Buildtech: Pragmatic Approach to the Methodology of Retrofitting Buildings

Supradip Das, Buildtech Products India Pvt. Ltd.

With the increase in construction of buildings in the last two decades, it has been observed that many of the structures are already showing signs of distress. In some cases, repair measures become necessary even within a span of 5 to 10 years of completion of structure. This may happen due to factors like bad quality concreting materials, poor workmanship, lack of maintenance, atmospheric effects, abuses, accidents or natural calamities.

Retrofitting of a concrete structure becomes necessary to extend its life. The rehabilitation envisages restoration of structural system as close as possible to the original. The distressed structure needs to be brought in line, level, and the required strength so that it can be put into service without endangering its safety and utility.

Looking to the magnitude and complexity of work involved in restoration, the requirement for various technologies and materials is going to take a giant leap in years to come. The concept of retrofitting & rehabilitation has also been accepted as one of the important disciplines of the construction industry.

The article presents one such case study of a cluster of buildings in Delhi where concrete had deteriorated due to poor concreting practice, quality and lack of maintenance, and its repairing solutions.

Broad Features

Based on the study of critically affected buildings, corrosion of reinforcement has been the prime cause for deterioration of RCC members. The corrosion occurred mainly due to leakage/overflow of water from a service water tank and leakages from the roof into the porous concrete. Severe distress was also due to lack of concreting knowledge, ignorance of the resultant effects and maintenance.

Most of the residential buildings in the area under MES showed the following distress: Frame 1: Distressed water tanks, balcony roof, and roof

Frame 1: Distressed water tanks, balcony roof, and roof

In some of the roofs, the cover was not adequate to protect the reinforcement. Frame 2: Photographs of critically effected buildings

Frame 2: Photographs of critically effected buildings

Chemical Kinetics

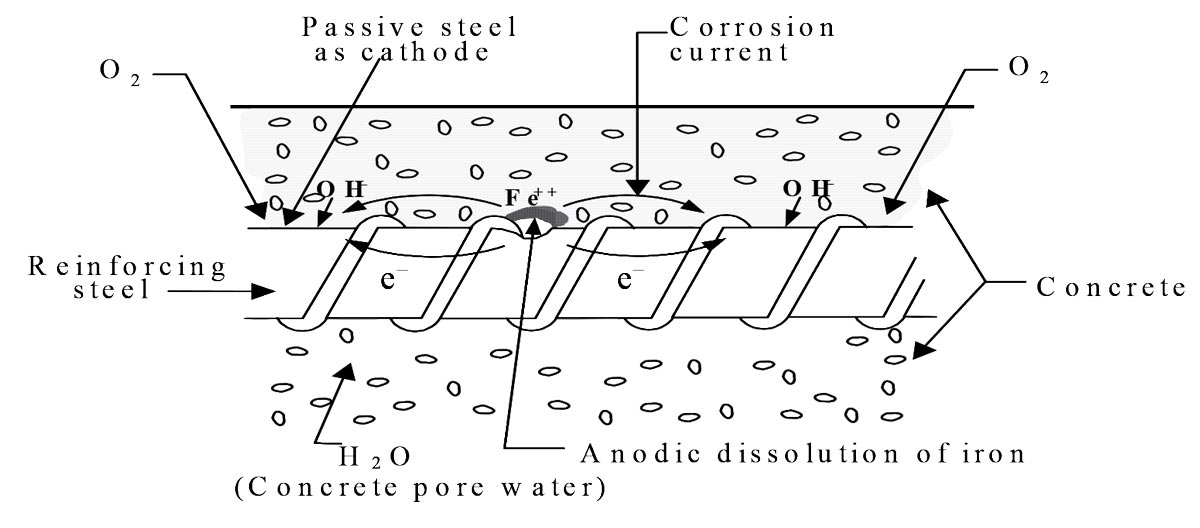

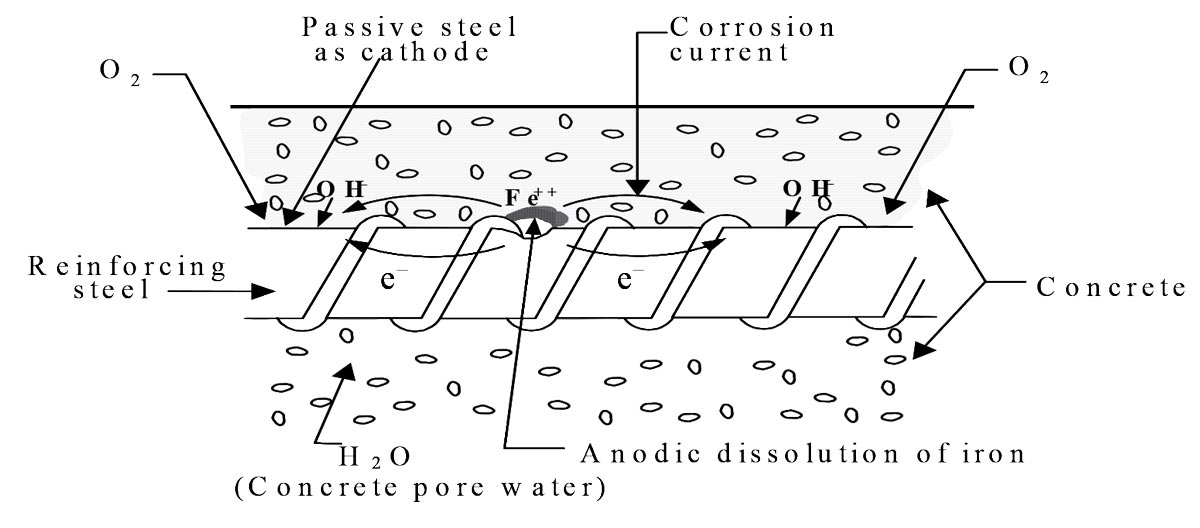

Most of the distress was related to severe corrosion in the reinforcement. The corrosion reaction i.e. localised breakdown of the passive film (cathode) on steel, mainly starts from the ingress of moisture, penetration of chloride and carbon dioxide through porous concrete. Corrosion of steel in concrete is an electrochemical process, which takes place as a result of the formation of a corrosion cell. (Frame 3).

