Tunnelling in Challenging Topography & Geological Conditions for a Railway Doubling Project in Eastern Ghats

S.S. Nirmal, L. Kumar, A. Shaz & R. Gupta, RITES Limited, Gurgaon

The East Coast Railway is constructing a new railway line parallel to an existing one in the Koraput-Singapur Road section. This 164-km long railway line has 36 existing tunnels and 24 tunnels for proposed second line. The existing line was constructed in 1982 through a dense forest and varying geology. This paper focuses on a smaller section of 45-km length between Tikri and Bhalumaska with 19 proposed tunnels.

The existing railway line passes through steep gradients with sharp curves. The region has a low population and dense forests. The proposed line is planned to increase the capacity of the section. Planning optimal alignment was a challenge due to a range of factors. The project encountered geological challenges during the design of the proposed Tunnel 23. This paper discusses the various failures that were recorded while it was being constructed, the challenges faced during its execution, and the decisions made while following sustainable practices.

Photo courtesy: hmrdc.com

Photo courtesy: hmrdc.com

RITES Limited was awarded the work for design of proposed alignment of tunnels, conducting geological and geo-technical investigations, and preparation of detailed project report (DPR) along with detailed designs and drawings for construction of railway tunnels between Tikri and Bhalumaska stations. The Tikri to Bhalumaska section is 45 km long within the 164 km long Koraput to Singapur Road railway line.

Challenges were faced in the design of the tunnels and in the railway alignment in the Tikri to Bhalumaska section, and during designing of Tunnel 23. Sustainability was a major focus area while deciding the railway alignment, with excavations and filling volumes optimized for reducing environmental loss and to have minimum impact on the existing biodiversity and land acquisitions.

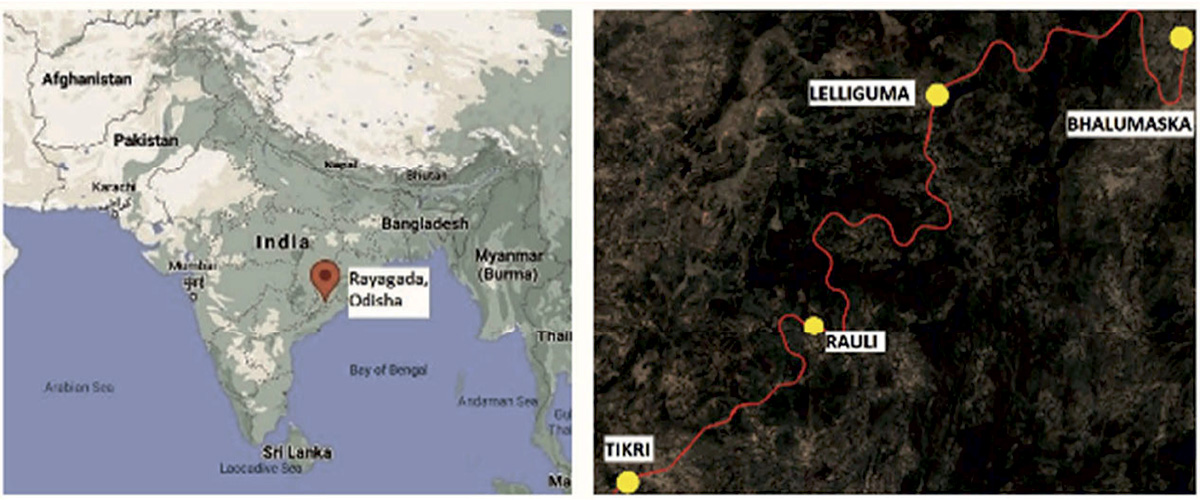

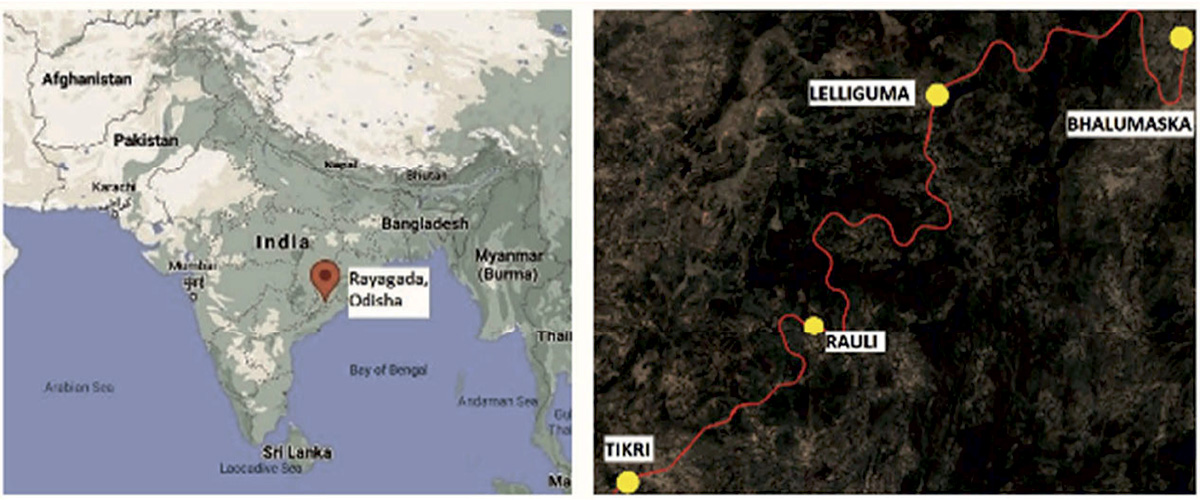

Figure 1: Location of the project Tikri- Bhalumaska section in Rayagada district, Odisha

Figure 1: Location of the project Tikri- Bhalumaska section in Rayagada district, Odisha

The Tikri Bhalumaska section has 19 proposed tunnels with total length of 12.1 km. The longest tunnel is 1.86 km long while the shortest tunnel is 120m long. Tunnels are located in a region with high variation in geology with fractured and weak rock to intact rock with very high strength.

The Eastern Ghat Mobile Belt (EGMB) is a well-defined entity forming a series of hill ranges parallel to the east coast of India from Mahanadi (Orissa) in the north to Nallamalai (Andhra Pradesh) in the south. It is a prominent Precambrian orogenic belt.

