IS:15462-2019: A Tactical Shift Towards Performance Grading of Modified Bitumen

Abhishek Mittal, Principal Scientist, Flexible Pavement Division, CSIR-CRRI, New Delhi

Gajendra Kumar, Senior Technical Officer, Pavement Evaluation Division, CSIR-CRRI, New Delhi

Sunil Bose, Chief Scientist (Retd.), CSIR-CRRI, New Delhi

Flexible pavements are the most common type of pavement systems in the country. In addition to being convenient to construct, they are also cost-effective and easy to maintain. These pavements constitute the surface course and binder course and are made up of bitumen and mineral aggregates. Bitumen is the main binder which binds the aggregates together to act as a structural layer. It is very important to control the properties of bitumen as the performance of the constructed pavement is based on the properties of the bitumen used and subjected to different loading and climatic conditions.

To ensure that the bitumen used for the road construction is of the required quality, it should meet the specified requirements for an appropriate grade. The need for a grading system for bitumen was necessitated by the fact that about 250 uses of bitumen have been reported (Read and Whiteoak 2003). In pavements also, it is used for many different applications. Each application has specific requirements which it should meet. The grading system adopted for bitumen simplifies the entire process by specifying different grades to be used for different applications. The grading system has also evolved considerably over the years based on field performance and appropriate method of testing (Kandhal 2007).

Why bitumen modification is required?

A direct reflection of the growth of a country’s economy can be seen in the increased pace of development in its infrastructure sector where roads constitute a major component, and in which a major portion of the infrastructure funds is spent. In the present era of economic development, the traffic demands placed on our pavements are significantly more than in the past. The increase in traffic growth coupled with increased axle loads and climatic variations has posed challenges for the road agencies to look into the demands made on the bitumen pavement construction. A quest for improved road performance led to the modification of bitumen. In this regard, as early as in 1980’s, modification to base bitumen was done by addition of certain additives like polymers, natural rubber, crumb rubber etc. to enhance the mechanical behavior of bitumen by physical modification. Later, chemical modification was also attempted using polyethylene, poly phosphoric acid etc (Kumar and Veeraragavan 2008). Table 1 indicates the categories of modified bitumen as specified in IS:15462 (2004).

Each of these categories is further subdivided into three grades: based on penetration value for Type A, B and C, and based on softening point value for Type D. So, Type A modified bitumen is further graded into PMB (P)120, PMB(P)70 and PMB(P)40. Type B modified bitumen is graded into PMB (E)120, PMB(E)70 and PMB(E)40. Type C modified bitumen is graded into NRMB120, NRMB70 and NRMB40. Similarly, Type D modified bitumen is graded into CRMB50, CRMB55 and CRMB60. The viscosity was also incorporated in the specifications with ranges given against each bitumen grade.

The use of modified bitumen in road construction significantly reduces the amount and severity of pavement distresses and increase service life. The primary benefit of using modified binders is improved rutting resistance, improved thermal cracking resistance, along with secondary benefits such as an improvement in the overall mixture durability. Additionally, some modified binders provide improved stripping (moisture damage) resistance. An additional four to six years of pavement life from a pavement constructed using modified bitumen is a reasonable expectation (IRC:SP:53 2010).

Performance based grading in IS:15462-2019

It is commonly known that bitumen plays the key role in the behavior of bituminous mix and the overall performance of bituminous pavements. The accumulated strain in the bitumen, as a consequence of repeated traffic loadings, is responsible for the permanent deformation or rutting in the bituminous pavements. In order to identify the contribution of bitumen to pavement rutting, the parameter G*⁄sin δ has been used (IS:15462-2004). The parameter G*⁄sin δ is the high temperature specification parameter used to indicate the rutting performance and is obtained through DSR testing. In the DSR, a torque is applied to the bitumen sample placed between two parallel plates and response is measured. The specified criteria for rutting parameter G*⁄sin δ is 1.00 kPa for unaged and 2.2 kPa for the RTFO-aged binder. The criteria remain the same regardless of the location of the pavement and the high temperature to which it might be exposed to. The minimum values of test temperatures at which these criteria must be met are also specified regardless of the location of the pavement. However, researchers have reported that this rutting parameter (G*⁄sin δ) has poor correlation with field rutting (Carswell and Green 2000) and is inadequate in describing the rutting performance of polymer modified binders, in particular. In addition to the adoption of inadequate rutting parameter, the other shortcomings of IS:15462-2004 include:

