Sandvik: Underground & Surface Mining equipment & technology

“Sandvik is transforming the landscape of the mining and construction sector through its state-of-the-art technology and Made-in-India machines. uring Excon’23, we will showcase a selection of our products, highlighting our expertise in cutting-edge, domestically manufactured tunnelling jumbos, and surface drill rigs.

Our dedication lies in guaranteeing reliability, safety, operational excellence, minimising downtime, and ultimately optimising both time and resources for our valued customers.

Manojit Haldar - Managing Director, Sandvik Mining and Rock Technology India and President, Sales Area, India

Sandvik Mining and Rock Technology India

Sandvik Mining and Rock Technology India is a leading technology provider in the underground, surface mining and infrastructure segment. Our products include hauling trucks, loaders and drilling machines for hard rock mining, various surface drills and tunnelling jumbos for construction and infrastructure segment, continuous miners for underground coal mining, technologically advanced rock tools and ground support system.For underground mining alone, Sandvik India has a fleet of over 300 machines currently operating in the mines of zinc, copper and uranium. In surface mining, over 450 Sandvik machines are working in dimensional stones quarries, iron ore, manganese, and chromium mines and in cement and road construction projects. Besides these machines, Sandvik India has an active fleet of over 200 hydraulic, automatic and semi-automatic Tunnelling Jumbos working in various railways, roads, and hydro power tunnel projects.

For the Pune headquartered company, the biggest asset is its round the clock 24x7 parts and service support by qualified and factory trained Sandvik engineers.

Sandvik India, a part of the 100 BSEK Swedish multinational, has forged a formidable market presence in the mining and construction segment. With local manufacturing of high-end rock tools and technologically advanced equipment in Hyderabad and Pune, the company is contributing to the India’s growth story in a significant way.

As a futuristic brand, Sandvik embraces proactive partnerships, forward-thinking solutions, and sustainable processes that indicate the company's commitment to advancing the world through expert engineering.

Asoktaru Chattopadhyay - President & Country Manager Sandvik Rock Processing Solutions India, Korea, Japan, Philippines, Indonesia and SEA

Sandvik Rock Processing Solutions

Sandvik Rock Processing Solutions is a business area within Sandvik Mining and Rock Technology India. Our comprehensive range of products include stationary jaw, cone and VSI crushers and complete range of screening solutions for processing rock and minerals. Through years spent in quarries around the world, we have learned how to help customers produce more, waste less, and enjoy a better profit margin.Sandvik has accumulated a wealth of knowledge in the art of crushing and screening and as authorities in this industry, the company has a deep understanding of the technical and mechanical aspects involved. However, going beyond the technicalities, we have forged close relationships with our customers, and through them, gained valuable insights into the real-world performance of our products. This has allowed us to recognize the transformative potential of crushing and screening in enhancing productivity, safety, and sustainability of the entire operation.

Not only this, at Sandvik's R&D centre, we help customers in analysing their raw material, as a result of which, we can suggest the most suitable equipment for their projects and also offer customised products tailored to their specific requirements. For example, our CH660 cone crusher can be used for a variety of crushing jobs, including secondary, tertiary, quaternary, and pebble-crushing. Equipped with the innovative hydraulic Hydroset™ system, the crusher offers the essential safety features and convenient setting adjustments. Its automation system enables realtime performance management, such that customers can monitor their crushers and optimize the crushing efficiency and productivity.

Sandvik's full strength on display at Excon'23

Sandvik India will be exhibiting its entire range of products, including tunnelling jumbos, surface drill rigs, drum cutters, cone crushers, rock tools and DSI products that are used for roof and rock support in underground mining and tunnelling sector.Sandvik has always been at the forefront when it comes to providing high technology products and solutions for the mining and construction industry. With an expertise of over 160 years, everything that we do at Sandvik has the customer in focus. From electrification of mining machinery to developing technologies that enable a connected future, Sandvik is acing the tech game for its customers and the entire construction industry. Our tech-rich products have helped reduce machine downtime across the industry, thereby saving our customers their precious money, time, and efforts by helping them complete projects on time.

In this edition of Excon, the focus will be more on the products which have now been localised and are being manufactured in India to substantially cut down their delivery time and also helping customers reduce their maintenance costs.

Sandvik India: Reinforcing Efficiency and Accuracy

Sandvik DT820 Tunnelling Drill - India's first Made in India JumboA tunnelling project is a race against time and costs. Getting it right from the very beginning requires a thorough knowledge and experience, along with the right equipment. At Sandvik, we have been providing drilling solutions for more than 50 years, and have created cutting-edge technologies that meet the construction needs of modern day tunnelling projects.