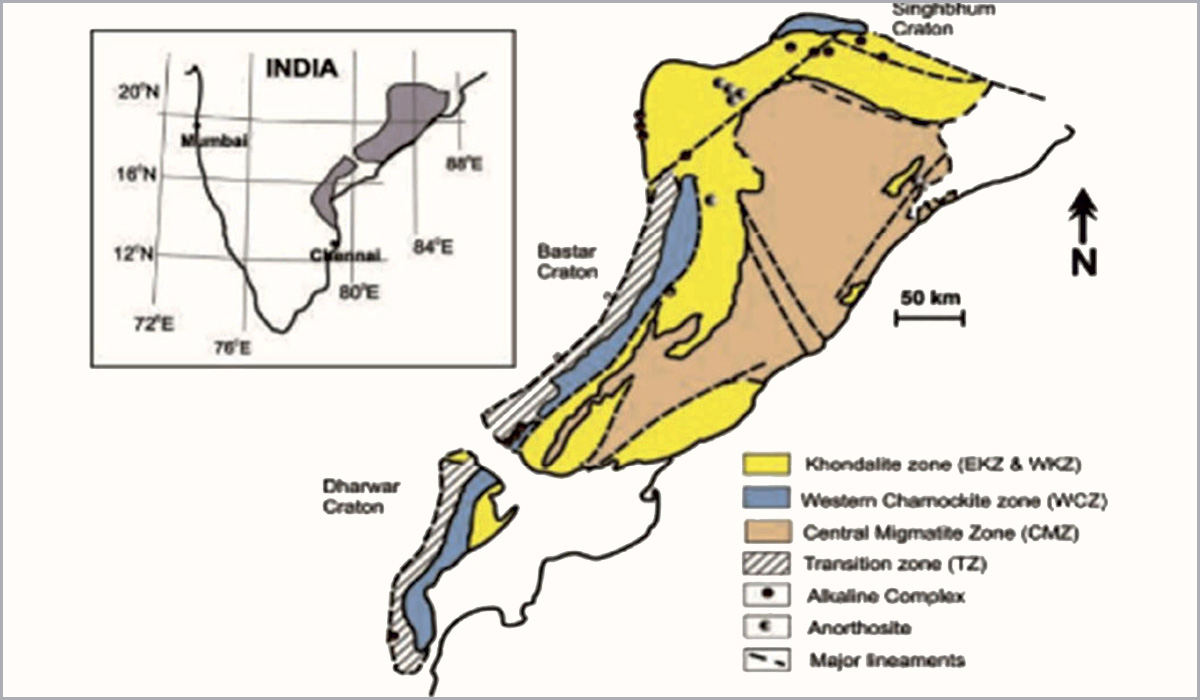

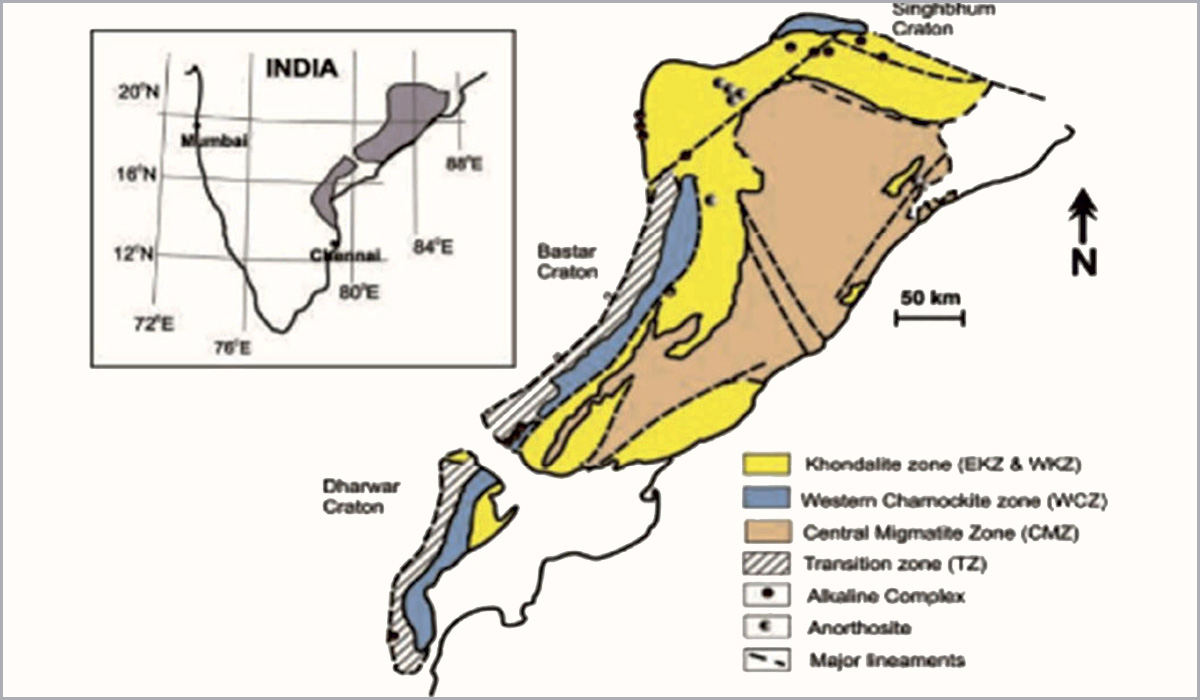

Figure 2: Eastern Ghat Belt based on lithological characters (Ramakrishnan, 2008)

Figure 2: Eastern Ghat Belt based on lithological characters (Ramakrishnan, 2008)

The principal rock units of the eastern ghats are the granite gneisses, the charnockite series, the khondalite series, and the granites. The charnockite series and the khondalite series are more in proportion in the hill ranges, whereas the granite gneisses are more in proportion with the plains between the hill ranges and the east coast (Sriramadas, 1960). Eastern Ghat supergroup of rocks comprises several linear patches of khondalite, quartzite, calc granulite, charnockite, and granite.

Majorly, granitic gneiss is observed along the proposed tunnel locations. Granitic gneiss is moderately to highly weathered in general, and completely weathered at places, jointed, and medium strong to weak in strength. Although, it was observed from the unlined portions of existing tunnels that the rock one expected to encounter inside the proposed tunnel was of good quality, intact and self- supporting. Detailed geotechnical investigations further supported the observations.

Tunnel 23 had a large variation in geology across its length with high geotechnical risks and experiences from the construction of first line, which indicated that a detailed investigation was necessary for this tunnel to eliminate the risks. The geological challenges and mitigation measures associated with Tunnel 23 are mentioned in detail in this paper.

Figure 3: Easter ghat hills rich in biodiversity

Figure 3: Easter ghat hills rich in biodiversity

Apart from topographical challenges, there were environmental impact challenges as well. The existing alignment passes through dense forests in the hills of eastern ghat with rich biodiversity of flora and fauna.

The client provided preliminary alignment before start of the project, which was studied and modifications were proposed to optimize the alignment to mitigate project risks.

As the alignment passes through a highly uneven topography, the existing railway line has many major and minor bridges, along with 21 existing tunnels. It is common to notice large fillings and high cuttings along the existing railway line.

Due to topography variations and existing major structures (bridges and tunnels), it was not possible to propose a railway line with a fixed distance from the existing line. Hence, the initial criteria to make decisions on proposed alignments was to decide its distance from existing railway line at locations with tunnels, major bridges and at flat terrain, as mentioned in Table 1.

Existing major bridges were constructed with wide footings and hence safe center to center distance of 20m was decided for proposed parallel major bridges. It was proposed to minimize the impact on existing bridges during construction of proposed bridges. Similarly, proposed tunnels were decided to be 35m apart (axis to axis) considering the geology, space requirements, and to avoid any impact on existing tunnels during construction of the proposed tunnels.

The complete alignment of 45 km was mapped with guiding aspects as per Table 1 for proposed track distances and then horizontal curves and transitions were designed between Tikri and Bhalumaska section as per the railway manual (Railway Board, Ministry of Railways, 2020).

