Excessive Idle Running of Diesel Engine and the Effects

While idle running is unavoidable and even essential to a certain extent, excess idle running is always dangerous for the engine and the environment.

By Bhaskarudu Peddakotla

Many people, particularly operators, have their own myths on idle running of engines of the machines they operate, such as idling is essential to warm up the engine before loading the engine (moving with or without load); idling is good for the engine and there will not be any load on the engine; keeping engine running in idle is better than frequent switch off and switch on. But the facts are entirely opposite as given below:

Idle running: Keeping the engine running at low idle without any work by the machine. Low idle RPM will normally be between 650 to 750 RPM

The allowable idle run: Normally, 15 to 20% of total run hours is allowable idle run. This provision is given to take care of the safety of the turbocharger and certain unavoidable working conditions like waiting at loading machine, waiting at dumping yard, momentary stoppages on haul roads during crossings, giving passage to loaded vehicles coming in the opposite direction, vehicles climbing gradients etc.

Excessive idle running: Any idle running beyond 20% of total run hours or >5 minutes in a single stretch is considered as excessive idle running. There are incidences of 60% idle running of machines in some worksites.

Effects of excessive Idling of engine: In a compression ignition engine, the cylinders are designed to be hot and maintain adequate temperature to burn the injected fuel completely. But during idle running, due to low reciprocating speed of piston, the compression inside the cylinder will not be as effective as during high piston speeds. Due to this, the temperature generated inside the combustion chamber will not be at the desired level, which will lead to the following issues:

- Piston rings do not expand adequately, causing insufficient sealing between piston ring and liners which again leads to leakage of compressed gases

- Incomplete burning of injected fuel and leaving unburnt fuel in the combustion chamber, and passing the unburnt fuel to engine sump through the gap between piston ring and liners

