Concrete Mix Design

The process of selecting suitable ingredients of concrete and determining their relative amounts with the objective of producing a concrete of the required, strength, durability, and workability as economically as possible, is termed the concrete mix design. The proportioning of ingredient of concrete is governed by the required performance of concrete in 2 states, namely the plastic and the hardened states. If the plastic concrete is not workable, it cannot be properly placed and compacted. The property of workability, therefore, becomes of vital importance.

The formation of concrete mix design requires following parameters to be considered:

Apart from these, weather condition and mixing process patterns also affect final concrete quality.

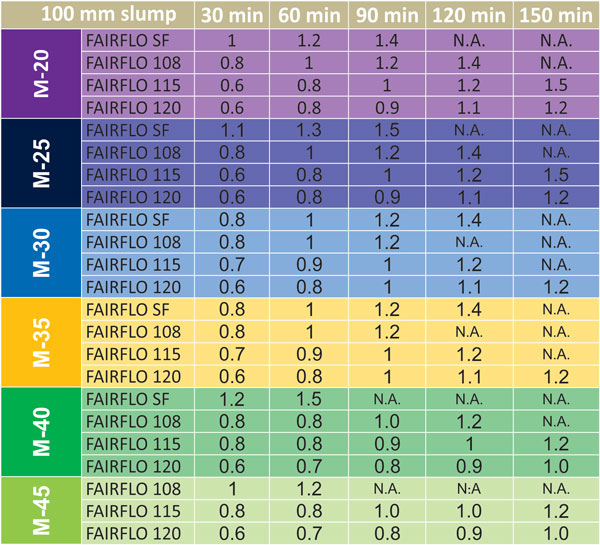

1. Fairflo SF

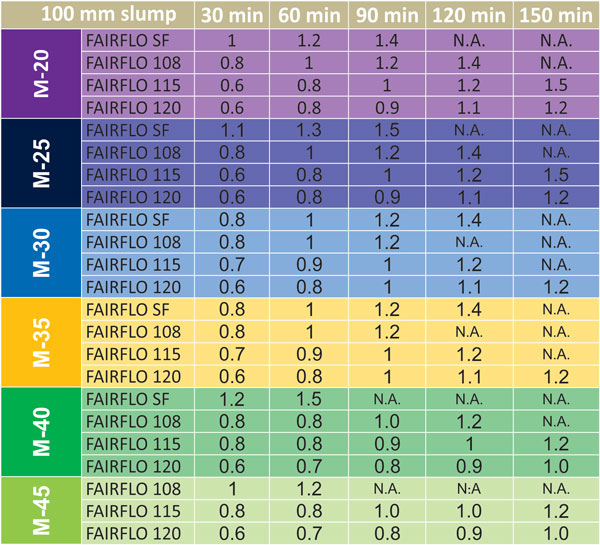

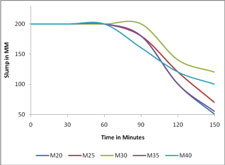

Trial results with standard mix designs at different grade from M20 to M40. Brand and grade of cement: Siddhi OPC-53; River Sand zone: zone II.

As it can be inferred from the graph, FAIRFLO SF works for M20 to M40 range of concrete and gives collapse slump for up to 60 minutes. Results can be changed by adjusting the dosage according to requirement. FAIRFLO SF is not suitable for M45 and above range of concrete.

2. Fairflo 108

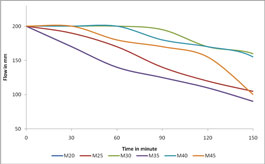

Trial results with standard mix designs at different grade from M20 to M45. Brand and grade of cement: Siddhi OPC-53; River Sand zone: zone II.

As it can be inferred from the graph, FAIRFLO 108 works for M20 to M45 range of concrete. Results can be changed by adjusting the dosage according to requirement.

3. Fairflo 115

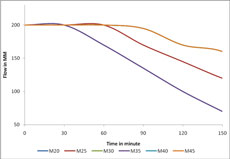

Trial results with standard mix designs at different grade from M20 to M45. Brand and grade of cement: Siddhi OPC-53; River Sand zone: zone II.

As it can be inferred from the graph, FAIRFLO 115 works for M20 to M45 range of concrete. Results can be changed by adjusting the dosage according to requirement.