Figure 4: Existing railway line passing though high cutting and deep valley

Figure 4: Existing railway line passing though high cutting and deep valley

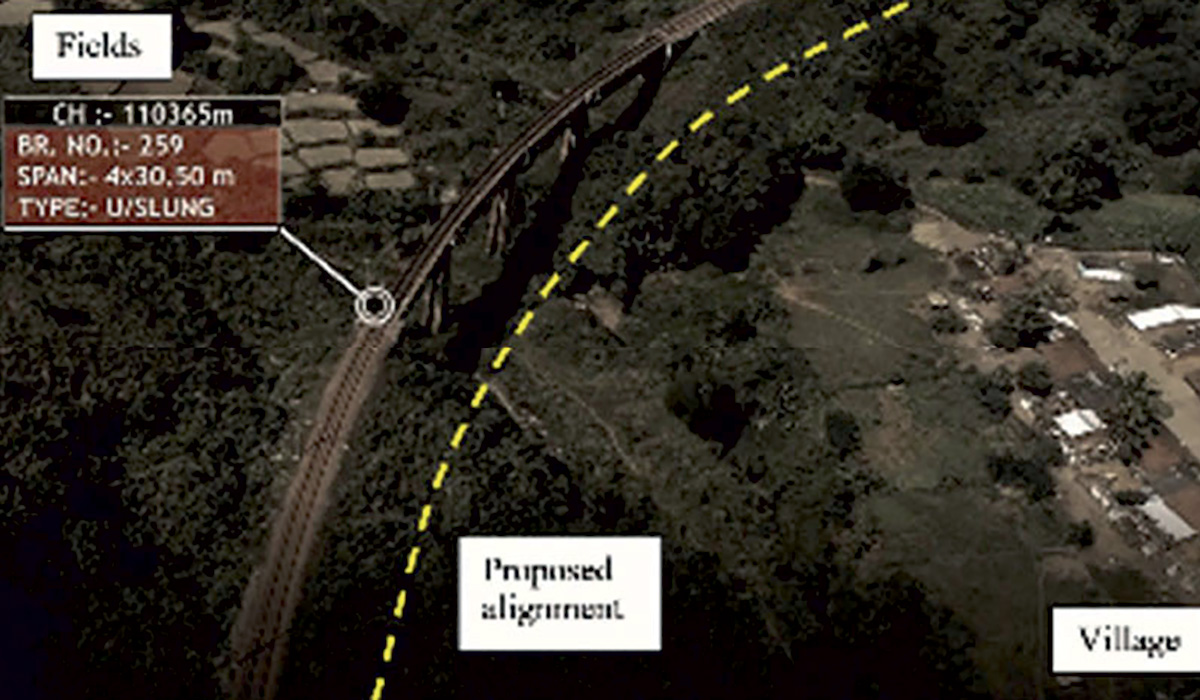

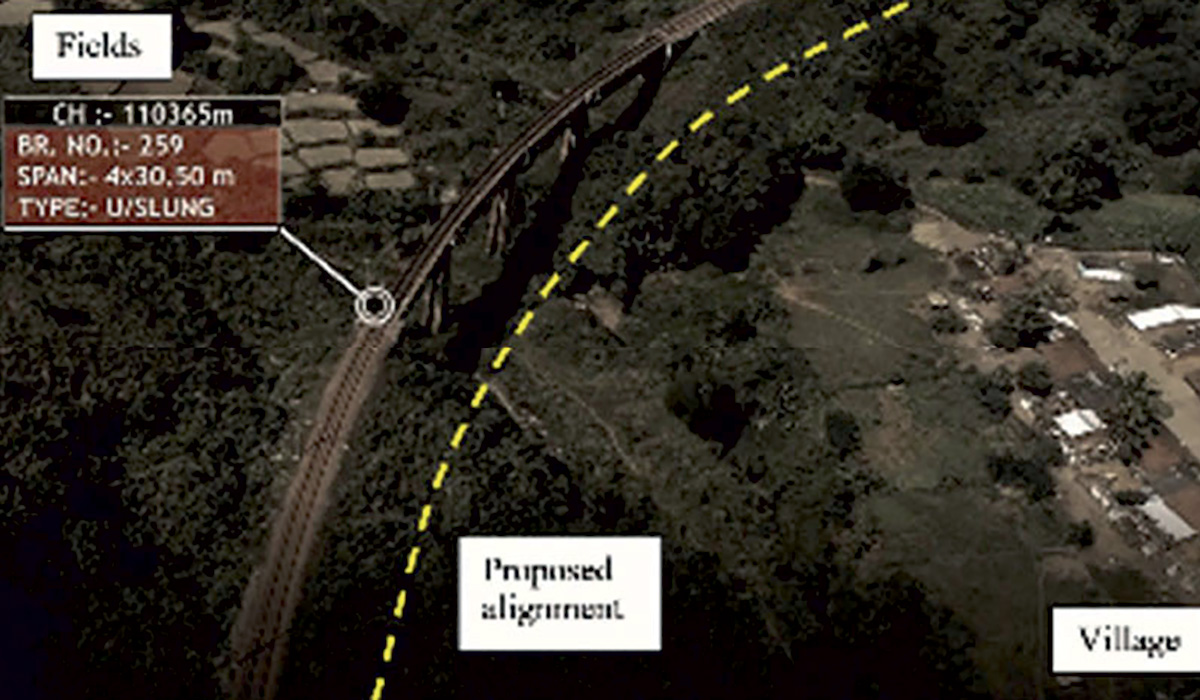

Figure 5 above is an example of where the location of alignment of the proposed railway line was decided to avoid agri fields and the village for land acquisition, hence, avoiding displacement of communities and adverse impact on agriculture land. Such decisions were taken for the alignment design of this 45 km long project.

Efficient design of alignment resulted in reducing impact by 37.5% in terms of forest land requirements, in comparison to the original proposal.

