Innovations in Crack Bridging with Self-Healing Bacteria in Concrete

The strength and durability of concrete are the major aspects while designing and during construction of any concrete structure. While strength of the structure can be achieved through a mixed design, its durability remains a concern. Cracks in concrete can be observed due to plastic shrinkage, differential settlement, creep, overload, design failure, fatigue, freeze and thaw. These minor and major cracks lead to corrosion of steel that result in spalling and failure of concrete structures.

These cracks can be remediated by conventional methods, polymer impregnation, epoxy injections, and chemicals. But these methods lead to higher repair cost and the inaccessibility of the position of cracks is also a drawback. So, concrete has to be produced such that it should have higher compressive strength and durability, and the capacity to repair its cracks autogeneously.

Crack remediation in concrete

Concrete is the most used construction material; its durability demands regular vigilance so that the structure can endure all kinds of stresses. In fact, durability in concrete is the direct measure of its quality. A rough estimation shows that around 50% of the total budget of construction is further used for repair of structures.

The major spoilsport for durability is cracking of concrete due to tension. Micro-cracks affect concrete’s durability and need to be repaired. This leads to a tremendous increase in the lifecycle cost of the structure due to its repair and maintenance. While care is being taken to prevent cracking, on the other hand, crack remediation is posing a new challenge.

To overcome the set of drawbacks thrown by the synthetic materials available for crack remediation, a special concrete known as Self-healing/bio-concrete has been developed since the 90s that has the ability to heal itself.

The crack remediation materials and techniques available in market such as, epoxy injection, routing and sealing, grouting etc. have various drawbacks. These techniques depend on type and extent of cracking. The treatments only aid the present intended remediation, and should be applied repeatedly if further cracking happens. Also, the durability of the available repair systems itself is questionable. The biggest threat is that the synthetic materials do not prove to be environment friendly. Hence, there is a need to develop an eco-friendly method to remediate cracks in concrete by utilizing locally available materials and considering the factors of the required environment. Therefore, developing bio-concrete by employing bacteria as healing agents demands intense research for the Indian scenario.

What Is Self-Healing Concrete?

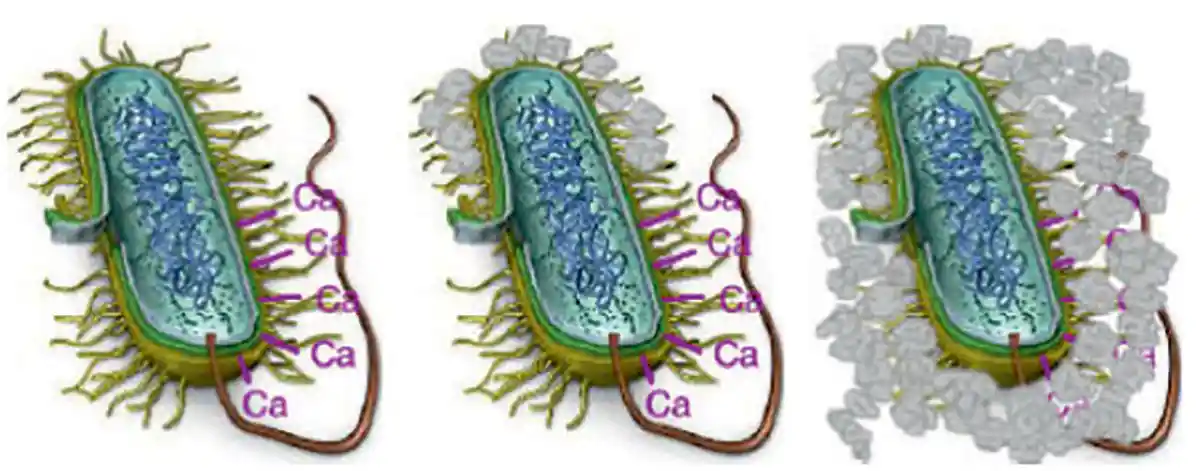

Self-healing concrete or bacterial concrete is its ability to produce lime/calcite (CaCO3) and fill the cracks when exposed to air and water. The lime produced fills the pores and increases the strength and durability of concrete.

Concrete has an autogenous capacity to heal itself through secondary hydration of existing and hydrated cement when in contact with air and water. But this might not become possible always as the extent of an hydrated cement left is unreliable and the duration is questionable. Also, increasing the cement content is not feasible. That is when the demand for fast, long lasting, efficient, and environment friendly method of healing led to the invention of self-healing concrete through microbial induction. There are various methods to bring about self-healing in concrete. These methods are weighed against each other and a set of desirable parameters to choose the best method applicable is made available.

History of Self-Healing of Concrete

Carolyn Dry, architect professor at the University of Illinois first considered the idea of incorporating mineral admixture and making concrete self-healing. Carolyn used glass capsules which contained methyl methacrylate glue, which would be released when the capsules were broken. However, the higher viscous glue didn’t have enough velocity to fill the cracks and glass capsules, being sensitive, would not survive in the concrete environment, which made this approach unyielding.

