Cements and Concrete Mixtures for Sustainability

Mehta, P. Kumar, University of California, Berkeley, U.S.A.

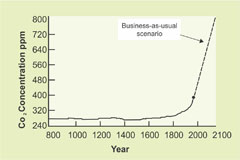

The climate changes, due to man-made global warming triggered by steeply rising volume of greenhouse gases, composed mostly of carbon-dioxide, is a very serious issue that is being addressed worldwide by every major sector of economy. There is a general acceptance of the view that firm measures must be taken without delay to bring down the global carbon emissions to the 1990 level or less during the next 15 years.

The focus of this paper is on portland-cement concrete, which is the most widely used manufactured product in the world today. Cement production is not only energy-intensive but also responsible for direct release of nearly 0.9 tonne carbon-dioxide for each tonne of portland clinker, which is the principal component of modern cements. Fifteen years ago, in 1990, the world production of cement was slightly more than 1 billion tonnes. In 2005, it already crossed 2 billion tonnes which means that direct CO2 emissions from the portland clinker production have nearly doubled. Fifteen years from now, with businessas- usual, the estimated cement requirement would be 3.5 bilion tonnes, and direct CO2 emissions from cement kilns would triple the 1990 level. Thus, the challenge before the global construction industry is how to meet the buildings and infrastructure needs of rapidly growing economies of the world, and at the same time, cutting down the CO2 emissions attributable to cement consumption to the 1990 level, in conformity with other sectors of economy.

Different options for consideration of the construction industry are presented in this paper.

The production and use of blended Portland cements containing large proportion of complementary cementing materials, such as coal fly ash and granulated blast-furnace slag provide an excellent strategy for immediate and substantial reduction of direct CO2 emissions associated with the manufacture of portland-cement clinker. Both EU and North American cement standards now permit more than 50 % clinker replacement in composite cements. Furthermore, the use of composite cements and concrete mixtures containing large addition of complementary cementing materials would yield crackresisting structural elements of radically enhanced durability. High-volume fly ash concrete applications for recently built structures in North America are cited as typical examples of possible CO2 reduction.

Sustainability–an Introduction

During the 1990s, it became abundantly clear that industrialization of the world is happening at an unsustainable speed. Among the major sustainability issues of public concern are high rates of consumption of energy and materials, short service life of manufactured products, and lack of space for safe disposal of huge volumes of solid, liquid, and gaseous wastes generated by human activities. Global warming, the cumulative effect of these problems, has emerged today as the most serious sustainability issue of the 21st century.

|

| Figure 1: Historical and Future Atmospheric CO2, Based on IPCC Reports (1) |

Evidence of global warming is not confined to temperature measurements. The following list includes some of the observable effects of the phenomenon:

- A sharp increase in the melting rates of glaciers, polar caps, and ice sheets.

- Rising ocean levels–a potential threat to coastal populations.

- Unusual increase in frequency and intensity of rainstorms, flash floods, cyclones, hurricanes, heat waves, droughts, and wild fires.

- Adverse impact on current sources of agriculture and water.

- Disruption of the earth's carbon cycle due to changes in the botanical species on land and oceans.

Although climate change is a global phenomenon, it has to be tackled in every country individually by each of the major CO2 emitting sectors of economy, such as power generation, transportation, and energy consumption associated with the use of buildings, and manufacture of structural materials like concrete and steel. According to Kyoto Protocol, proposed in 1990 and signed in 2005 by 141 countries, the signatories agreed to stabilize the greenhouse gas emissions by 2012 to 6 % below the 1990 level. The two largest polluting countries, the U.S. and China, which are responsible for nearly half of the global CO2 emissions, have yet to show a willingness to commit to any specific goals. However, in 2005, many multinational corporations, State governments in the U.S., and over 400 mayors representing 60 million Americans have signed on to programs that intend to meet or beat the Kyoto targets by 2020. In September 2006, the State of California approved the Global Warming Solutions Act according to which, by 2020, California's CO2 emissions would be reduced to the 1990 level.