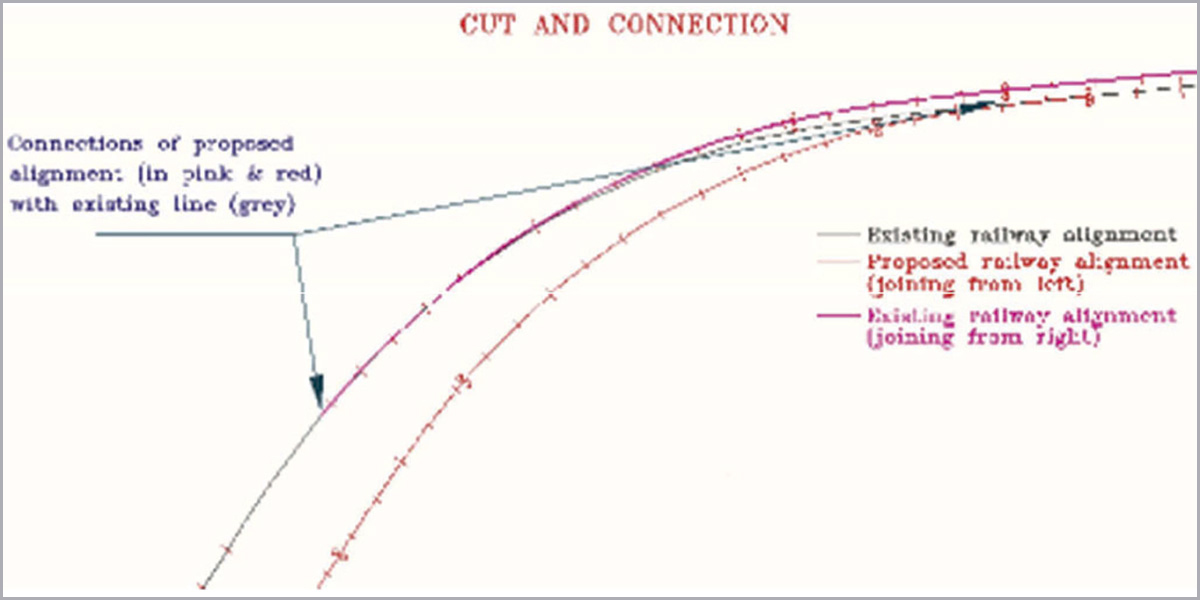

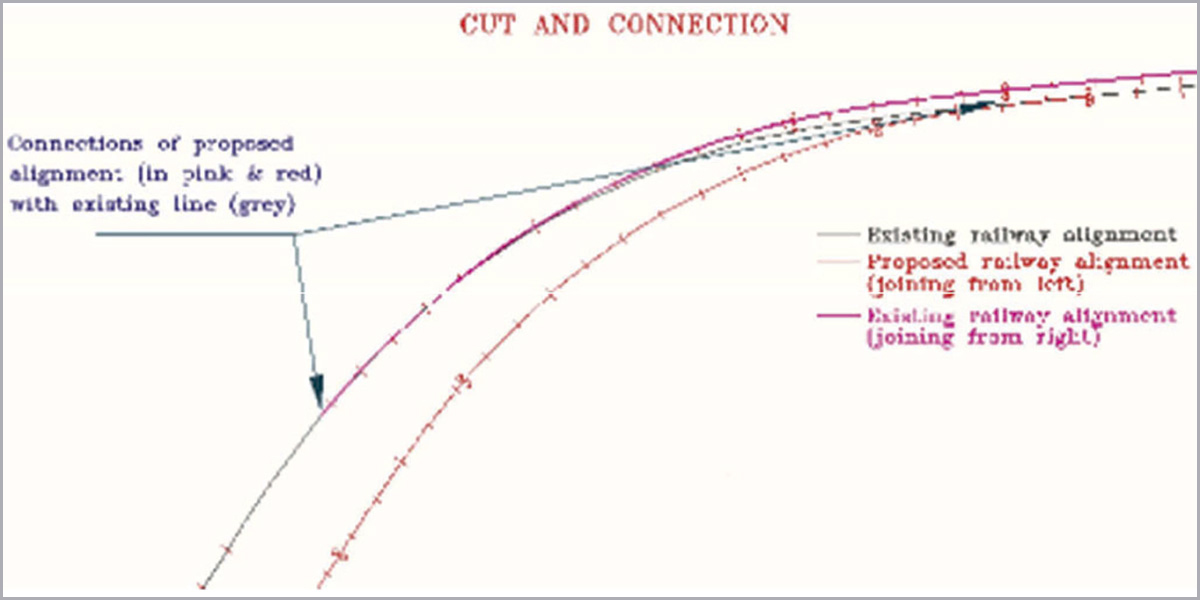

To reduce excavation and filling quantities for the proposed line, both left and right sides of the existing railway line were studied as preferable locations. Post detailed study, preferred locations for proposed line (left or right to existing line), were chosen, with preferable switches where required. Along the 45 km long stretch (moving from Rauli to Bhalumaska) the proposed alignment is on the right side of the existing alignment for first 5.5 km, on left for next 16.5 km, on right for next 7km, on left for next 9 km and on right for last 7 km. The switch of proposed alignment from left to right (or right to left) with respect to the existing line was designed as cut and connections (4 numbers). A sample of cut and connection proposed is as shown in Figure 6.

Figure 5: Alignment proposed to avoid the village and fields to minimize the impact

Figure 5: Alignment proposed to avoid the village and fields to minimize the impact

Apart from cut and connections, it was decided to start the tunnels with lower covers to crown and build retaining wall (both hill side and valley side) to reduce cuttings and fillings. This resulted in achieving a better solution and the overall reduction in cost and construction time.

As per Table 3, the impact of these initiatives was substantial and resulted in reducing carbon emissions due to reduction in excavation and filling works. It resulted in reduction in project cost by Rs. 1.3 billion (approx. USD 16 million).

The existing Tunnel 23 was constructed in 1982 with limited tunnel construction experience and technology available in India’s tunnelling industry. The existing tunnel is 1.6 km long with substantial variation in geology across its length. The tunnel has very strong and intact rock towards.

Figure 6: Cut and connection between Tikri and Bhalumaska stations

Figure 6: Cut and connection between Tikri and Bhalumaska stations

The portals, although a 300m long stretch in the center has very poor geology, with huge water ingress encountered during construction of existing tunnel. As soon as the tunnel construction reached the weaker strata, a large volume of water came into the tunnel, resulting in face collapse and eventually chimney failure, with creation of a large crater on the surface. Dewatering and jet grouting techniques were used from the surface to improve the ground before resuming tunnelling activities again. About 675,000 kg of cement was used to grout the whole region.

Once the ground was stabilized, heavier support such as steel ribs and fore polling were used to tunnel through the grouted ground until good rock was encountered again. The unexpected discovery of weaker strata led to a one year delay of the project and 4 times escalation in cost for the client. Further, limited availability of geological data led to overuse of resources (Rao, 2002). This failure was the best information available to make decisions for the proposed second tunnel for parallel railway line.