To take into account the above shortcomings, the performance-based grading was introduced in the revised specifications IS:15462 (2019). This was a tactical shift towards developing more robust specifications which relate well with the bitumen performance. Table 2 indicates the grades of modified bitumen specified in IS:15462 (2019) specifications.

The general format adopted for the nomenclature is PMB XX-YY. Here, ‘XX’ specifies the average maximum pavement temperature, at a depth of 20 mm, based on the high air temperature and latitude of the place of the project location. The data regarding the air temperatures can be obtained from the Indian Metrological Department (IMD). The formula relating air temperature and latitude with the pavement temperature is given below (IS:15462 2019) :

T20mm = 0.9545 ×( Tair - 0.00618 L2 + 0.2289 L + 42.2 ) - 17.78 (1)

Where, T20mm = average maximum pavement temperature at 20 mm below the road surface; Tair = high air temperature; and L = latitude in degrees for the place of project location.

The estimation of average maximum and minimum pavement temperature can be done as explained in the subsequent example for Delhi city. For example, Delhi has high air temperature of 48°C and its latitude is 28.7°N. So, the average maximum pavement temperature computed is 69.7°C. Therefore, PMB 70 should be used for Delhi conditions. Similarly, ‘YY’ specifies the minimum pavement temperature. The lowest air temperature is taken as minimum pavement temperature. For Delhi, the lowest air temperature recorded is 3 °C, which is taken to be the minimum pavement temperature. So, the grade of PMB to be chosen for Delhi is PMB 70-10. This chosen grade is only based on environmental conditions; ‘grade bumping’ might be needed depending on the traffic plying on the specific pavement. The concept of ‘grade bumping’ has been discussed in subsequent section.

Apart from introducing the grading based on the average maximum and minimum pavement temperatures, the other two significant changes in the new specifications are the inclusion of non-recoverable creep compliance (Jnr) based on multiple stress creep recovery (MSCR) testing and the use of long term aging parameter (G*⁄sin δ) with pressure aging vessel (PAV).

Why was MSCR test included?

During the measurement of the high temperature parameter, G*⁄sin δ, an oscillating load to the bitumen is applied at relatively low strain. Under a very low stress and strain level, it is unlikely that the polymer network in the modified bitumen would be really activated. So, in the present testing framework, the polymer is only viewed as a filler material that stiffens the bitumen (FHWA 2011). This is one of the reasons why the existing rutting parameter does not accurately represent the ability of polymer modified binders to resist rutting. However, the polymer chains in the modified bitumen can be rearranged substantially with increasing stress levels. Such higher levels of stress and strain are applied to the bitumen in MSCR testing, thereby better representing the actual field conditions experienced by the pavement. By using the higher levels of stress and strain in the MSCR test, the response of the bitumen captures not only the stiffening effects of the polymer, but also the elastic effects.

The MSCR test (ASTM D7405 (2015)) is carried out using a dynamic shear rheometer (DSR). It is based on the well-established creep and recovery test concept for the purpose of evaluating the binder’s potential for permanent deformation. The procedure involves applying a consecutive series of static loads, followed by a period of recovery to a binder sample. Using the DSR, a one-second creep load is applied to the aged bitumen sample. After the one-second load is removed, the sample is allowed to recover for nine seconds. The test starts with the application of a low stress (0.1 kPa) for 10 creep/recovery cycles, and then the stress in increased to 3.2 kPa and repeated for an additional 10 cycles. The testing for MSCR is done at the selected actual high pavement temperature with no grade bumping. Two separate parameters can be determined in the MSCR testing: non-recoverable creep compliance (Jnr) and percentage of recovery (MSCR Recovery) during each loading cycle. Values are reported as the average of ten loading cycles at each shear stress level. Physically, Jnr is a measure of the amount of residual strain left in the binder specimen after repeated creep and recovery, relative to the applied stress magnitude in kPa. The MSCR percent recovery is a measure of how much the sample returns to its previous shape after being repeatedly stretched and relaxed. The parameter Jnr has been found to correlate well with the field rutting data (D’Angelo 2009). If the bitumen meets the appropriate Jnr specification, then it is expected that the binder will minimize its contribution to rutting.