Frame 3 :Corrosion cell

Frame 3 :Corrosion cell

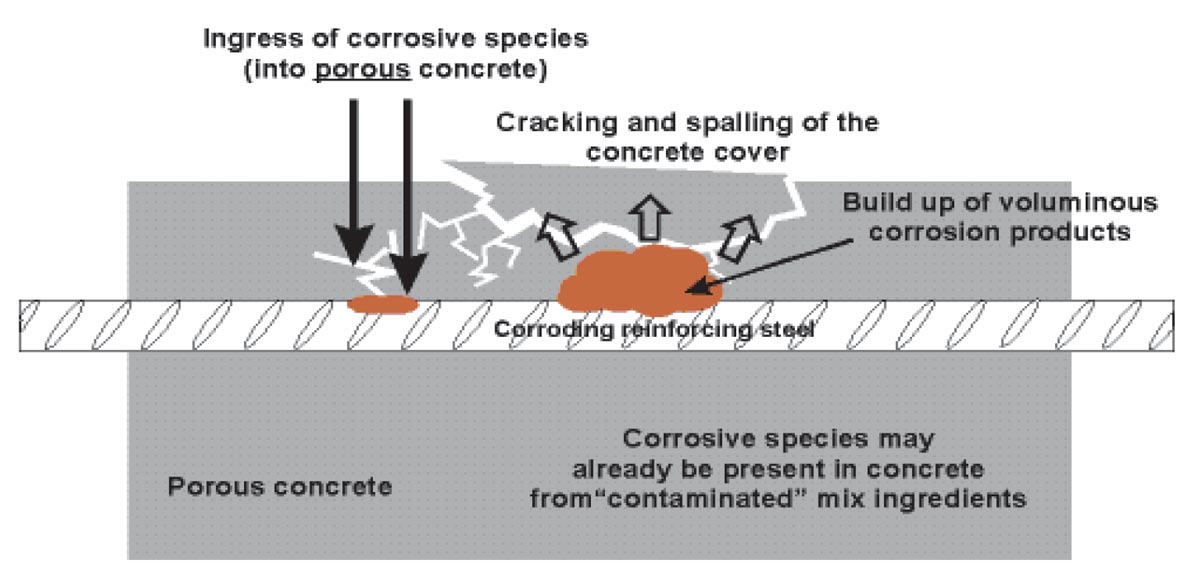

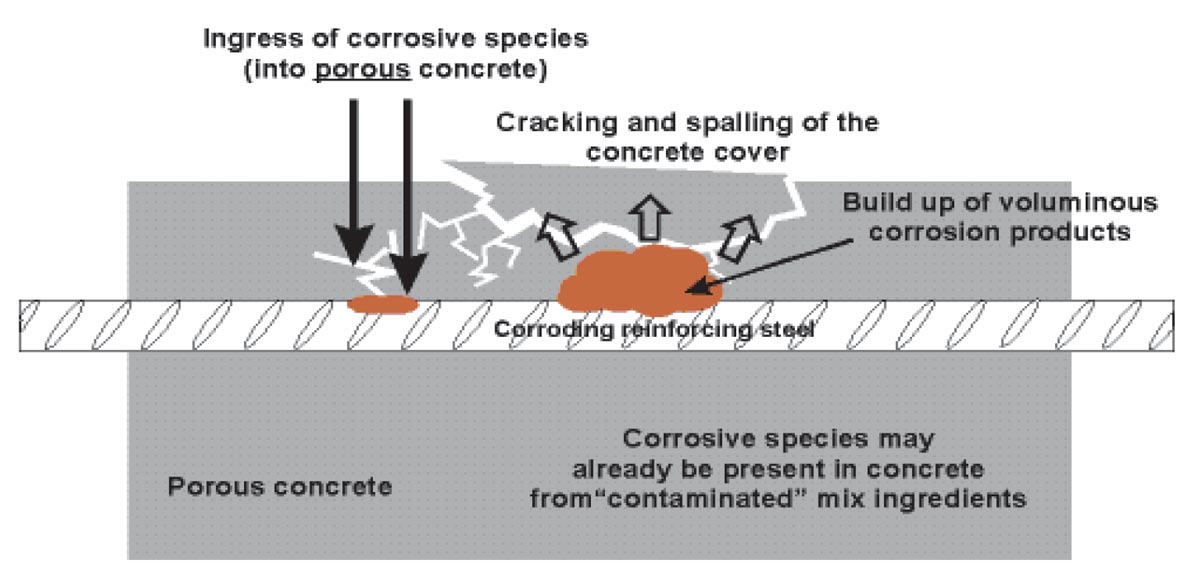

Mechanism of corrosion (Frame 4) shows the anodic reactions where metallic iron (Fe) transformed to rust (Fe2O3). The rust formation on the surface of reinforcement is accompanied by an increase in volume, maybe as large as 6 times the volume of Fe. Sound concrete with pH between 11.5 and 13.5 is an ideal environment for protection of steel, but as stated above, alkalinity can be lost due to the formation of alkali carbonates, sulphates & chlorides, and also due to anodic reaction in the presence of moisture. The anodic reaction can be explained from the following chemical reaction:

3Fe + 4H2O → Fe3O4 + 8H+ + 8e-

2Fe + 3H2O → Fe2O3 + 6H+ + 6e

Frame 4: Mechanism of corrosion

Frame 4: Mechanism of corrosion

In other words, if the carbonated front penetrates sufficiently into the concrete to intersect with the concrete reinforcement interface, protection is lost and since both oxygen and moisture are present, the steel is likely to corrode. The extent of the advance of the carbonation front depends to a considerable extent on the porosity and permeability of the concrete and on the conditions of the exposure. In the case of carbonation, atmospheric carbon dioxide (CO2) reacts with pore water alkali, according to the generalized reaction.

