GHH Fahrzeuge keen to tap India's tunneling business

German tunneling equipment conglomerate GHH Fahrzeuge that has been promoting its solutions successfully in the Indian mining industry with its range of dump trucks, loaders and drilling rigs, is now eyeing India's growing tunneling sector. Jan Petzold, MD, GHH Fahrzeuge, who was In India recently to inaugurate the company's new training facility at Udaipur, shares the company's business plans with P.P. Basistha on the sidelines of the event, while Rajeshwar Singh, Country Director, GHH India discloses their tunneling expertise and products' competitive edge.

What is your strategy to enter India's tunneling business?

Obtaining the requisite geological data in India is a deterrent for fast tracking tunneling projects by contractors. How will you address this issue?

By having a dedicated set-up in India, we will develop a closer association with our clients to better understand their construction requirements as per the geotechnical complications in the area. With this information, we will make the desired adjustments in our products, for example, in our jumbo drills for injecting the right concrete materials for roof bolting, and we will offer the necessary support for smooth execution of the projects. We will also forge a close association with geotechnical groups (as we do globally) to understand the character of the tunnels.

What kind of tunneling projects are you looking at for your products and solutions?

We will be targeting niche tunneling projects such as hydro tunnels with smaller diameters, and road infrastructure tunnel projects with bigger diameters. We will be offering our MKA- series of 15-20-ton dump trucks, and our entire range of MKA-series of 35-42-55-65-ton heavy dump trucks with buckets as per the project requirements. From Mine Master of Poland, we will be offering jumbo drill rigs with one, two and three booms comprising of FM 1.7, 2.3, and 3.0, with an option of baskets and FM2.5 NVDR for narrow vein tunnel. From MTS, we will offer tunnel boring machines upto 4.5-meter diameter tunnels, and our range of loaders. We will ensure that our equipment comply with our customers' needs so as to ensure optimum productivity and quicker execution of their projects.

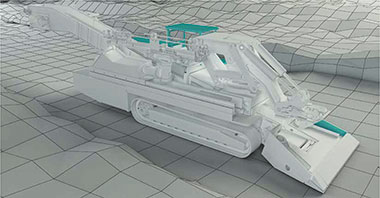

We have developed HRE series of multi-purpose equipment for small diameter tunneling project of minimum 3.2 m diameter. This machine can be mounted on rail track. A HRE single machine can do drilling,roof bolting, loading & shotcreting thereby helping the tunneling contractors as follows:

- Reduced machinery and manpower in operation

- Reduced amount of niches and niche volume (cost)

- Reduced total energy consumption

- Reduced emissions → reduced ventilation

- Higher utilization of machinery

- Reduced full cycle duration

With other premium tunneling manufacturers present in India, how will you position your products competitively?

Unlike many manufacturers, we do not offer standard products; rather, we carry out the required customization in our products as per project requirements. For example, we provide onboard weight measuring systems in our trucks to calculate the load volumes. In fact, all GHH products deliver high productivity, ease of operation and safety as they are equipped with ROPS and FOPS cabins. Our dump trucks have a bi-directional moving feature, which makes it easy for the operator to maneuver even in constricted underground sites, and they can make faster trips. Our equipment is hydraulically controlled with less electronics as we believe that simplified technologies make them easier to operate, plus, they comply with all the exhaust regulations.

Being a small company but with a vast global experience, we can meet the product support requirements of individual customers and design a service package accordingly. We offer container stations for stocking parts that are regularly replenished for timely supply. Our new 600 sqm training facility in Udaipur and our workshop for repairs, and our classroom training will leverage our customer support further.

GHH products are of high value and have limited utilization across the project cycle. What will be the cost competitiveness of your products?

Our equipment has a cost depreciation over several project's span and our customers are usually satisfied with their quality, given the higher productivity and ease of maintenance. However, to make the owning of the equipment economical, we provide the option of renting them out, backed by our operations, maintenance and parts support.

NBM&CW May 2018