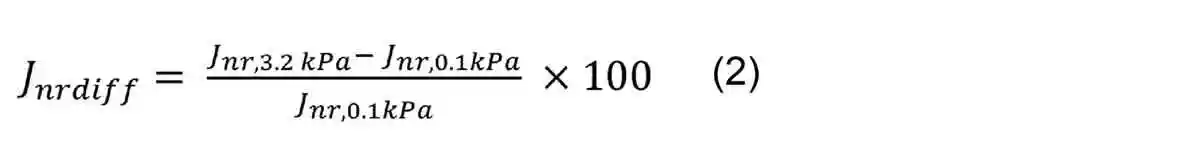

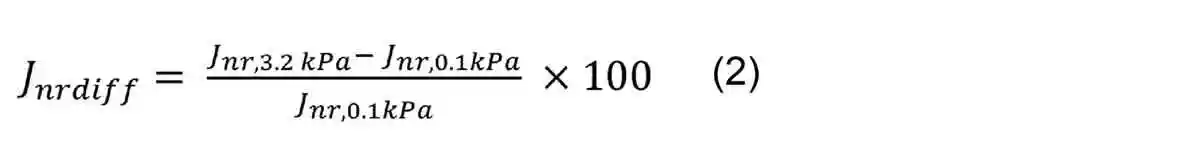

Though the main requirement for Jnr is determined at 3.2 kPa shear stress, the data determined at 0.1 kPa shear stress is also important. To minimize concerns that some bitumen may be overly sensitive to changes in shear stress and exhibit yielding at the higher stress level, another parameter Jnrdiff has been specified, whose maximum value should not exceed 75%. The formula to compute Jnrdiff is given in Equation (2).

Where, Jnr,0.1kPa = value of Jnr at stress level of 0.1 kPa; and Jnr,3.2 kPa = value of Jnr at stress level of 3.2 kPa.

Grade bumping through non-recoverable creep compliance (Jnr)

There was no concept of grade bumping in the original IS:15462-2004, however, the same has now been incorporated in the revised IS:15462-2019. The grade bumping is done on the basis of Jnr value. With MSCR, the bitumen testing is done at the high environmental temperature that the pavement is expected to experience. This means, if the pavement climate grade is PG64, the testing would be done at 64°C. A lower value of Jnr indicates a significant improvement in the stiffness of the bitumen. So, in order to accommodate for the higher traffic, lower value of Jnr would be required to reflect the increased stress the pavement will actually experience, without changing the testing temperature. Table 3 indicates the requirements of grade bumping for various service conditions

Conclusions and Way Forward

The present paper reviews the newly implemented IS:1546-2019. The new specifications include the MSCR testing and the grade bumping is done on the basis of Jnr value. Based on the review, the following conclusions may be drawn:

The authors would like to thank Prof. (Dr.) Satish Chandra, Director, CSIR-Central Road Research Institute (CSIR-CRRI), New Delhi, for his kind permission to publish this paper.

Disclosure statement

No potential conflict of interest was reported by the authors.

