Nanosilica Improves Recycled Concrete Aggregates

Swapna Kutcharlapati, Technical Assistant, Ramky Infrastructure, Hyderabad; A. K. Sarkar, Professor, Birla Institute of Technology and Science, Pilani; N P Rajamane, Head, Centre for Advanced Concrete Research, SRM University, Katankulathur

Major problems occurring while using Recycled Concrete Aggregates (RCAs) in concretes are: higher porosity and hence higher water absorption, lower mechanical strengths, residual impurities on the surface of the RCAs creating weaker bond between cement paste and aggregate, etc. The data in this paper shows that aqueous dispersions of nanosilica (NS) obtained from nano-technology can be used to treat RCAs so that the properties of RCAs such as aggregate crushing value (ACV), Lo Angeles Abrasion Loss, specific gravity, etc are improved; concretes made with NS treated Recycled Concrete Aggregates show enhanced compressive strengths.

Concrete, a very widely used material of construction, can be benefited by NT as concrete becomes more durable, stronger, easily placeable and compactable and self-curable. Nano materials modify the molecular structure of hydrated cement paste and thereby enhancing many properties. NT can make steel to become more tougher, stronger, and corrosion resistant. Using NT, Glass can be made to possess special characteristics such as self- cleaning, insulating and effective water repelling.

This paper deals with application of NT to recycled aggregates prepared from crushed concrete. The nano silica, a product from NT, is used to enhance the properties of recycled aggregates so that concretes with higher strengths can be made. The data in this paper is taken from the work carried out at BITS, Pilani.

Nanotechnology can be defined as ability to create materials, devices and systems, through control of matter in nanoscale by exploitation of properties and phenomena occurring at nanoscale. A Nano Composite is a bulk material containing added nanoparticles to improve the properties of the bulk material.

Self-cleaning glass has nanoparticles to make it photocatalytic and hydrophilic. When UV radiation from light hits the glass, nanoparticles become energized and begin to break down and loosen organic molecules (i.e, dirt). Water on contact with the glass spreads across evenly thereby causing washing action.

Polymeric coatings containing aluminum silicate nanoparticles have increased resistance to chipping/scratching and hence used in everything from cars to eyeglass lenses.

Carbon Nano Tubes (CNTs), first announced by Russian scientists in 1952, was found in the sword of Tipu Sultan as well as in Ajanta paintings [URL3]. The CNTs (with very high Aspect Ratio, (length-to-diameter ratio can be up to 132,000,000:1} have extraordinary strength in terms of tensile strength and elastic modulus [Wang, 2009]. It is observed that CNTs are cylindrical in shape with diameter of nano size and length of several millimeters; they have a density of 1.3 g/cc with a thermal conductivity of 3500 Wme1Ke1 (Note : Copper : 385 W·me1·Ke1) exhibiting an elongation of 15 to 23% at an ultimate tensile strength of about 3,600 MPa.

The nacre, known as mother-of-pearl, is 3,000 times more fracture-resistant than aragonite (basically a calcium carbonate) the mineral it is made of. ninety-five percent of the mass of this biomineral, nacre, is self-assembled, while only 5 percent is actively formed by the organism indicating efficiency of working with nano size particles.

Nanoscale materials can be naturally occurring (e.g. volcanic ash) or incidental (byproduct of human activity e.g., diesel exhaust particulates) or intentionally engineered.

Cellulose Nano-fibers (CNFs) are Ligno Celluloses based and can be made from common materials such as wood pulp (about 55% cellulose) and cottonseed fluff (about 94% cellulose). They are extremely strong and tougher than even Cast Iron (A nanocellulose based paper is stronger and tougher than an iron sheet!) Individual CNFs withstand more stress than glass fibres or steel wire. Cement matrix in presence of CNFs can have at least 10% more compressive strength accompanied by increased tensile strength by several times resulting in 40% more impact strength, and this is attributed to crack suppression & stabilization characteristics of CNFs [Swapna, 2008a and 2008b].

Nano Silica (NS) can contribute to efficient 'Particle Packing' in concretes by densifying the micro and nanostructure leading to improved mechanical and durability properties. NS can control degradation (through blocking of water entry on account of pore refinement) of the fundamental binder system of hydrated cement i.e., C-S-H gel caused usually due to calcium leaching out when immersed in water. NS improves behavior of freshly mixed cement concretes by imparting segregation resistance and by enhancing both workability/mouldability and cohesion of the matrix.

