Waterproofing Tunnels

Types of Tunnel Waterproofing Solutions

Waterproofing tunnels is vital for averting water leaks and safeguarding tunnel structures and their surroundings. There are multiple tunnel waterproofing membranes at one’s disposal, each presenting its unique advantages and disadvantages.Liquid Waterproofing Membrane: This system involves applying a hot liquid substance like rubber, tar, polymers, or asphalt emulsions to the tunnel surface. This liquid material forms a continuous and seamless layer that adheres to the substrate while filling cracks or voids.

Advantages:

- It can be applied to tunnels of any shape or geometry.

- It can adapt to minor structural movements or settlements.

- Easy repairs or modifications are possible when needed.

Disadvantages:

- Application requires specialized equipment and skilled labor.

- Sensitive to temperature and humidity during application and curing.

- Limited service life due to aging or degradation.

Advantages:

- Quick and straightforward installation without the need for heating or curing.

- The material’s swelling property allows for self-healing of minor damage or punctures.

- Resistant to chemical attacks from aggressive groundwater.

Disadvantages:

- Requires a dry surface for installation as moisture affects material swelling.

- May not conform well to irregular or curved surfaces, leading to gaps or wrinkles.

- Effectiveness may decrease over time due to desiccation or erosion.

Advantages:

- High tensile strength and elongation, accommodating significant deformations or vibrations.

- Long service life with resistance to aging, UV rays, and chemicals.

- Easy inspection and testing for leaks or defects.

Disadvantages:

- Requires meticulous preparation and quality control during installation to prevent performance compromises.

- Susceptible to punctures or tears from sharp objects or abrasion.

- Challenging to repair or replace, if damaged.

Why Membrane Waterproofing is Essential for Tunnels

One of the most effective methods for safeguarding tunnels from water damage is membrane waterproofing. This involves applying a thin layer of material to prevent water infiltration into the tunnel.

Membrane waterproofing prevents water leakage and seepage, averting corrosion, cracking, freezing, and mold growth in the tunnel. It reduces the risk of structural failure due to water pressure and soil movements, enhancing the tunnel’s lifespan and minimizing costly repairs and maintenance. Additionally, it improves the tunnel’s appearance and comfort by preventing dampness and staining while conserving energy and water resources by reducing heat loss and water consumption within the tunnel.

Membrane waterproofing stands as a proven technology utilized in numerous tunnel projects worldwide, such as the M5 Milan Metro Line in Italy, which employs SINTOFOIL TPO/FPO membranes, and the Ceneri Base Tunnel in Switzerland, which utilizes EUROFLEX PVC-P membranes. It is an integral component of tunnel engineering, ensuring the tunnel’s performance and safety over generations when the right membrane material and application method are chosen.

Waterproofing Tunnels with PVC and Low-Pressure Polyethylene Membranes

A common and effective approach to tunnel waterproofing involves the use of PVC (polyvinyl chloride) and low-pressure polyethylene membranes. These flexible plastic sheets are applied to the tunnel’s interior, establishing a watertight barrier between the tunnel and groundwater.PVC and low-pressure polyethylene membranes offer several advantages over other waterproofing materials:

- Resistant to chemicals, abrasion, punctures, and UV radiation.

- High tensile strength and elongation, allowing accommodation of tunnel movements and deformations.

- Easy installation and repair, as they can be welded together using hot air or extrusion.

- Long service life, ranging from 50 to 100 years.

- Preparing the tunnel surface by cleaning, smoothing, and repairing any cracks or defects.

- Applying a primer or adhesive to enhance the bond between the membrane and the substrate.

- Laying the membrane on the tunnel surface, ensuring edges overlap by at least 10 cm and securing it with washers and profiles.

- Welding the seams of the membrane using hot air or extrusion to establish a continuous and leak-proof joint.

- Applying a protective layer over the membrane such as concrete, shotcrete, or geotextile to prevent mechanical damage.

How to Select the Right Bentonite Type for Waterproofing

Tunnel waterproofing is a critical aspect of tunnel construction and maintenance. However, not all waterproofing systems are suitable for every tunnel project, and choosing the right one depends on various factors, such as soil and groundwater conditions, tunnel design and geometry, construction methods, durability requirements, and cost-benefit considerations.Bentonite, a natural clay mineral capable of expanding when exposed to water, can form a dense, impermeable barrier, sealing gaps and cracks in the concrete lining. Bentonite also possesses self-healing properties, allowing it to reseal itself when damaged by minor movements or settlements. To select the appropriate bentonite type for your tunnel project, consider the following criteria:

- Swelling capacity: This measures how much the bentonite can expand when wetted. A higher swelling capacity enhances its sealing ability, but excessive swelling may exert pressure on the concrete lining or deform the panel. Opt for a bentonite type with moderate swelling capacity, around 10 to 15 times its dry volume.

- Swelling time: This indicates the time required for bentonite to reach its maximum swelling capacity upon water exposure. A shorter swelling time allows the bentonite to react faster to water ingress and create a waterproof barrier. However, excessively short swelling times can impede proper installation and compaction of the panel. Choose a bentonite type with a swelling time of approximately 4 hours.