Concrete Industry's Environmental Impact

The subject of environmental impact of the concrete industry is covered by numerous publications across the world including those listed in References (1-6). The embodied energy content, i.e., the sum total of energy required to extract raw materials, manufacture, transport, and install building elements is only 1.3 MJ/kg for 30 MPa concrete, compared to 9 MJ/kg for recycled steel and 32 MJ/kg for new steel. However, being the largest manufactured product consumed in the world, quantitatively concrete represents considerable embodied energy.Worldwide today, approx. 17,000 million tonnes of concrete is being produced annually. Besides natural resources, such as aggregates and water, the concrete industry is a large consumer of cement– a manufactured product directly responsible for high CO2 emissions. In 2005, according to Cembureau, the global cement consumption was 2,270 million tonnes. Therefore, carbon footprints of the global cement industry are very significant considering the amount of fossil fuels and electrical power consumed for crushing, grinding and transport of materials, and for the 1400 to 1500°C burning operation to make portland clinker –the principal ingredient of hydraulic cements. The scope of this paper is limited to direct CO2 emissions, of which approx. 6.3%2 of the global emissions are attributable to portland clinker manufacture.

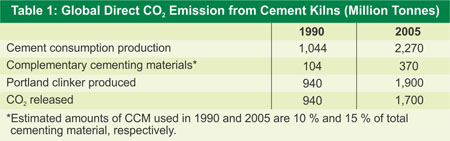

CO2 Emissions from Cement Kilns

Typically, ordinary portland cement is composed of 95 % clinker and 5 % gypsum, which is a complementary cementing material (CCM) because it enhances the cement performance by improving the setting and hardening characteristics of the product. Depending on the carbon content of fossil fuels used for clinkering, 0.9 to 1.0 tonnes of CO2 is directly released from cement kilns during the manufacture of clinker. In addition to gypsum, sometimes other mineral additives, commonly known as supplementary cementing materials (e.g., coal fly ash, granulated blast-furnace slag, natural and calcined pozzolans, pulverized limestone, and silica fume) can either be interground with clinker and gypsum or added directly during the concrete mixing operation. Large quantities of these materials are available as industrial by-products. As discussed in this paper, when properly used, the mineral additives have the ability to enhance considerably the workability and durability of concrete. Therefore, these additives too are treated as complementary cementing materials (CCM) in this paper.Global statistics for 1990 and 2005 on cement production, CCM consumption, and direct CO2 emission attributable to Portland clinker manufacture, are presented in Table 1. According to the U.S. Geological Survey records, the world consumption of cement in 1990 was 1,044 million tonnes. From the fragmentary information available it is estimated that, globally, the average clinker factor of cement (units of clinker per unit of cement) in 1990 was 0.9, which means that 940 million tonnes of clinker and 104 million tonnes of CCM were used. Assuming the average CO emission rate as 1.0 tonne CO2/ tonne clinker, in 1990 the direct CO2 emission from clinker production were 940 million tonnes.

In 2005, due to a gradual increase in the use of CCM, it is estimated that 370 million tones of CCM were incorporated into 2,270 million tonnes of cement. This gives a clinker factor of 0.84. Also, in 2005, due to increase in the use of alternate, low-carbon, fuels for burning clinker, the average CO2 emission rate dropped to 0.9 tonne per tonne of clinker. This means that, in 2005, 1,900 million tonnes of clinker was produced, with 1,700 million tonnes of direct CO2 release to the environment. In conclusion, the global cement industry has almost doubled its annual rate of direct CO2 emissions during the last 15 years.