Others have tried polymers, gels, clay and waxes as a self-healing agent, which resulted in varying degrees of success. In the mid-2000’s Jonkers and Schlangen did a research on bacteria as a medium in concrete and found success in the laboratory results. The world’s first structure with bacterial concrete at Delft University of Technology was constructed in the Netherlands. The building provides data on its strength and durability based on the performance of the bacterial concrete.

Self-Healing or Bacterial Concrete was invented by Dutch scientist H M Jonkers, with his vast research on bacterial concrete - a product that, despite its higher initial cost, could save money and work in the long run.

Why Bacteria in Self-Healing of Concrete

- Bacteria are unicellular micro-organisms found in several habitats.

- They are the most common amongst the micro-organisms.

- They can easily multiply by binary fission.

- Species that are alkaliphilic and thermophilic are suitable for the concrete environment.

- They are viable for 200 years which far exceeds the service life of any structure.

- They have spore forming ability and the aerobic bacteria becomes dormant during non-availability of water and oxygen.

- The bacteria should be easily available in accessible habitats.

- Owing to concrete environment, they should be alkaliphilic, thermophilic, and aerobic.

- They should be able to sustain the environmental conditions.

- They should be viable for long duration i.e. have spore forming ability. The endospores shall become active when in need to remediate and stay dormant otherwise.

- They should be harmless to the ecosystem, hence non-pathogenic.

Mechanism of Calcite Precipitation in Self-Healing Concrete

The reactions for calcite precipitation are as follows:

1 mole of urea is hydrolyzed intracellular to 1 mole of ammonia. Carbamate spontaneously hydrolyses to form additionally 1mole of ammonia and carbonic acid. These products subsequently form 1 mole of bicarbonate and 2 moles of ammonium and hydroxide ions. The last 2 reactions give rise to a pH increase. This in turn shifts the bicarbonate equilibrium resulting in the formation of carbonate ions.

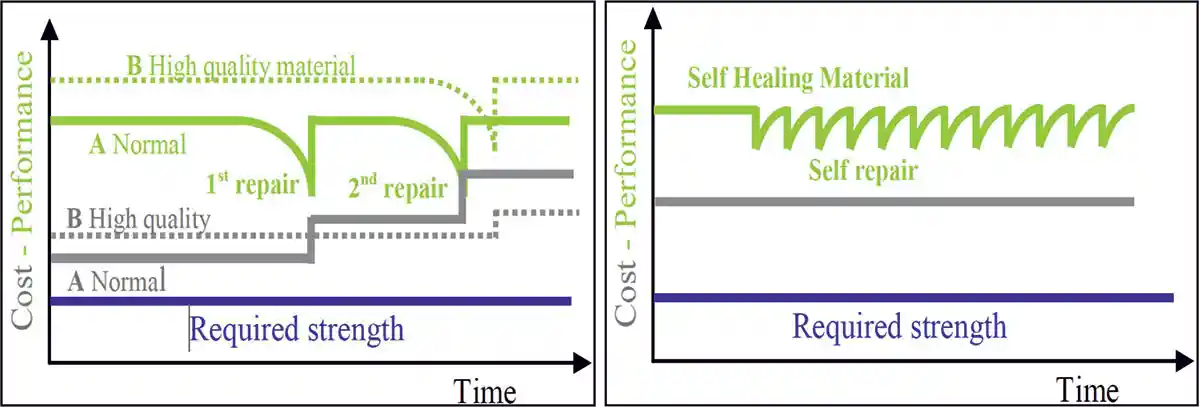

Comparision Between Normal Repair Material Concrete & Self Healing Material Concrete

Comparision Between Normal Repair Material Concrete & Self Healing Material ConcreteUrea is hydrolyzed to carbamate and ammonia in the presence of urease.

CO(NH2)2 + H2O ↔ NH2COOH + NH3

Carbamate is spontaneously hydrolyzed to form ammonia and carbonic acid.

NH2COOH+H2O → NH3 + H2CO3

Carbonic acid is hydrolyzed to form carbonate ion and hydrogen ion.

H2CO3 ↔ HCO-3+ H+

Ammonia spontaneously hydrolyzes to form ammonium and hydroxide ion.

2NH3+2H2O ↔ 2NH+4 + 2OH-

There is a rise in pH due to hydroxide ions which shifts the overall equilibrium of bicarbonate ion towards the formation of carbonate ions.

Calcium Carbonate crystals are formed.

Ca+2+CO3-2 ↔ CaCO3

From the above two graphs, it is assumed that self-healing concrete performs better compared to high quality repair material in repair and rehabilitation works. For the estimated required strength, the cost of repair doesn’t change in bacterial concrete and performance is also up to the required standards, whereas in other concrete with high quality repair material, it increases during the course of time and performance is below standards sometimes.

Types of Bacteria for Self-Healing of Concrete

Following are the different types bacteria that have the capability of calcite precipitation

- Bacillus Subtilis

- Bacillus Balodurais

- Bacillus Megatarium

- Lysinibacillus sphaeracus

- Bacillus Pasteurii

- Escherichia colli

- Bacillus Cohnii

- Enhances the compressive strength of concrete with calcite precipitation

- Improves the secondary hydration in concrete which result in dense and impermeable concrete

- Increases the tensile & flexural strength in concrete by bridging minor cracks through calcite precipitation

- Reduction in the repair and maintenance cost

- Reduced carbon emission as we are not using additional cement in the repair works.

