India is Ready for Quality Concrete Products with German Engineering

Masa is offering comprehensive solutions for production lines in India for manufacturing concrete products in different variants. Several projects with fully automated plants have already been commissioned across India. Masa plants not only ensure that production takes place in the desired quantity, but they are also designed to produce consistently high-quality results.

The Masa water dosing system Aquados supports the mixing process with precise and flexible water dosing. The innovative mixer is characterized by a rotating mixing trough in combination with a stationary agitator (twister). The mixer is on a 20° angle, which separates the mix transportation from the mixing process to prevent cement and color balling, and optimizes the homogenization of the mix even with fine aggregates and small batches.

Compared to the classic Masa XL series, the new Masa machine generation XL-R impresses with an even faster cycle time and upscale standard equipment. An amplitude-controlled vibration, servo hydraulics with pressure accumulator, energy-efficient drive concepts, mould leveling via servo hydraulics, an automatic mould change to optimize set-up times as well as servo controlled production pallet feed, and a servo-controlled lowering rocker synchronized with pallet feed designed as V-belt conveyor, are some of the features of the XL-R.

First, the fresh products are transported to the curing area via the well-proven Masa components walking beam conveyor, elevator, and finger car. The curing takes place in a curing chamber system. By means of a finger car, buffer finger car, lowerator, and walking beam conveyor, the cured products are transported to the energy-efficient Masa Cuboter, which works fully electrically and reduces operating costs. This modern cubing technology, in combination with other packaging systems, ensures that the final products are ready for dispatch.

Masa is optimistic about India’s economic development and expects a huge boost in the real estate and infrastructure sectors in 2022. With complete German engineering and intelligent solutions, it is the ideal partner for the world-class fully automatic production line to manufacture almost all kinds of concrete products such as solid/hollow blocks, pavers, slabs/tiles, curbstones, AAC blocks, etc. Having over 116 years of experience, Masa is looking forward to helping build the nation brick by brick.