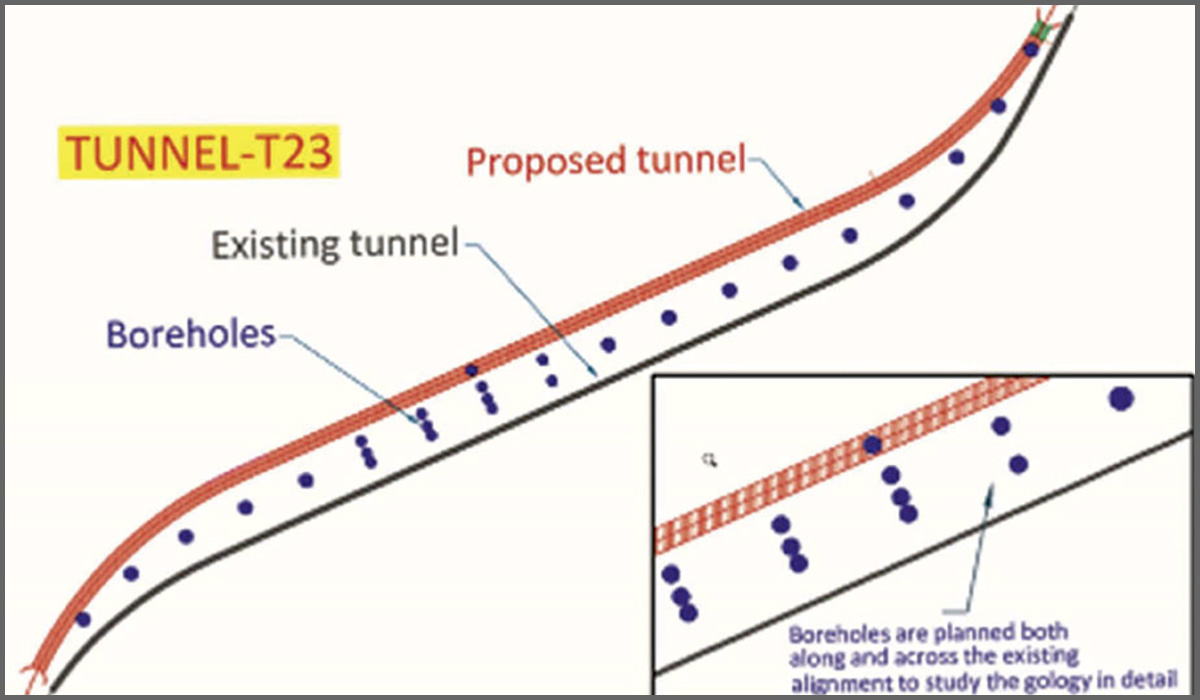

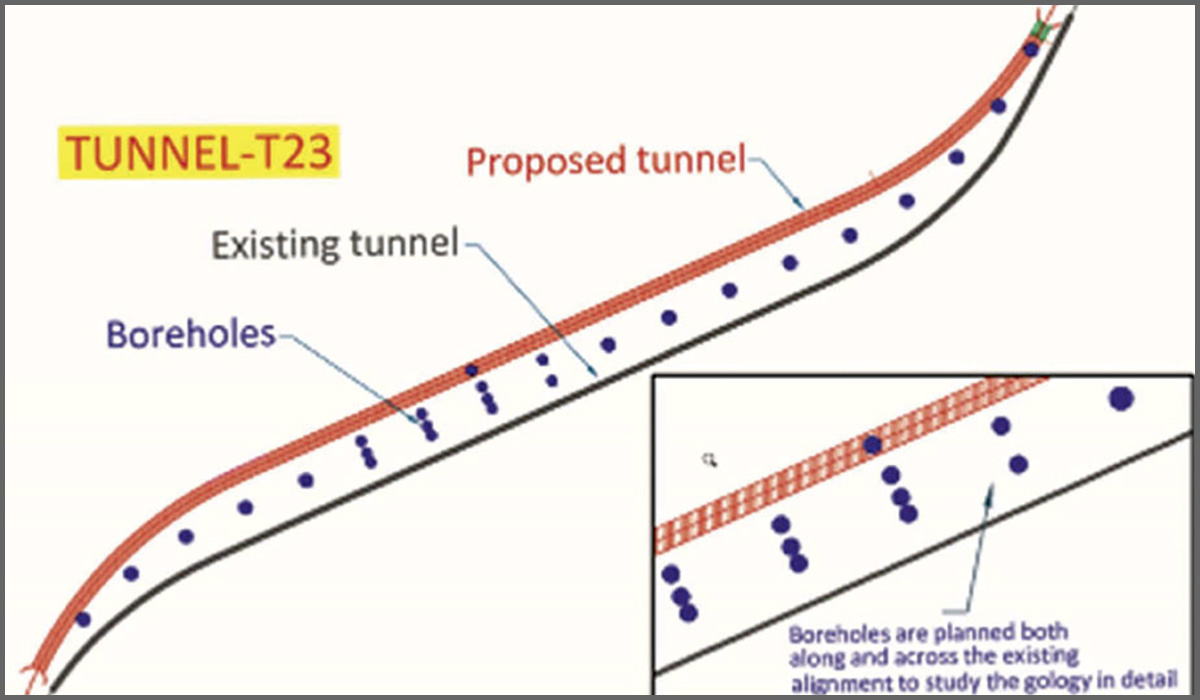

As limited data was available for the grouted ground in the vicinity of the existing tunnel, it was decided to go for extensive geotechnical investigations to get detailed information on ground conditions. Bore holes were planned both along the tunnel alignment and across the tunnel alignment to map the zone of weak ground in this region. Further, geophysical studies were conducted to co-relate the finding and have more data to observe the variation. Geological investigations indicated that if distance between the tunnels can be increased, then the proposed tunnel would encounter better ground. The alignment was revised to relocate the tunnel in better geology.

Figure 7: Geotechnical investigations conducted on Tunnel 23

Figure 7: Geotechnical investigations conducted on Tunnel 23

Extensive planning, assessment of geology, and preferred tunnel location led to informed decisions on tunnel design. Improved proposal avoided requirement of heavy supports (reducing steel requirements), grouting (reducing cement requirements), project delays, and groundwater contamination due to grouting. Further, good quality work was expected, unreinforced permanent lining was proposed reducing requirement for structural steel. Early planning and informed decision making for the revised proposal avoided carbon emissions that would have otherwise been added to the environment from overuse of 820,000 kg steel and 950,000 kg cement.

This project was proposed with consideration to each of these pillars of sustainability. The social aspects of sustainability were taken into consideration while deciding the alignment of the proposed railway line, avoiding old villages and fields. This led to conservation of ancient tribal culture and farming practices.

Figure 8: UN Sustainable development goals (United Nations, 2015)

Figure 8: UN Sustainable development goals (United Nations, 2015)

The human pillar of sustainability focuses on health, safety, access to service, nutrition, knowledge, and skills. The project brought many employment opportunities for the local community, which helped people from all genders to learn new skills and enhance their knowledge. Further, the proposed upgrade of rail network will open more opportunities due to easy access to transportation and hence access to services such as schools and medical facilities.

The economic pillar of sustainability deals with employment opportunities, growth and standard of living. The project has 45 km of railway line with many bridges and tunnels to be constructed and potential for employment opportunities for local people. Acquiring skills while working would raise the standard of living and increase employability of local communities in the long term.

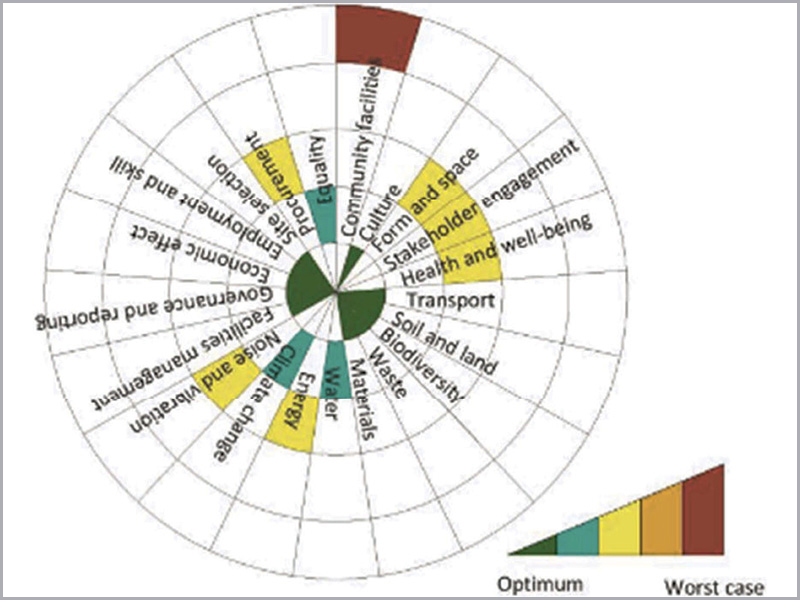

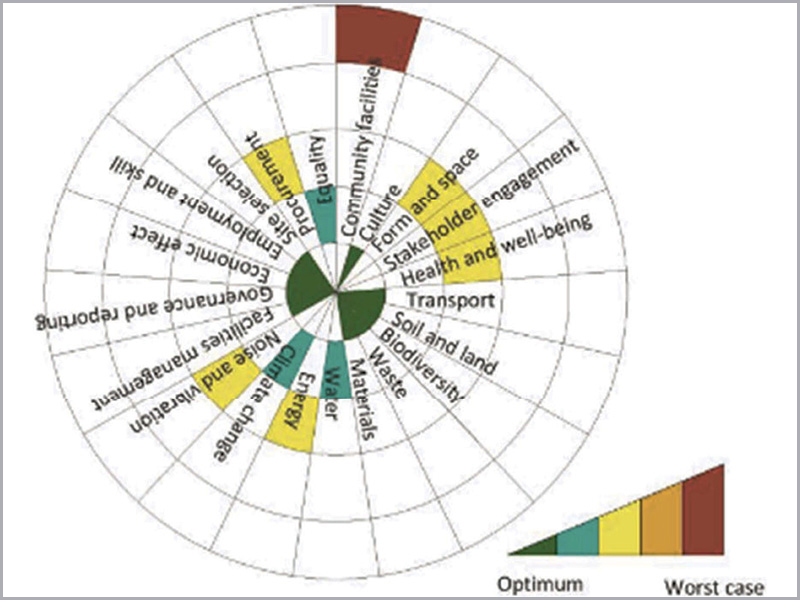

Figure 9: Uspear diagram for weighted comparison of sustainability indicators

The environment pillar of sustainability focuses on protection and efficient use of natural capital (land, water, air, minerals, etc). Decisions taken during alignment finalization and tunnel design helped to reduce land acquisitions, large excavations in cuttings and wide fillings, tree cuttings and reduction in use of steel and concrete. These initiatives resulted in efficient use of materials and resources contributing to sustainability of the project.

