Structural behaviour of Geopolymer Masonry

Radhakrishna, Professor and Head, Department of Civil Engineering, RV College of Engineering, Affiliated to Visvesvaraya Technological University, Bengaluru, Venugopal K, Associate Professor and Head, Department of Civil Engineering, SEA College of Engineering, Bengaluru, India, Vinod Sasalatti, Research Scholar, Department of Civil Engg, RV College of Engineering, Bengaluru, India.

Traditional masonry units are not sustainable and eco friendly due to consumption of fuel or cement. It is essential to find sustainable alternatives. This paper reports about preparation of geopolymer bricks, masonry prisms and wallets using flyash, GGBS and M-sand which were cured in open air. They were tested for compression, water absorption, initial rate of water absorption, dimensionality and modulus of elasticity etc. It was found that the properties of geopolymer bricks were superior to the traditional masonry units. Masonry efficiency increases with the thickness of geopolymer mortar. The compressive strength of axially and eccentrically loaded masonry wallets was found to be 1.9 and 1.6 MPa respectively. Hence, they can be recommended for structural masonry.

Masonry units are the main component of a masonry structure. They fill up the bulk of the space in the structure. They play a major role in the compressive strength of masonry and in resisting the structural loads [1]. There are many types of masonry units, for example, burnt clay bricks, hollow and solid concrete blocks, stabilized mud blocks etc. They are selected based on the consideration of required compressive strength, accessibility, cost and ease of construction [2]. Cement is the chief ingredient for manufacturing concrete blocks. Production of one tonne of cement liberates approximately same amount of carbon-di-oxide to the atmosphere. Cement industries are responsible for 5% of the total CO2 emissions and are subsequently responsible for 4% of the manmade global warming [3]. Due to increase of green house gas emissions, the consumption of cement needs to be reduced. Geopolymer technology is one in which conventional cement can be replaced by products such as fly ash and GGBS. Geopolymer is the term coined by professor Joseph Davidovits for the family of high alkali (K-Ca)-poly-(Sialate-siloxo) binders formed in a reaction called as geopolymerization resulting in 3 dimensional zeolitic frameworks [4]. Geopolymers are the family of binders formed using alkaline solutions and alumino silicates like fly ash, Ground granulated blast furnace slag (GGBS), resulting in three dimensional aluminosilicate polymeric gel. Geopolymers are environment-friendly as they make use of industrial by-products and eliminate the use of conventional cement.

Radhakrishna has reported that, it is also possible to manufacture geopolymer masonry units using class F fly ash by open curing [5-9]. Kunal et al. have reported that the extent of alkali silica reaction in flyash based geopolymers is relatively less than that of conventional concrete [10].

Other researchers have studied the optimum dosage of flyash and concluded that the bricks attained the highest compressive strength when 20% of clay was replaced by flyash [11-14]. It is reported that the bricks were porous, light weight, had low thermal conductivity and satisfactory compressive strength [15]. Anastasias et al reported the masonry prisms exhibited 10 times more strength than the mortar [16-18].

Though there is considerable research reported on brick and block masonry, the production of these masonry units is not sustainable. Hence there is a need to develop alternative masonry units, one of which can be geopolymer unit. This paper addresses the technology of making geopolymer units, prisms and wallets.

Objectives of the Research

The following materials were used to prepare geopolymer masonry bricks:

Results and Discussion

The results of water absorption test and density of the bricks are shown in Table 1. It was found that the water absorption of the masonry units was 8.25% which is considerably less compared to the conventional bricks [17]. The density of the masonry units ranges from 1800 to 2000 kg/m3 which are at par with the traditional masonry units. IRA of geopolymer bricks at 28 days was found to be less than 5% which indicates that the masonry mortar will have good water retentivity [17]. These properties are much less than the value specified in IS 2185: 2005.

The dimensionality test of the masonry units was conducted as per IS 1077:1992. The test results are shown in Table 2. It was found that the variations (dimensions) of the bricks are within the permissible of codal provisions.