4. Fairflo 120

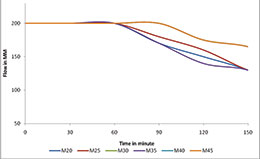

Trial results with standard mix designs at different grade from M20 to M45. Brand and grade of cement: Siddhi OPC-53; River Sand zone: zone II.

As it can be inferred from the graph, FAIRFLO 120 works for M20 to M45 range of concrete and gives collapse slump for up to 60 minutes. Results can be changed by adjusting the dosage according to requirement. FAIRFLO 120 will give collapse slump for up to 60 minutes, while it can last up to 90 minutes for M30 and M45 grade of concrete.

The formation of concrete mix design requires following parameters to be considered:

- Ultimate design strength of concrete

- Early age strength requirement for demoulding, lifting and movement to store

- Workability, consistency, and finishability

- Degree and type of reinforcement

- Size and shape of mould and element

- Durability Issues:

- Permeability

- Shrinkage

- Chemical resistance

- Raw material types and properties:

- Aggregate

- Cement

- Use of supplementary cementatious materials

- Use of recycled materials

General Observation

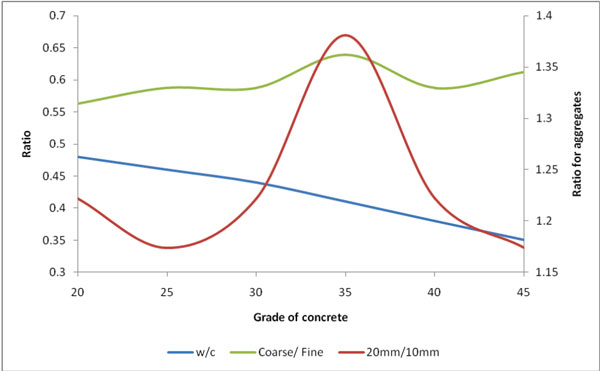

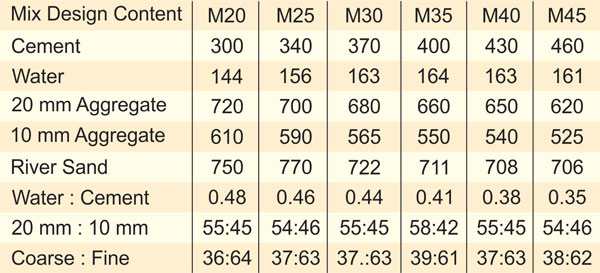

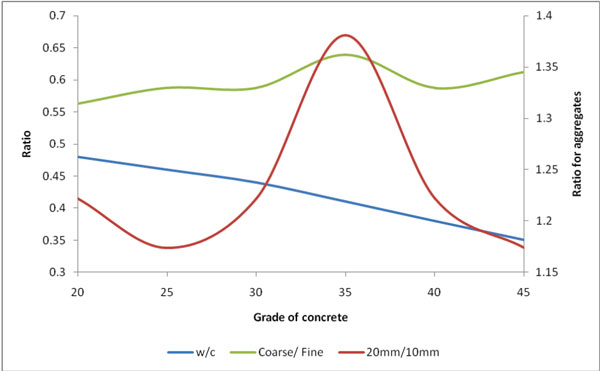

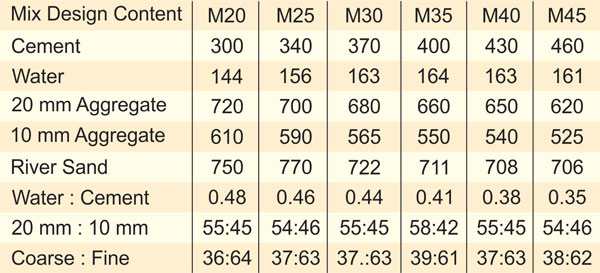

Concrete mix design strictly adheres to above parameters; however we can be sure of certain parameters such as water/cement ratio, coarse/fine ratio, 20mm to 10mm aggregate ratio for a particular grade of concrete. The following graph depicts the relationship between these parameters as grade of concrete increases.Apart from these, weather condition and mixing process patterns also affect final concrete quality.