Figure 9: Uspear diagram for weighted comparison of sustainability indicators

The environment pillar of sustainability focuses on protection and efficient use of natural capital (land, water, air, minerals, etc). Decisions taken during alignment finalization and tunnel design helped to reduce land acquisitions, large excavations in cuttings and wide fillings, tree cuttings and reduction in use of steel and concrete. These initiatives resulted in efficient use of materials and resources contributing to sustainability of the project.

UN SDGs were shared in 2016 with focus on a multi- dimensional agenda for sustainability for the year 2030. The sustainable initiatives and decisions taken during the design of this project contributed to goal number 8 (generating employment opportunities), 9 (creating railway infrastructure network), 11 (protecting community values), 12 (responsible consumption of materials and resources), 13 (reduction in carbon emissions from steel & cement use), 15 (minimizing impact on ‘life on land’ by reducing land acquisition and hill cuttings/fillings).

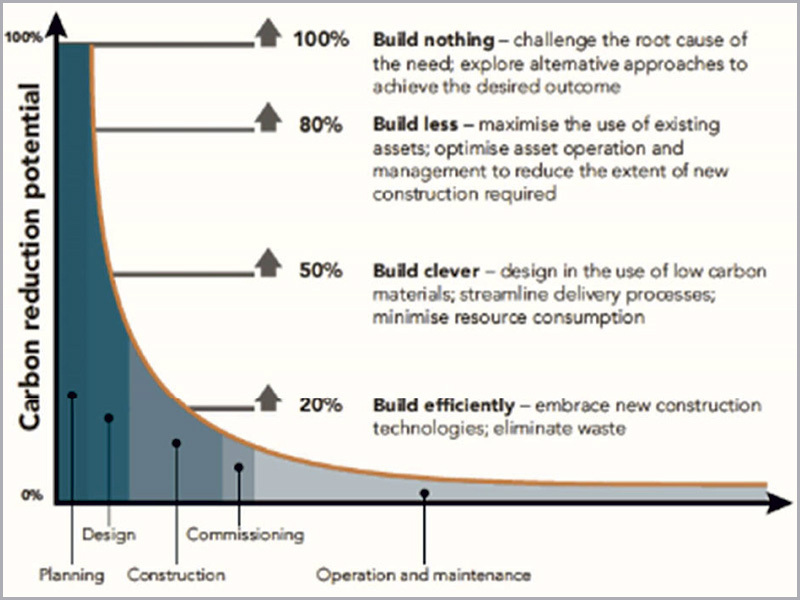

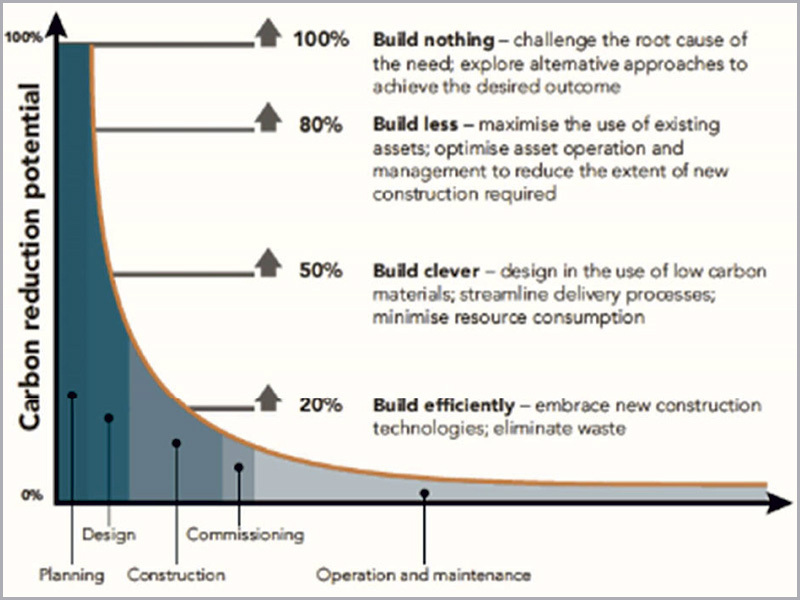

Figure 10: Carbon reduction potential with associate project stages (HM Treasury, 2013) & (Green Construction Board, 2013)

Sustainability initiatives taken for the project were measured with a tool known as Uspear. Uspear is developed as a decision/assessment support tool with a comprehensive indicator framework that specifically addresses sustainability issues in Urban Underground Space (UUS) development (Zargarian, 2016). The tool is tailor made to specific needs and is applicable to assess- ment in urban regions. Although, it is found useful with tunnels in non-urban regions and is used for this project, with some modifications it has scope to be more efficient for non-urban regions. It considers 21 indicators from economic, social and environmental aspects to help with decision making. The assessment of the project in discussion is shown in Figure 9.

Figure 10: Carbon reduction potential with associate project stages (HM Treasury, 2013) & (Green Construction Board, 2013)

Sustainability initiatives taken for the project were measured with a tool known as Uspear. Uspear is developed as a decision/assessment support tool with a comprehensive indicator framework that specifically addresses sustainability issues in Urban Underground Space (UUS) development (Zargarian, 2016). The tool is tailor made to specific needs and is applicable to assess- ment in urban regions. Although, it is found useful with tunnels in non-urban regions and is used for this project, with some modifications it has scope to be more efficient for non-urban regions. It considers 21 indicators from economic, social and environmental aspects to help with decision making. The assessment of the project in discussion is shown in Figure 9.

Further, as per (HM Treasury, 2013) and (Green Construction Board, 2013) maximum impact on the project can be made during early stages as shown in Figure 10. Following sustainable practices was at the heart of the decision making, right from the planning stages of this project. Major contributions were made to the project to reduce impact on environment while deciding alignment and designing tunnels to suit the best geology.

Railway board, Ministry of Railways, 2020. Indian railway permanent way manual. Pune: Indian Rail- ways Institute of Civil Engineering, Pune.

Ramakrishnan, M. & Vaidyanandhan, R. 2008. Geology of India- Volume 1. s.l.:Geological Society of India.

Rao, A. B., 2002. An engineering feat- construction of Koraput- Rayagada new railway line. Bhubanesh- war: SE Railway.

United Nations, 1987. Our Common Future, s.l.: Oxford University Press.

United Nations, 2015. Sustainable Development Goals kick off with start of new year. [Online] Available at: https://www.un.org/sustainabledevelopment/blog/2015/12/sustainable-development-goals-kick-off- with-start-of-new-year/ [Accessed 15 October 2022].

Zargarian, R., Hunt, D.V.L., Braithwaite, P., Bobylev, N. & Rogers C.D.F. 2016. A new sustainability framework for urban underground space. London, Institution of Civil Engineers.