Recycled Concrete Aggregates (RCAs) are obtained by crushing of concretes from demolition of concrete structural components in many structures such as: old buildings, concrete pavements, bridges & structures, at the end of their service life & utility, structures deteriorated beyond the possibility of repairs, structures that are turned into debris resulting from natural disasters (such as floods, earthquake, tsunami, manmade disaster/war, etc), structures not serving the needs in present scenario, old structures to be brought down to pave way for new construction for better economic growth.

RCAs fit into present day motto of 'Reducing, Reusing, Recycling and Regenerating'. Central Pollution Control Board reported in 2004 that solid waste generation in India was about 48 million tons/annum and more than 25% of this is from construction industry which consists of about 7-8 million tons of concrete and brick waste. The waste quantities are estimated to reach to level of atleast 65 million by 2010 (Kumar and Gaikwad, 2004).

RCAs is particularly very promising source of aggregates as 75 per cent of any typical concrete is made of aggregates. RCAs present a unique solution to the problems of large scale demolitions occurring now a days in India. This recycling industry for waste concretes helps reducing management/maintainance costs of dumpsites/landfills and transportation costs

RCAs actually results from crushing of waste concrete and this material as a replacement for natural aggregates can be employed in many applications such as: construction of low rise buildings, manufacture of paving blocks & tiles, laying of flooring and approach lanes, in sewerage structures and sub-base course of pavement, besides drainage layer in highways and retaining walls.

Some of the major problems associated with RCAs can be identified as: lower specific gravity, higher water absorption, lower level of strengths and durability in concretes, impurities on the surface of the RCAs, lack of strong bond between cement paste and RCAs in concrete matrix, etc. However, properties of RCAs can be improved by suitable organic or inorganic treatment systems.

RCAs in the present study are prepared by crushing (using jaw crusher) of concrete cubes made of M20 grade concrete and then sieving. Quantities of fine aggregates (size less than 4.75 mm) and coarse aggregates (20 mm size) obtained were 18% and 60% respectively.

Raw RCAs (Fig 2) were found to have specific gravity of 2.41, water absorption of 5.7%, Aggregate crus- hing value (ACV) of 30 % and a Los Angeles Abrasion Loss of 30 %.

It is noted here that Los Angeles test is a measure of degradation of mineral aggregates of standard gradings and it combines many actions such as abrasion or attrition, impact, and grinding. A rotating steel drum containing steel spheres is used to test the aggregate samples and following computation is made:

L.A. Abrasion Loss (%) = (Original Weight – Final Weight)*100/(Original Weight))

Treatment of RCAs with aqueous dispersion of NS is done by soaking the specimens in the solution for 10 days. The Nano-silica (shown in Fig 3) treated Recycled Aggregates have a specific gravity of 2.62 with water absorption of 0.92%. These treated RCAs recorded an Aggregate Crushing Value (ACV) of 5 % (Fig 4a). Indian Road Congress specifies ACV to be less than 30% for cement concrete pavement 45% for concrete other than for wearing surfaces. The ACV indicates ability of aggregate to resist crushing and a lower figure indicates stronger aggregate with greater ability to resist crushing.

The Los Angeles Abrasion Loss of Nano-silica treated RCAs is 5 % (Fig 4b). A reduction in Los Angeles Abrasion Loss indicate increase in strength of aggregates [Kahraman and Fener, 2007].

Cement : Coarse Aggregates : Sand : Water = 1:1.49:2.83: 0.45.

A 10% NS dispersion was also added to the fresh concrete mix containing RCAs. Curing of concrete specimens after demoulding was done conventionally by storing the specimens under water (Fig 5b).

NS solids could fill the voids between cement grains, resulting in immobilization of "free" water ("filler" effect) and thereby increasing the cohesivity of the fresh nix. Use of colloidal nano silica particles in aqueous medium aids better dispersion of nanoparticles in the concrete matrix and decreases agglomeration of nanoparticles which improves nanoparticles performance in concrete. NS enhances cohesiveness of mix besides reducing segregation and bleeding.

Concrete made with untreated RCAs had a slump of about 15 mm with a compressive strength of 16 MPa. But, concrete made with NS treated RCAs had a slump of about 35 mm with a compressive strength of 22 MPa.

It was observed that NS treatment to the RCAs enhances many aggregate characteristic properties such as abrasion, aggregate crushing value and compressive strengths. This enhanced properties of RCAs lead to higher level of compressive strengths in concretes.

