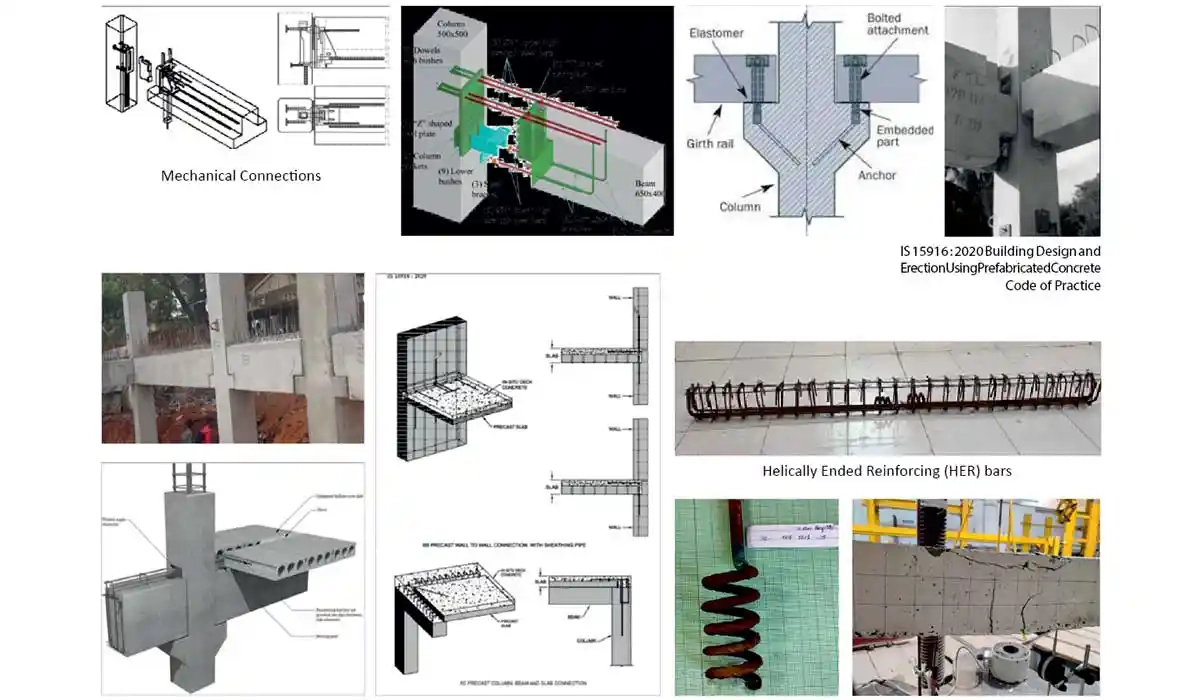

Joints in Precast Construction

Connections & Joints for Structural Stability

Connections and joints are responsible for stability as well as strength of precast structures and their main purpose is to transfer the load between components. There should be adequate design strength of joints in order to transfer the subjected load on the structure. Alternate load path should be always available in case of failure of joints. The type of material used in the joints between two components also plays an important role in the strength of the joints.

Difference between joints and connections

- A joint is a meeting point of elements / members of a structure.

- Action of forces takes place at the joint (such as compression, tension, shear etc).

- A joint may be horizontal, vertical, or inclined.

- A connection is an assembly of adjoining elements/members of the components of a joint.

- A connection is designed to resist the action of forces or moments.

- To transmit forces between structural components

- To provide overall stability

- To provide strength to the structure

- To prevent external leakages

- To resist unpredictable loads due to fire, impact & explosion

- Strength: the connection must resist the forces to which it is subjected during its lifetime. Forces such as those caused by dead and live gravity loads, wind, earth, water pressure, etc.

- Ductility: The ability of the connection to undergo large deformations without failure.

- Change in volume: Combined shortening due to creep, shrinkage and temperature reduction induces tensile stresses in precast components.

- Durability: An exposed section in a connection should be periodically inspected and maintained.

- Fire resistance: A connection which may be weakened by exposure to fire should be protected by concrete or grout, enclosed or sprayed with fire resistance materials.

Joints can broadly be classified as dry and wet joints based on the method of connection of precast members at the site.

- Dry joint: Joint accomplished by simple placing of two members by means of fastening.

- Wet joint: Joint that requires not only casting with cement but also concreting and grouting material.

- Column to foundation

- Wall to foundation

- Wall to wall

- Wall to column

- Wall to beam

- Column to column

- Beam to column

- Beam to slab

- Wall to slab

- Stairs to wall

Commonly used connections and jointing techniques and materials

- Welding of cleats or projecting steel

- Overlapping reinforcement, loops and linking steel grouted by concrete

- Reinforced concrete ties all around a slab

- Pre-stressing

- Epoxy grouting

- Cement or lime grout with non-shrink additive

- Polymer slurry grouting at dowel cast bolts and nuts connection

- Rebar fastener, chemical fastener, and expansion fastener

- Reinforcement coupler

- Combination of the above

- Any other method proven by test

Issues with joints and connections

- Adequate number of joints should be provided to transfer the forces.

- The joints and connection between core structure and components should be strong enough to transfer different kinds of loads.

- Joints must have adequate strength to transfer gravity and lateral load between precast elements.

- If joints and connections are not well finished and accomplished, it will result in leakage.

The main purpose of the structural connections is to transfer forces between the precast elements in order to enable the intended structural interaction when the system is loaded. The connections and elements must be well designed and detailed such that the flow of forces is not only logical and natural, but the forces to be resisted by the connection can be transferred into the element and further onto the overall load-resisting system.

For more details, please contact at:

Concrete Construction April - May 2022