The East Coast Railway is constructing a new railway line parallel to an existing one in the Koraput-Singapur Road section. This 164-km long railway line has 36 existing tunnels and 24 tunnels for proposed second line. The existing line was constructed in 1982 through a dense forest and varying geology. This paper focuses on a smaller section of 45-km length between Tikri and Bhalumaska with 19 proposed tunnels.

The existing railway line passes through steep gradients with sharp curves. The region has a low population and dense forests. The proposed line is planned to increase the capacity of the section. Planning optimal alignment was a challenge due to a range of factors. The project encountered geological challenges during the design of the proposed Tunnel 23. This paper discusses the various failures that were recorded while it was being constructed, the challenges faced during its execution, and the decisions made while following sustainable practices.

Photo courtesy: hmrdc.com

Photo courtesy: hmrdc.comRITES Limited was awarded the work for design of proposed alignment of tunnels, conducting geological and geo-technical investigations, and preparation of detailed project report (DPR) along with detailed designs and drawings for construction of railway tunnels between Tikri and Bhalumaska stations. The Tikri to Bhalumaska section is 45 km long within the 164 km long Koraput to Singapur Road railway line.

Challenges were faced in the design of the tunnels and in the railway alignment in the Tikri to Bhalumaska section, and during designing of Tunnel 23. Sustainability was a major focus area while deciding the railway alignment, with excavations and filling volumes optimized for reducing environmental loss and to have minimum impact on the existing biodiversity and land acquisitions.

Location of Project

The project is located in the Rayagada district of Odisha (in the south-eastern region of India) as shown in Figure 1. It lies in the Eastern Ghats of India with hills up to 900m height with Tikri at 825m elevation from the Mean Sea Level (MSL) and Bhalumaska at 485m above MSL. The length of the proposed project to construct a second parallel railway line in this region is 45 km out of an entire railway line of 164 km. The alignment has a ruling gradient of 1 in 100 and curves with sharp radius up to 5 degrees, as shown in Figure 1. Figure 1: Location of the project Tikri- Bhalumaska section in Rayagada district, Odisha

Figure 1: Location of the project Tikri- Bhalumaska section in Rayagada district, OdishaThe Tikri Bhalumaska section has 19 proposed tunnels with total length of 12.1 km. The longest tunnel is 1.86 km long while the shortest tunnel is 120m long. Tunnels are located in a region with high variation in geology with fractured and weak rock to intact rock with very high strength.

Geology

The region is a part of Eastern Ghats Mobile Belt (EGMB) covering parts of Odisha, Andhra Pradesh, Tamil Nadu, and a small part of Karnataka. It comprises of a typical assemblage of charnockite and khondalite groups, migmatitic gneisses, granitoid, and pegmatite, all metamorphosed to high-grade granulite facies.The Eastern Ghat Mobile Belt (EGMB) is a well-defined entity forming a series of hill ranges parallel to the east coast of India from Mahanadi (Orissa) in the north to Nallamalai (Andhra Pradesh) in the south. It is a prominent Precambrian orogenic belt.

Figure 2: Eastern Ghat Belt based on lithological characters (Ramakrishnan, 2008)

Figure 2: Eastern Ghat Belt based on lithological characters (Ramakrishnan, 2008)The principal rock units of the eastern ghats are the granite gneisses, the charnockite series, the khondalite series, and the granites. The charnockite series and the khondalite series are more in proportion in the hill ranges, whereas the granite gneisses are more in proportion with the plains between the hill ranges and the east coast (Sriramadas, 1960). Eastern Ghat supergroup of rocks comprises several linear patches of khondalite, quartzite, calc granulite, charnockite, and granite.

Majorly, granitic gneiss is observed along the proposed tunnel locations. Granitic gneiss is moderately to highly weathered in general, and completely weathered at places, jointed, and medium strong to weak in strength. Although, it was observed from the unlined portions of existing tunnels that the rock one expected to encounter inside the proposed tunnel was of good quality, intact and self- supporting. Detailed geotechnical investigations further supported the observations.

Tunnel 23 had a large variation in geology across its length with high geotechnical risks and experiences from the construction of first line, which indicated that a detailed investigation was necessary for this tunnel to eliminate the risks. The geological challenges and mitigation measures associated with Tunnel 23 are mentioned in detail in this paper.

Railway Alignment Design And Challenges

Making decisions on alignment of this railway section was a challenging task as it has multiple sharp curves with 5 degree radius and steep rise and fall up to 1 in 100 gradients. Various factors related to land topography were considered while making the decisions. The existing railway line follows the edge of the hills at most of the places, making it difficult to propose a second parallel rail- way line, without creating high cuttings or fillings. Figure 3: Easter ghat hills rich in biodiversity

Figure 3: Easter ghat hills rich in biodiversityApart from topographical challenges, there were environmental impact challenges as well. The existing alignment passes through dense forests in the hills of eastern ghat with rich biodiversity of flora and fauna.

The client provided preliminary alignment before start of the project, which was studied and modifications were proposed to optimize the alignment to mitigate project risks.

The following are the key aspects for decision making related to proposed alignment:

The proposed railway alignment was designed parallel to the existing alignment to share the existing infrastructure (such as station buildings, service & maintenance buildings, electricity & water supply, signaling systems and approach roads).As the alignment passes through a highly uneven topography, the existing railway line has many major and minor bridges, along with 21 existing tunnels. It is common to notice large fillings and high cuttings along the existing railway line.

Due to topography variations and existing major structures (bridges and tunnels), it was not possible to propose a railway line with a fixed distance from the existing line. Hence, the initial criteria to make decisions on proposed alignments was to decide its distance from existing railway line at locations with tunnels, major bridges and at flat terrain, as mentioned in Table 1.

| Table 1. Distance between proposed alignment and existing alignment at location of key structures. | ||

| S.No. | Structure Type | Distance of proposed alignment |

| 1 | Major Bridge | 20 m |

| 2 | Tunnel | 30-35 m |

| 3 | Open sections | 6.5 m |

| 4 | Tunnel approaches | 20-30 m |

The complete alignment of 45 km was mapped with guiding aspects as per Table 1 for proposed track distances and then horizontal curves and transitions were designed between Tikri and Bhalumaska section as per the railway manual (Railway Board, Ministry of Railways, 2020).

| Table 2. Reduction in land acquisition and requirement due to refinement of alignment. | ||

| Land requirement (original) | Land requirement (revised) | Reduction |

| 778,540 m2 | 566,211 m2 | 37.5 % |

Land Acquisitions

This region is an isolated forest land with limited transportation and communication networks. Most of the people staying in this region follow tribal culture and traditions which are centuries old, and they have limited exposure to technology and new developments. Their agricultural practices are also unique to the local communities. Since, the tribal culture, traditions and practices are the natural heritage of our country, it is the legal and social responsibility of the professionals involved with the project to protect them. Figure 4: Existing railway line passing though high cutting and deep valley

Figure 4: Existing railway line passing though high cutting and deep valleyFigure 5 above is an example of where the location of alignment of the proposed railway line was decided to avoid agri fields and the village for land acquisition, hence, avoiding displacement of communities and adverse impact on agriculture land. Such decisions were taken for the alignment design of this 45 km long project.

Efficient design of alignment resulted in reducing impact by 37.5% in terms of forest land requirements, in comparison to the original proposal.