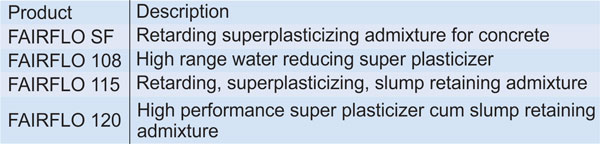

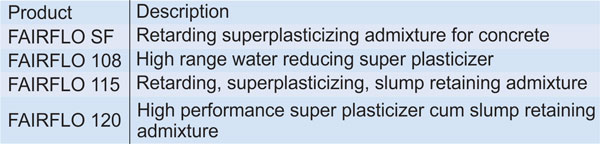

A New Development In Admixture Technology

- Fairmate has been in the market for long to understand market requirements thoroughly and develops top quality products that suit varying requirement of clients.

Mechanism Of Working

- SNF based admixtures consist of polymers which are absorbed by the cement granules; which wrap around the granules’ surface areas at the very early stage of the concrete mixing process. The sulphonic groups of the polymer chains increase the negative charge of the cement particle surface and disperse these particles by electrical repulsion. This electrostatic mechanism causes the cement paste to disperse and has the positive consequence of requiring less mixing water to obtain a given concrete workability.

- PCE blended admixtures have a different chemical structure from the traditional superplasticisers. The third generation PCE used in blended products is specially engineered for ready-mix concrete. The particular configuration of PCE polymer, allow its delayed and sustained absorption on to the cement particles and disperse them efficiently. As compared with other PCE superplasticisers, it is possible to obtain a high quality concrete mix with accelerated strength development and extended workability without delaying setting characteristics. It allows the production of high performance concrete and/or concrete with high workability.

Benefits

- Reduced thermal peaks

- High workability for longer periods

- Lower pumping pressure

- Resistance to segregation even at high workability

- Extended setting with longer workability

- Reduced water content for a given workability

- Higher ultimate strength

- Reduced permeability and improved durability

- Reduced shrinkage and creep

- Better resistance to aggressive atmospheric conditions

- Increased ease in finishing concrete

Product Performance

The entire range of product is tested under standard humidity and temperature condition. The results as products have performed are shown below.Standard Mix Design

1. Fairflo SF

Trial results with standard mix designs at different grade from M20 to M40. Brand and grade of cement: Siddhi OPC-53; River Sand zone: zone II.

As it can be inferred from the graph, FAIRFLO SF works for M20 to M40 range of concrete and gives collapse slump for up to 60 minutes. Results can be changed by adjusting the dosage according to requirement. FAIRFLO SF is not suitable for M45 and above range of concrete.

2. Fairflo 108

Trial results with standard mix designs at different grade from M20 to M45. Brand and grade of cement: Siddhi OPC-53; River Sand zone: zone II.

|

|

As it can be inferred from the graph, FAIRFLO 108 works for M20 to M45 range of concrete. Results can be changed by adjusting the dosage according to requirement.

3. Fairflo 115

Trial results with standard mix designs at different grade from M20 to M45. Brand and grade of cement: Siddhi OPC-53; River Sand zone: zone II.

As it can be inferred from the graph, FAIRFLO 115 works for M20 to M45 range of concrete. Results can be changed by adjusting the dosage according to requirement.

4. Fairflo 120

Trial results with standard mix designs at different grade from M20 to M45. Brand and grade of cement: Siddhi OPC-53; River Sand zone: zone II.

|

|

As it can be inferred from the graph, FAIRFLO 120 works for M20 to M45 range of concrete and gives collapse slump for up to 60 minutes. Results can be changed by adjusting the dosage according to requirement. FAIRFLO 120 will give collapse slump for up to 60 minutes, while it can last up to 90 minutes for M30 and M45 grade of concrete.

Quality Assurance

Fairmate manufactures entire range of construction chemicals under compliance of ISO 9001, ISO (EMS) 14001 & OHSAS 18001 (Occupational Health and Safety) certified by ISOQAR / UK.TECHNICAL SERVICES

Mix Design: Fairmate has a dedicated advisory service on Concrete Mix Design and can be contacted if assistance is required. "While new advances and changes will take place but one thing will never change is quality and meeting special needs of our customers. Our laboratory in Baroda and technical personnel & experts are available to provide additional information and technical assistance. We are eager to work with you in development of new product and resolve your problem."

NBM&CW October 2013