Reducing the CO2 Emissions

Comparing the 1990 and 2005 global CO2 emissions directly attributable to clinker production (Table 1), the magnitude of the problem becomes at once clear. Not only the annual rate of cement consumption in the world has nearly doubled during the last 15 years but also, at the current rate of economic growth in many developing countries, by the end of the next 15 years the cement requirement is expected to go up to about 3,500 million tonnes a year. Assuming that during the same period the use of CCM increases from 15 to 20 % of the total cement, the global clinker production and CO2 emission in 2020 would amount to 2,800 million tonnes, and 2,520 million tonnes, respectively. To bring down the CO2 emission from 2,520 to 940 million tonnes (the 1990 level) involves nearly a two-third reduction in clinker requirement, which is unlikely barring a global catastrophe.In the portland clinker manufacturing process, direct release of CO2 occurs from two sources, namely the decomposition of calcium carbonate (the principal raw material) and the combustion of fossil fuels. The former accounts for about 0.6 kg CO2/kg clinker and the latter 0.25-0.35 kg CO2/kg clinker (depending on the carbon content of the fossil fuel); the global average being 0.9 kg CO2/kg clinker. Alternate sources of energy other than fossil fuels are being sought but, at present, they are too expensive. Also, there are some cements that do not require calcium carbonate as a raw material (e.g., magnesium phosphate cements) but they are neither economical nor technically feasible for large-scale production. Obviously, it will not be possible to achieve any drastic cuts in CO2 emission as long as technical and economic reasons favor the use of portland clinker as the major component of hydraulic cements.

The golden rule or mantra for successful resolution of all sustainability issues is, "Consume less, and think more." Based on this mantra, the author proposes the following three tools, the simultaneous use of which would enable the cement industry to reduce greatly the direct CO2 emission attributable to clinker production:

- Reduce the consumption of concrete: Architects and structural designers must develop innovative designs that minimize the consumption of concrete. Service life of repairable structures should be extended as far as possible by the use of proper materials and methods of repair. Low-priority projects should be postponed or even canceled when possible. Foundations, massive columns and beams of concrete, and pre-cast building components that can be assembled or disassembled as needed, should be made with highly durable concrete mixtures described in this paper.

- Reduce the cementing materials in concrete mixtures: Mix design procedures that involve prescriptive codes (e.g., minimum cement content, maximum w/cm, and much higher than needed strength) lead to considerable waste of cement, besides adversely affecting the durability of concrete. Such prescriptive codes have outlived their usefulness and must be replaced with performance-based specifications that promote durability and sustainability. For example, to achieve durability, it is not the w/c but the cement paste content which should be minimized through optimum aggregate grading, use of plasticizing admixtures, and specifying 56 or 91-day strength for the structural components that do not have to meet a minimum 28-day strength requirement.

- Reduce the clinker factor of cement: Every tonne of clinker saved would reduce the direct CO2 release from cement kilns by an equivalent amount. Furthermore, as explained below, concrete products made with cements of low clinker factor are expected to be much more durable when compared to ordinary portland cement products.

Published literature contains numerous reports showing that high-early strength concrete mixtures used in modern, high-speed, construction often suffer from lack of durability because they are usually made with high content of a cementing material and a high clinker factor of cement. The hardened product contains a heterogeneous cement paste, with weak interfacial bonding, and is vulnerable to cracking from excessive thermal shrinkage and drying shrinkage. According to Reinhardt (7), to minimize the shrinkage, volume of the paste (cement plus mixing water) in concrete should not exceed 290 L/ m3. High-volume fly ash concrete mixtures, described in this paper are made with cements of low clinker factor (0.4 – 0.5), and less than 290 L/m3 cement paste content. Therefore, they can be used for making relatively crack-free products of excellent durability without any added cost.

Options

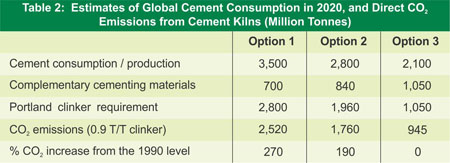

As shown in Table 1, compared to the base year 1990, global carbon emissions direct from Portland clinker production have already doubled in the past 15 years. If no serious measures are put into place quickly by the world's construction industry, i.e. with business-as-usual it is estimated that the rate of direct carbon emissions from cement kilns will almost triple in the next 15 years (Table 2, Option 1). Table 2 also includes data on two other options, an easy option (Option 2) and a challenging but preferable option (Option 3). Note that Option 1 (business-as-usual) data will be used as a reference point for both Options 2 and 3, that are discussed next.