References

Gajendra Kumar, Senior Technical Officer, Pavement Evaluation Division, CSIR-CRRI, New Delhi

Sunil Bose, Chief Scientist (Retd.), CSIR-CRRI, New Delhi

Flexible pavements are the most common type of pavement systems in the country. In addition to being convenient to construct, they are also cost-effective and easy to maintain. These pavements constitute the surface course and binder course and are made up of bitumen and mineral aggregates. Bitumen is the main binder which binds the aggregates together to act as a structural layer. It is very important to control the properties of bitumen as the performance of the constructed pavement is based on the properties of the bitumen used and subjected to different loading and climatic conditions.

To ensure that the bitumen used for the road construction is of the required quality, it should meet the specified requirements for an appropriate grade. The need for a grading system for bitumen was necessitated by the fact that about 250 uses of bitumen have been reported (Read and Whiteoak 2003). In pavements also, it is used for many different applications. Each application has specific requirements which it should meet. The grading system adopted for bitumen simplifies the entire process by specifying different grades to be used for different applications. The grading system has also evolved considerably over the years based on field performance and appropriate method of testing (Kandhal 2007).

Why bitumen modification is required?

A direct reflection of the growth of a country’s economy can be seen in the increased pace of development in its infrastructure sector where roads constitute a major component, and in which a major portion of the infrastructure funds is spent. In the present era of economic development, the traffic demands placed on our pavements are significantly more than in the past. The increase in traffic growth coupled with increased axle loads and climatic variations has posed challenges for the road agencies to look into the demands made on the bitumen pavement construction. A quest for improved road performance led to the modification of bitumen. In this regard, as early as in 1980’s, modification to base bitumen was done by addition of certain additives like polymers, natural rubber, crumb rubber etc. to enhance the mechanical behavior of bitumen by physical modification. Later, chemical modification was also attempted using polyethylene, poly phosphoric acid etc (Kumar and Veeraragavan 2008). Table 1 indicates the categories of modified bitumen as specified in IS:15462 (2004).

| Table 1 : Categories of modified bitumen as per IS:15462 (2004) | ||

| S. No. | Category of modified bitumen | Type of modifier used for modification |

| (a) | Type A – PMB(P) | Plastomeric thermoplastics (eg. - Polyethylene, Ethylene-Vinyl Acetate copolymer, Ethylene-Methyl Acrylate copolymer, Ethylene-Butyl Acrylate copolymer) |

| (b) | Type B – PMB(E) | Elastomeric thermoplastic (eg. - Ethylene Ter polymer, Styrene-Butadiene-Styrene block copolymer, Styrene-Isoprene-Styrene copolymer) |

| (c) | Type C – NRMB | Natural rubber and SBR latex |

| (d) | Type D – CRMB | Crumb rubber / treated crumb rubber |

Each of these categories is further subdivided into three grades: based on penetration value for Type A, B and C, and based on softening point value for Type D. So, Type A modified bitumen is further graded into PMB (P)120, PMB(P)70 and PMB(P)40. Type B modified bitumen is graded into PMB (E)120, PMB(E)70 and PMB(E)40. Type C modified bitumen is graded into NRMB120, NRMB70 and NRMB40. Similarly, Type D modified bitumen is graded into CRMB50, CRMB55 and CRMB60. The viscosity was also incorporated in the specifications with ranges given against each bitumen grade.

The use of modified bitumen in road construction significantly reduces the amount and severity of pavement distresses and increase service life. The primary benefit of using modified binders is improved rutting resistance, improved thermal cracking resistance, along with secondary benefits such as an improvement in the overall mixture durability. Additionally, some modified binders provide improved stripping (moisture damage) resistance. An additional four to six years of pavement life from a pavement constructed using modified bitumen is a reasonable expectation (IRC:SP:53 2010).