Ca(OH)2 + CO2 → CaCO3 + H2O

It consumes alkalinity and reduces pore water pH to the 8–9 range, where steel is no longer passive.

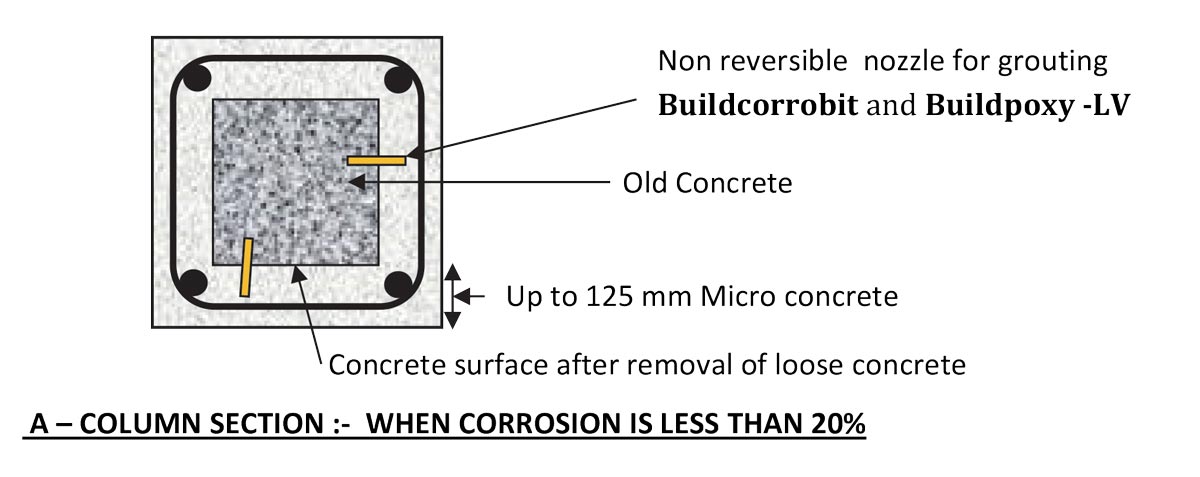

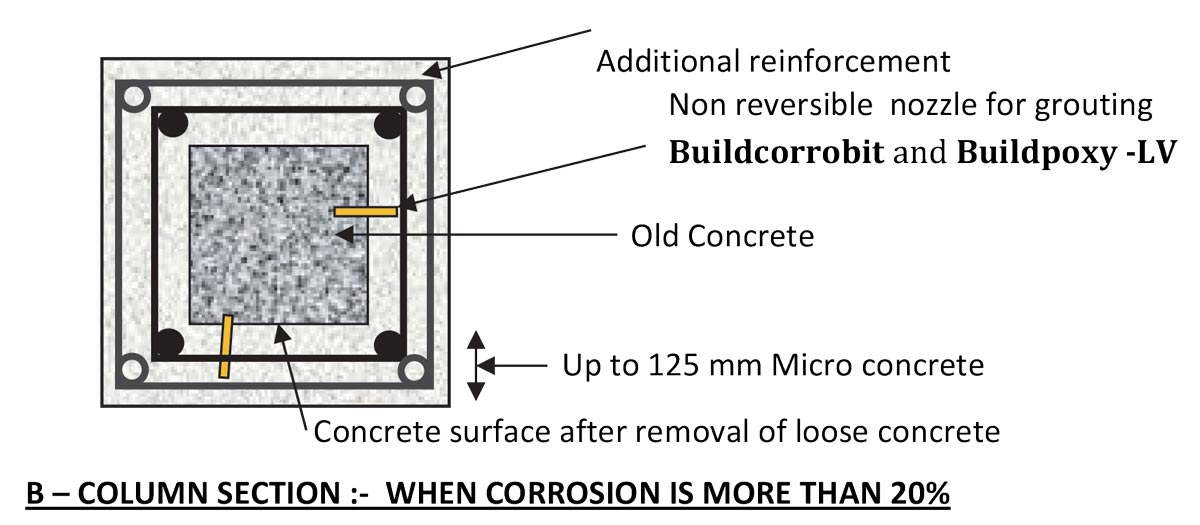

Frame 5: Extent of corrosion and addition of steel

Frame 5: Extent of corrosion and addition of steel

Repairing Method

Since repair & rehabilitation of a structure expects to set right the damaged areas, it is therefore obvious that repairs need assured inputs of right material, quality workmanship, and the proper system or specification to be adopted in a phased manner. In this case, a complete retrofitting plan of constructional defects was chalked out, based on the investigation. Main treatments were required for strengthening the structure, arrest of the corrosion, cover protection and consolidation of the concrete. Since no adequate treatment was carried out for the water tightness during the construction and its maintenance afterwards, special emphasis was given on the consolidation of the concrete. Among various techniques and newer material available for restoration of distressed concrete structures, it was proposed to use cementitious repairing material for cover & low viscous epoxy as grouting material for consolidation, purely because of the structural and thermal compatibility and similar physical properties to those of the parent concrete.

Since each material has its own characteristics, it requires very careful study for selecting the right material for a particular application. While selecting a system one should be careful to evaluate whether it meets all the requirements such as placing problem, strength development & durability. For any repair & rehabilitation job, it is always better to take the manufacturer into confidence on the various characteristics of the material & its suitability for that particular type of job. Based on the investigation & type of building, a detailed system for treatment was chalked out. It included type of material, tools to be used, work schedule & rehabilitation design. The repair was carried out under strict supervision of quality control experts.