Reducing open excavations and filling

As discussed above, the existing alignment is placed along the hill edge, which brings a challenge to decide the proposed railway alignment parallel to it, without cutting of hills or filling in valleys. Reduction in amount of cutting and fillings across the railway line was a priority in order to save project cost, construction time, land acquisition, and to make the project sustainable.To reduce excavation and filling quantities for the proposed line, both left and right sides of the existing railway line were studied as preferable locations. Post detailed study, preferred locations for proposed line (left or right to existing line), were chosen, with preferable switches where required. Along the 45 km long stretch (moving from Rauli to Bhalumaska) the proposed alignment is on the right side of the existing alignment for first 5.5 km, on left for next 16.5 km, on right for next 7km, on left for next 9 km and on right for last 7 km. The switch of proposed alignment from left to right (or right to left) with respect to the existing line was designed as cut and connections (4 numbers). A sample of cut and connection proposed is as shown in Figure 6.

Figure 5: Alignment proposed to avoid the village and fields to minimize the impact

Figure 5: Alignment proposed to avoid the village and fields to minimize the impactApart from cut and connections, it was decided to start the tunnels with lower covers to crown and build retaining wall (both hill side and valley side) to reduce cuttings and fillings. This resulted in achieving a better solution and the overall reduction in cost and construction time.

As per Table 3, the impact of these initiatives was substantial and resulted in reducing carbon emissions due to reduction in excavation and filling works. It resulted in reduction in project cost by Rs. 1.3 billion (approx. USD 16 million).

| Table 3. Reduction in volume of excavations and filling under railway track due to refinement of alignment. | |||

| Original proposal | Revised proposal | Reduction | |

| Excavation | 4,235,500 m3 | 3,711,700 m3 | 12 % |

| Filling | 142,800 m3 | 68,932 m3 | 51 % |

Geological Challenges with Tunnel 23 and Planning in Advance for Mitigation

Decisions taken during the design of Tunnel 23 played an important role in demonstrating that planning in the early phases of project leads to sustainable construction by efficient use of resources and preparedness for upcoming challenges.The existing Tunnel 23 was constructed in 1982 with limited tunnel construction experience and technology available in India’s tunnelling industry. The existing tunnel is 1.6 km long with substantial variation in geology across its length. The tunnel has very strong and intact rock towards.

Figure 6: Cut and connection between Tikri and Bhalumaska stations

Figure 6: Cut and connection between Tikri and Bhalumaska stationsThe portals, although a 300m long stretch in the center has very poor geology, with huge water ingress encountered during construction of existing tunnel. As soon as the tunnel construction reached the weaker strata, a large volume of water came into the tunnel, resulting in face collapse and eventually chimney failure, with creation of a large crater on the surface. Dewatering and jet grouting techniques were used from the surface to improve the ground before resuming tunnelling activities again. About 675,000 kg of cement was used to grout the whole region.

Once the ground was stabilized, heavier support such as steel ribs and fore polling were used to tunnel through the grouted ground until good rock was encountered again. The unexpected discovery of weaker strata led to a one year delay of the project and 4 times escalation in cost for the client. Further, limited availability of geological data led to overuse of resources (Rao, 2002). This failure was the best information available to make decisions for the proposed second tunnel for parallel railway line.

As limited data was available for the grouted ground in the vicinity of the existing tunnel, it was decided to go for extensive geotechnical investigations to get detailed information on ground conditions. Bore holes were planned both along the tunnel alignment and across the tunnel alignment to map the zone of weak ground in this region. Further, geophysical studies were conducted to co-relate the finding and have more data to observe the variation. Geological investigations indicated that if distance between the tunnels can be increased, then the proposed tunnel would encounter better ground. The alignment was revised to relocate the tunnel in better geology.

Figure 7: Geotechnical investigations conducted on Tunnel 23

Figure 7: Geotechnical investigations conducted on Tunnel 23Extensive planning, assessment of geology, and preferred tunnel location led to informed decisions on tunnel design. Improved proposal avoided requirement of heavy supports (reducing steel requirements), grouting (reducing cement requirements), project delays, and groundwater contamination due to grouting. Further, good quality work was expected, unreinforced permanent lining was proposed reducing requirement for structural steel. Early planning and informed decision making for the revised proposal avoided carbon emissions that would have otherwise been added to the environment from overuse of 820,000 kg steel and 950,000 kg cement.

Reduced Environmental Impact

In 1987, the (United Nations, 1987) defined sustainability as “meeting the needs of the present without compromising the ability of future generations to meet their own needs”. Further to understand if an action/project/process is sustainable, four pillars of sustainability were defined as social, human, economic and environmental.This project was proposed with consideration to each of these pillars of sustainability. The social aspects of sustainability were taken into consideration while deciding the alignment of the proposed railway line, avoiding old villages and fields. This led to conservation of ancient tribal culture and farming practices.

Figure 8: UN Sustainable development goals (United Nations, 2015)

Figure 8: UN Sustainable development goals (United Nations, 2015)The human pillar of sustainability focuses on health, safety, access to service, nutrition, knowledge, and skills. The project brought many employment opportunities for the local community, which helped people from all genders to learn new skills and enhance their knowledge. Further, the proposed upgrade of rail network will open more opportunities due to easy access to transportation and hence access to services such as schools and medical facilities.

The economic pillar of sustainability deals with employment opportunities, growth and standard of living. The project has 45 km of railway line with many bridges and tunnels to be constructed and potential for employment opportunities for local people. Acquiring skills while working would raise the standard of living and increase employability of local communities in the long term.

Figure 9: Uspear diagram for weighted comparison of sustainability indicators

Figure 9: Uspear diagram for weighted comparison of sustainability indicatorsUN SDGs were shared in 2016 with focus on a multi- dimensional agenda for sustainability for the year 2030. The sustainable initiatives and decisions taken during the design of this project contributed to goal number 8 (generating employment opportunities), 9 (creating railway infrastructure network), 11 (protecting community values), 12 (responsible consumption of materials and resources), 13 (reduction in carbon emissions from steel & cement use), 15 (minimizing impact on ‘life on land’ by reducing land acquisition and hill cuttings/fillings).

Figure 10: Carbon reduction potential with associate project stages (HM Treasury, 2013) & (Green Construction Board, 2013)

Figure 10: Carbon reduction potential with associate project stages (HM Treasury, 2013) & (Green Construction Board, 2013)Further, as per (HM Treasury, 2013) and (Green Construction Board, 2013) maximum impact on the project can be made during early stages as shown in Figure 10. Following sustainable practices was at the heart of the decision making, right from the planning stages of this project. Major contributions were made to the project to reduce impact on environment while deciding alignment and designing tunnels to suit the best geology.

References

Green Construction Board, 2013. Low Carbon Routemap for the UK Built Environment, London. HM Treasury, 2013. Infrastructure Carbon Review, London.Railway board, Ministry of Railways, 2020. Indian railway permanent way manual. Pune: Indian Rail- ways Institute of Civil Engineering, Pune.

Ramakrishnan, M. & Vaidyanandhan, R. 2008. Geology of India- Volume 1. s.l.:Geological Society of India.

Rao, A. B., 2002. An engineering feat- construction of Koraput- Rayagada new railway line. Bhubanesh- war: SE Railway.

United Nations, 1987. Our Common Future, s.l.: Oxford University Press.

United Nations, 2015. Sustainable Development Goals kick off with start of new year. [Online] Available at: https://www.un.org/sustainabledevelopment/blog/2015/12/sustainable-development-goals-kick-off- with-start-of-new-year/ [Accessed 15 October 2022].

Zargarian, R., Hunt, D.V.L., Braithwaite, P., Bobylev, N. & Rogers C.D.F. 2016. A new sustainability framework for urban underground space. London, Institution of Civil Engineers.

NBM&CW November 2023