Polish precaster inBet launches second Carrousel Plant

Maciej Jęczmyk, CEO of inBet, is very satisfied with the company’s further expansion and investment into modern precast technologies.

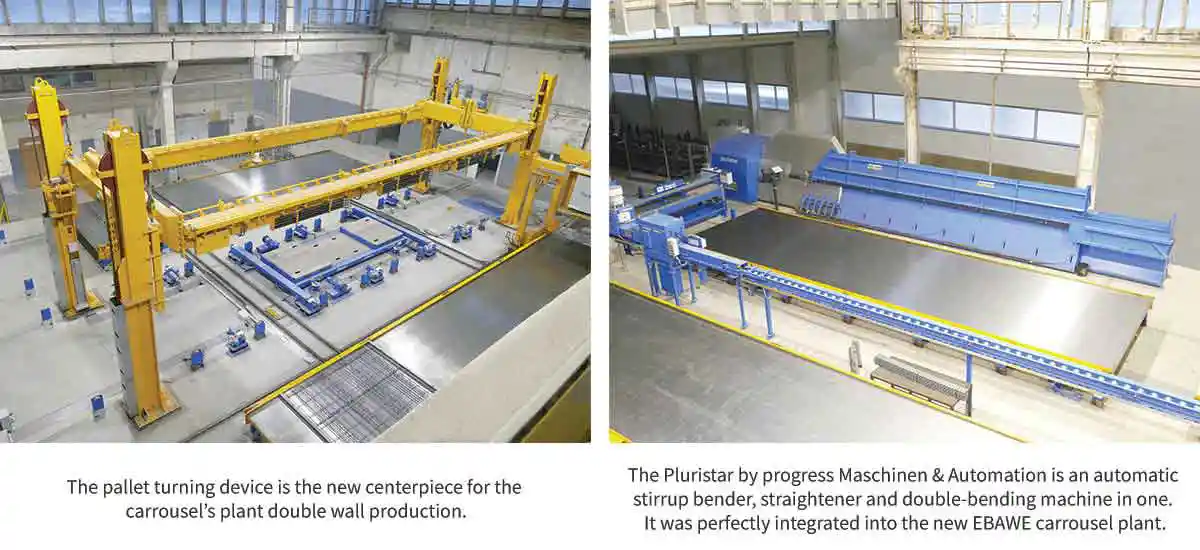

Founded in 1999, Kolbudy-based inBet can look back on two decades of successful precast history in Poland, and even beyond. While the company in the first years worked on standard stationary production tables, inBet started its first modern carrousel plant for the production of lattice girder floors in 2017. The Polish precast specialist has now successfully launched its second precast factory - a state-of-the-art carrousel plant for the production of double walls and lattice girder floors - again supplied by the German precast plant and machinery manufacturer EBAWE and its sister company Progress Maschinen & Automation, one of the seven companies belonging to the precast specialist Progress Group.

Only 10 workers are running the new EBAWE carrousel plant in the city of Kolbudy.

Only 10 workers are running the new EBAWE carrousel plant in the city of Kolbudy.Strength through Diversification

Though precast accounts for 50% of the company’s activities, inBet, since its beginnings, has shown strength through diversification: In addition to its precast activities, approximately one third of its business activities is focused on metal products; 10% on ready-mix concrete; in addition to a few other business activities such as reinforcement mesh and trusses. Though the company’s regional stronghold traditionally is in greater Kolbudy near Gdansk, it covers a radius of roughly 100kms, including Gdansk, Sopot, Gdynia and Rumia, and also markets its precast products to the south of Sweden.