Material used for Retrofitting

During the rectification process, a large number of materials starting from corrosion inhibitor to micro-concrete were used at different stages. The selection of material does contribute to the performance of the repairing system in the long term. It has been observed in many cases, that the compatibility of various chemicals with cement depends on the physio-mechanical behavior of the system & plays an important role in the performance. In this case, products from Buildtech Products were used as follows:

Pre-treatment guidelines were chalked out prior to commencement of treatment. This was done to ensure the safety of the structure & also to make proper working conditions:

Surface preparation of concrete

Reinforcement was exposed by removing all loose and honeycombed concrete. All the spalling was removed. The concrete was chipped off to a minimum depth of 25mm behind the reinforcement. This was required to treat the corroded reinforcement. Concrete surface & reinforcement were washed with water jet to remove all soluble & insoluble salt such as chlorides present as indicated in the report.

Surface preparation of reinforcement

Removal of the rust from reinforcement completely by rubbing with wire brush or emery paper. Proper cleaning of the existing exposed reinforcement with BUILDKLENE – Rust Converter. This de-rusting compound starts reacting within few minutes after application and converts the rust into a non-metallic complex compound of black colour. It forms a non-porous, impermeable and moister repelling coating of good mechanical stability. It shall be applied liberally by brush till such time it penetrates through the rust layer. Though the reaction starts within few minutes, it generally takes 6 hours to complete the same. However, next activity should start only after 24 hours.

Provision of additional reinforcement

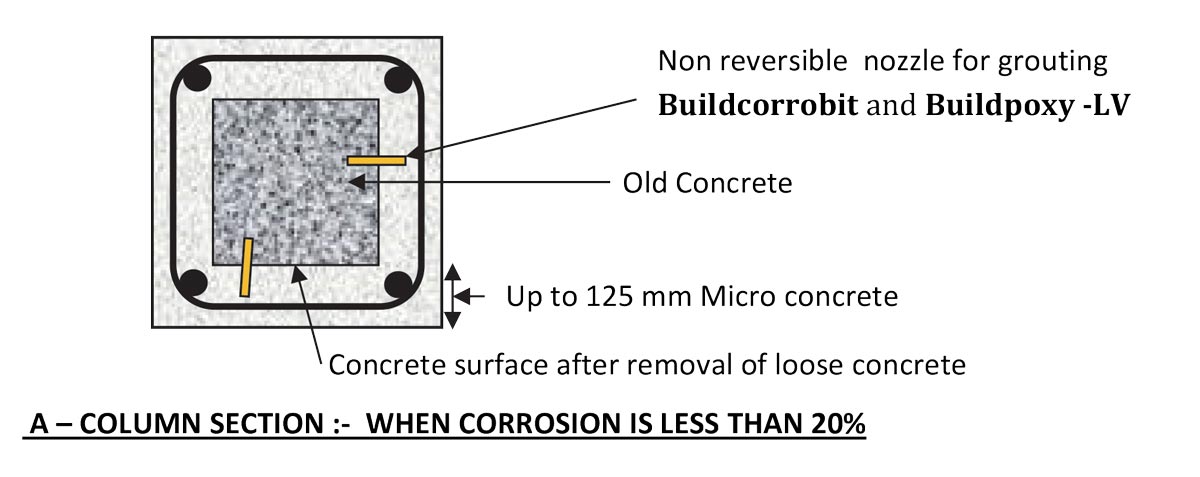

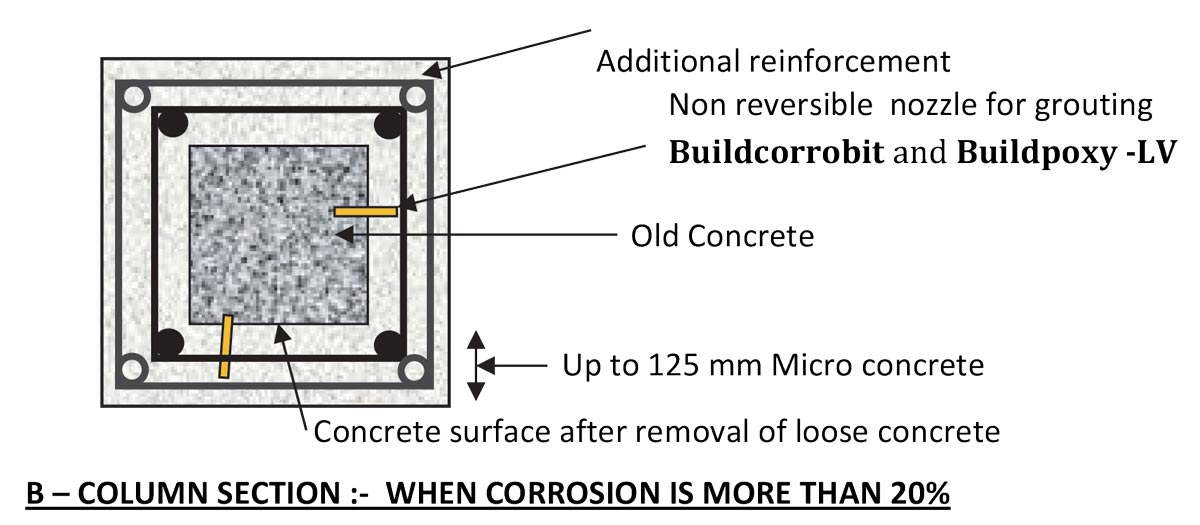

In case of severe corrosion (diameter of reinforcement bar is reduced substantially - say more than 20%), the affected bars were anchored with equivalent additional reinforcement by wilding. This was done in consultation with the structural engineer at site. (Frame 5b).

