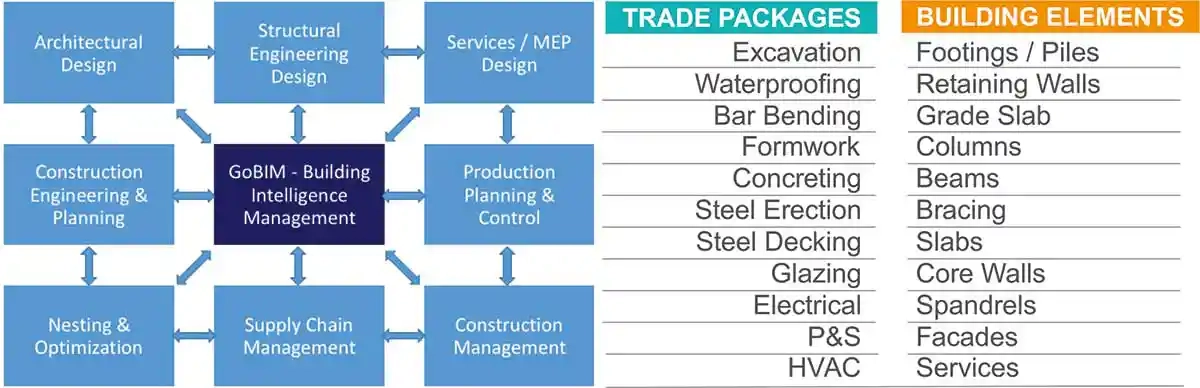

From Design to Delivery

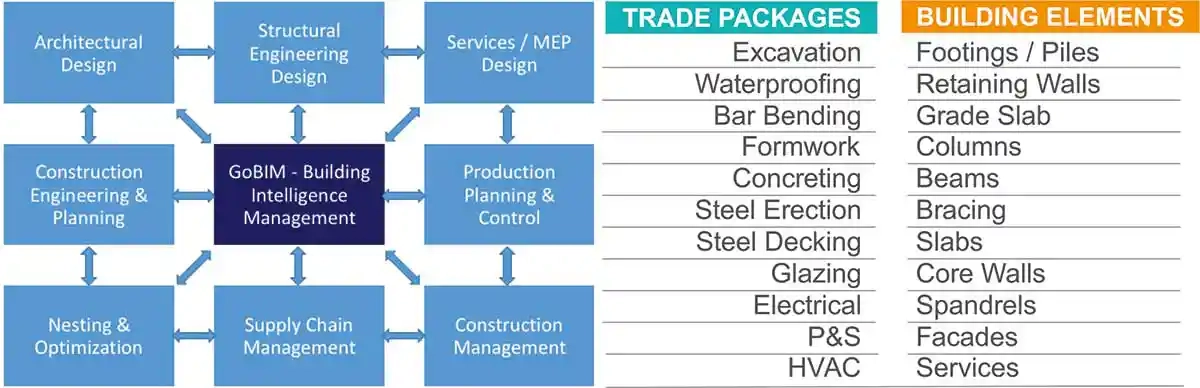

The framework for the design and construction of modern complex buildings are inter-disciplinary, interactive and convoluted. Many attempts have been made in the past to create a system for coordinating these disciplines and activities. The current approach of using BIM (Building Information Modelling) in various forms can provide some success if used prospectively instead of retrospectively. The next generation BIM will be a platform for Building Intelligence Management instead of the passive information modelling in the previous generation of BIM. The chart shown below shows the interrelationship between the disciplines and automated activities with BIM.

Design decisions have a significant impact on the project cost, delivery timelines and performance. The design & construction process is best optimized by examining the owners’ and users’ requirements, and meeting them with appropriate construction technologies. Technologies vary for building elements and trades, and decisions to use offsite technologies have to be taken at a very early stage after due consideration by experts.