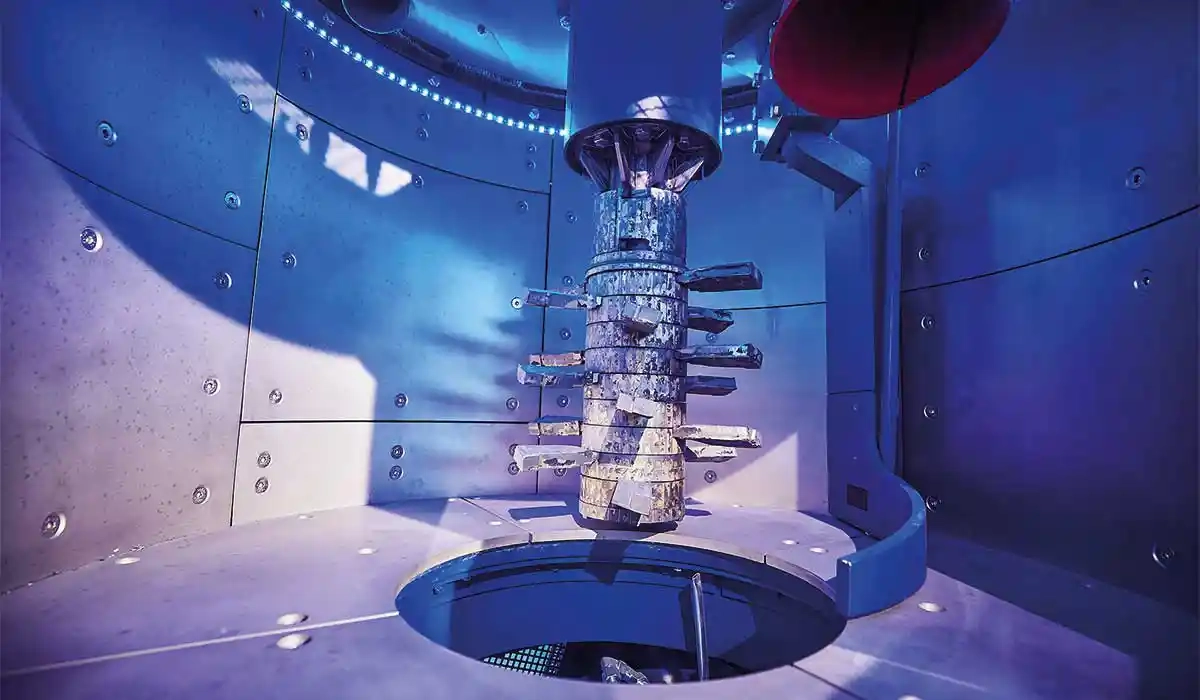

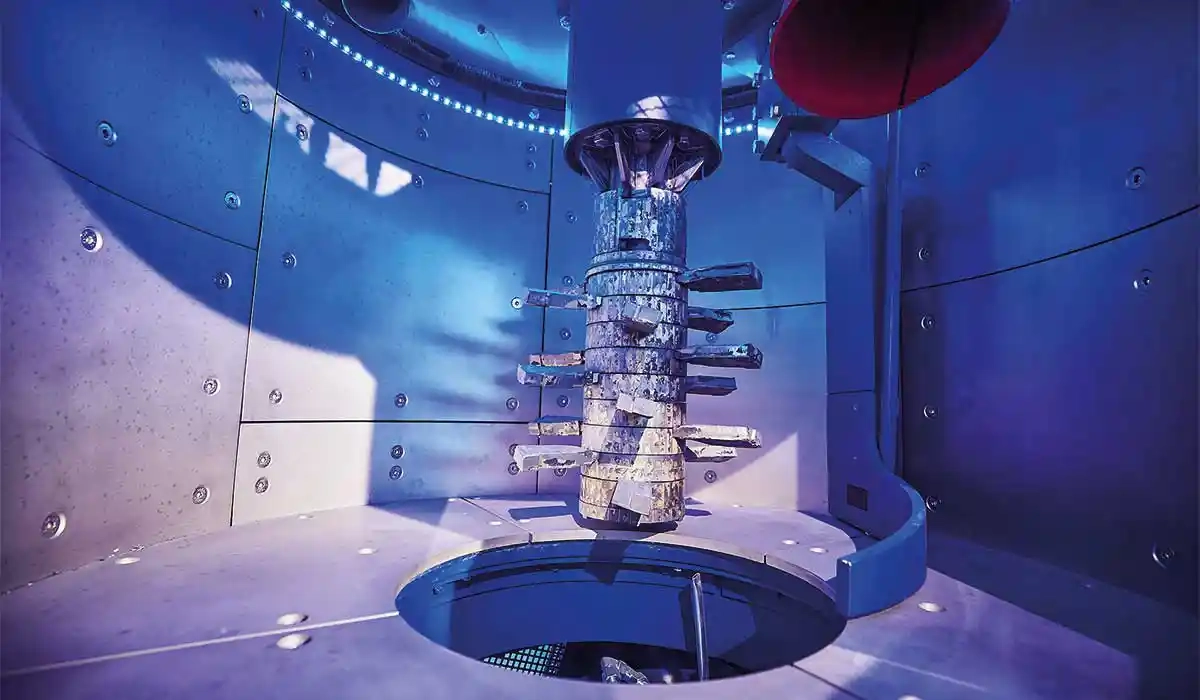

Masa Concrete Mixer S 350/500

The Masa product portfolio takes different concepts into account for the production of main and face mix concrete. While the models in the PH series are designed for the demands of main mix concrete production, the S 350/500 face mix concrete mixer is designed for particularly small concrete batches of the highest quality.

The Masa water dosing system Aquados supports the mixing process with precise and flexible water dosing. The innovative mixer is characterized by a rotating mixing trough in combination with a stationary agitator (twister). The mixer is on a 20° angle, which separates the mix transportation from the mixing process to prevent cement and color balling, and optimizes the homogenization of the mix even with fine aggregates and small batches.