Application of corrosion inhibitor

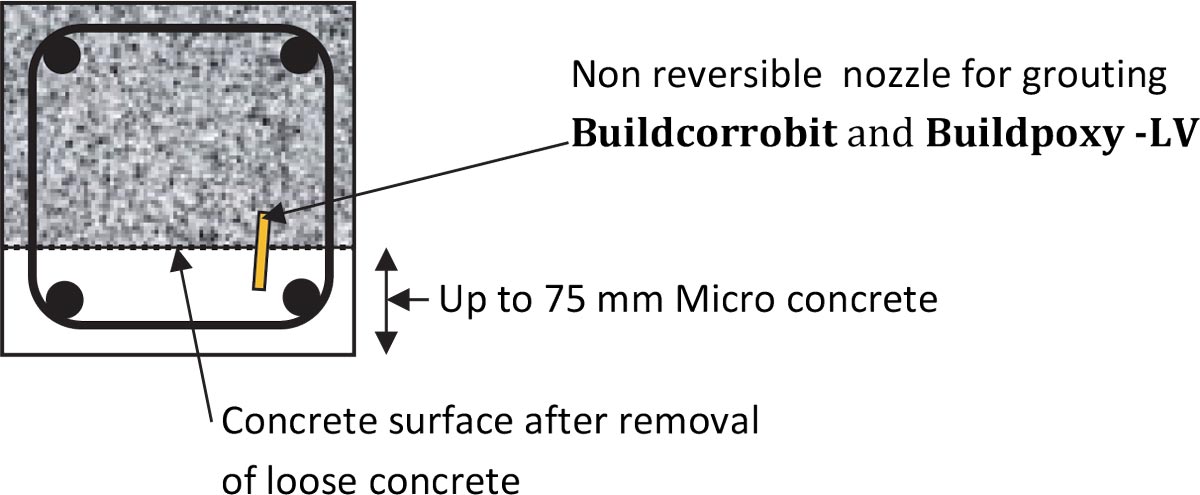

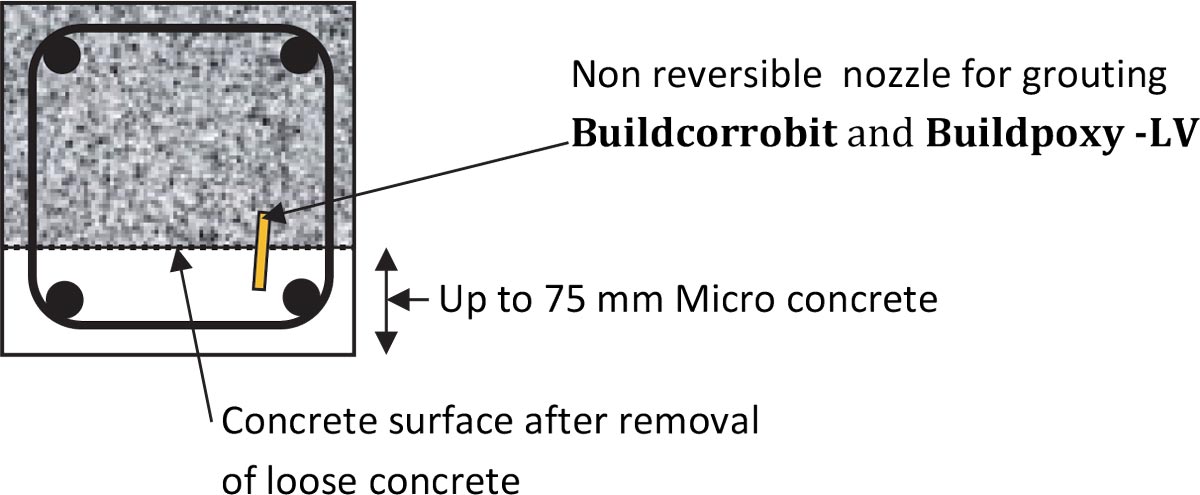

The concrete was porous. Due to the ingress of acidic water, the pH value of the concrete slowly got reduced. In many areas, the pH was observed to be below 10 when concrete tends to be acidic & accelerates the process of corrosion (refer Frame 4). This was taken care of by injecting BUILDCORROBIT through non-reversible nozzle into the concrete. With this process, pH of the concrete tends to increase to a safer level of 12.5 & 13. The process involved drilling of holes at a grid pattern on the concrete, and non-reversible nozzles were fixed using fast setting cementitious compound. In case of very poor concrete, the nozzles were fixed after the strengthening of the structure. (Frame 6).

Frame 6: Injection of Buildcorrobit through non-reversible pump

Frame 6: Injection of Buildcorrobit through non-reversible pump

Treatment of Reinforcement

New & old reinforcement were treated with BUILDCOTE ZP - zinc rich epoxy . This anti-corrosive epoxy coating acts as a barrier and also stops propagation. The coating was applied in a manner such that the dry film thickness was around 60 microns.

Pressure grouting

For consolidation of weak concrete & strengthening the pressure grouting was carried out through the non-returnable nozzles of 6 to 12 mm dia. at a spacing of 400-500 mm c/c in zigzag pattern by drilling operation. During drilling & fixing of nozzles, precaution should be taken that damage to the concrete is minimal. Minimum depths of nozzle should be 40 to 50 mm. Firstly, BUILDCORROBIT is to be injected, and subsequently, low viscous epoxy BUILDPOXY – LV is to be injected into the concrete at a pressure of 2 to 3 kg/cm2. Once the grouting is over, the nozzles are to be removed. Pressure grouting operation is to be carried out before polymer cement mortar plaster (cover concrete) and plaster.

Provision of bonding agent

Prior to the application of Cover mortar plaster/micro concrete, the existing surface was treated with a coat of epoxy based bonding agent BUILDBOND to bond old to new concrete. Bonding agent was applied on the surface of old concrete after removing all loose concrete & some hacking was done on it. This epoxy bond coat also acts as a barrier preventing entry of chlorides and other harmful agents.