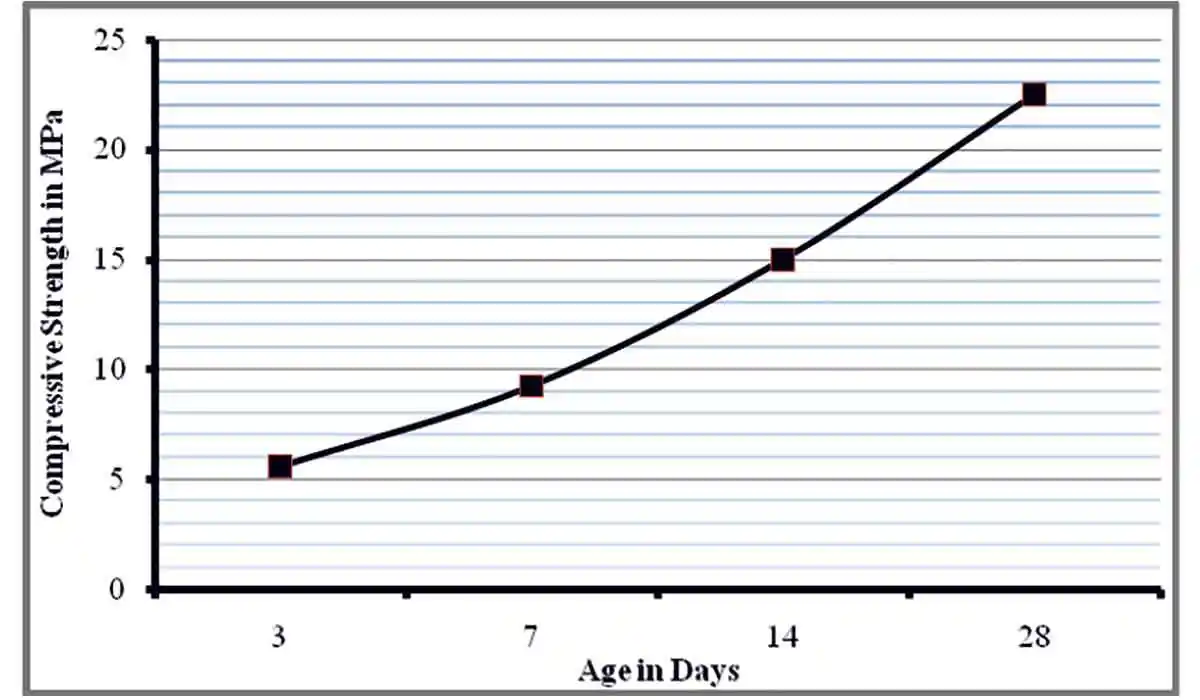

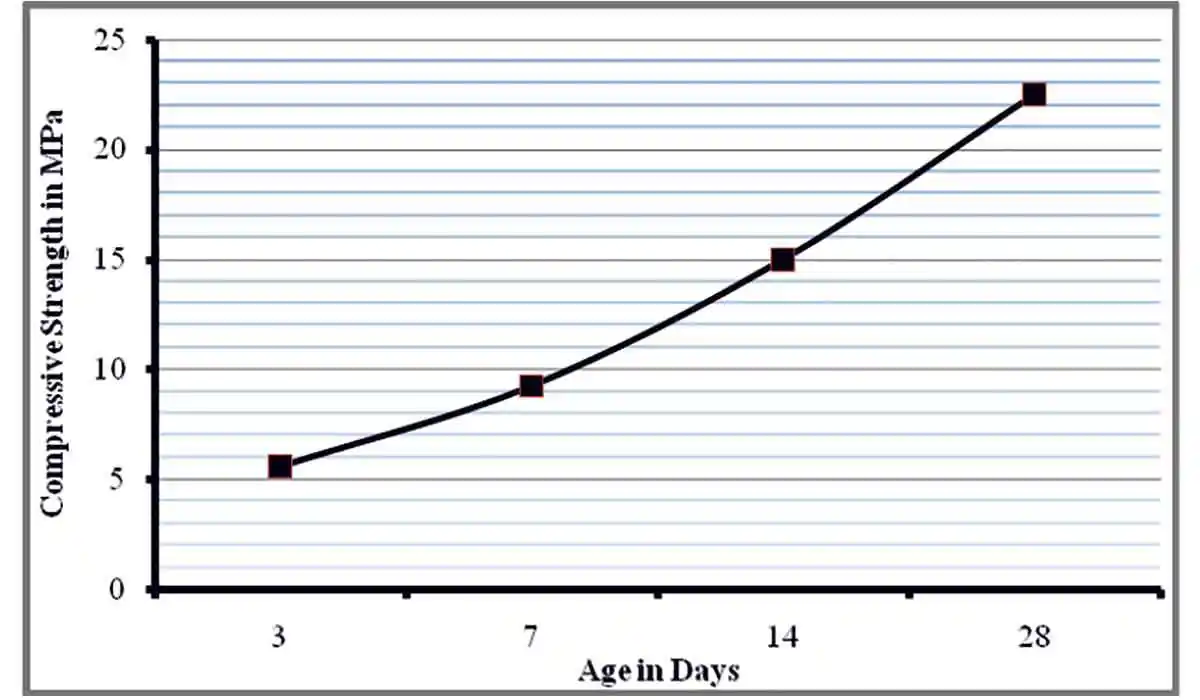

The variation of the compressive strength of the masonry units with age is shown in Fig. 1. It was observed that the compressive strength of the masonry units at the age of 24 hours is more than 5 MPa. This order of strength would be sufficient to handle the masonry units for various purposes. Also, the minimum compressive strength for a brick is 3.5MPa at the time of using them in masonry construction [17]. The strength increases with age ranging from 5-22 MPa for the masonry units. This high strength of masonry units can be recommended for high raised buildings by avoiding framed structures.

Figure 1: Compressive strength of Geopolymer bricks with age

Figure 1: Compressive strength of Geopolymer bricks with age

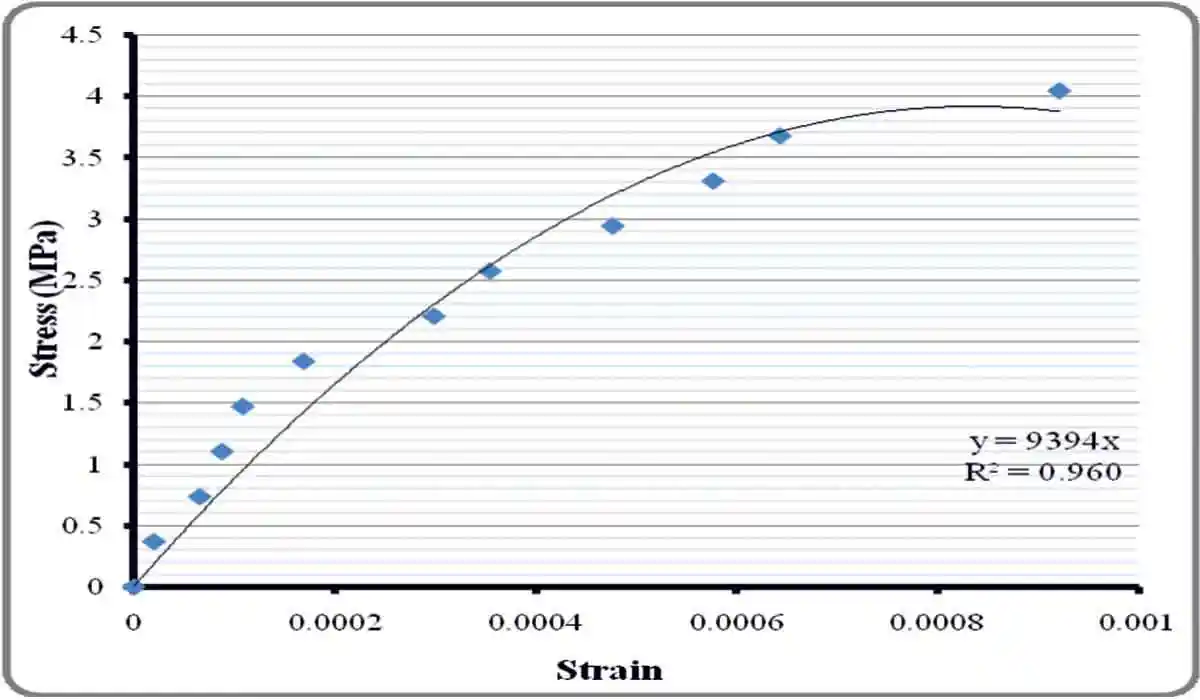

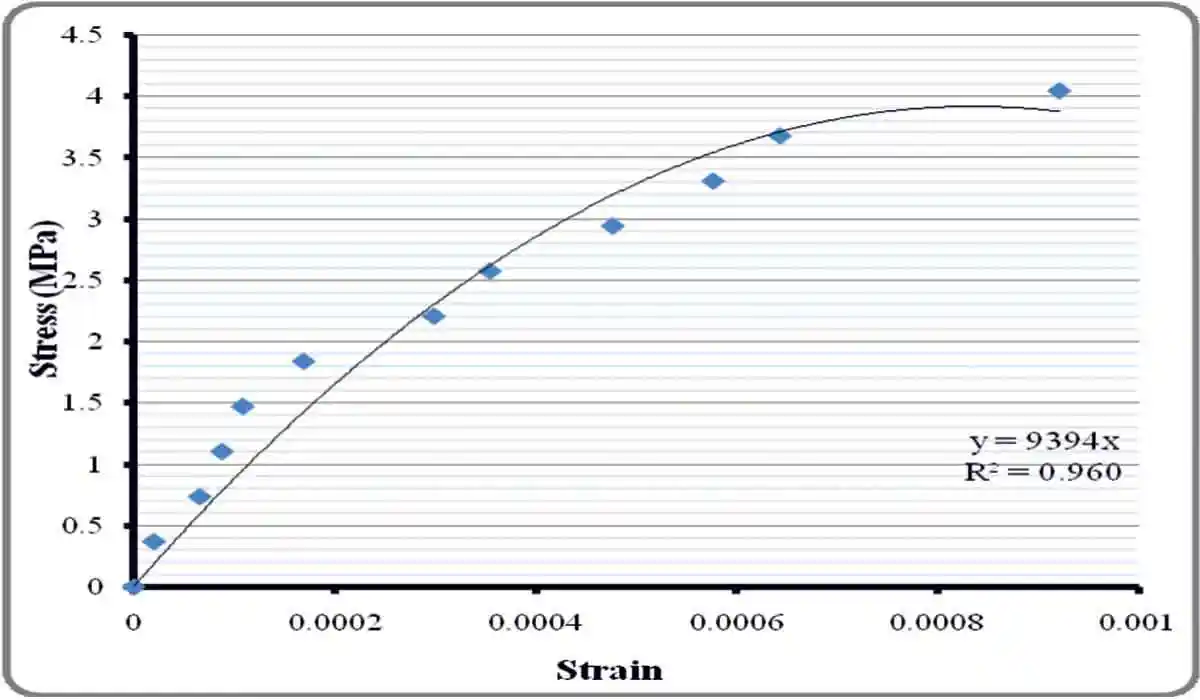

The variation of stress and strain for geopolymer brick is indicated in Fig 2. The modulus of elasticity of geopolymer masonry brick was found to be 9394 MPa at the age of 28 days. This is superior compared to traditional burnt brick [17].