The above chart shows typical building elements and trades encountered in the various building performance systems, which are briefly characterized below:

Floor Plate Systems:

Gravity Load Systems:

Lateral Load Resisting System

Walls around building cores act as lateral load resisting systems, particularly in taller buildings. They are of different materials, structural configurations and technologies:

Industrialising Steel Erection

Industrialization changed the world of manufacturing from the manual methods to mass-produced automated methods. While the current revolution in manufacturing revolves around IOT, one-piece flow, flexible manufacturing, just-in- time and single piece 3D printing, construction is still stuck in first generation one-off working. The need of the hour is to implement the following approaches to construction:

Offsite Production of Components

The need to use standardized processes, manpower, equipment and materials to control costs makes for a strong business case to centralize the production in a single location. On the contrary, the logistics issues in transportation, delivery, storage at site and erection makes a strong case for site-based production if not in-situ working. The following guidelines can be considered for such decisions:

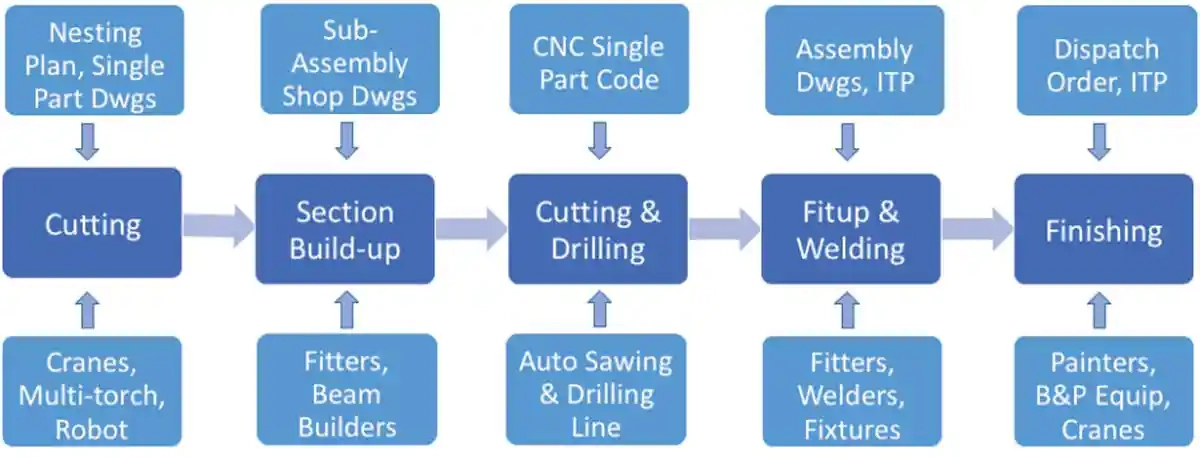

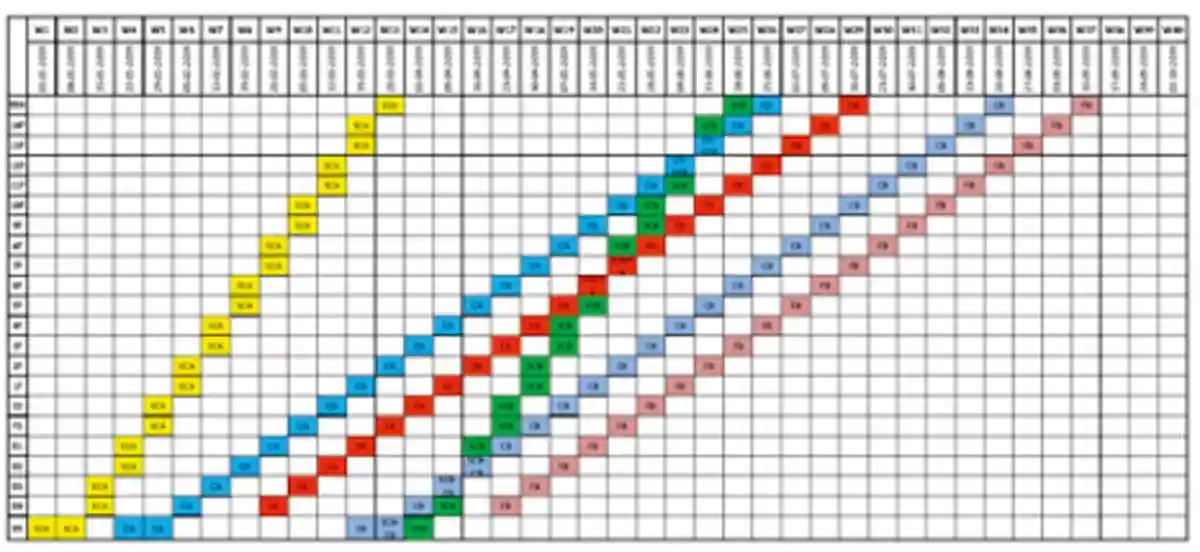

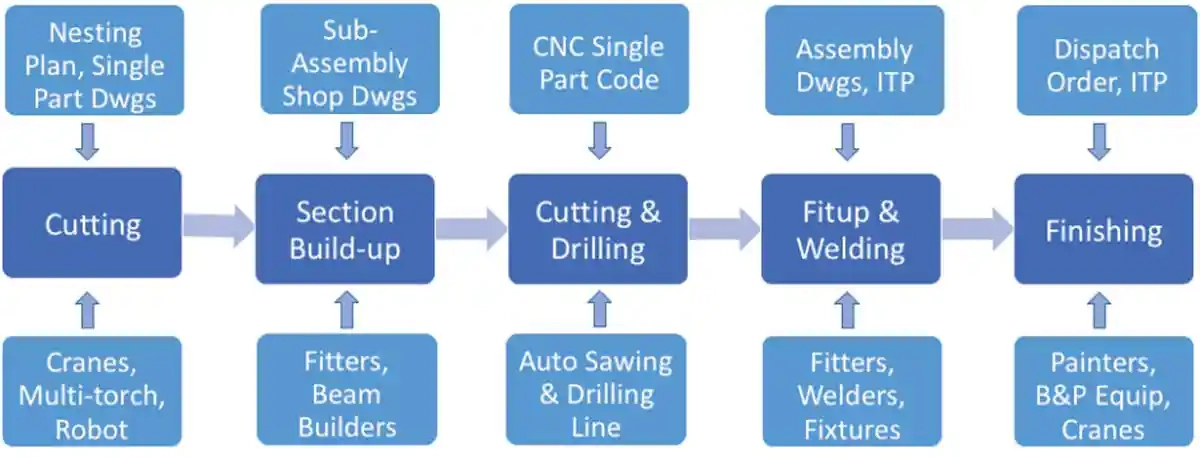

The physical transformation of raw materials into finished or semi-finished products in factories involve several trades and engineering activities. The process of producing a pre-fabricated element is quite simple but the unique and one-off nature of the final product in terms of its traceability, final fit in location and other design parameters make it complex, as shown in the chart:

