Design & Construction of Composite Structures

Composite construction is fast gaining acceptance in the non-residential multi-storey building sector of India. Its success is mainly due to the strength and stiffness achieved, with minimum use of materials.

The reason why composite construction is considered so good can be expressed in a simple way: concrete is good in compression and steel is good in tension. Combining these two materials structurally enhances their strengths, which can be exploited to create a highly efficient and lightweight design.

The reduced weight of the composite elements has a knock-down effect by reducing the forces in the elements supporting them, including the foundations. Composite systems also offer benefits in terms of speed of construction. The floor depth reductions that can be achieved using composite construction can also provide significant benefits in terms of the costs of services and the building envelope.

Case Study 1: Prestige Trade Towers

This project is located in the central business district of Bangalore, close to the state legislature and main road leading to the airport and northern Bangalore. It is subject to heavy and frequent VIP traffic movement due to which, access to concrete trucks during normal working hours is severely restricted. The presence of high-end apartments and residences, and a major school in the vicinity posed further restrictions in using conventional construction techniques.

Site constraints for design of basements: The Towers have 2 deep basements with 5-level stacked car parking, 3 levels of retail floors, and 21 office floors, and an overall height of 117m. The need for a large number of car parks for the office tower necessitated pit parking in the lower basement, in addition to 2-level stack parking above this. The upper basement too consisted of a 2-level stack parking. As a result, the depth of excavation to the bottom of the raft was approximately 11m. Presence of ground water at a depth of 6m compounded the challenge of keeping the excavation dry for construction work.

Extensive shore piling system with whaler beams and struts with sacrificial piles were provided as part of the shoring works. Both deep well dewatering and vacuum dewatering systems had to be adopted because of the amount of ground water encountered.

Design of the structural system: It was decided at the outset with the concurrence of the building owners and other stakeholders that composite construction would be the ideal solution for the superstructure for the following reasons:

- It would mitigate issues of large concrete pours

- Construction timelines could be speeded up leading to early access to the offices

- Lighter structure leading to lighter foundations considering the subsoil conditions

- Construction activity at multiple levels during the execution of the works

The lift banks, toilets and staircase shafts proved to be ideal for this concrete core envisaged. The architectural need for a minimum 3.0m floor to ceiling clearance after incorporation of all services meant that a ‘ flat slab like ‘ solution had to be provided.

Two systems were considered for the composite construction; the first option was slightly more sophisticated comprising:

- Concrete filled hollow tubes for the columns

- Asymmetrical floor beams with wider bottom flange

- Deep Deck sheeting with structural screeding

- Steel columns with welded steel plates encased in concrete

- 3-plate beam sections welded using submerged arc welding technique

- 1.0 mm thick decking sheets 80mm high at the crest sitting on top of the floor beams with a structural concrete topping both for fire protection and composite action.

Construction: The construction sequence adopted was to ensure that the lateral core would commence first and would be at least 4 to 6 levels ahead of the structural steel framework. The sequence of works would be as follows:

- Construct the RCC core using self-climbing shuttering

- Raise structural steel columns for two levels

- Fix main beams and secondary beams

- Place decking sheets and concrete and encase columns in concrete

- Carry out cementitious fireproof coating on the exposed beams.

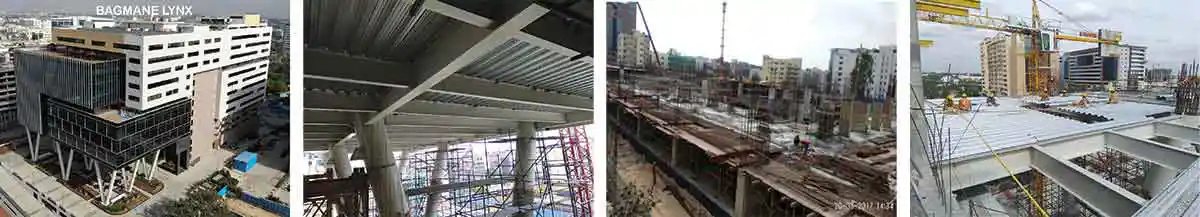

Case Study 2 Bagmane Lynx

This prestigious office building located in the heart of the IT belt on the Outer Ring Road in Bangalore, is a microcosm of the multiple structural systems that have been successfully amalgamated to produce landmark office buildings. The structure consists of 2 basements housing car parks and MEP equipment, a 4-level arrival space, and 14 levels of office floors.

Design - V columns: The basements and the office spaces are generally designed as conventional flat slab systems with periphery beams. A strong central core of lift and stair shafts provide lateral stability to the building. A specific architectural requirement of providing an unconventional arrival space by means of V columns is the unique design feature in this structure.

The V columns are concrete filled tubes springing from a pedestal sitting atop the basement and podium columns. The V columns then terminate onto a heavy structural steel transfer beam which supports 7 levels of office space above.

The structural system was modelled and fabricated using state of the art software, resulting in optimised cutting lengths and minimal wastage. An elaborate testing and quality assurance procedure ensured the quality control required.

Construction: The reinforced steel bar arrangement using couplers, extension of the steel tubes fabricated in lengths of 6m and transported to site, were a challenge.

A collaborative effort with the specialist vendor along with the design team led to successful completion of the project and within the specified time period. Temporary towers were required to be constructed to facilitate extension of the columns. A conventional concrete deck slab at the fifth level was finally poured to connect it with the reinforced concrete flat slab system.

NBM&CW August 2019