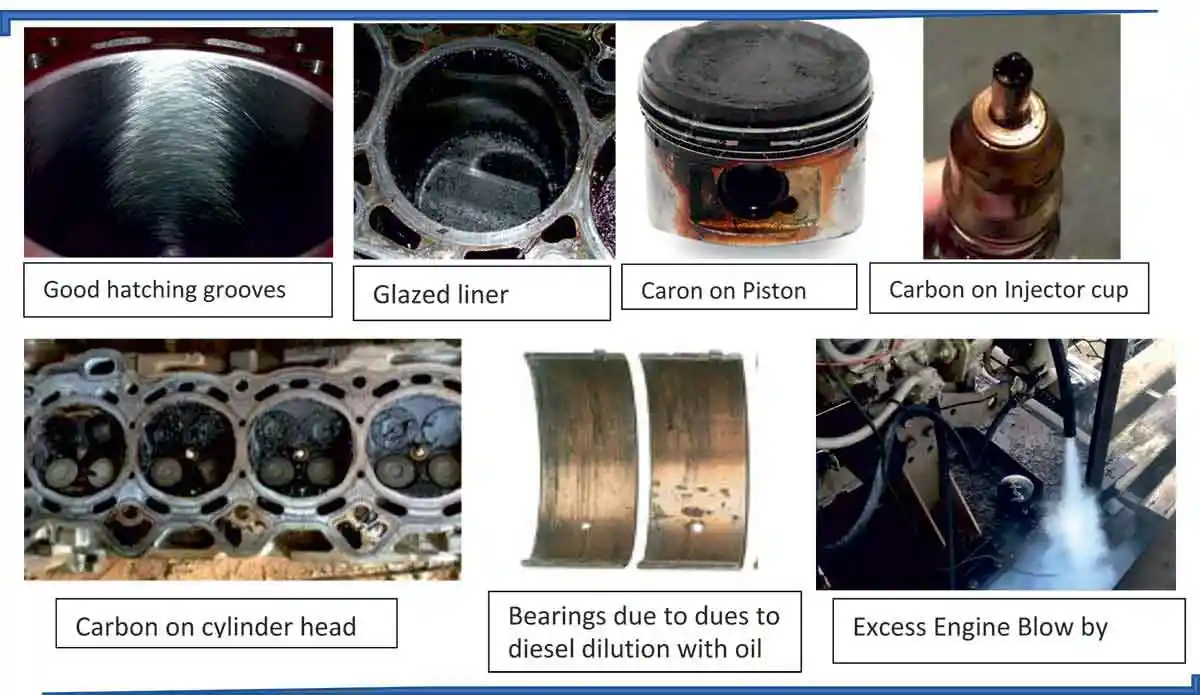

- When fuel starts passing through the gap between the piston ring and the cylinder walls, the fuel washes the piston rings and cylinder liners and dilutes the lubricating oil. This action gradually develops a glazing/shining surface on the liners, eroding the crosshatch marks provided for lubricating oil retention

- Glazing not only loses oil retention in liners but also slowly erodes the oil film which leads to accelerated wear of piston rings and loss of compression. This further increases the gap between the liner and the rings causing severe leakage of compressed gases into the crank case, leading to excess blow-by

- Excess blow-by means loss of compression pressure, loss of power and time to overhaul the engine. Further continuation of running with same status leads to throwing lube oil through exhaust gases (lube oil passing into the combustion chamber through the increased gap between liner and rings)

- Improper burning or poor compression leads to excess carbon formation in piston rings grooves, piston crown, ring band, cylinder head, valves, injector tips etc

- Excess carbon formation leading to stucking of piston rings in grooves, leakage of gases between valve and valve seats, improper fuel spray due to blocked injector spray holes and ultimately aggravating all issues mentioned above and loss of power

- Diesel dilution in engine causing drop in lube oil viscosity and washing out bearing surfaces, dropping lube oil pressure, killing oil film and making metal to metal contact of moving parts and ultimately faster wear of bearings and journals and premature overhaul of engine

- Diesel mixing with lube oil also leads to faster wear of lube oil pump components and reducing pump efficiency

- Improper combustion of gases emits lot of harmful substances like carbon monoxide, nitrous oxide, carbon dioxide, sulphur dioxide, particulate matters etc., through exhaust gases causing health issues to public

- Wear rate of diesel engine during idle running will be 60% more compared to normal operation

- Further idle running of engine means burning the fuel for no work and increasing operating cost unnecessarily

- For every litre of burning of diesel 2.65 kgs of carbon dioxide is released in the atmosphere

- An engine which may give life of 20000 hours may come for overhauling even at 8000 hours due to excess idling of engine

However, certain amount of idling is necessary for the engines. For example a turbo-charged engine has to be kept idle for 60 to 180 seconds before shutting down and after starting, i.e before accelerating. Also, while waiting at loading areas and other miscellaneous jobs.

How to control or minimize idle running

- Utilize the data from machine, downloaded through electronic tool and remote monitoring devices, as all present generation machines are equipped with electronic devices to monitor the operating practices

- Analyse the reports and identify areas of improvements which can be done machine- wise or even operator-wise

- Gaps may be in synchronization of loading machines with hauling machines, waiting machines at refuelling area, unloading area, communication between supervisor and operator, electrical problems like self-starter, alternator, batteries etc., and sleeping of operator inside the cabin- all of which are avoidable

- Follow good maintenance practices of all the auto electrical components by keeping a ready stock of all the consumable parts

- Allocate the right number of dumpers to loading machines with proper work planning

- Educate and guide operators and other staff associated with the operation and maintenance in plugging the gaps and keep monitoring performance with periodical reviews

- Create ownership among all the stakeholders at site and recognize and reward best performers

At a site where 10 dumpers and 3 loaders were deployed, the idle running of dumpers was 56% and the loaders was 45%. Fuel consumption during idle running of dumpers is 5 LPH and loaders 7 LPH and average utilization of each machine is 3000 hours per year. Imagine the savings from the fuel if this site can bring down the idle running to 20% maximum on all the machines. The savings will be 66,000 ltr of diesel per year, which amounts to Rs. 48 lakhs. Imagine the savings if the fleet size is large and has higher capacity machines. It is not only saving money through the diesel but a lot by protecting the engine from premature wear and protecting the environment from pollutants.