Figure 2: Normalized stress strain curve for Brick

Figure 2: Normalized stress strain curve for Brick

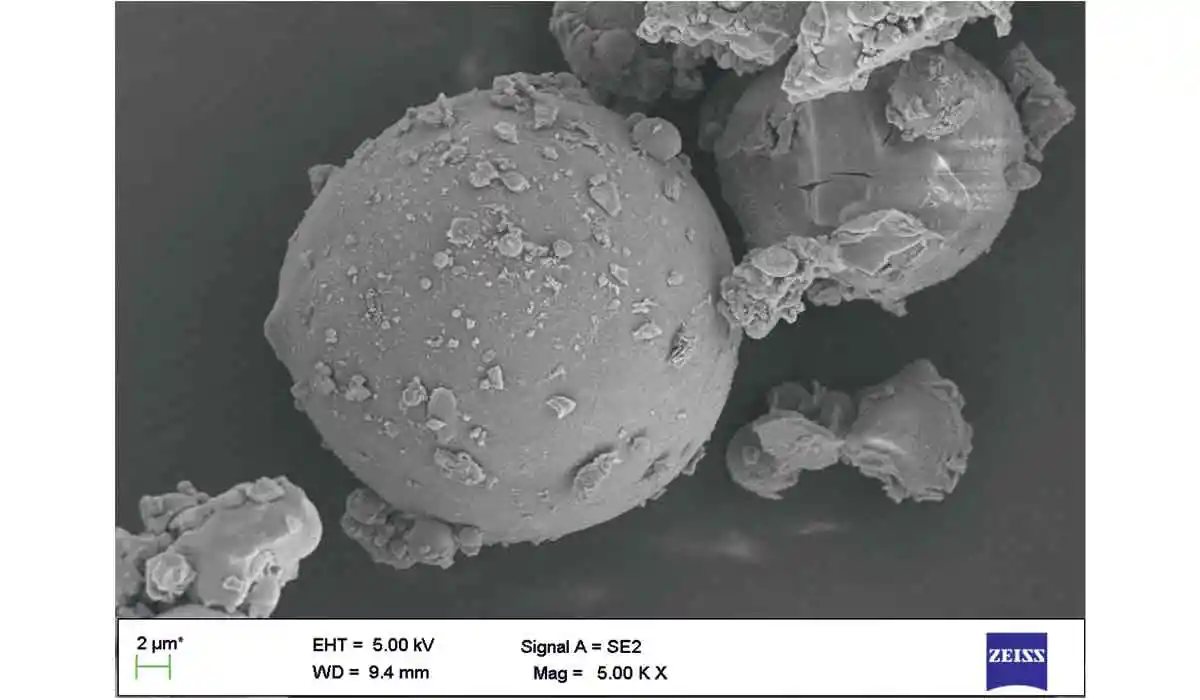

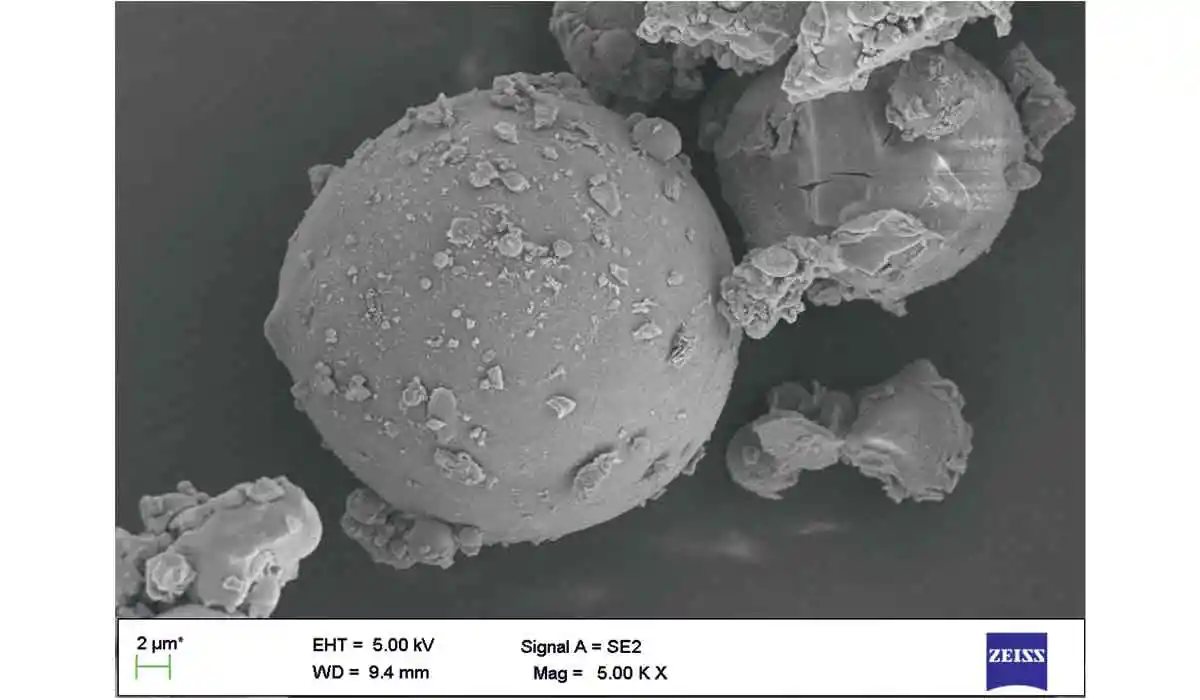

Scanning Electron Microscope image of 8M NaOH brick is as shown in Fig.3 at the age of 28 days. Microstructure shows the presence of some unreacted flyash particles and aluminosilicate gel phases. The unreacted flyash particles were of size less than 2µm. Low molarity of alkaline solution may not have been influenced by all the fly ash available. There is a possibility of activating these particles at higher molarity and develop higher strength.