- Inappropriate usage of bacteria in concrete may affect the structure’s lifespan

- Improper knowledge about bacteria can cause health hazard to human beings

- Higher initial cost in concrete production

- Not suitable for higher grade concrete due to lack of elaborate research on the subject

- Skilled labor required.

Civil engineering and concrete research scientists are keen to develop sustainable technologies that enable a low carbon footprint, while satisfying the strength and durability aspects. Self-healing bacteria is a leading invention in this context. Using bacterial concrete, we are minimizing the repair and rehabilitation cost of concrete structures and thereby reducing the building material usage which results in reduced carbon footprint.

The above study shows a strong possibility of using commonly available non-pathogenic bacterial species as an ingredient of self-healing concrete. It also emphasizes the healing capacity of each bacterium selected. The ingredients have to be chosen precisely to develop bio-concrete/self-healing concrete, as the microorganisms in it will portray higher sensitivity than normal concrete.

References

- Victor C Li and Emily Herbert, “ Robust Self-healing Concrete for Sustainable Infrastructure”, Journal of Advanced Concrete Technology, vol 10, pp 207-218, 2012

- Ali Amiri, Mahzad Azima and Zeynep Basaran Bundur, “Crack remediation in mortar via biomineralization: Effects of chemical admixtures on biogenic calcium carbonate”, Construction and Building materials (Elsevier), pp 317-325, 2018.

- Christine Farrugia, Ruben Paul Borg, Joseph Buhagiar and Liberato Ferrara, “Application of Lysinibacillus sphaericus for concrete healing using different calcium sources”, SynerCrete 18: International Conference on Interdisciplinary Approaches for Cement based Materials and Structural Concrete, pp 1053-1058, 2018.

- E Schlagen, H Jonkers, S Qain and A Gareia, “Recent advances on self-healing of concrete”, Proceedings FRAMCOS7, 2010.

- Erini Triviloglou, Virginie Wiktor, Henk M. Jonkers and Erik Schlagen, “Selection of Nutrient Used in Biogenic Healing Agent for Cementitious Materials”, Frontiers in Materials, vol.4, pp 1-7, 2017.

- Victor C. Li and Emily Herbert, “Robust Self-healing Concrete for Sustainable Infrastructure”, Journal of Advanced Concrete Technology, vol.10, pp 207-218, 2012.

- M. G Sierra Beltran and H M Jonkers, “Crack self-healing based on bacteria”, Journal of Ceramic Processing Research, vol.16, pp 33-39, 2015.

- K. Paine, I. Horne, L. Tan, T. Sharma, A. Heath and R. Cooper, “Microencapsulated spores and growth media for self- healing mortars”, Life-Cycle Analysis and Assessment in Civil Engineering: Towards an integrated vision (Taylor & Francis Group), pp 2247-2253, 2019.

- Mohamed Alazhari, Trupti Sharma, Andrew Heath, Richard Cooper and Kevin Paine, “Application of expanded perlite encapsulated bacteria and growth media for self- healing concrete”, Construction and Building materials (Elsevier), pp 610-619, 2018.

- N De Belie and W De Muynck, “Crack Repair in Concrete using Bio-deposition”, Concrete Repair, Rehabilitation and Retrofitting (Taylor and Francis Group), vol.3, pp 777-781, 2009.

- N De Belie and W De Muynck, “Remediation of Concrete using Microorganisms”, ACI Material Journal, vol.98, pp 3-9, 2001.

- Nidhi Nain, R. Surabhi, Yathish N. Y, V. Krishnamurthy, T. Deepa and Seema Tharannum, “Enhancement in strength parameters of concrete by application of Bacillus bacteria”, Construction and Building materials (Elsevier), pp 904-908, 2019.

- P. Jagannathan, K. S Satyanarayanan, Kantha devi Arunachalam and Sathish Kumar Annamalai, “Studies on mechanical properties of Bacterial concrete with two bacterial species”, Materials Today: Proceedings 5 (Science Direct), pp 8875-8879, 2018.

- Henk M Jonkers and Erik Schlagen, “A two-component Bacteria based Self-healing concrete”, Concrete Repair, Rehabilitation and Retrofitting (Taylor and Francis Group), vol.3, pp 215-220, 2009.

- Sookle S Bang, Johnna K Galinat and V Ramakrishnan, “Calcite Precipitation involved by Polyurethane Immobilized Bacillus pasteurii,” Enzyme and Microbial Technology (Elsevier), vol.98, pp 404-409, 2000.

- IS 12269:1987, “Specifications for 53 Grade Ordinary Portland Cement”, BIS, New Delhi.

- IS 2386 (Part 1 and Part 3), “Methods of Test for Aggregates for Concrete- particle size and shape”, BIS, New Delhi.

- IS 383: 1970, “Specifications for Coarse and Fine Aggregates from Natural Sources for Concrete”, BIS, New Delhi.

Concrete Construction September - October 2022