NS treatment to RCAs densifies the loose/weak mortar present on surfaces of RCAs. The reactive and filler nature of NS binds the densified surface mortar to the base stone aggregates. Well-dispersed nanoparticles act as centre of crystallization of cement hydrates, thereby accelerating hydration. However, real challenge is always to get an effective dispersion into NS solids into cement matrix.

NS particles favour the formation of both small-sized crystals of Ca (OH)2 and uniform gel clusters of C-S-H gel. The NS particles very efficiently participate in pozzolanic reactions, resulting in consumption of Ca (OH)2 and formation of an 'additional' C-S-H. Nano-size and superior pozzolanic activity of NS improve/refine/densify interfacial transition zone (ITZ) between aggregates' surface and cement paste, resulting in better bond between aggregates and cement paste.

Major problems occurring while using Recycled Concrete Aggregates (RCAs) in concretes are: higher porosity and hence higher water absorption, lower mechanical strengths, residual impurities on the surface of the RCAs creating weaker bond between cement paste and aggregate, etc. The data in this paper shows that aqueous dispersions of nanosilica (NS) obtained from nano-technology can be used to treat RCAs so that the properties of RCAs such as aggregate crushing value (ACV), Lo Angeles Abrasion Loss, specific gravity, etc are improved; concretes made with NS treated Recycled Concrete Aggregates show enhanced compressive strengths.

Introduction

Nanotechnology (NT) is neither a new science nor a new technology; it helps scientists to develop composites with improved and desired characteristics. The size of the particles in the composites is crucial as at the length scale of a nanometer, the properties of many materials could be quite different from their bulk state. Applications of NT are in vary divergent fields and are already employed to enhance properties of many construction materials such as concrete, steel, glass, etc.Concrete, a very widely used material of construction, can be benefited by NT as concrete becomes more durable, stronger, easily placeable and compactable and self-curable. Nano materials modify the molecular structure of hydrated cement paste and thereby enhancing many properties. NT can make steel to become more tougher, stronger, and corrosion resistant. Using NT, Glass can be made to possess special characteristics such as self- cleaning, insulating and effective water repelling.

This paper deals with application of NT to recycled aggregates prepared from crushed concrete. The nano silica, a product from NT, is used to enhance the properties of recycled aggregates so that concretes with higher strengths can be made. The data in this paper is taken from the work carried out at BITS, Pilani.

Nano Materials

Nano materials have atleast one dimension of the order of a nano which is one billionth of a meter. We may note here that a strand of DNA is only a 2 nm wide and a human hair could have a length of 100,000 nm. A nano particle becomes a quantum dot with dimension of the order of 10 nm and this size is so small that jumps in energy levels occur. Quantum dots are semiconductors whose electronic characteristics are closely related to the size and shape of the individual crystal; the smaller the size of the crystal, the larger the band gap, the greater the difference in energy between the highest valence band and the lowest conduction band becomes, therefore more energy is needed to excite the dot, and concurrently, more energy is released when the crystal returns to its resting state.Nanotechnology can be defined as ability to create materials, devices and systems, through control of matter in nanoscale by exploitation of properties and phenomena occurring at nanoscale. A Nano Composite is a bulk material containing added nanoparticles to improve the properties of the bulk material.

Self-cleaning glass has nanoparticles to make it photocatalytic and hydrophilic. When UV radiation from light hits the glass, nanoparticles become energized and begin to break down and loosen organic molecules (i.e, dirt). Water on contact with the glass spreads across evenly thereby causing washing action.

Polymeric coatings containing aluminum silicate nanoparticles have increased resistance to chipping/scratching and hence used in everything from cars to eyeglass lenses.

Carbon Nano Tubes (CNTs), first announced by Russian scientists in 1952, was found in the sword of Tipu Sultan as well as in Ajanta paintings [URL3]. The CNTs (with very high Aspect Ratio, (length-to-diameter ratio can be up to 132,000,000:1} have extraordinary strength in terms of tensile strength and elastic modulus [Wang, 2009]. It is observed that CNTs are cylindrical in shape with diameter of nano size and length of several millimeters; they have a density of 1.3 g/cc with a thermal conductivity of 3500 Wme1Ke1 (Note : Copper : 385 W·me1·Ke1) exhibiting an elongation of 15 to 23% at an ultimate tensile strength of about 3,600 MPa.

The nacre, known as mother-of-pearl, is 3,000 times more fracture-resistant than aragonite (basically a calcium carbonate) the mineral it is made of. ninety-five percent of the mass of this biomineral, nacre, is self-assembled, while only 5 percent is actively formed by the organism indicating efficiency of working with nano size particles.

