Improving Life of Structures by Secondary Waterproofing

Present Scenario of Concrete & Masonry Structures:

- Primary Waterproofing is always provided by an elastic coating/membrane. However, the general resistance to water penetration and the resultant improved durability of structures is often ignored but can be achieved through Secondary Waterproofing.

- More than 85% of the concrete produced in India is still made by volume batching. There is lack of control of W/C ratio at sites. The control on quality of sand and aggregate is very limited. The concrete usually has high permeability.

- In the foundation concrete, and concrete used for DPC there is ingress of salts and water. This causes deterioration of concrete and also the ground water rises in the walls through the capillaries in mortar and bricks. This leads to persistent rising dampness and peeling-of paints in walls at the ground level.

- The pollutants like CO2 etc. along with water enter the concrete above ground leading to rebar corrosion and deterioration of concrete.

- Site-mixed mortar and plaster are commonly in use, unlike pre-mix mortars used in many other countries. The site-mixed mortars lack adhesion and cohesive properties compared to the international practice. Ultimately, cracks appear in mortar and plaster surfaces.

- All in all, cracks and dampness in concrete & masonry structures bring down their actual service life from the designed level.

Solution : Dr. Fixit Pidiproof LW+

- Dr. Fixit Pidiproof LW+ is a unique cement additive having judicious combination of various selective polymers which work in different manner to give different properties such as,

- Improved dispersion mechanism leading to water demand reduction of 6-8%.

- Increase in compressive strength

- Micro structure refinement which reduces permeability

- Corrosion resistance

Comparison of normal concrete with Dr. Fixit Pidiproof LW+ concrete

For the same set of cement, sand, aggregates and water, the effect of adding Dr. Fixit Pidiproof LW+ into the concrete has been compared below.| Mix Proportion | ||

| Components | Control mix kg/m3 |

Mix with Dr. Fixit Pidiproof LW+ kg/m3 |

| Cement (PPC) | 380 | 380 |

| Fine aggregate | 926 | 926 |

| CA - I | 452 | 452 |

| CA-II | 552 | 552 |

| Water | 190 | 179 |

| Dr. Fixit LW+ | – | 200 ml /50 kg bag of Cement |

- The compressive strength of concrete specimen with Dr. Fixit Pidiproof LW+ shows an increase of 7% in 28 days. The RCPT value (measure of chloride penetration), water permeability and drying shrinkage of the concrete specimen with Dr. Fixit Pidiproof LW+ shows 27%, 39% and 30% reduction which is quite significant. What is remarkable is that Dr. Fixit Pidiproof LW+ concrete has shown improved impermeability over PPC concrete, which by itself is more impermeable than OPC concrete.

| Comparative Properties | |||

| Test Parameters | Aging days | Control mix | Mix with Dr. Fixit LW+ |

| Rapid Chloride Penetration Test in Coulomb, (as per ASTM-C-1202-2007) | 28 days | 1481 | 1079 |

| Water Permeability in mm, (avg. of three samples) (as per DIN-1048) at pressure 5 kg/cm | 28 days | 18.00 | 11.00 |

| Drying Shrinkage, %.(average of three samples) as per IS-2185 Part-1) | 28 days | 0.278 | 0.193 |

| Compressive strength (N/mm2) | 3 days | 14.20 | 16.71 |

| 7 days | 21.76 | 23.84 | |

| 28 days | 36.28 | 38.78 | |

| Water Soluble Chloride %, | 0.0051 | 0.0042 | |

No other liquid integral waterproofing compound or admixture in the market which offers all the features for concrete /mortar improvement like the unique Dr. Fixit Pidiproof LW+.

| Comparison of Dr. Fixit Pidiproof LW+ with other usual Integral Waterproofing Compounds | |

| Dr. Fixit Pidiproof LW+ | Usual Integral Waterproofing Compounds |

| Conforms IS 2645 and 9103 | Usual Integral Waterproofing conforms only IS 2645 hence no improvement in strength |

| Resists Corrosion | Not observed |

| Acts against capillary water rising dampness. Therefore, improve durability in foundations | No evidence in simple types of Integral waterproofing compounds |

The normal admixtures do not reduce water permeability, hence no secondary waterproofing is achieved.

How does Dr. Fixit Pidiproof LW+ work?

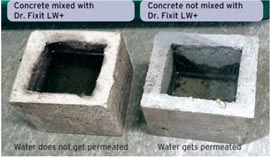

- Narrow lanes called capillaries are formed during hydration of cement. These voids become a route for ingress of chlorides, sulphates etc. Dr. Fixit Pidiproof LW+ breaks these capillaries. Some hydrophobic polymeric molecules present in Dr. Fixit Pidiproof LW+, fill the pores and imparts a hydrophobic environment, which repels the water molecule and increases the impermeability property of the mortar or concrete.

- The polymeric and the cement particles have the same charge and hence particles disperse and release locked water. This improves workability, hydration and increases strength of concrete/mortar.

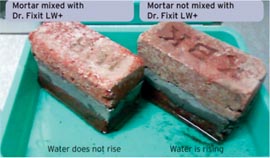

- Some selective polymeric particles also get into the pores and the impermeability gives the delaying corrosion property and also act against rising dampness. These particles are very fine micro-particles which reach all the rear points and throughout the mortar or concrete matrix.

- There is improvement in cohesiveness. This reduces the rebound loss in trowelling, leading to higher mason productivity.

- An overall effect of reduced cracking is observed.

|

|

| Effect of Dr. Fixit LW+ in containing capillary rise in concrete | Effect of Dr. Fixit LW+ in Brick Masonry |

|

|

| Effect of Dr. Fixit LW+ on water permeation through concrete | The photograph shows improved cohesion of Dr. Fixit Pidiproof LW+ mortar sticking to the trowel whereas normal mortar slips down |

NBM&CW September 2012