According to Option 2, by 2020, if the global concrete construction industry is able to reduce the concrete consumption by 20 % (compared to Option 1) and at the same time increase the CCM utilization to 30 % of the total cement, these steps will have the effect of reducing the direct CO2 emissions from cement kilns to 1,760 million tonnes. This is nearly twice as much as the 1990 emissions rate of 940 million tonnes.

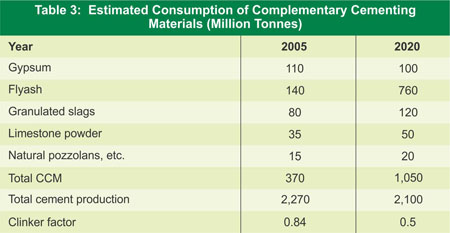

According to Option 3, in 2020, the total cementing material (2,100 tonnes) would comprise 1050 million tonnes of portland clinker and the same amount of complementary cementing materials. In Table 3, estimates of different types and amounts of complementary cementing materials that would be available for use in 2020 are given. Note that coal fly ash is expected to make up 760 million tonnes or nearly threefourths of the total CCM. Would such a large quantity of fly ash be available in 2020? It is difficult to provide a definite answer, but let us examine the assumptions under which this is possible.

In the foreseeable future, fossil fuels will continue to remain the primary source of power generation, and due to the low cost of coal, expansion of the coal-fired power industry will continue in major coalproducing countries such as China, India, and the United States. According to one estimate, approximately 1200 million tones of fly ash would be available in 2020. It would indeed be a formidable job to ensure that nearly two-thirds of the fly ash produced by coal-fired power plants is suitable for use as a complementary cementing material. This goal can be accomplished, provided the key players, i.e., the producers of fly ash, the consumers of cement and concrete, and individuals or organizations responsible for specifications work together to overcome the problems, discussed below.

The power sector of the global economy is the largest single source of carbon emissions in the world. It is estimated that about 7 billion tonnes a year of CO2 is being released today from the combustion of all fossil fuels, and that the coalfired power plants alone generate 2 billion tonnes of CO2. Besides carbon emissions, according to Malhotra (5), coal combustion in 2005 generated approximately 900 million tonnes of solid by-products including 600 million tonnes of fly ash. Due to rapidly changing rates of fly ash production and use in the two large economies of the world, China and India, which meet threequarters of their electrical power requirement from coal-fired furnaces, accurate data on today's global rates of flyash production and utilization are not available. However, a rough estimate shows that the current rate of fly ash production is approximately 750 million tonnes/ year, and that nearly 140 million tonnes/year is being consumed as an ingredient of blended cements and concrete mixtures. The remaining fly ash either ends up in low-value applications, such as road sub-bases and embankments, or is disposed to landfills and ponds.

When used as a complementary cementing material, each tonne of fly ash can replace a tonne of portland clinker. Diverting fly ash from the waste stream and using it to reduce direct carbon emissions from the cement industry is like killing two birds with one stone. Therefore, increasing the utilization of most of the available fly ash as a complementary cementing material is, unquestionably, the most powerful tool for reducing the environmental impact of two major sectors of our industrial economy, namely the cement industry and the coal-fired power industry.

In spite of proven technical, economic, and ecological benefits from the incorporation of high volumes of fly ash in cements and concrete mixtures, why does the fly ash utilization rate as a complementary cementing material remain so low? Obsolete prescriptive codes, lack of state-ofthe- art information to architects and structural designers, and lax quality control in power plants are among some of the reasons. Also, all of the currently produced fly ash is not suitable for use as a complementary cementing material, however cost-effective methods are available to beneficiate the material that does not to meet the minimum fineness and maximum carbon content requirements–the two important parameters by which the flyash suitability is judged by the cement and concrete industries (5).