Nanoscale materials can be naturally occurring (e.g. volcanic ash) or incidental (byproduct of human activity e.g., diesel exhaust particulates) or intentionally engineered.

Cellulose Nano-fibers (CNFs) are Ligno Celluloses based and can be made from common materials such as wood pulp (about 55% cellulose) and cottonseed fluff (about 94% cellulose). They are extremely strong and tougher than even Cast Iron (A nanocellulose based paper is stronger and tougher than an iron sheet!) Individual CNFs withstand more stress than glass fibres or steel wire. Cement matrix in presence of CNFs can have at least 10% more compressive strength accompanied by increased tensile strength by several times resulting in 40% more impact strength, and this is attributed to crack suppression & stabilization characteristics of CNFs [Swapna, 2008a and 2008b].

Nano Silica (NS) can contribute to efficient 'Particle Packing' in concretes by densifying the micro and nanostructure leading to improved mechanical and durability properties. NS can control degradation (through blocking of water entry on account of pore refinement) of the fundamental binder system of hydrated cement i.e., C-S-H gel caused usually due to calcium leaching out when immersed in water. NS improves behavior of freshly mixed cement concretes by imparting segregation resistance and by enhancing both workability/mouldability and cohesion of the matrix.

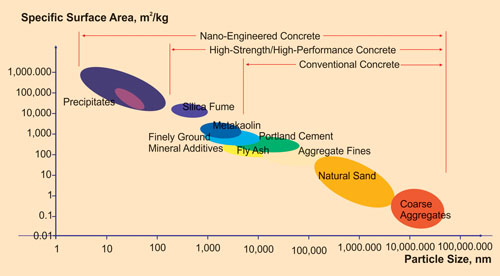

Specific Surface Area of Ingredients of Concrete

Several sizes of particles in a concrete mix cause good filler effect so that the net void volume generated is minimised and thereby an optimum mix with desirable properties is obtained. The actual packing in a multi-size particulate mix depends upon the so called 'grading span' – difference between maximum and minimum sizes of particles in the mix; addition of nanoparticles increases the 'grading span' substantially and thereby contributing to rational packing of particles in concrete mix. |

| Figure 1: Specific Surface Area of Ingredients of Concrete |

Nanosilica for Recycled Concrete Aggregates

Recycled Concrete Aggregates

Recycled Concrete Aggregates (RCAs) are obtained by crushing of concretes from demolition of concrete structural components in many structures such as: old buildings, concrete pavements, bridges & structures, at the end of their service life & utility, structures deteriorated beyond the possibility of repairs, structures that are turned into debris resulting from natural disasters (such as floods, earthquake, tsunami, manmade disaster/war, etc), structures not serving the needs in present scenario, old structures to be brought down to pave way for new construction for better economic growth.

RCAs fit into present day motto of 'Reducing, Reusing, Recycling and Regenerating'. Central Pollution Control Board reported in 2004 that solid waste generation in India was about 48 million tons/annum and more than 25% of this is from construction industry which consists of about 7-8 million tons of concrete and brick waste. The waste quantities are estimated to reach to level of atleast 65 million by 2010 (Kumar and Gaikwad, 2004).

RCAs is particularly very promising source of aggregates as 75 per cent of any typical concrete is made of aggregates. RCAs present a unique solution to the problems of large scale demolitions occurring now a days in India. This recycling industry for waste concretes helps reducing management/maintainance costs of dumpsites/landfills and transportation costs

RCAs actually results from crushing of waste concrete and this material as a replacement for natural aggregates can be employed in many applications such as: construction of low rise buildings, manufacture of paving blocks & tiles, laying of flooring and approach lanes, in sewerage structures and sub-base course of pavement, besides drainage layer in highways and retaining walls.

Some of the major problems associated with RCAs can be identified as: lower specific gravity, higher water absorption, lower level of strengths and durability in concretes, impurities on the surface of the RCAs, lack of strong bond between cement paste and RCAs in concrete matrix, etc. However, properties of RCAs can be improved by suitable organic or inorganic treatment systems.

