Mother India Forming manufactures steel tube & Roll-formed profile for OEMs

Mother India Forming, Dhirendra Shankla - COO

We provide innovative, customized solutions, a diversified product line, and have invested strongly in R&D. With our locally produced roll-formed components, OEMs can develop sustainable, cost-effective, and high quality, export-finished products for the rest of the world.

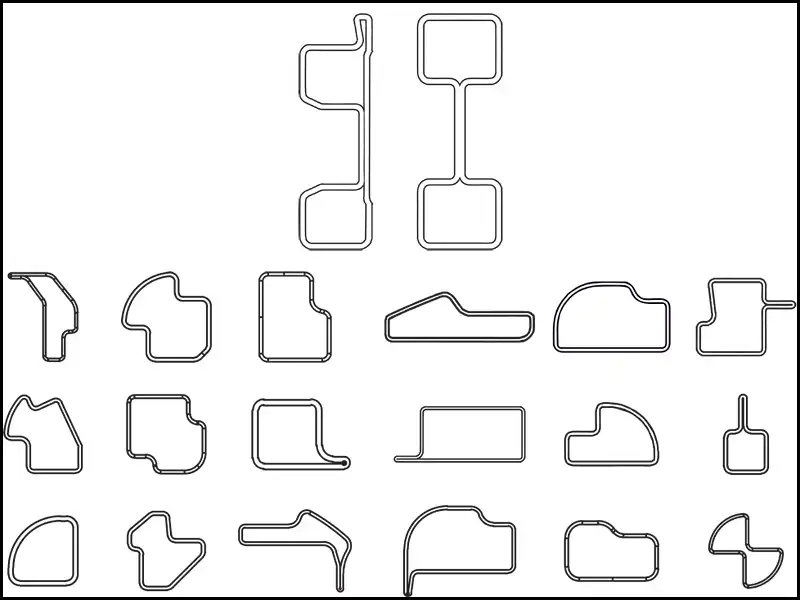

Mother India Forming is a leading organization with over four decades of experience in manufacturing innovative and customized products like tubes and ready-to-use components, making it a one-stop-solution for all roll forming needs. It undertakes localization of critical safety parts in Construction Equipment, Formworks, Elevators, Road Safety Components, etc. and has become a frontrunner in the roll-forming industry.

Fueling growth through innovativeness and customer-centric approach

The company has embraced advanced technologies and harnessed skill expertise to offer customized tubes, profiles and complex components that cater to a wide spectrum of industries, from automotive to construction and more. All our operations are fully integrated - from digitally conceptualized ideas and concepts using the most advanced simulation software to developing a component using computer-aided design.

The addition of tubular laser cutting and conveyorized powder coating used in post processing of cold rolled products adds value for OEMs as it provides better control on quality and cost of the components.

Catering to diverse industries

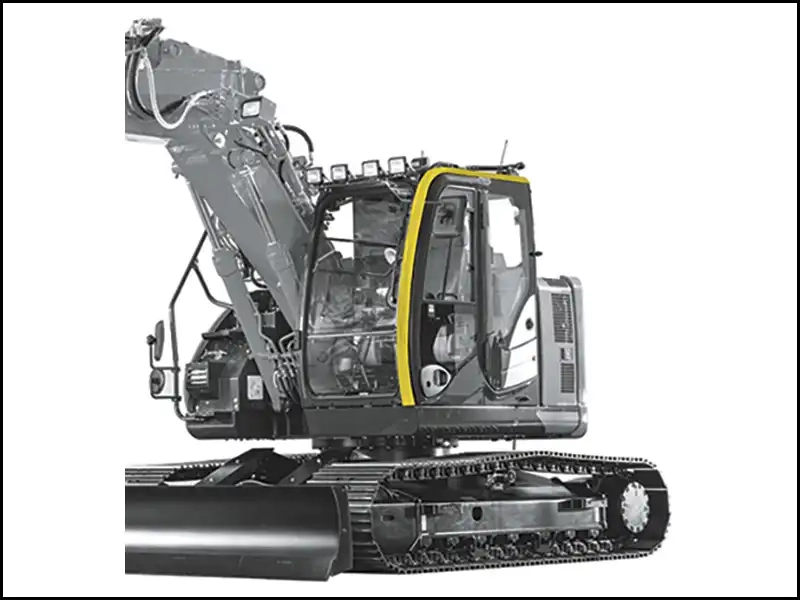

Construction equipment: Employing cold roll forming techniques, we manufacture A pillars, B pillars, structural elements, Roll Over Protected Structure (ROPS) and Fall Over Protected Structure (FOPS) for operator cabins in construction machinery.

Road safety components: Our delineators are a common sight in major highways across India.

Formworks for infrastructure: Our localized formwork profiles are offering a cost-effective and versatile solution for various construction projects.

Elevators: Playing a key role in vertical transportation industry, we manufacture components such as hollow guide rails, door stiffeners, and track profiles using advanced roll-forming.

Automotive: Our high strength, lightweight tubes are used by leading bus body manufacturers in India. These precision roll formed tubes and profiles meet stringent safety and quality standards.

Custom Solutions: We provide custom roll forming solutions for textile machinery, storage solutions, electric cabinets, home appliances, and other specialized applications, bringing precision and reliability to every project.

Localization in harmony with Make in India initiative

By producing roll-formed components in the country clients enjoy cost efficiency, faster project timelines, and the ability to contribute to the local economy. Local production enables customization, collaboration, quality standard, and supply chain reliability for timely deliveries. Moreover, local production creates jobs, supports economic growth, and minimizes the environmental impact of transportation.By choosing locally sourced roll-formed components, clients align with a sustainable, efficient, and nationally beneficial manufacturing process and further enhances OEMs to export finished products to the rest of the world.

Ensuring quality and consistency in products for a global market

Addressing market trends and challenges

The primary challenge most sheet metal industries face is the price of steel being higher and product demand being low in India compared to China, resulting in low growth rate of industries in India. Mother India Forming navigates industry trends by embracing Industry 4.0. The company has invested in IoT-enabled systems to enhance efficiency and optimize operations. We follow sustainable practices like roof top solar panels to generate power, recycling scrap metal, and energy-efficient manufacturing processes.Future market expansion plans

The company intends to expand its market reach and increase its product offerings. Internationally, the company’s strategy for market penetration includes exploring opportunities to be a global business partner.Our online presence and regional offices enhance accessibility to customers. We provide innovative, customization solutions, diversified product lines, and have invested strongly in R&D. We have strategic partnerships, undertake value engineering and analysis, and focus on customer profitability and success.

NBM&CW - December 2023