Figure 3: Scanning Electron Microscope Image of 8M NaOH Brick

Figure 3: Scanning Electron Microscope Image of 8M NaOH Brick

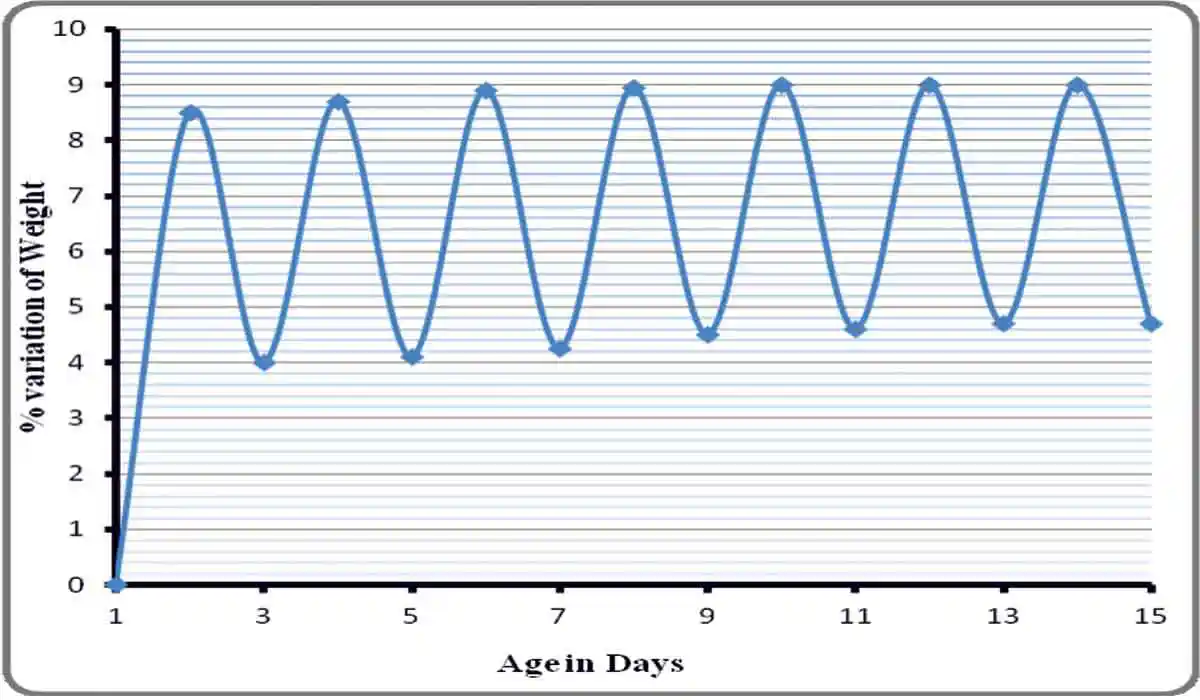

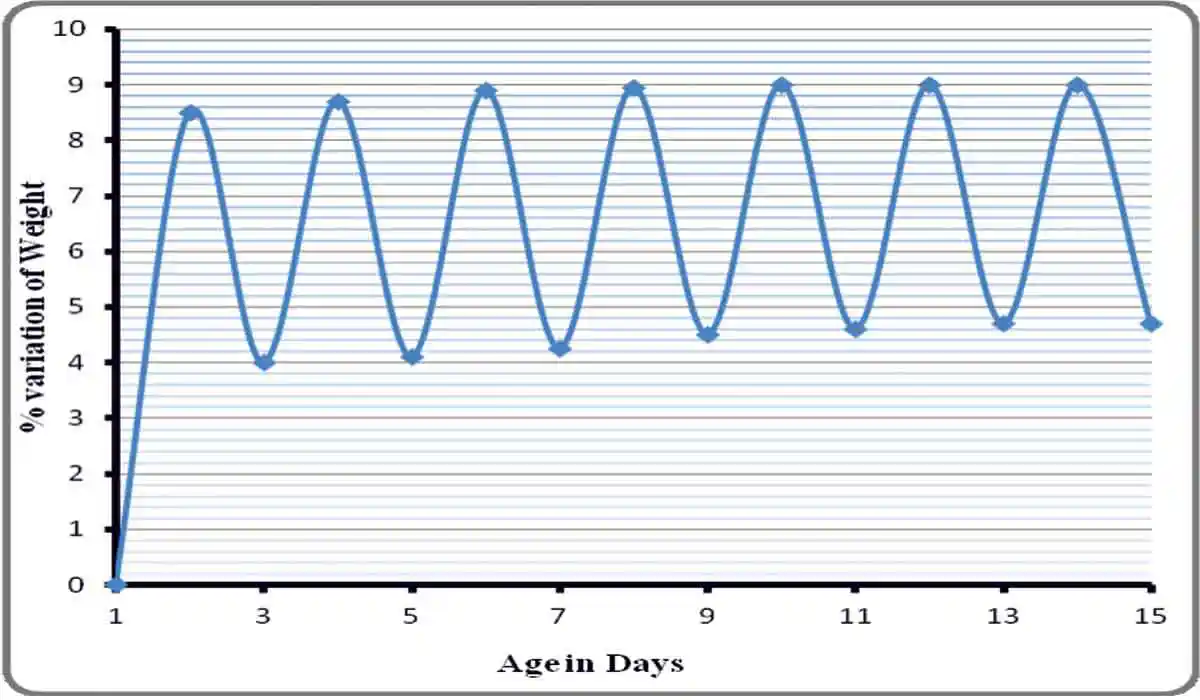

The compressive strength was evaluated after completion of 7 cycles of alternative drying and wetting test. The typical variation in the weight of geopolymer brick are represented in Fig. 4. It was found that percentage weight gain after 7 cycles was 5.20 % and the percentage of reduction in strength of geopolymer brick was 26.66%. These properties are comparatively better than the traditional masonry units [17].

Figure 4: Alternate wetting and drying test on geopolymer brick

Figure 4: Alternate wetting and drying test on geopolymer brick

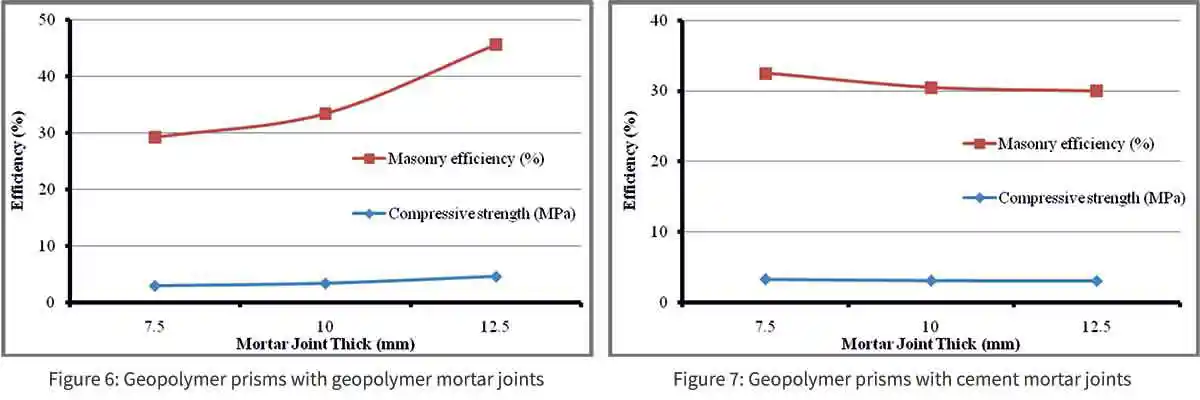

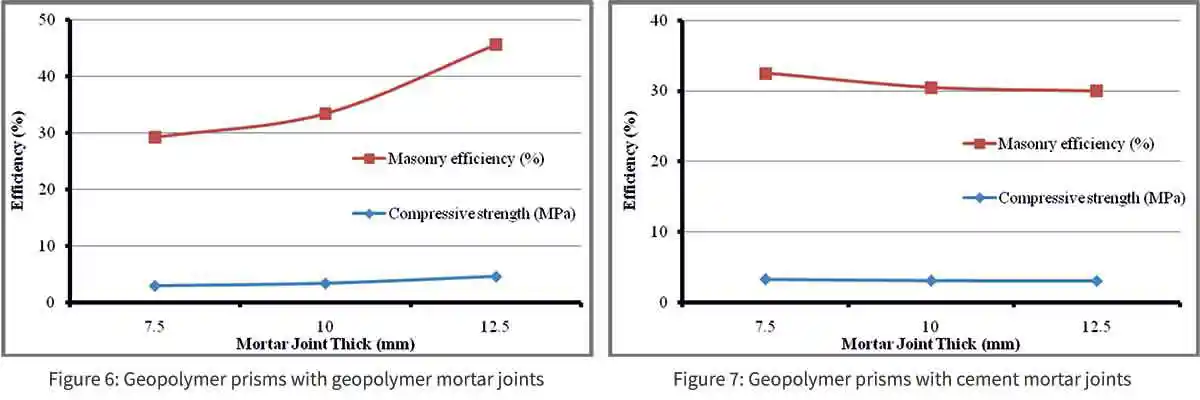

The test setup for the geopolymer masonry prisms are shown in Fig. 5. The variation of compressive strength and masonry efficiency for geopolymer prisms with geopolymer mortar and geopolymer prism and cement mortar is shown in Fig. 6 and 7 respectively.