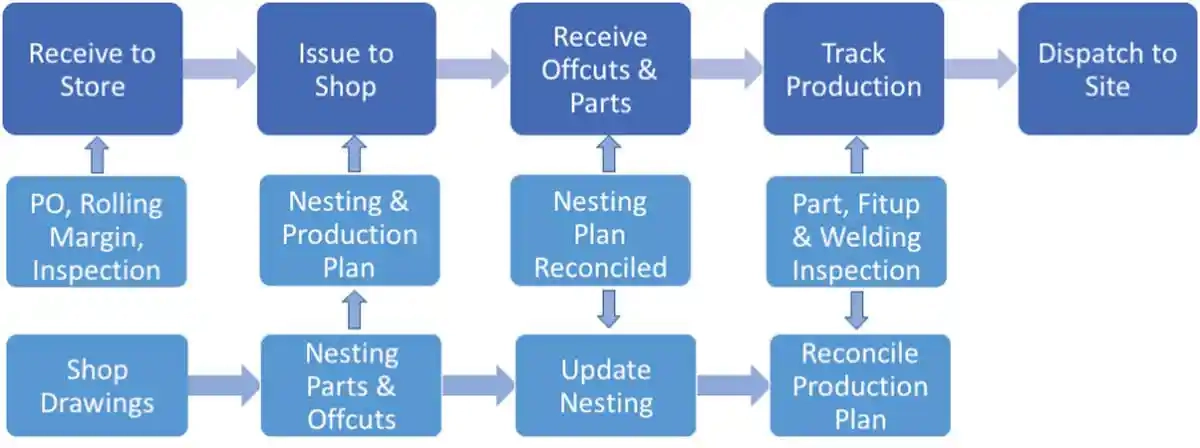

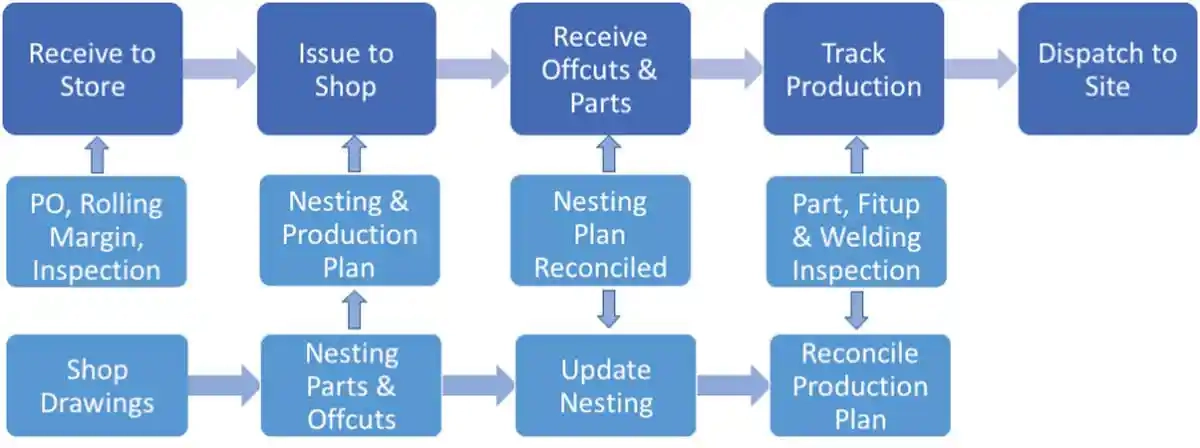

Added to the above direct engineering efforts, the administrative efforts required to ensure cost and time control and manage the materials flow is quite elaborate as shown in the chart below:

Conclusion

While the need for offsite working is paramount, such decisions and their execution is a subject matter of expertise and cannot be taken lightly or anecdotally. Offsite working provides a robust delivery system and radically reduces the implementation period though, paradoxically, increasing the planning duration. However, the overall savings in time and cost will far outweigh any apparent reduction that may accrue due to early mobilizing in the traditional ‘fast-track’ or conventional ‘General Contract’ approaches.

Srinidhi Anantharaman is the Founder & Managing Director of Geodesic Techniques, a design & build company with a successful track record of over three decades in complex steel prefabrication industry.

Concrete buildings are ubiquitous in India whereas the western world had adapted to steel and composite buildings a century ago. India did have some steel buildings in the early to mid-19th century but was overwhelmed by concrete subsequently.

When there is an apparent abundance of low-cost labour, concrete and brick & mortar buildings, they appear to be economical; however, in the present environment of low productivity, high maintenance workforce, and demand for high quality facilities, there is a clear business case to move to industrialized production of buildings using fewer high-skilled workers.

Steel-composite and precast concrete building technologies are the front runners in this scenario as they exploit off-site manufacturing. While both have their pros and cons, there is now a realization that the final answer lies in an appropriate mix of steel, precast, composite, and concrete technologies, along with traditional on-site technologies for certain building elements.

Conventional ‘On-site’ concrete intensive buildings have been slow and lumbering to build but suited some sectors that depended on slow sales revenues to fund the project. It is however not suited for any investment-based project as the cost of time is not factored in traditional construction. The other issue in conventional construction was its dependence on apparently cheap and abundant ‘migrant’ labour, which is neither cheap not freely available.

Off-site construction technologies cover both Steel-Concrete Composite & Precast technologies. Both these technologies have been prevalent and popular in the west and they respect time value of money.

Steel prefabrication leads to light, fast to erect and precise buildings with just ‘low-skill’ rigging workforce onsite. The ‘high-skill’ workforce offsite is utilized more efficiently due to the industrialized production possibilities.

Typical Work Breakdown

Offsite refers to any work done away from its final position. Logistically, steel works may be fabricated on site or concrete may be precast on site but not in-situ.

While RCC is also a steel-concrete composite with steel rebar embedded in concrete, the term is now referred specifically to structural steel and RCC behaving as a single integral structural system.

Projects have multiple stakeholders and teamwork is the main ingredient for a successful project. The various stakeholders have been broadly identified in the following chart.

Work Breakdown Structure (WBS) is based on a classification hierarchy starting with the project level spatial features and ending with the single- part production item or the raw material / bought- out item.