The Sandvik 800 series DT820, a twin boom electrohydraulic semi-automatic tunnelling Jumbo, provides both efficiency and accuracy during excavation. It is designed to be fast, accurate, and user-friendly, and is known to produce results of the highest quality with the lowest operational costs.

Customer feedback on DT820 by one of our esteemed customers M/S KSR Group, Hyd

KSR Group, a Sandvik customer for the last 12 years, is engaged in tunnelling jobs, material handling, granite quarrying, and in variousconstruction activities since the last 30 years. In 2022, the company placed an order for 2 units of DT820 for their East Coast Rail Project, located at Aruku in the Visakhapatnam district of Andhra Pradesh. Sandvik India supplied its first made in India unit to KSR Group from its Hinjewadi factory in January 2023.As per our customer, the machine has already clocked over 800hours; it has helped complete a 135-meter railway tunnel with all the safety precautions in place, including pipe roofing, lattice girder, and rock bolt. Since the last 7 months, the machine is working well without facing any issues, and our customer is completely satisfied with its performance.

DC122R Surface Drill Rig: Accurate, Efficient & Economical

Whether you need a drill rig for foundation drilling, road cutting, trenching, demolition, or for dimensional stone quarrying, Sandvik Commando™ DC122R can handle all the jobs efficiently.The compact design 4-wheel drive, self-propelled hydraulic drilling machine can manoeuvre easily in tight spaces and in tough conditions. In the tough granite, marble and stone quarries, the machine offers exceptional reliability and produces excellent block quality each time.

The modularly designed machine has anti-jamming and a hydraulic drilling control system that ensure a high level of safety along with ease of operation. It can drill holes up to a diameter of 45 mm, and can perform line drilling, splitting, trimming and pilot-hole drilling.

Sandvik DC122R drill rig is also being widely used in the construction of shafts and canals and for riverlinking in large irrigation projects. It can be used for drilling perimeter holes on the circumference owing to its capability to drill both vertical, horizontal, and inclined holes, with a 360-degree freedom of movement of the feed. With excellent stability in different terrains and its portability, the machine is ideal for civil construction - especially shaft sinking, trenching and pipeline work in urban areas.

The versatile surface drill rig is finding extensive use in road construction. Be it a difficult and highaltitude terrain or canal work deep down, this drill rig ensures that the job is done with precision and ease. Its efficient dust collection and suppression technology, along with dustproof components, makes it the right choice for longer lifecycles, reduced maintenance costs, especially suitable for urban jobs.

Rock Tools and Systems

Sandvik offers a complete range of rock tools for bench drilling, raise boring, coal and mineral cutting, tunnelling, trenching, road grading and cold planning. Its top hammer and down the hole drilling tools are designed to increase productivity and sustainability while reducing total operational cost. Sandvik's Alpha 340 innovative asymmetric thread profile tools and power carbide speedy bits not only ensure increased productivity and longer life but also provide high level of collaring accuracy. All the tools are designed based on years of research, experience and customer feedback.

DSI ground support making tunnelling safer, economical & efficient

DSI is the latest division within Sandvik Mining and Rock Technology (SMRT) globally, and has started working in India also. The division provides rock and roof support products for mines and tunnels and also caters to the demand from TBM tunnels for specialized products like sealing rings and support systems.Tunnel construction is one of the most difficult, challenging, and at the same time fascinating work in civil engineering. Modern tunnels are becoming longer and often feature larger cross-sections. With increased complexities in geological conditions, the need for ground support is of prime importance. With over 160 years of our proven innovative systems, Sandvik is well poised to support construction of tunnelling by delivering safe, efficient, and cost-effective solutions. Our global product and service portfolio includes bolts, injection and sealing systems, fore-poling systems, passive support, as well as special rock support products, all of which are being used in countless projects worldwide. DSI provides a complete range of ground control solutions - all from a single source.

Pre-support (before excavation)

Pre-support comprises various support elements that are selected depending on the conditions encountered. These elements are installed from the actual face in the advance direction into the not yet excavated ground, where they serve to create a stable and safe working area when excavation starts. Additional drainage measures stabilize the ground by improving its properties.Post-support (complete range)

Underground excavation is typically supported by radial bolts, reinforced shotcrete, and, if required, by steel arches. While shotcrete lining provides passive support, radial bolts stabilize and reinforce the surrounding ground and create a so-called supporting arch in the area. The main intention is to increase the capacity of the ground with respect to shear load and tension.Bolts are an essential part of the primary support in tunnel construction and must also be selected carefully so that they are completely suited for the expected ground conditions.