It was observed that the masonry efficiency and strength were increased with the increase in mortar thickness in geopolymer prisms with geopolymer mortar joints. Whereas, the efficiency and strength increased as the mortar thickness reduces for prisms with cement mortar. The vertical cracks were developed from top of a brick and it propagates till the bottom of the brick in the prism. It was observed that bottom most brick was crushed to considerable extent.

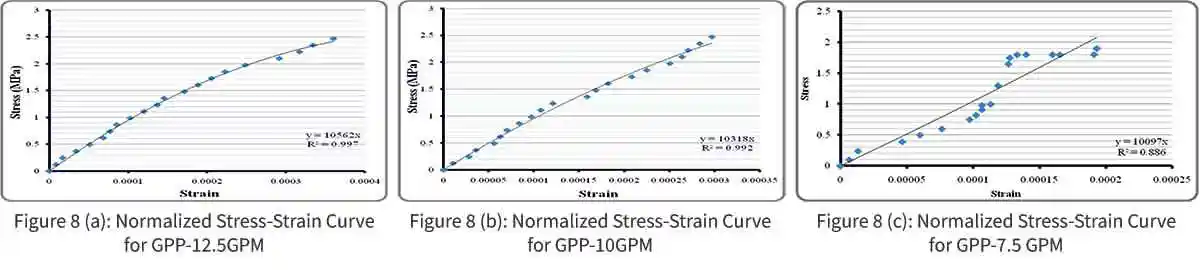

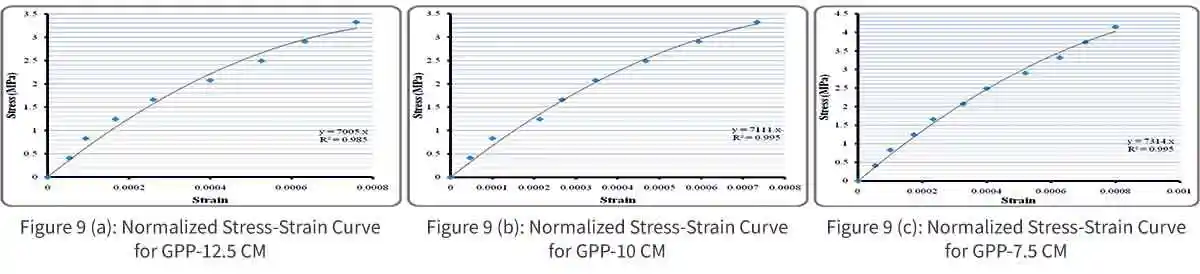

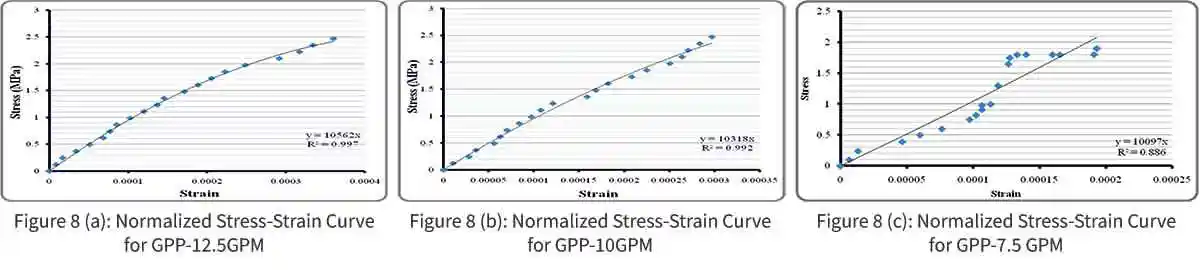

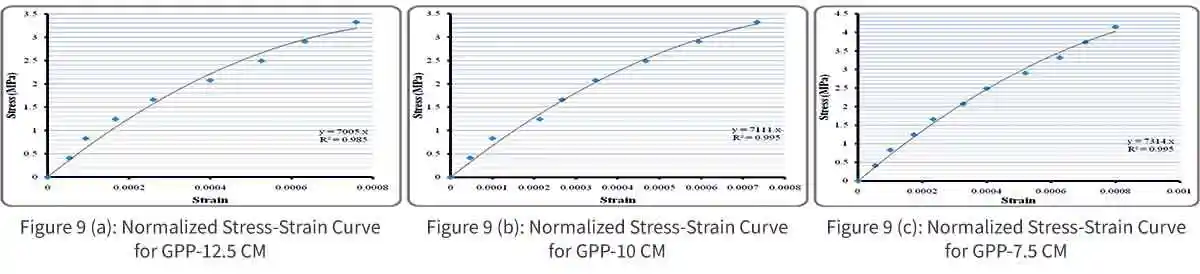

The normalized stress strain curves for the geopolymer masonry prism with geopolymer mortar are shown in Figs. 8 (a), (b) & (c) and the geopolymer prisms with cement mortar joints are shown in Fig. 9 (a), (b) & (c) respectively [18]. It was observed that the young’s modulus increased with the increase in mortar thickness in geopolymer prisms with geopolymer mortar joints. Whereas the young’s modulus increased as the mortar thickness reduces for prisms with cement mortar.