From Design to Delivery

The framework for the design and construction of modern complex buildings are inter-disciplinary, interactive and convoluted. Many attempts have been made in the past to create a system for coordinating these disciplines and activities. The current approach of using BIM (Building Information Modelling) in various forms can provide some success if used prospectively instead of retrospectively. The next generation BIM will be a platform for Building Intelligence Management instead of the passive information modelling in the previous generation of BIM. The chart shown below shows the interrelationship between the disciplines and automated activities with BIM.

Design decisions have a significant impact on the project cost, delivery timelines and performance. The design & construction process is best optimized by examining the owners’ and users’ requirements, and meeting them with appropriate construction technologies. Technologies vary for building elements and trades, and decisions to use offsite technologies have to be taken at a very early stage after due consideration by experts.

The above chart shows typical building elements and trades encountered in the various building performance systems, which are briefly characterized below:

Floor Plate Systems:

- RCC beam-slab, with very high cycle time

- Flat slab with drop, with high cycle time

- PT flat slab with drop, with high cycle time

- Composite steel beam and solid RCC slab:

- Moderate cycle time, optimum cost

- Integrated fire protection to steel

- Composite steel beam and deck slab:

- Low cycle time, moderate cost Laying, nailing, studs, fire rebar

- Deep decks- reduced secondary beams

Gravity Load Systems:

- RCC columns - bulky but economical

- Pure steel columns - slender but expensive

- RCC encased steel columns:

- Stocky, slow, moderate cost

- Formwork for encasement a challenge

- Concrete filled tube (CFT) columns:

- Compact, easy, moderate cost

- Infill concrete along with slabs

- Column rebar eliminated for speed

- Infill concrete increases fire resistance

Lateral Load Resisting System

Walls around building cores act as lateral load resisting systems, particularly in taller buildings. They are of different materials, structural configurations and technologies:

- RCC core walls are the most common:

- Typically cast in place (CIP)

- Moderate cycle time with jump-form

- Faster with climbing / slip-form

- Onsite rebar work is a challenge

- Not synchronised with steel erection

- Core walls always on critical path

- Concrete filled steel walls (CFSW):

- Significantly faster than CIP RCC

- Structurally reliable but expensive

- Braced steel frames:

- Comparable to CFSW

- Structurally reliable but expensive

- Moment connected Steel & RCC frames:

