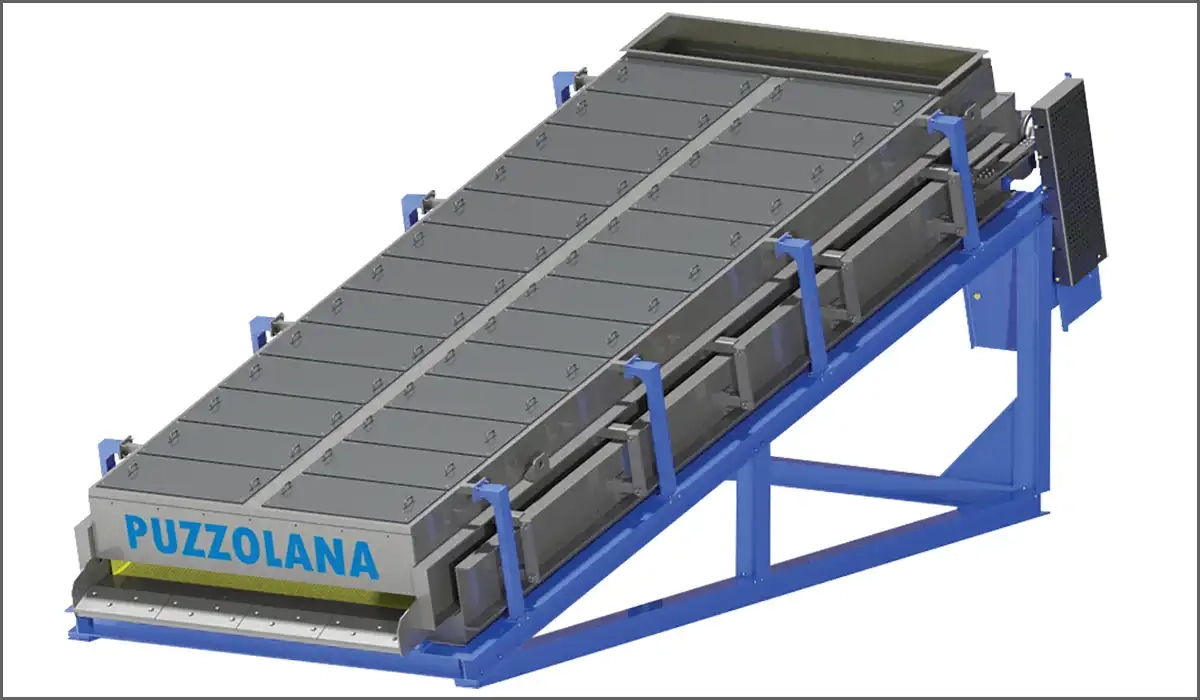

Puzzolana: High-Capacity & Hybrid Crawler Crushers, Screens & sanders

Puzzolana, Abhijeet Pai - President

Our aim is to develop products that integrate the latest technologies and features so that they can compete in global markets.

Puzzolana is adopting the latest technologies and bringing sustainability in its construction equipment. The company has optimized its production processes by incorporating robotics in painting and assembly, with the aim of achieving sustainability and consistent quality.

New equipment and features that optimize equipment utilization

We are launching innovative crushers designed to enhance efficiency and capacity, along with automation and safety certification (CE) suitable for European markets.We have introduced Hybrid Type Crawler/Mobile units that offer the flexibility to switch between electric power and diesel fuel operation. This innovation enhances plant efficiency, cost-effectiveness, and environmental friendliness, as it allows the adoption of alternative fuels to reduce emissions.

Our new, high-capacity crushers feature larger feed sizes for the Primary Jaw Crusher (allowing for a 1200mm feed and a capacity of 1000TPH), along with a secondary Hydrocone Crusher designed to efficiently process the output from the primary crusher and generate secondary products. This development aims to optimize equipment utilization.

To ensure seamless operations, our equipment have features designed to facilitate plant automation and digitalization, enabling remote operation and efficient control of processes and product scheduling. This approach embraces connected and digital construction practices.

Lifecycle support to customers’ equipment

Puzzolana has set up a full-fledged workshop for refurbishment of old crushers, while integrating in them the latest improvements to ensure higher productivity and efficiency, such that the equipment can use the latest /improvised spares in the older equipment. This will enhance the life of the equipment.Puzzolana ensures lifecycle support to the plants through periodical maintenance and parts support, refurbishment, operation and training to ensure plants’ performance and efficiency.

By integrating safety features and data collection capabilities, we are ensuring that our customers have dependable data for parts planning and maintenance, fostering trust in our brand in the process. Our service team is in constant touch with the operation team, which creates confidence in the O&M of the plants.

Value additions that enhance brand value

We are providing training for the operations team in maintenance and parts planning to ensure comprehensive life cycle support for their machines. In situations requiring immediate attention, we offer floating crushers to maintain plant and project progress, minimize idle time, and ensure continuous operation of our customers’ crushers while they are being repaired.Puzzolana as an approved training partner, is authorized by IESC (Infrastructure Equipment Skill Council) to provide training and skill enhancement for operators engaged in the operation and maintenance of crushing plants, and subsequently certify them through IESC.

Outlook for construction sector in 2024

The increasing development of road projects in the Northern and Eastern regions, enhancing connectivity in the border states, strengthening of the railway sector, Bullet Train corridors being built, and numerous other mega infra projects, will ensure continuous growth in infra development and the resultant growth in the construction equipment industry.Though there could be a little slowdown during the general elections in 2024, there will not be any adverse effect on the construction sector’s progress. OEMs have started focusing on BS V norms and the industry will soon be geared up for implementation of these norms.