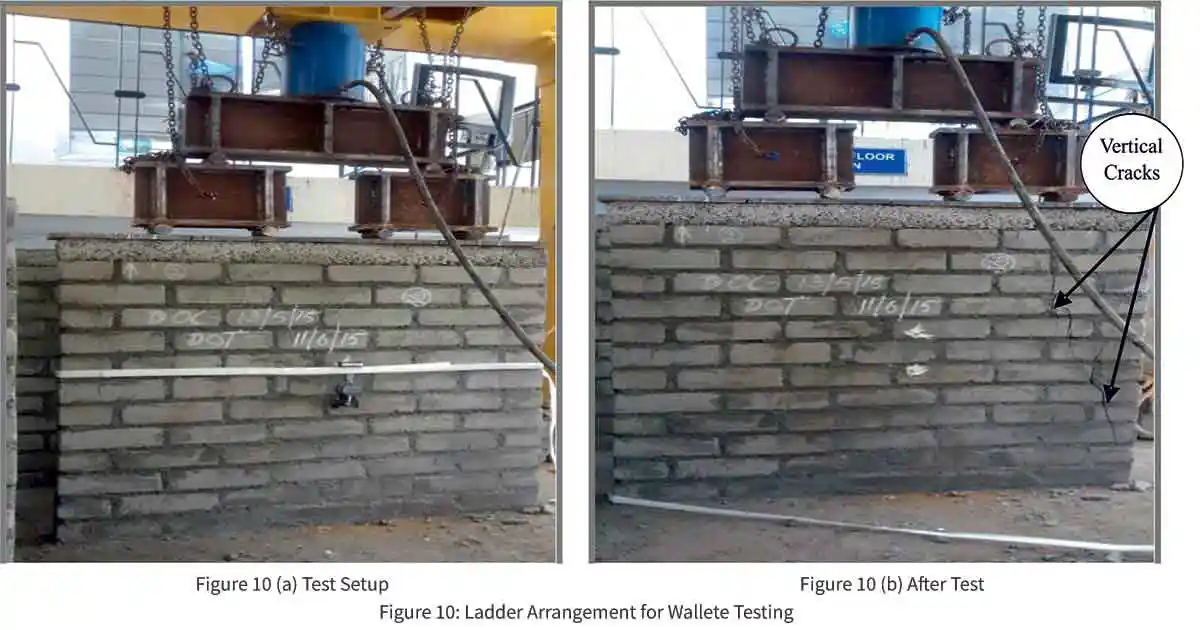

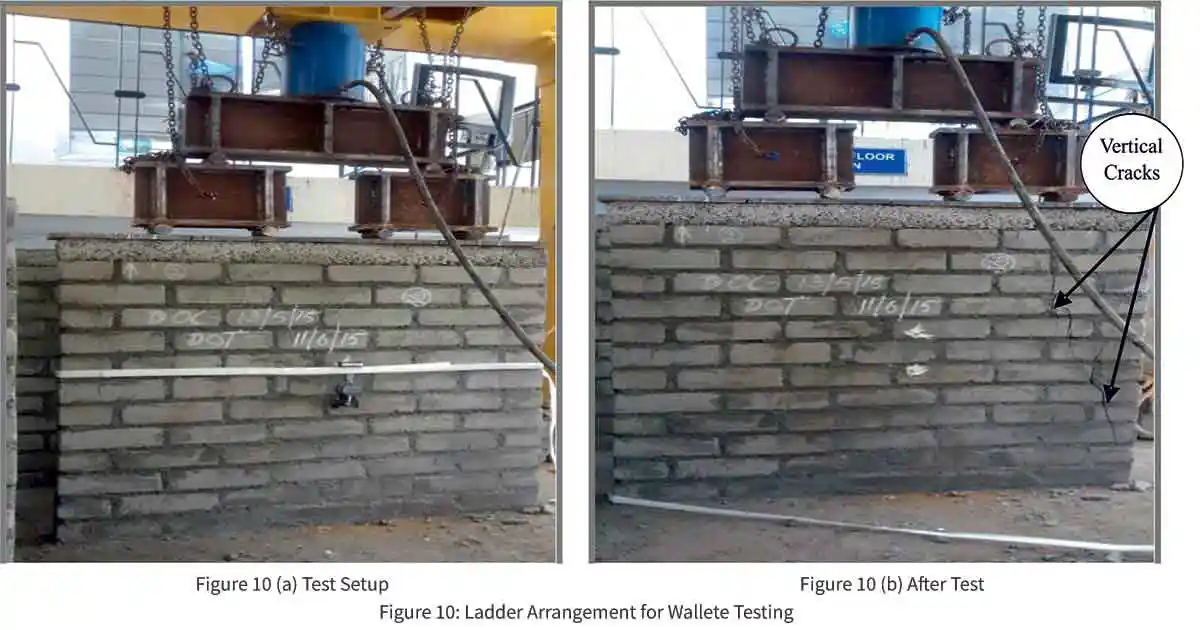

The test setup of geopolymer masonry wallets are shown in Fig 10. It is observed that the average compressive strength of the axially loaded and eccentrically loaded wallets was 1.99 and 1.66 MPa respectively. It is comparatively higher to the conventional block wallets of same geometry [18]. The vertical cracks were developed from top of a wallette and propagated till one third of the height from top of the wallette as shown in Fig. 13(b). This behaviour is in line with any masonry wallet.

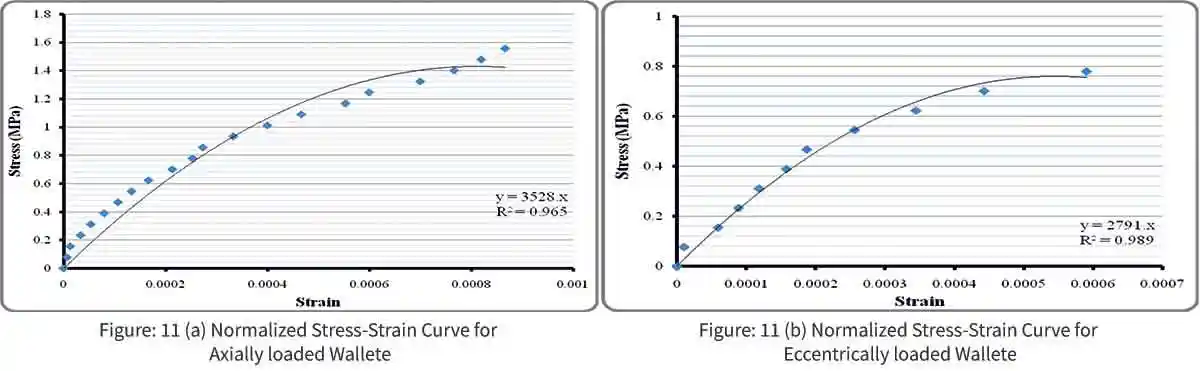

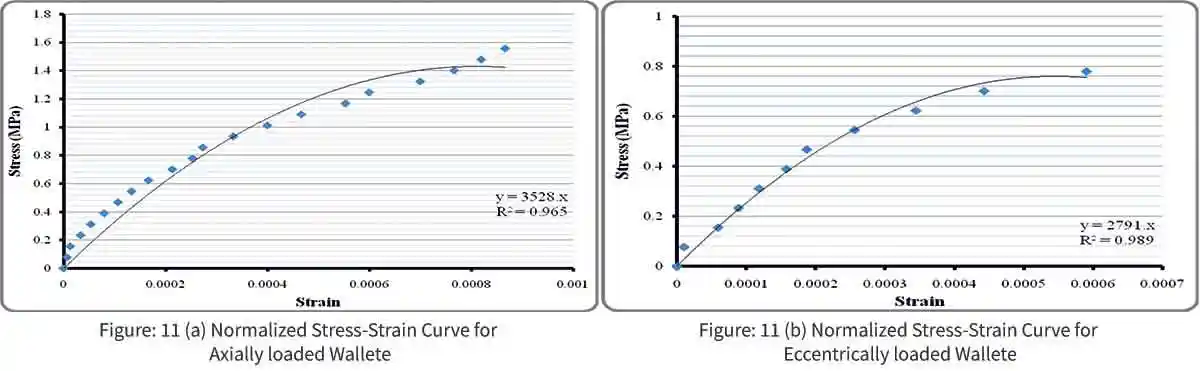

The normalized stress strain curve for the geopolymer masonry walletes with cement mortar are shown in Figs. 11 (a) & (b) and the modulus of elasticity for the axially loaded and eccentrically loaded walletes was found to be 3528 and 2791 MPa respectively.

Following are broad conclusions based on the limited study on geopolymer masonry.

The authors would like to thank the authorities of Jain University-Bangalore for their continuous support and encouragement.

References Prof. Venugopal. K was born on 14th August 1982 in Karnataka state of India. He obtained bachelor degree in Civil Engineering from Visvesvaraya Technological University, India in 2007. He completed ME in Construction Technology during 2009 from Bangalore University, Bangalore, Karnataka. He is presently pursuing his Ph.D in Concrete Technology under Jain university, Bangalore and presently serving as Associate Professor and Head, Department of Civil Engineering at SEA College of Engineering and Technology, Bangalore, India. He has over 08 years of teaching experience in various Civil Engineering subjects. He has published 08+ research papers in various journals/Conferences.

Prof. Venugopal. K was born on 14th August 1982 in Karnataka state of India. He obtained bachelor degree in Civil Engineering from Visvesvaraya Technological University, India in 2007. He completed ME in Construction Technology during 2009 from Bangalore University, Bangalore, Karnataka. He is presently pursuing his Ph.D in Concrete Technology under Jain university, Bangalore and presently serving as Associate Professor and Head, Department of Civil Engineering at SEA College of Engineering and Technology, Bangalore, India. He has over 08 years of teaching experience in various Civil Engineering subjects. He has published 08+ research papers in various journals/Conferences.

He is a life member of Indian Society of Technical Education (LM-101997), Association of Consulting Civil Engineers. (LM-3774L), Indian Concrete Institute. (LM-10472). His areas of interest includes Masonry structures and fly ash composites.