Jacketing & strengthening of columns using Micro Concrete

In case of severe damages, 50 mm or thickness or as per site requirement, micro-concrete to be used for jacketing the columns. BUILDMICROKRIT cementitious non-shrink free flow high strength micro concrete with ultimate compressive strength of 650kg/cm2 was used. In some cases, it was substituted with maximum of 25% of 4.75 mm downgraded aggregates. The proportion of the mix in many areas varied between 10 to 25% based on the site conditions. This was done as per the manufacturer’s instructions in the product data sheet. For bulk pouring, mechanical mixer too be used or can be mixed manually for smaller requirements. Water / Powder ratio to be adjusted between 0.14 & 0.18 depending on the site condition. Physical properties of Micro-Concrete used is given in Table 1.

Repair to columns

The first step was undertaken by repairing the column starting from the ground floor. Repair to columns was undertaken one by one. The most distressed column in the structure was taken first. The repair process was as follows:

Cover/Finished Plaster

Cover/Finished Plaster

20mm thick cement mortar plaster admixed with BUILDCRETE provided on the micro-concrete for finishing.

Curing

All the treated areas like columns to be cured using BUILDCURE curing compound & other areas to be cured with conventional systems.

Protective Coating

After the curing, the treated surface is to be provided with a polyurethane based clear coating BUILDCOTE (PUR). Dry film thickness of around 100micron. This coating will protect the concrete from aggressive attack & will make the repaired surface durable for a considerable period of time.

Frame 7 : Jacketing of columns for micro-concrete

Frame 7 : Jacketing of columns for micro-concrete

Conclusion

Frame 8: Fixing of nozzles after filling up with micro-concrete

The repair rehabilitation measure suggested in the report was initially executed in one of the buildings in Delhi Cantt. It has been periodically inspected since the last three years & on the basis of the performance, MES–Delhi zone has specially included the above methodology in their BOQs for other structures. It is always required to study the behaviour of the restored structure and in the present case also the same assessment pattern was undertaken to check whether the affected structural elements were properly repaired or not. The performance of the rehabilitation measure was satisfactory. Some of the photographs are shown below.

Frame 8: Fixing of nozzles after filling up with micro-concrete

The repair rehabilitation measure suggested in the report was initially executed in one of the buildings in Delhi Cantt. It has been periodically inspected since the last three years & on the basis of the performance, MES–Delhi zone has specially included the above methodology in their BOQs for other structures. It is always required to study the behaviour of the restored structure and in the present case also the same assessment pattern was undertaken to check whether the affected structural elements were properly repaired or not. The performance of the rehabilitation measure was satisfactory. Some of the photographs are shown below.

Frame 8: P-61 Building at Stn Workshop before treatment

Frame 8: P-61 Building at Stn Workshop before treatment

Frame 9: Station Workshop during treatment and after treatment

Frame 9: Station Workshop during treatment and after treatment

Bibliography

With the increase in construction of buildings in the last two decades, it has been observed that many of the structures are already showing signs of distress. In some cases, repair measures become necessary even within a span of 5 to 10 years of completion of structure. This may happen due to factors like bad quality concreting materials, poor workmanship, lack of maintenance, atmospheric effects, abuses, accidents or natural calamities.

Retrofitting of a concrete structure becomes necessary to extend its life. The rehabilitation envisages restoration of structural system as close as possible to the original. The distressed structure needs to be brought in line, level, and the required strength so that it can be put into service without endangering its safety and utility.

Looking to the magnitude and complexity of work involved in restoration, the requirement for various technologies and materials is going to take a giant leap in years to come. The concept of retrofitting & rehabilitation has also been accepted as one of the important disciplines of the construction industry.

The article presents one such case study of a cluster of buildings in Delhi where concrete had deteriorated due to poor concreting practice, quality and lack of maintenance, and its repairing solutions.

Broad Features

Based on the study of critically affected buildings, corrosion of reinforcement has been the prime cause for deterioration of RCC members. The corrosion occurred mainly due to leakage/overflow of water from a service water tank and leakages from the roof into the porous concrete. Severe distress was also due to lack of concreting knowledge, ignorance of the resultant effects and maintenance.

Most of the residential buildings in the area under MES showed the following distress:

- Concrete at several places, especially on the columns, mumty holding the water tank, staircase & roof clearly showed aging, severe honeycombing, poor compaction, and corrosion, resulting in spalling of cover concrete.

Frame 1: Distressed water tanks, balcony roof, and roof

Frame 1: Distressed water tanks, balcony roof, and roofIn some of the roofs, the cover was not adequate to protect the reinforcement.

- Exterior column-beam junctions had developed vertical cracks on almost all the faces.

- Column of the balcony had vertical cracks where the concrete showed aging, honeycombing, poor compaction, corrosion of reinforcement, resulting in spalling of cover concrete. (Frame 1 & 2).

- In some places, especially on the mumty columns, the corrosion was very heavy due to ingress of water from the overflowing water tanks.

- The diameter of the bar was been reduced to less than 50% of its original diameter.

- On the staircase, the concrete was getting corroded. Cracks had started developing on the slopped portion.

Frame 2: Photographs of critically effected buildings

Frame 2: Photographs of critically effected buildingsChemical Kinetics

Most of the distress was related to severe corrosion in the reinforcement. The corrosion reaction i.e. localised breakdown of the passive film (cathode) on steel, mainly starts from the ingress of moisture, penetration of chloride and carbon dioxide through porous concrete. Corrosion of steel in concrete is an electrochemical process, which takes place as a result of the formation of a corrosion cell. (Frame 3).