- Water absorption: This represents the amount of water the bentonite can retain within its structure. Higher water absorption makes the bentonite more durable and resistant to drying out. However, excessively high water absorption may compromise its strength and stability. Opt for a bentonite type with water absorption ranging from 400% to 600% of its dry weight.

- Chemical compatibility: This assesses the extent to which bentonite can withstand degradation or alteration when exposed to various chemicals in groundwater or soil. Lower chemical compatibility increases the likelihood of bentonite losing its swelling and sealing properties over time. Therefore, choose a bentonite type with high chemical compatibility with local groundwater and soil conditions.

Waterproofing in Cold Climates & High Altitudes

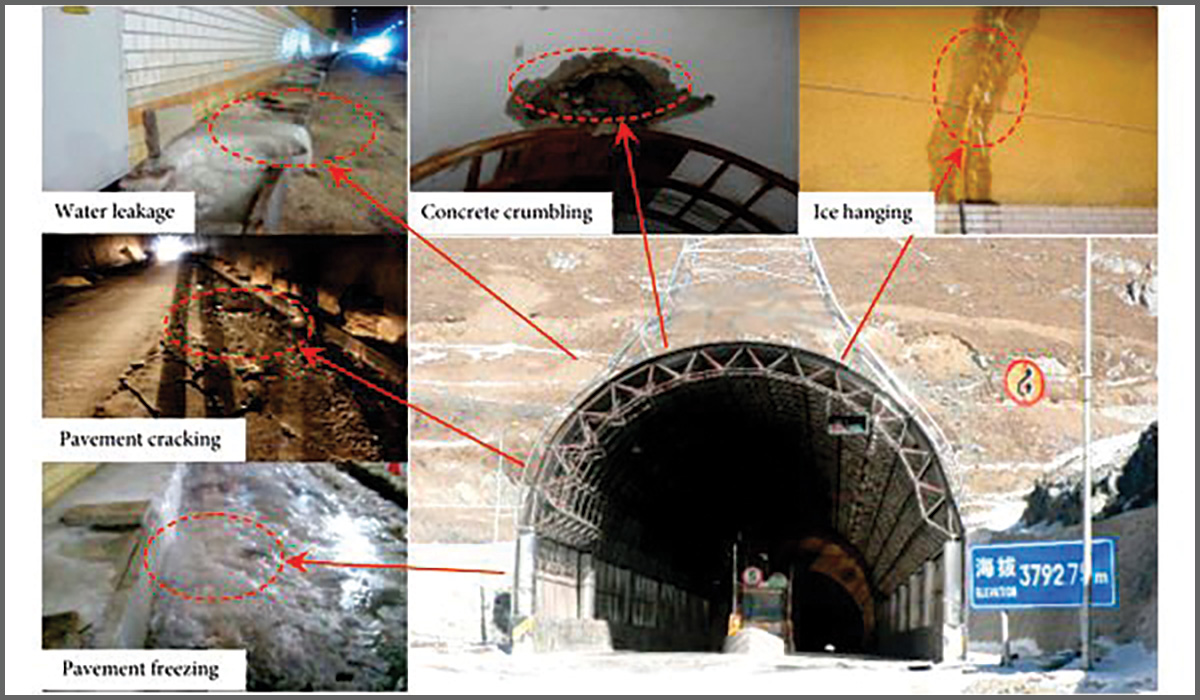

Tunnels serve as vital connectors between regions, facilitating transportation, communication, and trade. However, constructing and maintaining tunnels in cold climates and high altitudes presents significant challenges, especially in terms of waterproofing.One of the primary issues tunnels face in cold regions is frost damage, which occurs when water freezes and expands within the tunnel structure, leading to cracks, spalling, deformation, and seepage. Frost damage can jeopardize the tunnel’s safety, longevity, and performance, as well as the environment and groundwater resources. Factors contributing to frost damage include temperature, moisture content, freezing depth, frost heaving force, ventilation, and tunnel drainage systems.

To prevent or mitigate frost damage, several techniques can be employed during the tunnel project’s design, construction, and maintenance phases:

- Insulation: This method involves installing an insulating layer between the tunnel lining and the surrounding soil to reduce heat transfer and prevent freezing and thawing cycles. Insulation materials may include polystyrene foam, polyurethane foam, mineral wool, or geotextiles.

- Active heating: Active heating maintains a temperature above freezing point within the tunnel structure by applying a heat source. Methods for active heating include electric heating cables, hot water pipes, or warm air blowers.

- Waterproofing membranes: Flexible sheets of synthetic or natural materials, like polyvinyl chloride (PVC), high-density polyethylene (HDPE), ethylene propylene diene monomer (EPDM), or bitumen, can be attached to the tunnel lining to establish a watertight barrier and prevent water ingress.

- Drainage: A drainage system comprising pipes, channels, pumps, or wells can be installed to collect and discharge excess water from the tunnel. Proper drainage helps reduce water pressure and moisture content in the tunnel structure, preventing icing and flooding.

NBM&CW November 2023