Dr. Radhakrishna is presently Associate professor at R V College of Engineering, Bangalore, India. He has over 25 years of teaching experience in various Civil Engineering Programs. He has published 60+ research papers in various journals/conferences. He is a life member of Indian Concrete Institute, Association of Consulting Civil Engineers (I), Swadeshi Vignana Andolana. He is a reviewer for seven international journals and has guided two Ph.D scholars. Presently he is guiding five Ph.D scholars. His areas of interest is alternative building materials with particular reference to geopolymers, FaL-G and high volume fly ash concrete.

Dr. Radhakrishna is presently Associate professor at R V College of Engineering, Bangalore, India. He has over 25 years of teaching experience in various Civil Engineering Programs. He has published 60+ research papers in various journals/conferences. He is a life member of Indian Concrete Institute, Association of Consulting Civil Engineers (I), Swadeshi Vignana Andolana. He is a reviewer for seven international journals and has guided two Ph.D scholars. Presently he is guiding five Ph.D scholars. His areas of interest is alternative building materials with particular reference to geopolymers, FaL-G and high volume fly ash concrete.

Col. Sasalatti Vinod M was born on 15th July 1963 in Karnataka state of India. He obtained bachelor’s degree in Civil Engineering from Karnataka University, Dharwad, India during 1986 and completed M Tech in Structural Engineering during 1998 from Jawaharlal Nehru University, New Delhi, India. He is presently perusing his Ph.D in Concrete Technology under Visvesvaraya Technological University, Belgaum, India.

Col. Sasalatti Vinod M was born on 15th July 1963 in Karnataka state of India. He obtained bachelor’s degree in Civil Engineering from Karnataka University, Dharwad, India during 1986 and completed M Tech in Structural Engineering during 1998 from Jawaharlal Nehru University, New Delhi, India. He is presently perusing his Ph.D in Concrete Technology under Visvesvaraya Technological University, Belgaum, India.

He is Presently Staff Officer Grade-1 (Design), Headquarter Chief Engineer Jodhpur Zone, Jodhpur, India. He has over 02 years of teaching experience in Civil Engineering Programs and 26 years of military service which includes 06 years “experiences in designing of RCC structures for Defense and 03 years” experience in construction of RCC structures for the Indian Navy. Attended 01 International seminar at Indian Institute of Technology, Chennai, India.

He is life member of Indian Building Congress (ML-6297).His areas of interest are structural engineering and fly ash based geopolymer concrete.

Traditional masonry units are not sustainable and eco friendly due to consumption of fuel or cement. It is essential to find sustainable alternatives. This paper reports about preparation of geopolymer bricks, masonry prisms and wallets using flyash, GGBS and M-sand which were cured in open air. They were tested for compression, water absorption, initial rate of water absorption, dimensionality and modulus of elasticity etc. It was found that the properties of geopolymer bricks were superior to the traditional masonry units. Masonry efficiency increases with the thickness of geopolymer mortar. The compressive strength of axially and eccentrically loaded masonry wallets was found to be 1.9 and 1.6 MPa respectively. Hence, they can be recommended for structural masonry.

Masonry units are the main component of a masonry structure. They fill up the bulk of the space in the structure. They play a major role in the compressive strength of masonry and in resisting the structural loads [1]. There are many types of masonry units, for example, burnt clay bricks, hollow and solid concrete blocks, stabilized mud blocks etc. They are selected based on the consideration of required compressive strength, accessibility, cost and ease of construction [2]. Cement is the chief ingredient for manufacturing concrete blocks. Production of one tonne of cement liberates approximately same amount of carbon-di-oxide to the atmosphere. Cement industries are responsible for 5% of the total CO2 emissions and are subsequently responsible for 4% of the manmade global warming [3]. Due to increase of green house gas emissions, the consumption of cement needs to be reduced. Geopolymer technology is one in which conventional cement can be replaced by products such as fly ash and GGBS. Geopolymer is the term coined by professor Joseph Davidovits for the family of high alkali (K-Ca)-poly-(Sialate-siloxo) binders formed in a reaction called as geopolymerization resulting in 3 dimensional zeolitic frameworks [4]. Geopolymers are the family of binders formed using alkaline solutions and alumino silicates like fly ash, Ground granulated blast furnace slag (GGBS), resulting in three dimensional aluminosilicate polymeric gel. Geopolymers are environment-friendly as they make use of industrial by-products and eliminate the use of conventional cement.

Radhakrishna has reported that, it is also possible to manufacture geopolymer masonry units using class F fly ash by open curing [5-9]. Kunal et al. have reported that the extent of alkali silica reaction in flyash based geopolymers is relatively less than that of conventional concrete [10].

Other researchers have studied the optimum dosage of flyash and concluded that the bricks attained the highest compressive strength when 20% of clay was replaced by flyash [11-14]. It is reported that the bricks were porous, light weight, had low thermal conductivity and satisfactory compressive strength [15]. Anastasias et al reported the masonry prisms exhibited 10 times more strength than the mortar [16-18].

Though there is considerable research reported on brick and block masonry, the production of these masonry units is not sustainable. Hence there is a need to develop alternative masonry units, one of which can be geopolymer unit. This paper addresses the technology of making geopolymer units, prisms and wallets.

Objectives of the Research

- To determine the properties of geopolymer masonry units.

- To evaluate the properties of geopolymer masonry prisms.

- To determine the properties of the geopolymer masonry wallets.

The following materials were used to prepare geopolymer masonry bricks:

- Class F Fly ash and Ground granulated blast furnace slag (GGBS),

- Manufactured sand of zone II having specific gravity of 2.55.

- Recycled water

- Commercially available Sodium hydroxide and Sodium silicate.

Results and Discussion

The results of water absorption test and density of the bricks are shown in Table 1. It was found that the water absorption of the masonry units was 8.25% which is considerably less compared to the conventional bricks [17]. The density of the masonry units ranges from 1800 to 2000 kg/m3 which are at par with the traditional masonry units. IRA of geopolymer bricks at 28 days was found to be less than 5% which indicates that the masonry mortar will have good water retentivity [17]. These properties are much less than the value specified in IS 2185: 2005.

| Table 1: Water absorption and dry density tests for bricks. | |||

| Series | Water Absorption [ % ] |

Initial Rate of water absorption IRA [Kg/m2/min] | Average Dry Density [kg/m3] |

| Geopolymer Brick | 8.5 | 3.0 | 1800 |

| IS 2185:2005 | < 20 | < 5.0 | 1800 to 2000 |

The dimensionality test of the masonry units was conducted as per IS 1077:1992. The test results are shown in Table 2. It was found that the variations (dimensions) of the bricks are within the permissible of codal provisions.

| Table 2: Dimensionality tests of Bricks. | ||||||

| Number of block in each type : 20 no’s | ||||||

| Type of block | Over all dimensions measured along | Size of the Brick (mm) | Dimensions (mm) | Average Dimensions (mm) | Variation in dimension (mm) | Codal Provision IS 1077:1992 |

| Geopolymer Brick | Length (L) | 225 | 4557 | 227.85 | +2.85 | +5 |

| Breadth (W) | 107 | 2155 | 107.75 | +0.75 | +3 | |

| Height (H) | 75 | 1510 | 75.50 | +0.50 | +3 | |

Figure 1: Compressive strength of Geopolymer bricks with age

Figure 1: Compressive strength of Geopolymer bricks with ageThe variation of stress and strain for geopolymer brick is indicated in Fig 2. The modulus of elasticity of geopolymer masonry brick was found to be 9394 MPa at the age of 28 days. This is superior compared to traditional burnt brick [17].