Sustainable Cements

Sustainable, portland-clinker based cements can be made with 0.5 or even lower clinker factor using a high volume of granulated blast furnace slag (gbfs), or coal fly ash (ASTM Class F or C), or a combination of both. Natural or calcined pozzolans, in combination with fly ash and/or gbfs, may also be used. Compared to portland cement, the high-volume flyash and slag cements are somewhat slower in setting and hardening, but they are more suitable for producing highly durable concrete products. Unfortunately, worldwide, the conventional concrete construction practice is dominated by prescriptive specifications that do not permit the use of high volume of mineral additives.Cement containing a high volume of complementary cementing materials can now be manufactured in accordance with ASTM C 1157–a new standard specification for hydraulic cements, which is performance-based. However, in North America significant amount of blended portland cements are not produced, because it is customary to add mineral admixtures at the readymixed concrete plants. According to American Coal Ash Association, at present about 14 million of the available 70 million tonnes/year fly ash is being used as a complementary cementing material in concrete mixtures. Reliable estimates are not available from China and India, however, it is reported that significant quantities of blended cements containing 20- 30 % flyash, are being manufactured in these countries.

The European Cement Specification EN 197/1, issued in 2002, contains 26 types of blended portland cements including three cement types that have clinker factors ranging between 0.35 and 0.64. Type III-A Cement covers slag cements with 36-65 % gbfs; Type IV-B Cement covers pozzolan cements with 36-55 % pozzolans including fly ash, natural or calcined pozzolanic minerals, and silica fume; Type V-A Cement covers composite cements containing 18-30 % gbfs plus 18-30% pozzolans. According to Cembureau statistics for 2005, the consumption of ordinary portland cement in the European Union countries has dropped to 30 % of the total cement produced, whereas blended portland cements containing up to 25% CCM have captured 57% of the market share, and blended cements with more than 25% CCM are approaching 10% of the total cement consumption.

Sustainable Concrete Mixtures

For reducing direct carbon emissions attributable to Portland clinker production, the emerging technology of high-volume flyash (HVFA) concrete is an excellent example showing how highly durable and sustainable concrete mixtures, with clinker factor of 0.5 or less, can be produced by using ordinary coal fly ash (ASTM Class F or Class C), which are available in most parts of the world in large amounts. The composition and characteristics of HVFA concrete are discussed in many publications and are briefly described below. Note that concrete mixtures with similar properties can be produced by using a high volume of granulated blast-furnace slag or a combination of flyash and slag, with or without other mineral admixtures.The cementing material in HVFA concrete is composed of ordinary portland cement together with at least 50% flyash by mass of the total cementing material. The mix has a low water content (100- 130 kg/m3), and a low content of cementing materials (e.g. 300 kg/ m 3 for ordinary strength and max. 400 kg/m3 for high-strength). The plasticizing action of the high volume of flyash imparts excellent workability even at w/cem of the order of 0.4. However, chemical plasticizers are often used, when lower w/cem are required.

Occasionally, an air-entraining admixture is also included in the mix when protection against frost action is sought.

Compared to portland-cement concrete, the HVFA concrete mixtures designed to achieve the same 28-d strength exhibit superior workability without segregating even at slump values of 200-250 mm. Typically, the concrete is slow in setting and hardening, i.e. develop slightly lower strength at 3 and 7-d, similar strength at 28-d, and much higher strength at 90-d and 1-year. The pozzolanic reaction leading to complete removal of calcium hydroxide from cement hydration products enables the HVFA concrete to become highly resistant to alkaliaggregate reaction, sulfate and other chemical attacks, and reinforcement corrosion (due to very low electric conductivity). Furthermore, the HVFA concrete mixtures are much less vulnerable to cracking from both the thermal shrinkage (less heat of hydration), and the drying shrinkage (less volume of cement paste). Therefore, in addition to very low clinker factor, the ability of HVFA concrete to enhance the durability by factor 5 to10 makes it a highly suitable material for construction of sustainable structures in the future. The author has been involved with many field applications of HVFA concrete that are described in earlier publications (8-11). Three recently built structures in the U.S., with large reduction in CO2-emissions resulting from the use of HVFA concrete, are described below.

|

| Figure 2: The BAPS Hindu Temple, Chicago, 2004 High-Volume Flyash was used for Unreinforced Monolith Foundations and Drilled Piers |

|

|

|

| Figure 3a: Utah State Capitol Building after Seismic Rehabilation, 2006 high-volume Flyash was used for reinforced foundation, beams, and Shear Walls | Figure 3b: Utah State Capitol Building after Seismic Rehabilation, 2006 Excellent Pumpability and Workability of Nearly Self-consolidating Concrete Mixtures |