Performance based grading in IS:15462-2019

It is commonly known that bitumen plays the key role in the behavior of bituminous mix and the overall performance of bituminous pavements. The accumulated strain in the bitumen, as a consequence of repeated traffic loadings, is responsible for the permanent deformation or rutting in the bituminous pavements. In order to identify the contribution of bitumen to pavement rutting, the parameter G*⁄sin δ has been used (IS:15462-2004). The parameter G*⁄sin δ is the high temperature specification parameter used to indicate the rutting performance and is obtained through DSR testing. In the DSR, a torque is applied to the bitumen sample placed between two parallel plates and response is measured. The specified criteria for rutting parameter G*⁄sin δ is 1.00 kPa for unaged and 2.2 kPa for the RTFO-aged binder. The criteria remain the same regardless of the location of the pavement and the high temperature to which it might be exposed to. The minimum values of test temperatures at which these criteria must be met are also specified regardless of the location of the pavement. However, researchers have reported that this rutting parameter (G*⁄sin δ) has poor correlation with field rutting (Carswell and Green 2000) and is inadequate in describing the rutting performance of polymer modified binders, in particular. In addition to the adoption of inadequate rutting parameter, the other shortcomings of IS:15462-2004 include:

- Viscosity test is specified to be conducted at one standard temperature (150°C) without regard to the climate in which the bitumen will be used.

- Only short-term aging is considered. The specification doesn’t take into consideration the long-term aging during the service life of the pavement.

- It also doesn’t adequately capture the low temperature behavior/performance of bitumen. Only Fraass breaking point is to be identified for a particular grade of bitumen. Fraass breaking point may be modified / changed due to the addition of modifier. Also, it has been reported that the Fraass breaking point generally has a poor correlation with the low temperature behavior of bituminous mixtures (Lu et al. 2017). So, the specifications do not adequately describe the low temperature behavior of bitumen.

- The specification requirements were different for the different types of additives, i.e. they were not blind to the modification.

To take into account the above shortcomings, the performance-based grading was introduced in the revised specifications IS:15462 (2019). This was a tactical shift towards developing more robust specifications which relate well with the bitumen performance. Table 2 indicates the grades of modified bitumen specified in IS:15462 (2019) specifications.

| Table 2: Grades of modified bitumen specified in IS:15462-2019 | ||

| S. No. | Binder grade | Specified temperature ranges |

| 1. | PMB 64 -10 | Average maximum pavement temperature < 64 °C and Minimum pavement temperature > (-10) °C |

| 2. | PMB 70 -10 | Average maximum pavement temperature < 70 °C and Minimum pavement temperature > (-10) °C |

| 3. | PMB 76 -10 | Average maximum pavement temperature < 76 °C and Minimum pavement temperature > (-10) °C |

| 4. | PMB 82 -10 | Average maximum pavement temperature < 82 °C and Minimum pavement temperature > (-10) °C |

| 5. | PMB 76 -22 | Average maximum pavement temperature < 76 °C and Minimum pavement temperature > (-22) °C |

The general format adopted for the nomenclature is PMB XX-YY. Here, ‘XX’ specifies the average maximum pavement temperature, at a depth of 20 mm, based on the high air temperature and latitude of the place of the project location. The data regarding the air temperatures can be obtained from the Indian Metrological Department (IMD). The formula relating air temperature and latitude with the pavement temperature is given below (IS:15462 2019) :

T20mm = 0.9545 ×( Tair - 0.00618 L2 + 0.2289 L + 42.2 ) - 17.78 (1)

Where, T20mm = average maximum pavement temperature at 20 mm below the road surface; Tair = high air temperature; and L = latitude in degrees for the place of project location.

The estimation of average maximum and minimum pavement temperature can be done as explained in the subsequent example for Delhi city. For example, Delhi has high air temperature of 48°C and its latitude is 28.7°N. So, the average maximum pavement temperature computed is 69.7°C. Therefore, PMB 70 should be used for Delhi conditions. Similarly, ‘YY’ specifies the minimum pavement temperature. The lowest air temperature is taken as minimum pavement temperature. For Delhi, the lowest air temperature recorded is 3 °C, which is taken to be the minimum pavement temperature. So, the grade of PMB to be chosen for Delhi is PMB 70-10. This chosen grade is only based on environmental conditions; ‘grade bumping’ might be needed depending on the traffic plying on the specific pavement. The concept of ‘grade bumping’ has been discussed in subsequent section.