Figure 2: Normalized stress strain curve for Brick

Figure 2: Normalized stress strain curve for BrickScanning Electron Microscope image of 8M NaOH brick is as shown in Fig.3 at the age of 28 days. Microstructure shows the presence of some unreacted flyash particles and aluminosilicate gel phases. The unreacted flyash particles were of size less than 2µm. Low molarity of alkaline solution may not have been influenced by all the fly ash available. There is a possibility of activating these particles at higher molarity and develop higher strength.

Figure 3: Scanning Electron Microscope Image of 8M NaOH Brick

Figure 3: Scanning Electron Microscope Image of 8M NaOH BrickThe compressive strength was evaluated after completion of 7 cycles of alternative drying and wetting test. The typical variation in the weight of geopolymer brick are represented in Fig. 4. It was found that percentage weight gain after 7 cycles was 5.20 % and the percentage of reduction in strength of geopolymer brick was 26.66%. These properties are comparatively better than the traditional masonry units [17].

Figure 4: Alternate wetting and drying test on geopolymer brick

Figure 4: Alternate wetting and drying test on geopolymer brickThe test setup for the geopolymer masonry prisms are shown in Fig. 5. The variation of compressive strength and masonry efficiency for geopolymer prisms with geopolymer mortar and geopolymer prism and cement mortar is shown in Fig. 6 and 7 respectively.

It was observed that the masonry efficiency and strength were increased with the increase in mortar thickness in geopolymer prisms with geopolymer mortar joints. Whereas, the efficiency and strength increased as the mortar thickness reduces for prisms with cement mortar. The vertical cracks were developed from top of a brick and it propagates till the bottom of the brick in the prism. It was observed that bottom most brick was crushed to considerable extent.

The normalized stress strain curves for the geopolymer masonry prism with geopolymer mortar are shown in Figs. 8 (a), (b) & (c) and the geopolymer prisms with cement mortar joints are shown in Fig. 9 (a), (b) & (c) respectively [18]. It was observed that the young’s modulus increased with the increase in mortar thickness in geopolymer prisms with geopolymer mortar joints. Whereas the young’s modulus increased as the mortar thickness reduces for prisms with cement mortar.

The test setup of geopolymer masonry wallets are shown in Fig 10. It is observed that the average compressive strength of the axially loaded and eccentrically loaded wallets was 1.99 and 1.66 MPa respectively. It is comparatively higher to the conventional block wallets of same geometry [18]. The vertical cracks were developed from top of a wallette and propagated till one third of the height from top of the wallette as shown in Fig. 13(b). This behaviour is in line with any masonry wallet.

The normalized stress strain curve for the geopolymer masonry walletes with cement mortar are shown in Figs. 11 (a) & (b) and the modulus of elasticity for the axially loaded and eccentrically loaded walletes was found to be 3528 and 2791 MPa respectively.

Following are broad conclusions based on the limited study on geopolymer masonry.

- The compressive strength of geopolymer brick attains more than 5MPa within 24 hours which influences the user to handle without any issues.

- The water absorption, initial rate of water absorption, dimensionality, alternative drying and wetting method and modulus of elastic of the units were well within the limits prescribed in the relevant codal provision.

- Geopolymer mortar can be used as mortar in building masonry structures as it exhibits better compressive strength than cement mortar. Its compressive strength was higher than that specified in IS 2250-1981.

- The use of geopolymer bricks and cement mortar joints have a great influence in the preparation of masonry units.

- The performance of the axial and eccentrically loaded wallette was found to be superior compared to the conventional cement brick masonry. They satisfy the requirements of IS 2185:2008 (part 4)

The authors would like to thank the authorities of Jain University-Bangalore for their continuous support and encouragement.

References

- Anita Fódi and István Bódi (2011) Basics of reinforced masonry, Concrete structures, 3(1), pp 69-77

- Robert G. Drysdale and Ahmad A. Hamid (2008) “Masonry structures behavior and design,” Third edition, Mcmaster University, Hamilton, Ontario.

- “Climate change and the cement industry” (2002) GCL-Environmental special issue.

- Joseph Davidovits (1994) “Properties of geopolymer cements,” Proceedings of Kiev state technical university conference, Ukraine, pp 131-149.

- Radhakrishna, Shashishankar A., Udayashankar.B.C and Renuka Devi. M.V. (2010) “Compressive Strength Assessment of Geopolymer Composites by a Phenomenological Model,” Journal of Reinforced Plastics and Composites, 4 Vol. 29, No. 6 pp 840-852.

- Radhakrishna (2008) “A Phenomenological Model To Re-Proportion Geopolymer Compressed Blocks,” Concrete Technology Today, Oct, vol 7 No. 3 pp. 46-48.

- Radhakrishna, Renuka Devi. M.V. and Udayashankar. B.C. (2009) “Use of fly ash in Construction Industry for sustainable development,” Journal of Environmental Research and Development, volume 03, pp1211-1221.

- Radhakrishna, Shashishankar A. and Udayashankar.B.C (2008) “Analysis and Assessment of Strength Development in Class F Fly Ash Based Compressed Geopolymer Blocks,” Indian Concrete Journal, Vol 82, No.8.pp.31-37.

- Radhakrishna, Manjunath GS., C Giridhar and Mahesh Jadav (2011) “Strength Development in Geopolymer pastes and Mortars,” International Journal of Earth Sciences, ISSN 0974-5904, Volume 04, No 06 SPL, pp. 830-834.

- Kunal Kupwade-Patil and Erez N. Allouche (2013) “Impact of alkali silica reaction on flyash based geopolymer concrete,” Journal of materials in civil engineering, 25(1), pp 131-139.

- Paki Turgut (2010) “Masonry composite material made of limestone powder and flyash,” Powder technology 204, pp 44-47.

- Xu Lingling, Guo Wei, Wang Tao, Yang Nanru (2005) “Study on fired bricks with replacing clay by flyash in high volume ratios,” Construction and building materials 19, pp 243-247.

- Chou MI, Chou SF, Patel V, Pickering MD, Stucki JW (2006) “Manufacturing fired bricks with class F fly ash from Illinois basin coals,” Combustion byproduct recycling consortium. Project number 02-CBRC-M12.

- Kute S, Deodhar SV (2003) “Effect of fly ash and temperature on properties of burnt Clay bricks,” Journals of civil engineering, pp 82–85.

- Mucahit Sutku and Sedat Akkurt (2009) “The use of recycled paper processing residues in making porous brick with reduced thermal conductivity,” Ceramics journal, 35(7), pp 2625-2631.

- Anastasios Drougkas, Pere Roka, Clement Molins (2015) “Compressive strength and elasticity of pure lime mortar masonry,” Journal of materials and structures.

- G. Sarangapani, B. V. Venkatarama Reddy and K. S. Jagadish (2002) “Structural characteristics of bricks, mortars and masonry,” Journal of Structural Engineering. No.29-11, pp. 101-107.

- G. Sarangapani, B.V.Venkatarama Reddy and K.S.Jagadish (2005) “Brick-Mortar Bond and Masonry Compressive Strength,” Journal of Materials in Civil Engineering. Vol.17, No.2, pp. 229–237.

He is a life member of Indian Society of Technical Education (LM-101997), Association of Consulting Civil Engineers. (LM-3774L), Indian Concrete Institute. (LM-10472). His areas of interest includes Masonry structures and fly ash composites.

He is Presently Staff Officer Grade-1 (Design), Headquarter Chief Engineer Jodhpur Zone, Jodhpur, India. He has over 02 years of teaching experience in Civil Engineering Programs and 26 years of military service which includes 06 years “experiences in designing of RCC structures for Defense and 03 years” experience in construction of RCC structures for the Indian Navy. Attended 01 International seminar at Indian Institute of Technology, Chennai, India.

He is life member of Indian Building Congress (ML-6297).His areas of interest are structural engineering and fly ash based geopolymer concrete.

NBM&CW December 2020