The Utah State Capitol Building, Salt Lake City, underwent seismic rehabilitation in 2006 (Figure 3a). Due to heavily congested reinforcement in the foundations, floor beams, and shear walls, a nearly self-consolidating mix containing 160 kg/m3 ordinary portland cement, 200 kg/m3 ASTM Class F flyash, 138 kg/m3 water, and 1 L/m3 superplasticizer was used. The clinker factor of this mix was 0.44, and the w/cem was 0.38. The specified slump and 28-d compressive strength were 150 mm and 27 MPa, respectively. The field concrete showed an average of 225 mm slump and 34 MPa strength. It is estimated that this 4,500m3 HVFA concrete job, enabled 900 tonnes of reduction in CO2 emissions attributable to clinker saving.

The CITRIS Building at the University of California at Berkeley contains 10,700m3 HVFA concrete – the largest volume ever used for construction of a single building. For foundations and mats, a concrete mix containing 160 kgm3 of ASTM Type II portland cement, 160 kg of Class F fly ash, and 123 kg/m3 water (0.37 w/cem) was used. For heavily reinforced columns, walls, beams, girders and slabs, a concrete mix containing 200 kg/m3 ASTM Type II portland cement, 200 kg/m3 Class F flyash, and 140 kg/ m3 water (0.35 w/cem) was used. In both cases the clinker factor is 0.50. The specified compressive strength was 27 MPa @ 28-d for all structural members except the foundations and mats which were designed for a specified strength of minimum 27 MPa @ 56-d. Note that the concrete used for reinforced columns achieved 20 MPa strength @ 7-d, and nearly 40 MPa @ 56-d. It is estimated that the choice of HVFA concrete as a structural material for the CITRIS Building resulted in a reduction of 1950 tonnes of direct CO2 Emissions attributable to the low clinker factor of the cementing material.

|

|

|

| Figure 4a: CITRIS Bldg., Univ. of California, 2007 Mat Foundation Under Construction | Figure 4b: CITRIS Bldg., Univ. of California, 2007 Heavily Reinforced Columns under Construction |

Economic and Technical Barriers

For utilization of high proportions of complementary cementing materials in general construction, human perception appears to be a far more formidable barrier than actual economic and technical barrier. According to Meryman and Silman (12):Sometimes, there is a perception that a "green" material or practice is more costly, but on further examination, it proves no to be so; often it is just a matter of getting on the other side of the learning curve. We must clarify the difference between life cycle cost and first cost, since many sustainable products have better life cycle performance. We need to define the term 'economic' and include the collateral cost of using non-sustainable practices.

The use of sustainable cements and concrete mixtures, described in this paper, would undoubtedly produce structural members of high durability. However, a statistical life-cycle analysis is not possible because there are no reliable laboratory tests for quantitative assessment of longterm durability of field structures. Other major barriers are lack of codes of recommended practice and unwillingness of structural designers and engineers to be among the first to champion the use of new materials. Again, according to Meryman and Silman (12):

How can an underused material or method become tried, trusted and ultimately the standard? These materials and methods need advocates. As technical professionals, structural engineers can use specifications to communicate a commitment to and confidence in more sustainable choices. By taking responsibility for those practices, we become their advocates.

From my own personal experience, I confirm the observations of Meryman and Silman. I have come to the conclusion that it is the hand that writes the specifications which holds the power of leading the concrete construction industry to an era of sustainability. Codes of recommended practice advocated by organizations, such as American Concrete Institute and U.S. Green Building Council, can play an important part in accelerating the sustainability of the concrete industry. For instance, the USGBC point-rating system for new construction has already become a powerful driving force for sustainable building designs. The rating system awards sufficient points for buildings that would consume less energy in their use. A similar emphasis is needed in favor of sustainable materials that produce less CO2 during their manufacture. By suitably amending the rating system so that some points based on CO2 emissions reduction are directly assigned for the use of sustainable materials in new construction, the USGBC can help sustainability of the cement and concrete industries.