Precast Products for Leading Building Projects

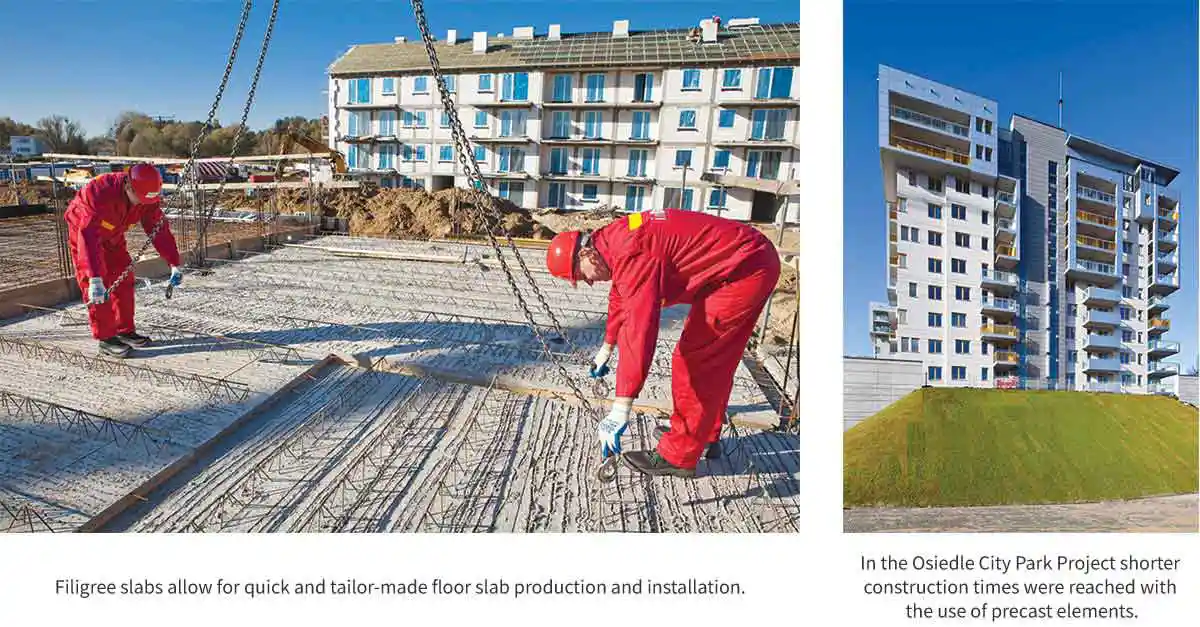

The company covers a wide portfolio of precast products, including lattice girder floors, double walls, stairs, and balcony elements. With the high quality of its products and increased production capacities, inBet has been able to offer precast elements to leading building projects all over the region, including both single multi-storey residential buildings as well as complete residential areas. Well known reference projects include the Osiedle City Park Project, the Hynka Housing Development and the Old Tenement Quarter.

Good Reasons for a new Investment

In 2020, inBet’s latest investment - a brand new Made in Germany carrousel plant for double walls and lattice girder floors - started its production. The company’s strategy for setting up a new precast factory was twofold: on the one hand, inBet’s aim was to increase its filigree production output, and on the other hand, it became possible for the company to introduce new products like the double wall, which offers numerous advantages.

The company had realized that more and more building companies and developers were looking to create buildings with precast elements due to the lower construction times and reduced need for workers. It, therefore, set up a new factory whose key elements represent a modern and highly efficient filigree and double wall production.

Key Elements of the new Carrousel Plant

- The horizontal and vertical compacting process enables the best possible concrete compaction at low noise levels, thus creating a better work environment.

- In production halls with limited space, the combined plotter and pallet cleaner enables two working processes to be carried out in one single working station.

- The plotting machine allows for a reduction of human errors and high precision of the produced precast elements.

- Progress Group’s in-house software and master computer ‘ebos’ ensures the best possible overall control of the carrousel plant. Among others, ebos offers functions such as automatic pallet assignment, print modules for work sheets, label and report printing modules, etc.

In addition to a state-of-the-art carrousel plant by Eilenburg based EBAWE, inBet made use of the ability of Progress Group to provide turnkey and tailor-made solutions for their precast factory, not only in the field of precast concrete technology but also in the field of reinforcement and steel processing. Consequently, inBet also included the Pluristar by Progress Maschinen & Automation into the new investment.

The Pluristar is an automatic stirrup bender, straightener, and double-bending machine in one. It can process wire diameters of 6 – 16 mm. The heart of the Pluristar is the combined straightening system consisting of a roller straightening unit and a rotor straightening unit. This unique combination allows the flexible manufacture of stirrups, straight rebars and rebars with large bends using a single machine. Depending upon the given product, the suitable straightening unit is fully automatically inserted. The wire is changed fully automatically or manually, as needed. The Pluristar can also be equipped with a 3-D bending system - enabling not only 2-dimensional, but also 3-dimensional stirrups.

The Old Tenement Quarter project of inBet also used numerous precast products.

The Old Tenement Quarter project of inBet also used numerous precast products.Importance of Strong Partnerships

inBet CEO Maciej Jęczmyk is highly satisfied with his second experience with EBAWE and Progress Maschinen & Automation. He sums up his cooperation with the Progress Group companies as follows: ”We were very satisfied with our interaction with EBAWE and Progress in 2017, and also now, for our new factory, we decided again for the same machinery partner. It was easy for us to work together, and we very much appreciate the support, trust and reliability of EBAWE and Progress.”

inBet is confident that the second carrousel plant, which is already running in two shifts, will be as successful as the first carrousel plant.