Improving Properties of Recycled Concrete Aggregates with Nanosilica

Treatment of RCAs with Nano silica (NS) is one of the options available for beneficiation of RCAs. The NS used is usually in the form of stable dispersions of nanometer size silica particles and this dispersion is generally in water or other liquid medium [Hosseini, 2009]. Particle sizes of NS range from 4 to 100 nano-meters in diameter with very high surface area of up to 750 m2/gram of silica solids (note the surface area of Portland cement ranges from 0.25 to 0.40 m2/gram). NS is available commercially now as an aqueous solution with a colloidal solid percentage of 30% (nano-particles of SiO2 dispersed in water).Preparation and Properties of Recycled Concrete Aggregates

|

| Figure 2: Crushed Aggregates of different sizes |

|

| Figure 3: TEM image of silica nano-silica particles |

Raw RCAs (Fig 2) were found to have specific gravity of 2.41, water absorption of 5.7%, Aggregate crus- hing value (ACV) of 30 % and a Los Angeles Abrasion Loss of 30 %.

It is noted here that Los Angeles test is a measure of degradation of mineral aggregates of standard gradings and it combines many actions such as abrasion or attrition, impact, and grinding. A rotating steel drum containing steel spheres is used to test the aggregate samples and following computation is made:

L.A. Abrasion Loss (%) = (Original Weight – Final Weight)*100/(Original Weight))

Treatment of RCAs with aqueous dispersion of NS is done by soaking the specimens in the solution for 10 days. The Nano-silica (shown in Fig 3) treated Recycled Aggregates have a specific gravity of 2.62 with water absorption of 0.92%. These treated RCAs recorded an Aggregate Crushing Value (ACV) of 5 % (Fig 4a). Indian Road Congress specifies ACV to be less than 30% for cement concrete pavement 45% for concrete other than for wearing surfaces. The ACV indicates ability of aggregate to resist crushing and a lower figure indicates stronger aggregate with greater ability to resist crushing.

The Los Angeles Abrasion Loss of Nano-silica treated RCAs is 5 % (Fig 4b). A reduction in Los Angeles Abrasion Loss indicate increase in strength of aggregates [Kahraman and Fener, 2007].

|

| Figure 4: Tests on Coarse Aggregates |

Preparation of Concrete Specimens

RCAs were used as coarse aggregates to prepare concrete cube specimens (Fig 5a) made from concrete with mix proportions (by weight) of:Cement : Coarse Aggregates : Sand : Water = 1:1.49:2.83: 0.45.

A 10% NS dispersion was also added to the fresh concrete mix containing RCAs. Curing of concrete specimens after demoulding was done conventionally by storing the specimens under water (Fig 5b).

|

| Figure 5: Preparation of Concrete Specimens |

Discussion of Test Results

Cement hydration generates capillary voids of 10 to 1000 nm size and in a well hydrated paste with a low w/c ratio, the pore size would be less than 100 nm. Hence, NS with nano size dimensions can contribute effectively to the pore size refinement of the hydrated cement matrix.NS solids could fill the voids between cement grains, resulting in immobilization of "free" water ("filler" effect) and thereby increasing the cohesivity of the fresh nix. Use of colloidal nano silica particles in aqueous medium aids better dispersion of nanoparticles in the concrete matrix and decreases agglomeration of nanoparticles which improves nanoparticles performance in concrete. NS enhances cohesiveness of mix besides reducing segregation and bleeding.

Concrete made with untreated RCAs had a slump of about 15 mm with a compressive strength of 16 MPa. But, concrete made with NS treated RCAs had a slump of about 35 mm with a compressive strength of 22 MPa.

It was observed that NS treatment to the RCAs enhances many aggregate characteristic properties such as abrasion, aggregate crushing value and compressive strengths. This enhanced properties of RCAs lead to higher level of compressive strengths in concretes.

NS treatment to RCAs densifies the loose/weak mortar present on surfaces of RCAs. The reactive and filler nature of NS binds the densified surface mortar to the base stone aggregates. Well-dispersed nanoparticles act as centre of crystallization of cement hydrates, thereby accelerating hydration. However, real challenge is always to get an effective dispersion into NS solids into cement matrix.

NS particles favour the formation of both small-sized crystals of Ca (OH)2 and uniform gel clusters of C-S-H gel. The NS particles very efficiently participate in pozzolanic reactions, resulting in consumption of Ca (OH)2 and formation of an 'additional' C-S-H. Nano-size and superior pozzolanic activity of NS improve/refine/densify interfacial transition zone (ITZ) between aggregates' surface and cement paste, resulting in better bond between aggregates and cement paste.

Concluding Remarks

- Recycling and reuse of building wastes is an appropriate solution to the problems of dumping hundreds of thousands tons of debris accompanied with shortage of natural aggregates.