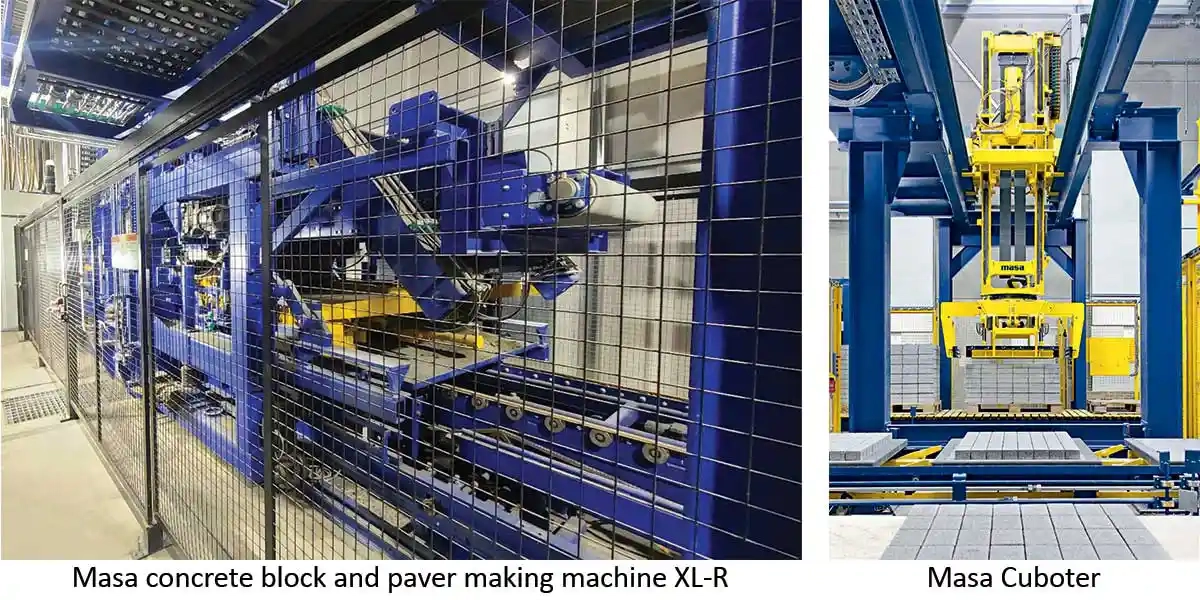

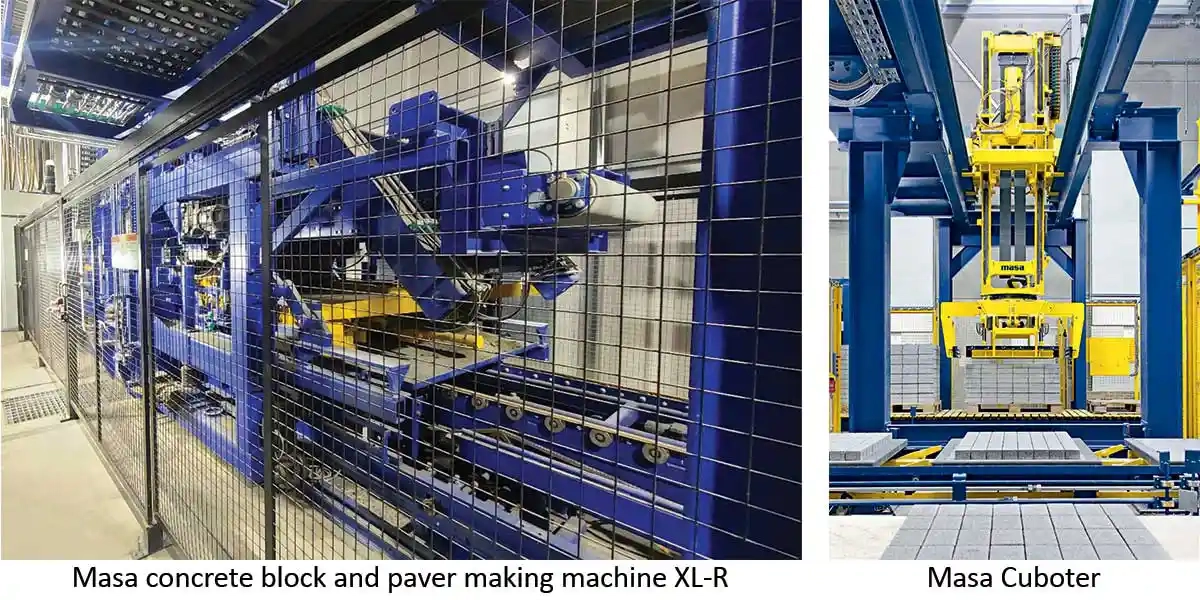

Concrete Block & Paver Making Machine XL-R

The heart of every concrete block and paver making plant is undoubtedly the concrete block making machine. The Masa product range includes powerful basic and classic as well as comfortable premium models in the section “vibration machines”. The fully automated Masa machines are designed to produce concrete blocks with or without face mix layer.

Compared to the classic Masa XL series, the new Masa machine generation XL-R impresses with an even faster cycle time and upscale standard equipment. An amplitude-controlled vibration, servo hydraulics with pressure accumulator, energy-efficient drive concepts, mould leveling via servo hydraulics, an automatic mould change to optimize set-up times as well as servo controlled production pallet feed, and a servo-controlled lowering rocker synchronized with pallet feed designed as V-belt conveyor, are some of the features of the XL-R.

Handling with Care

Due to the sensitivity of (green) products, transport of fresh products to the curing area and subsequent removal and transfer of the cured products requires an intelligent interaction of various plant components.First, the fresh products are transported to the curing area via the well-proven Masa components walking beam conveyor, elevator, and finger car. The curing takes place in a curing chamber system. By means of a finger car, buffer finger car, lowerator, and walking beam conveyor, the cured products are transported to the energy-efficient Masa Cuboter, which works fully electrically and reduces operating costs. This modern cubing technology, in combination with other packaging systems, ensures that the final products are ready for dispatch.

Masa is optimistic about India’s economic development and expects a huge boost in the real estate and infrastructure sectors in 2022. With complete German engineering and intelligent solutions, it is the ideal partner for the world-class fully automatic production line to manufacture almost all kinds of concrete products such as solid/hollow blocks, pavers, slabs/tiles, curbstones, AAC blocks, etc. Having over 116 years of experience, Masa is looking forward to helping build the nation brick by brick.

NBM&CW December 2021