Frame 3 :Corrosion cell

Frame 3 :Corrosion cellMechanism of corrosion (Frame 4) shows the anodic reactions where metallic iron (Fe) transformed to rust (Fe2O3). The rust formation on the surface of reinforcement is accompanied by an increase in volume, maybe as large as 6 times the volume of Fe. Sound concrete with pH between 11.5 and 13.5 is an ideal environment for protection of steel, but as stated above, alkalinity can be lost due to the formation of alkali carbonates, sulphates & chlorides, and also due to anodic reaction in the presence of moisture. The anodic reaction can be explained from the following chemical reaction:

3Fe + 4H2O → Fe3O4 + 8H+ + 8e-

2Fe + 3H2O → Fe2O3 + 6H+ + 6e

Frame 4: Mechanism of corrosion

Frame 4: Mechanism of corrosionIn other words, if the carbonated front penetrates sufficiently into the concrete to intersect with the concrete reinforcement interface, protection is lost and since both oxygen and moisture are present, the steel is likely to corrode. The extent of the advance of the carbonation front depends to a considerable extent on the porosity and permeability of the concrete and on the conditions of the exposure. In the case of carbonation, atmospheric carbon dioxide (CO2) reacts with pore water alkali, according to the generalized reaction.

Ca(OH)2 + CO2 → CaCO3 + H2O

It consumes alkalinity and reduces pore water pH to the 8–9 range, where steel is no longer passive.

Frame 5: Extent of corrosion and addition of steel

Frame 5: Extent of corrosion and addition of steelRepairing Method

Since repair & rehabilitation of a structure expects to set right the damaged areas, it is therefore obvious that repairs need assured inputs of right material, quality workmanship, and the proper system or specification to be adopted in a phased manner. In this case, a complete retrofitting plan of constructional defects was chalked out, based on the investigation. Main treatments were required for strengthening the structure, arrest of the corrosion, cover protection and consolidation of the concrete. Since no adequate treatment was carried out for the water tightness during the construction and its maintenance afterwards, special emphasis was given on the consolidation of the concrete. Among various techniques and newer material available for restoration of distressed concrete structures, it was proposed to use cementitious repairing material for cover & low viscous epoxy as grouting material for consolidation, purely because of the structural and thermal compatibility and similar physical properties to those of the parent concrete.

Since each material has its own characteristics, it requires very careful study for selecting the right material for a particular application. While selecting a system one should be careful to evaluate whether it meets all the requirements such as placing problem, strength development & durability. For any repair & rehabilitation job, it is always better to take the manufacturer into confidence on the various characteristics of the material & its suitability for that particular type of job. Based on the investigation & type of building, a detailed system for treatment was chalked out. It included type of material, tools to be used, work schedule & rehabilitation design. The repair was carried out under strict supervision of quality control experts.

Material used for Retrofitting

During the rectification process, a large number of materials starting from corrosion inhibitor to micro-concrete were used at different stages. The selection of material does contribute to the performance of the repairing system in the long term. It has been observed in many cases, that the compatibility of various chemicals with cement depends on the physio-mechanical behavior of the system & plays an important role in the performance. In this case, products from Buildtech Products were used as follows:

- Rust converter RUSTKLENE converts rust on the reinforcement to a protective chemical barrier & dissolves the ferric oxide.

- Corrosion Inhibitor BUILDCORROBIT slows down the corrosion reaction in the concrete & helps in regaining its alkalinity by creating a passive film.

- Low viscous epoxy BUILDPOXY LV is used to densify the concrete, and consolidate the structure by filling up the voids, fissures & capillaries.

- Zinc rich primer BUILDCOTE ZP is a two-component system used as an inhibitive epoxy primer in coating of reinforcement.

- Bonding agent BUILDBOND is a two-component epoxy used as bonding agent between old & new concrete.

- Micro concrete BUILDMICROKRIT is a high performance, high strength, self-leveling concrete used for strengthening by jacketing various places to minimize the porosity & enhancing the density.

- Protective coating BUILDCOTE (PUR) is a Polyurethane-based clear coating that protects the concrete from aggressive attacks such as ingress of moisture.

- Acrylic polymer BUILDCRETE is a Single Component Acrylic polymer for cement-based waterproofing system for providing effective & economical cementitious acrylic plaster.

Pre-treatment guidelines were chalked out prior to commencement of treatment. This was done to ensure the safety of the structure & also to make proper working conditions:

- Erection of scaffolding: This shall be done keeping in mind the locations where repairs are to be carried. Adequate precautions are necessary while erecting the scaffolding to facilitate proper working conditions.

- Repair to column: The repair shall be undertaken from bottom and then progressed upwards. Column length between floors shall be considered for repair only after column below are repaired.

- Repair to beams, slab and stair case waist slab: After completing column repairs, works of beams and slabs are to be undertaken.

- Before undertaking repair work, appropriate propping must be provided, preferably using steel pipes: The supporting structure should be such that it should transfer the load coming on the member under consideration. Locations of props should be such that the proper force flow is maintained. This aspect is important to ensure safety during the course of repairs. The slabs and beams transferring the load to the particular column shall be supported before repair to that column is undertaken.

Surface preparation of concrete

Reinforcement was exposed by removing all loose and honeycombed concrete. All the spalling was removed. The concrete was chipped off to a minimum depth of 25mm behind the reinforcement. This was required to treat the corroded reinforcement. Concrete surface & reinforcement were washed with water jet to remove all soluble & insoluble salt such as chlorides present as indicated in the report.

Surface preparation of reinforcement

Removal of the rust from reinforcement completely by rubbing with wire brush or emery paper. Proper cleaning of the existing exposed reinforcement with BUILDKLENE – Rust Converter. This de-rusting compound starts reacting within few minutes after application and converts the rust into a non-metallic complex compound of black colour. It forms a non-porous, impermeable and moister repelling coating of good mechanical stability. It shall be applied liberally by brush till such time it penetrates through the rust layer. Though the reaction starts within few minutes, it generally takes 6 hours to complete the same. However, next activity should start only after 24 hours.

Provision of additional reinforcement

In case of severe corrosion (diameter of reinforcement bar is reduced substantially - say more than 20%), the affected bars were anchored with equivalent additional reinforcement by wilding. This was done in consultation with the structural engineer at site. (Frame 5b).