Round-the-clock parts and service support

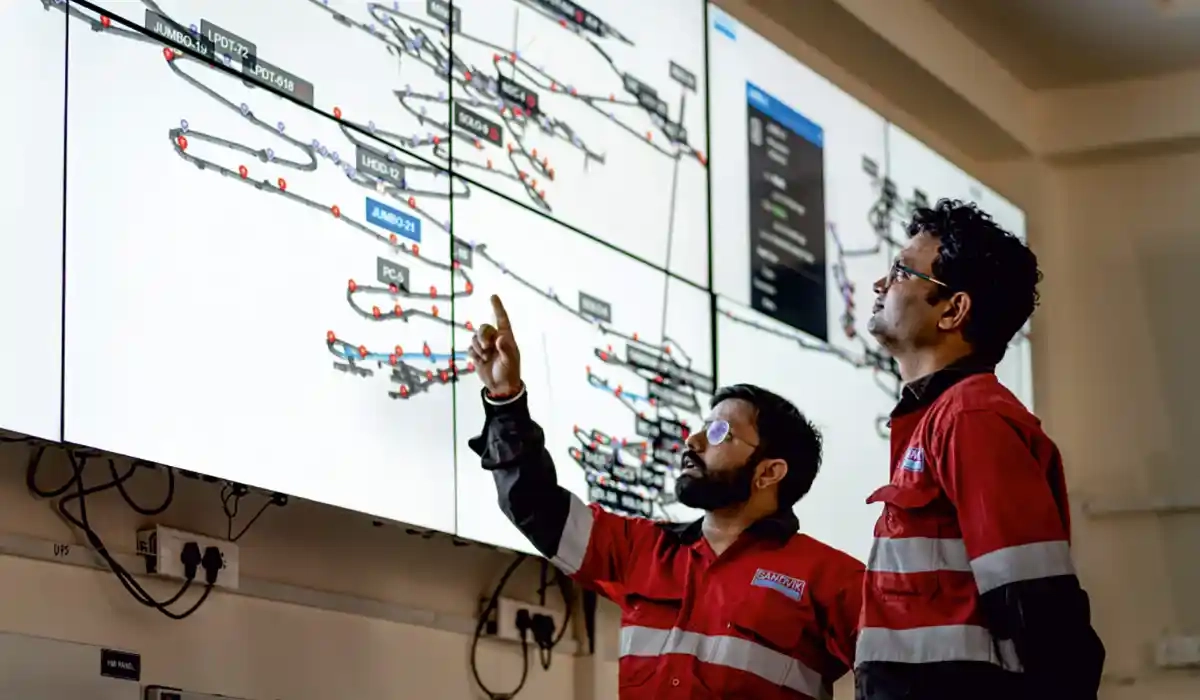

In the world of mining, machine uptime and availability can make all the difference to the work at hand. Having a good machine is only part of the job. What also matters is timely support like maintenance and parts supply to prevent machine downtime. This is what makes working with Sandvik India unbeatable; the company offers customers the option of lifetime support, in addition to access to genuine parts & components, services, and digital innovations.

We currently have over 750 trained personnel for providing 24x7 support to an active fleet of over 1000 machines deployed across the country, ensuring the highest uptime. We also have major stock points at strategic locations across India, a skilled workforce, integrated processes, and real-time supplies.

Digitalization in Mine Operations

Sandvik has been always at the forefront in offering the most advanced automation and teleoperation systems like Artificial Intelligence (AI), Internet of Things (IoT), and internet-connected equipment. These solutions significantly improve productivity and safety, while lowering the total cost of ownership. The software systems help operators and owners to monitor their machines, get real time information on several working parameters, and enable them to control and optimize operations.

MA520 drum cutter

Sandvik MA520 excavator mounted twin cutter attachment is designed for applications in subways, road tunnels, shaft sinking projects, rehabilitation of existing tunnels, excavation in underground cavers, and for demolition work, where it has demonstrated both flexibility and efficiency.

It has a compact and alloy steel robust design for extended service life, and is now made in India to provide the best technology to our customers along with optimised initial and operational costs.

NBM&CW - December 2023