Apart from introducing the grading based on the average maximum and minimum pavement temperatures, the other two significant changes in the new specifications are the inclusion of non-recoverable creep compliance (Jnr) based on multiple stress creep recovery (MSCR) testing and the use of long term aging parameter (G*⁄sin δ) with pressure aging vessel (PAV).

Why was MSCR test included?

During the measurement of the high temperature parameter, G*⁄sin δ, an oscillating load to the bitumen is applied at relatively low strain. Under a very low stress and strain level, it is unlikely that the polymer network in the modified bitumen would be really activated. So, in the present testing framework, the polymer is only viewed as a filler material that stiffens the bitumen (FHWA 2011). This is one of the reasons why the existing rutting parameter does not accurately represent the ability of polymer modified binders to resist rutting. However, the polymer chains in the modified bitumen can be rearranged substantially with increasing stress levels. Such higher levels of stress and strain are applied to the bitumen in MSCR testing, thereby better representing the actual field conditions experienced by the pavement. By using the higher levels of stress and strain in the MSCR test, the response of the bitumen captures not only the stiffening effects of the polymer, but also the elastic effects.

The MSCR test (ASTM D7405 (2015)) is carried out using a dynamic shear rheometer (DSR). It is based on the well-established creep and recovery test concept for the purpose of evaluating the binder’s potential for permanent deformation. The procedure involves applying a consecutive series of static loads, followed by a period of recovery to a binder sample. Using the DSR, a one-second creep load is applied to the aged bitumen sample. After the one-second load is removed, the sample is allowed to recover for nine seconds. The test starts with the application of a low stress (0.1 kPa) for 10 creep/recovery cycles, and then the stress in increased to 3.2 kPa and repeated for an additional 10 cycles. The testing for MSCR is done at the selected actual high pavement temperature with no grade bumping. Two separate parameters can be determined in the MSCR testing: non-recoverable creep compliance (Jnr) and percentage of recovery (MSCR Recovery) during each loading cycle. Values are reported as the average of ten loading cycles at each shear stress level. Physically, Jnr is a measure of the amount of residual strain left in the binder specimen after repeated creep and recovery, relative to the applied stress magnitude in kPa. The MSCR percent recovery is a measure of how much the sample returns to its previous shape after being repeatedly stretched and relaxed. The parameter Jnr has been found to correlate well with the field rutting data (D’Angelo 2009). If the bitumen meets the appropriate Jnr specification, then it is expected that the binder will minimize its contribution to rutting.

Though the main requirement for Jnr is determined at 3.2 kPa shear stress, the data determined at 0.1 kPa shear stress is also important. To minimize concerns that some bitumen may be overly sensitive to changes in shear stress and exhibit yielding at the higher stress level, another parameter Jnrdiff has been specified, whose maximum value should not exceed 75%. The formula to compute Jnrdiff is given in Equation (2).

Where, Jnr,0.1kPa = value of Jnr at stress level of 0.1 kPa; and Jnr,3.2 kPa = value of Jnr at stress level of 3.2 kPa.

Grade bumping through non-recoverable creep compliance (Jnr)

There was no concept of grade bumping in the original IS:15462-2004, however, the same has now been incorporated in the revised IS:15462-2019. The grade bumping is done on the basis of Jnr value. With MSCR, the bitumen testing is done at the high environmental temperature that the pavement is expected to experience. This means, if the pavement climate grade is PG64, the testing would be done at 64°C. A lower value of Jnr indicates a significant improvement in the stiffness of the bitumen. So, in order to accommodate for the higher traffic, lower value of Jnr would be required to reflect the increased stress the pavement will actually experience, without changing the testing temperature. Table 3 indicates the requirements of grade bumping for various service conditions

| Table 3 : Jnr requirements for grade bumping | ||

| Service Condition | values | Traffic Levels |

| Standard (S) | Traffic repetitions less than 10 million Equivalent Single Axle Loads (ESALs) and more than the standard traffic speed (more than 70 km/h) | |

| Heavy (H) | Traffic repetitions between 10-30 million ESALs or slow-moving traffic (20 to 70 km/h) | |

| Very Heavy (V) | Traffic repetitions of more than 30 million ESALs or very slow moving/standing traffic (less than 20 km/h) | |

| Extremely heavy (E) | Traffic repetitions of more than 30 million ESALs and very slow moving/ standing traffic ( less than 20 km/h) | |