- Suitable for low-rise buildings

- RCC fraught with quality issues

- Can be combined with other systems

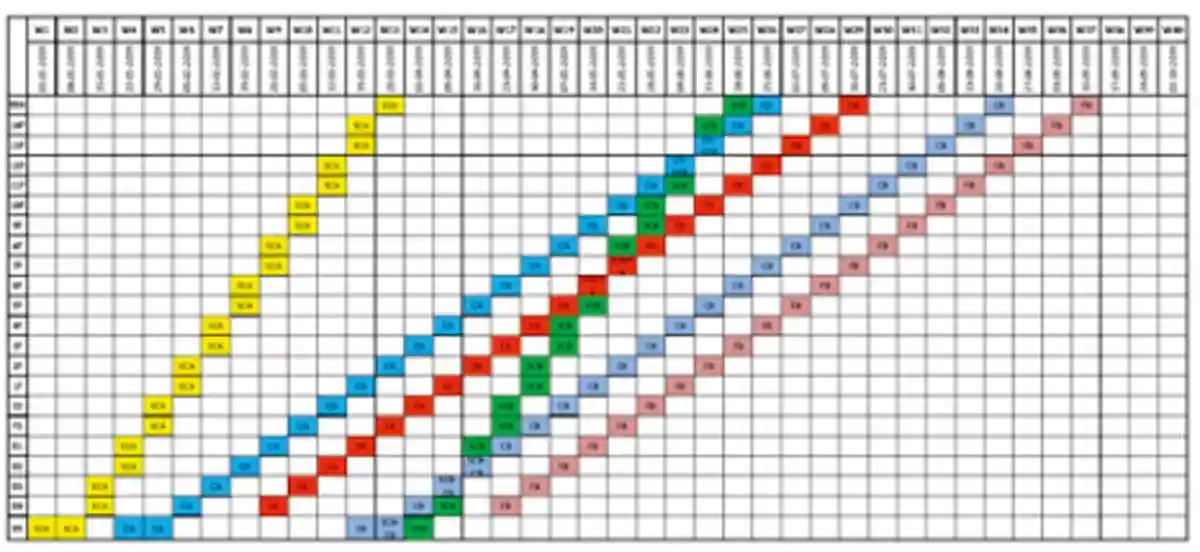

Industrialising Steel Erection

Industrialization changed the world of manufacturing from the manual methods to mass-produced automated methods. While the current revolution in manufacturing revolves around IOT, one-piece flow, flexible manufacturing, just-in- time and single piece 3D printing, construction is still stuck in first generation one-off working. The need of the hour is to implement the following approaches to construction:

- Connections to suit construction methods

- Operational planning for construction

- Cumulative erection tolerance analysis

- Crane location for reach and redundancy

- Crane lifts based on radius, luffing height

- Synchronized tower crane operations

- JIT deliveries to minimise handling

- Gang lift for erecting multiple assemblies

- Line-of-balance approach to planning

- Visual production & erection techniques

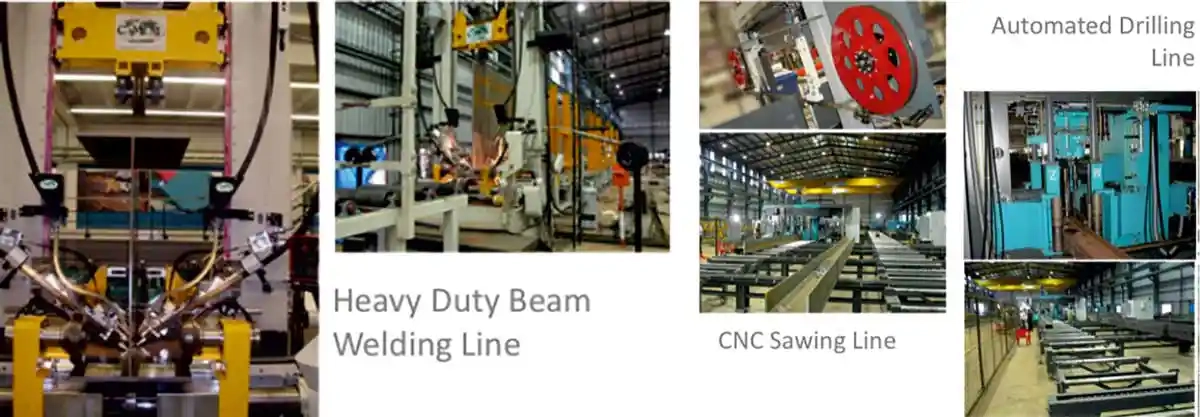

Offsite Production of Components

The need to use standardized processes, manpower, equipment and materials to control costs makes for a strong business case to centralize the production in a single location. On the contrary, the logistics issues in transportation, delivery, storage at site and erection makes a strong case for site-based production if not in-situ working. The following guidelines can be considered for such decisions:

- Convert construction to mass production

- Eliminate or minimize manual methods

- Avoid moment connections

- Minimise stiffeners, openings & notches

- Modularise and repeat elements

- Standardise widths of strips and parts

- Maximize yield and minimize cuts

- Optimise nesting of raw materials

- Use automation and IOT for mass production

The physical transformation of raw materials into finished or semi-finished products in factories involve several trades and engineering activities. The process of producing a pre-fabricated element is quite simple but the unique and one-off nature of the final product in terms of its traceability, final fit in location and other design parameters make it complex, as shown in the chart:

Added to the above direct engineering efforts, the administrative efforts required to ensure cost and time control and manage the materials flow is quite elaborate as shown in the chart below:

Conclusion

While the need for offsite working is paramount, such decisions and their execution is a subject matter of expertise and cannot be taken lightly or anecdotally. Offsite working provides a robust delivery system and radically reduces the implementation period though, paradoxically, increasing the planning duration. However, the overall savings in time and cost will far outweigh any apparent reduction that may accrue due to early mobilizing in the traditional ‘fast-track’ or conventional ‘General Contract’ approaches.

Srinidhi Anantharaman is the Founder & Managing Director of Geodesic Techniques, a design & build company with a successful track record of over three decades in complex steel prefabrication industry.

Concrete Construction April - May 2022