Concluding Remarks

The high carbon dioxide emission rate of today's industrialized society has triggered climate change that is potentially devastating to life on the planet earth. To meet the global concrete demand, which was 17 billion tonnes in 2005, two billion tonnes of CO2 were directly released to the atmosphere from the manufacturing process of portlandcement clinker, which is the major component of modern hydraulic cements. With business-as-usual, the direct CO2 emissions from portland clinker production, in the year 2020, would triple the 1990 level unless immediate steps are taken to bring down the emissions by making significant reductions in the: (a) global concrete consumption, (b) volume of cement paste in concrete, and (c) proportion of portland clinker in cement.Examples of recently built structures prove that by using high volume of coal flyash and other industrial wastes as complementary cementing materials with portland clinker, we can produce low cost, highly durable, and sustainable cements and concrete mixtures that would significantly reduce both the carbon footprints of the cement industry and the environmental impact of the coal-fired power generation industry.

It seems that the game of unrestricted growth, in a finite planet, by reckless use of energy and materials, is over. Most sectors of the global economy have already initiated action plans to bring down their share of carbon emission to the 1990 level or less, by the year 2020. The construction industry is already pursuing the goal of designing and constructing sustainable buildings that consume less energy and resources to maintain. Now, all segments of the construction industry–owners, designers, contractors, and cement and concrete manufacturers–will have to join the new game of building sustainable structures using only sustainable materials.

We have the tools to win this game. What is needed now is the will and the individual initiative. To paraphrase John F. Kennedy, "Ask not what others can do. Ask what you can do to promote the use of sustainable construction materials."

Acknowledgement

The author would like to thank Mason Walters of Forell Elsesser Engineers, San Francisco, for the photographs in Figures 3 and 4.References

- P.K. Mehta, and P.J.M. Monteiro, "Concrete: Microstructure, Properties, and Materials," McGraw-Hill, New York, 2006

- ACI Board Advisory Committee on Sustainable Development, "White Paper on Sustainable Development," Concrete International, American Concrete Institute, Vol. 27 No. 2, 2005, pp. 19-21

- The Concrete Center of U.K., "Sustainable Concrete," www.concretecenter.com, 2007, 18 pages

- World Business Council for Sustainable Development, "The Cement Sustainability Initiative,"www.wbcsdcement.org, Geneva, Switzerland, 2007

- V.M. Malhotra, "Reducing CO2 Emissions," Concrete International, American Concrete Institute, Vol. 28 No. 9, 2006, pp. 42-45

- P.K. Mehta, "Greening of the Concrete Industry for Sustainable Development," ibid., Vol. 24 No.7, 2002, pp. 23-28

- H.W. Reinhardt, "New German Guideline for Design of Concrete Structures for Containment of Hazardous Materials," Otto Graf Journal, FMPA, Univ. of Stuttgard, Germany, Vol. 17, 2006, pp. 9-17

- P.K. Mehta and W.S. Langley, "Monolith Foundation Built to Last a 1,000 Years," Concrete International, American Concrete Institute, Vol. 22 No. 7, July 2000, pp. 27-32

- D. Manmohan and P.K. Mehta, "Heavily Reinforced Shear Walls and Reinforced Foundations Built with Green Concrete," ibid., Vol. 24 No. 8, 2002, pp. 64-70

- P.K. Mehta and D. Manmohan, "Sustainable, High-Performance Concrete Structures," ibid., Vol. 28 No. 7, 2006, pp. 37-42

- V.M. Malhotra and P.K. Mehta, "High-Performance, High-Volume Flyash Concrete," Supplementary Cementing Materials for Sustainable Development, Ottawa, Canada, 2002

- H. Meryman and R. Silman, "Sustainable Engineering–Using Specifications to Make it Happen," Structural Engineering International, Vol. 14 No. 3, Aug. 2004, pp 216-219.

Acknowledgement

The article has been reproduced from the SEWC'07 proceeding with the kind permission from the SEWC organisers.

NBM&CW July 2008