Conclusions and Way Forward

The present paper reviews the newly implemented IS:1546-2019. The new specifications include the MSCR testing and the grade bumping is done on the basis of Jnr value. Based on the review, the following conclusions may be drawn:

- The non-recoverable creep compliance (Jnr) is better correlated with rutting potential than the original rutting parameter (G*⁄sin δ).

- The MSCR testing is done corresponding to the actual pavement high temperature, regardless of traffic speed and loading. To account for the traffic loading and/or speed, grade bumping is done on the basis of the value of Jnr parameter, as given in Table 3.

- There is a criterion to eliminate the binders that are overly stress sensitive and potentially susceptible to rutting in the field. This criterion is given by Jnrdiff and its acceptable value is less than or equal to 75 %.

- The revised specifications for modified bitumen IS:15462 (2019) has still retained the conventional elastic recovery (ER) test (in the ductilometer) to evaluate the presence of polymer in binders. This may be replaced with the MSCR recovery which provides a better estimate of the established polymer network in the binder. Higher value of MSCR recovery indicates more robust cross-linked polymer structure. In order to validate that the bitumen has been polymer-modified, a minimum requirement for MSCR recovery value may be included in the specifications, in place of the conventional elastic recovery test. Adopting the MSCR recovery in place of ER would provide the added advantage as the MSCR test is relatively simple and quicker to perform compared to ER testing.

- Better test methods such as bending beam rheometer testing should be included in place of Fraass breaking point to describe the low temperature behavior of modified bitumen.

The authors would like to thank Prof. (Dr.) Satish Chandra, Director, CSIR-Central Road Research Institute (CSIR-CRRI), New Delhi, for his kind permission to publish this paper.

Disclosure statement

No potential conflict of interest was reported by the authors.

References

- ASTM-D7405. (2015). Standard test method for multiple stress creep and recovery (MSCR) of asphalt binder using a Dynamic Shear Rheometer. American Society for Testing of Materials (ASTM).

- Carswell, J., and Green, P. J. (2000). Prediction of rutting resistance in hot rolled asphalt using rheological parameters. The Asphalt Yearbook 2000, Institute of Asphalt Technology, UK.

- D’Angelo, J. A. (2009). “The relationship of the MSCR test to rutting.” Road Materials and Pavement Design, Taylor & Francis Group, 10, 61–80.

- FHWA. (2011). The Multiple Stress Creep Recovery (MSCR) Procedure. Office of Pavement Technology - FHWA-HIF-11-038.

- IRC:SP:53. (2010). Guidelines on use of modified bitumen in road construction. Indian Roads Congress, New Delhi, India.

- IS:15462. (2004). Polymer and rubber modified bitumen - Specification. Bueau of Indian Standards, New Delhi.

- IS:15462. (2019). Polymer modified bitumen - Specification. Bureuu of Indian Standards, New Delhi.

- Kandhal, P. S. (2007). “An overview of the viscosity grading system adopted in India for paving bitumen.” Indian Highways, 35(4).

- Kumar, S. A., and Veeraragavan, A. (2008). “Needed characterisation of modified binders in India.” New Building Materials and Construction World, 14(3).

- Lu, X., Uhlback, P., and Soenen, H. (2017). “Investigation of bitumen low temperature properties using a dynamic shear rheometer with 4 mm parallel plates.” International Journal of Pavement Research and Technology, Elsevier B.V., 10(1), 15–22.

- Read, J., and Whiteoak, D. (2003). The Shell Bitumen Handbook, 5th edition. The Shell Bitumen Handbook, Thomas Telford Ltd, UK.