Spartan to Launch India Make Tower Cranes at Excon

What has been the business performance of Spartan Engineering Industries Pvt. Ltd in the past three quarters of 2013 in this tough economic scenario?

Economic Scenario as you are aware is not too healthy for any business as of now, and that too with construction and infrastructure industry, it is not too supportive. Hike in dollar currency has further dampened the sustainability. Many projects in India are either halted or closed down due to economic slow down or government policies. But I believe, only these situations test the best against the rest and come out a winner. We have taken this slowdown as an opportunity to bring in new machines, which would revolutionize the way man and material handling solutions are provided. We are sure we would pass over this tough situation with our to be launched promising range of man & material movement equipments.

With a rich engineering expertise, Spartan is today the largest seller of bar bending and cutting machine in India. What are the other products the company has in its portfolio which get burgeoning response from the market? How have these products proved to be eco-friendly as well as cost-effective in the construction sector compared to others available in the market?

Your new plant in China has started manufacturing various models of Tower Cranes which are available both in India and China. How challenging Spartan found to make its presence in this new segment where already numbers of foreign players have their strong hold? What new technical inputs, the company proposes to add to gain a foothold in this segment?

Due to recent fluctuations in dollar, which makes it incompetent to import, we are starting manufacturing of the entire Tower Crane in India at our Atgaon factory. This will make us more price competitive and more aggressive to take on bigger market share of booming Indian market. Also, we will be using European Gear Box motor and state of the art electrical control panel with VFDs to save on power and develop a rugged and maintenance free Tower Crane with world class safety features. We will have 4 models with 40, 50, 55 & 60 mtr. jib of inner climbing type, stationary & travelling models to cater to all types of customers having various budgets & requirements. We are launching India make Tower Crane at Excon 2013, Bangalore.

How has the fall of Rupee impacted Spartan business operation? What enabling steps you are taking to minimize the impact?

In its quest to produce more innovative products, the company launched new and rugged cutting machines sometime back. What are the special features of this product and market acceptance it received so far?

We have taken various steps taken to make our Cutting & Bending Machines more efficient, economical and with world class safety features. We have re-engineered the machines to sell at the most competitive price, thereby increased savings on initial cost, operating cost and maintenance cost. We have considerably reduced spares rates and further offer you more discounts, after signing Spare Rate Contract. We insist our customers to sign the contract, which would save time, money & unwanted paper work. We are seeing a good amount of positive response from our customers and hope to further evolve.

The equipment market has reached at that critical point where key competitive differentiator would be after market and innovations. How are you looking on this aspect?

We agree that the key competitive differentiator would be to have focused and come closer to customers by conducting Preventive Maintenance Clinics (PMC) and signing Spare Parts Rate Contracts. Additionally we have increased the number of service engineers to 150. We have invested in world-class Oracle ERP System for receiving call management & service module. As far as innovations are concerned, we have ramped up our strength of people to our design team from 2 to 20 numbers in last one year and invested in high end IT systems and 3D softwares for faster & accurate designs.

Trained operators and technician and preventive & periodical maintenance play a big role in equipment performance. Please brief us on your operators training programs and other related services.

We are amongst the very few companies which have fully dedicated Customer Delight Department. AMC (Annual Maintenance Contracts) & PMC (Preventive Maintenance Clinics) are conducted for all our machines for better life & less downtime for the Machines. Spartan has recruited and trained 150+ Engineers. We have armed them with bikes to reach your sites immediately and are spread across India. We do conduct Operator Training Programs at our customer’s sites on periodic basis. Our engineers are well trained to train. We do have various presentation kits for every product, which is shared with them and explained them on every minute feature and safety norm of the machines, not just to operate but how to avoid breakdowns and to increase the life of machine. So far we have received various acknowledgements for the same, and we thank our customers to give us an opportunity for the same.

What are Spartan’s plans to participate in the mega CE event EXCON 2013? What are the new products, services and developments proposed to be launched at this mega event? Do you think the event will pep up the market?

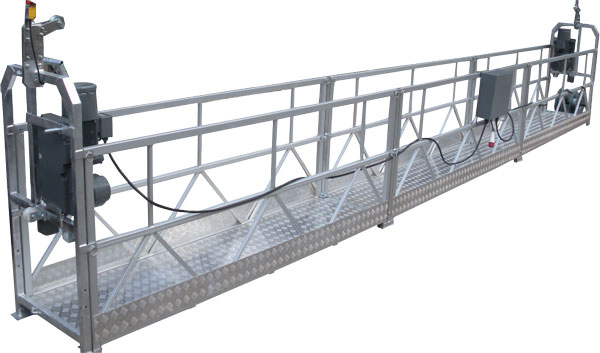

As I shared with you before, we plan to launch couple of Multi-Functional man & material handling Hoists at Excon 2013. I would like to introduce our whole new range of Material & Passenger Hoists- SPM 100 & 150 and SMH 100, 150 & 200. Research and feedback from more than 500 customers using our material Hoists for more than 8 years have inspired us to introduce these machines. Spartan has always been a trendsetter in bringing world-class designs with international safety features in Hoists. Our multi-functionality approach to hoists has put us in a league of being innovative, thereby delivering value added products. The multi-functionality has been the ‘main feature’ of these machines. By multi-functionality, we mean our machines can carry various types of material used at construction sites. The cage can carry material like sand, mortar, cement bags etc. The revolutionary horizontal rebar attachment, can carry various sizes upto 9 mtr length rebars. The ‘roof attachment’ can carry 10 – 12 nos. of labour at various heights. And all these at the price of single machine. Hence it is the best alternative to the Expensive Tower Crane, and also saves cost on purchasing, erection and dismantling of the same. Our design team has studied and researched many Indian and European machines, and this is the result of our survey and learnings. We have erected these machines at various sites in India, on test basis, and got a very positive and motivating feedback. With certain modifications in the design and operation, we have finally come up with the best design to cater to Indian construction site conditions. I am sure, you would agree to allow me to open all my cards there at Excon 2013 in Bangalore...

NBMCW November 2013