Application of corrosion inhibitor

The concrete was porous. Due to the ingress of acidic water, the pH value of the concrete slowly got reduced. In many areas, the pH was observed to be below 10 when concrete tends to be acidic & accelerates the process of corrosion (refer Frame 4). This was taken care of by injecting BUILDCORROBIT through non-reversible nozzle into the concrete. With this process, pH of the concrete tends to increase to a safer level of 12.5 & 13. The process involved drilling of holes at a grid pattern on the concrete, and non-reversible nozzles were fixed using fast setting cementitious compound. In case of very poor concrete, the nozzles were fixed after the strengthening of the structure. (Frame 6).

Frame 6: Injection of Buildcorrobit through non-reversible pump

Frame 6: Injection of Buildcorrobit through non-reversible pumpTreatment of Reinforcement

New & old reinforcement were treated with BUILDCOTE ZP - zinc rich epoxy . This anti-corrosive epoxy coating acts as a barrier and also stops propagation. The coating was applied in a manner such that the dry film thickness was around 60 microns.

Pressure grouting

For consolidation of weak concrete & strengthening the pressure grouting was carried out through the non-returnable nozzles of 6 to 12 mm dia. at a spacing of 400-500 mm c/c in zigzag pattern by drilling operation. During drilling & fixing of nozzles, precaution should be taken that damage to the concrete is minimal. Minimum depths of nozzle should be 40 to 50 mm. Firstly, BUILDCORROBIT is to be injected, and subsequently, low viscous epoxy BUILDPOXY – LV is to be injected into the concrete at a pressure of 2 to 3 kg/cm2. Once the grouting is over, the nozzles are to be removed. Pressure grouting operation is to be carried out before polymer cement mortar plaster (cover concrete) and plaster.

Provision of bonding agent

Prior to the application of Cover mortar plaster/micro concrete, the existing surface was treated with a coat of epoxy based bonding agent BUILDBOND to bond old to new concrete. Bonding agent was applied on the surface of old concrete after removing all loose concrete & some hacking was done on it. This epoxy bond coat also acts as a barrier preventing entry of chlorides and other harmful agents.

Jacketing & strengthening of columns using Micro Concrete

In case of severe damages, 50 mm or thickness or as per site requirement, micro-concrete to be used for jacketing the columns. BUILDMICROKRIT cementitious non-shrink free flow high strength micro concrete with ultimate compressive strength of 650kg/cm2 was used. In some cases, it was substituted with maximum of 25% of 4.75 mm downgraded aggregates. The proportion of the mix in many areas varied between 10 to 25% based on the site conditions. This was done as per the manufacturer’s instructions in the product data sheet. For bulk pouring, mechanical mixer too be used or can be mixed manually for smaller requirements. Water / Powder ratio to be adjusted between 0.14 & 0.18 depending on the site condition. Physical properties of Micro-Concrete used is given in Table 1.

| Table 1 : Physico-mechanical properties of Buildmicrokrit | ||

| Sl. No. | Properties | Result |

| 1. | w/p ratio | 0.14 – 0.15 |

| 2. | 10mm down size | 25% max |

| 3. | Compressive strength (kg/cm2) 24 hrs 72 hrs 168 hrs |

220 380 510 |

| 4. | Wet density | 2200kg/m3 |

The first step was undertaken by repairing the column starting from the ground floor. Repair to columns was undertaken one by one. The most distressed column in the structure was taken first. The repair process was as follows:

- Removal of all plaster over the distressed column.

- Remove cover and concrete up to 25 mm clear from the main reinforcement bar using electric cutter/pneumatic chipper or manually to completely expose the reinforcement.

- It has to be ensured that during the removal of cover, there should not be any damage to the concrete element.

- Quantification of deterioration/distress.

- Treatment of columns to be taken up as per the suggestions given below:

- In case the distress at the location is restricted to single face, no jacketing will be required. Repair be carried out as given in sketch

- If the distress is more than on face of a column and reinforcement is corroded less than 20%, no new reinforcement is needed; only jacketing is required as per sketch A shown below. If the corrosion is more than 20%, the treatment to be done as per sketch B.

20mm thick cement mortar plaster admixed with BUILDCRETE provided on the micro-concrete for finishing.

Curing

All the treated areas like columns to be cured using BUILDCURE curing compound & other areas to be cured with conventional systems.

Protective Coating

After the curing, the treated surface is to be provided with a polyurethane based clear coating BUILDCOTE (PUR). Dry film thickness of around 100micron. This coating will protect the concrete from aggressive attack & will make the repaired surface durable for a considerable period of time.

Frame 7 : Jacketing of columns for micro-concrete

Frame 7 : Jacketing of columns for micro-concreteConclusion

Frame 8: Fixing of nozzles after filling up with micro-concrete

Frame 8: Fixing of nozzles after filling up with micro-concrete Frame 8: P-61 Building at Stn Workshop before treatment

Frame 8: P-61 Building at Stn Workshop before treatment Frame 9: Station Workshop during treatment and after treatment

Frame 9: Station Workshop during treatment and after treatmentBibliography

- Das Supradip & et al, ‘Repair and Rehabilitation of Concrete Structure: A Case Study”, CE&CR, Mar’05

- IS 516: 1959, Method of test for strength of concrete.

- IS 456: 2000, Plain and reinforced concrete – Code of Practice.

- Das Supradip, “Repair and rehabilitation of concrete structures a case study.”: New Building Materials & Construction World,: pp 150 – 157. ( Feb’2007)

- Sivagnanam B. “Damage Assessment and rehabilitation of concrete structures: Three case studies.” : Indian Concrete Journal (Dec’2002)

- Das Banabir & Rajendra Kumar (Dec’2003): Civil Engineering & Construction Review, “Rehabilitation of Leaky Basement-A case study.

- Das Supradip: Rectification & Consolidation of water retaining structure: case study

NBM&CW April 2019