- Recycled aggregates can prove to be a valuable building material from many considerations such as technical, environment and economical.

- Recycled aggregates possess, as compared to natural aggregate

- relatively lower

- bulk density,

- crushing

- impact values

- relatively higher

- water absorption.

- relatively lower

- Compressive strength of untreated recycled aggregate concrete can be lower by about 15% compared to original concrete.

- Properties of Recycled Concrete Aggregates and concrete made with them are enhanced by addition of appropriate nano-materials such as Nano-silica.

- Crack-bridging property of silica nanoparticles and interlocking of silica in the pores of aggregates helps to make the crushed concrete aggregates to gain

- Regarding cost, it may be noted that

- Crushed aggregate has almost a zero investment

- Every 250 grams of Nano-silica solution costs about Rs 150

- Optimized value 10% implies that only a tiny amount of nano-silica solution is utilised.

- Use of waste materials means reduced management/requirements of dumpsites, landfills and transportation costs.

Acknowledgments

The test data used in this paper is based on the works carried out by Miss Swapna Kutcharlapati at BITS, Pilani. The authors acknowledge the technical interactions occurred after the invited key note speak given on the topic by Shri N P Rajamane, during the 'Third Edition of Workshop on Emerging Materials and its Applications ( WEMA )' held on 2nd Dec, 2010, at Aarupadai Veedu Institute of Technology (AVIT), Chennai, organised in association with Madras Metallurgical Society.References

- Francois De Larrard, (1999), "Concrete Mixture Proportioning: A Scientific Approach", ISBN 0419235000, E & FN Spon, p 440

- Hosseini P., A. Booshehrian, M. Delkash, S. Ghavami, M.K. Zanjani, (2009), "Use of Nano-SiO2 to Improve Microstructure and Compressive Strength of Recycled Aggregate Concretes", Proceed of the NICOM3, Nanotechnology in Construction, Springer ISBN 978-3-642-00979-2, pp 215-222

- Ji, T. (2005), "Preliminary study on the water permeability and microstructure of concrete incorporating nano-SiO2", Cement and Concrete Research, Vol 35, pp 1943 – 1947.

- Jonathan S. Belkowitz, and Dr Daniel Armentrout, (2010), "An investigation of nano silica in the cement hydration process', Concrete Sustainability Conference, National Ready Mixed Concrete Association, pp 1-15

- Kahraman S. and M. Fener, (2007), "Predicting the Los Angeles abrasion loss of rock aggregates from the uniaxial compressive strength", Materials Letters, Volume 61, Issue 26, October, pp 4861-4865

- Kumar, S. and Gaikwad, S.A., (2004) "Municipal Solid Waste Management in Indian urban centers: An approach for betterment", Urban development debates in the new millennium, edited by K.R.Gupta, Atlantic Publishers, New Delhi, pp.100-10.

- Lin K.L., W.C. Chang, D.F. Lin, H.L. Luo and M.C. Tsai, (2008), "Effects of nano-SiO2 and different ash particle sizes on sludge ash–cement mortar", Journal of Environmental Management 88, pp 708–714.

- Swapna Kutcharlapati, (2009), "A Report On Use Of Nano SiO2 In Recycled Aggregate Concrete", Lab Oriented Project Report on Course BITS C314, Guide: Prof. A. K. Sarkar, Birla Institute Of Technology And Science, Pilani, April.

- Swapna Kutcharlapati, S.B. Singh and N.P. Rajamane. (2008a), "Influence of Nano Cellulose Fibres on Portland Cement Matrix," National Conference on Advanced materials and Characterization", VIT, Vellore, July23-25 pp. 1-10.

- Swapna Kutcharlapati, S.B. Singh and N.P. Rajamane. (2008b), "Influence of Nano Cellulose Fibres on Portland Cement Matrix,"Metals Materials And Processes, V. 20, No. 3, pp. 307-314

- URL1, http://science.howstuffwork s.com/nanotechnology3.htm

- URL2, http://www.nano.org.uk/forum/viewtopic.php

- URL3, http://www.eanveshan.com/node/134

- URL4, http://en.wikipedia.org/wiki/Quantum_dot

- Wang, X., Li, Q., Xie, J., Jin, Z., Wang, J., Li, Y., Jiang, K., Fan, S., (2009), "Fabrication of Ultralong and Electrically Uniform Single-Walled Carbon Nanotubes on Clean Substrates", Nano Letters, Vol 9, pp 3137–3141

NBM&CW January 2011