Anirban Sen, Business Line Manager – Underground Division, Epiroc Mining (India), explores the technologies, methods and benefits of modern intelligent face drilling equipment, the reasoning behind selection of ‘smarter’ face drills for Civil Tunnelling and Mining Houses, and why use of intelligent systems to control face drills is finding increasing interest.

We have progressed from flint, to bronze, to iron, to steel, and other materials. At the same time, the methods and technologies used to extract these minerals have also evolved to allow more economical and efficient mining practices. As is often the case, technologies that can be applied to one industry may have their roots in another. In essence, borrowing the technical know-how from the development work in an area for the betterment of another area. For example, there are a lot of technologies and techniques that can be taken from civil tunnelling and applied in other spheres of work with minimal alterations. The computer controlled face drills used in civil tunnelling allow miners to become more efficient, thereby reducing cost of production and putting more money in the pockets of the shareholders.

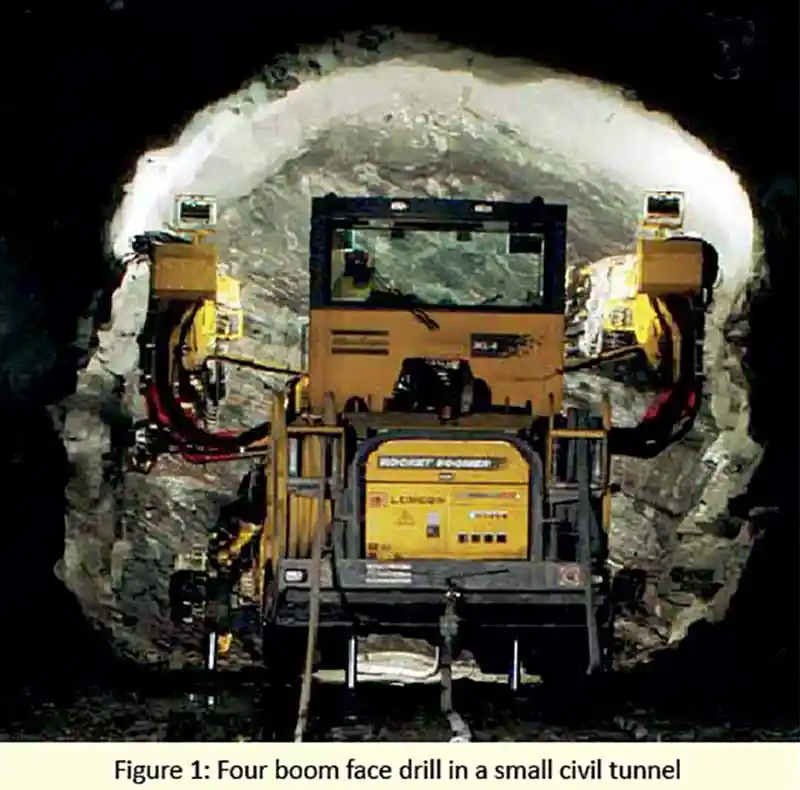

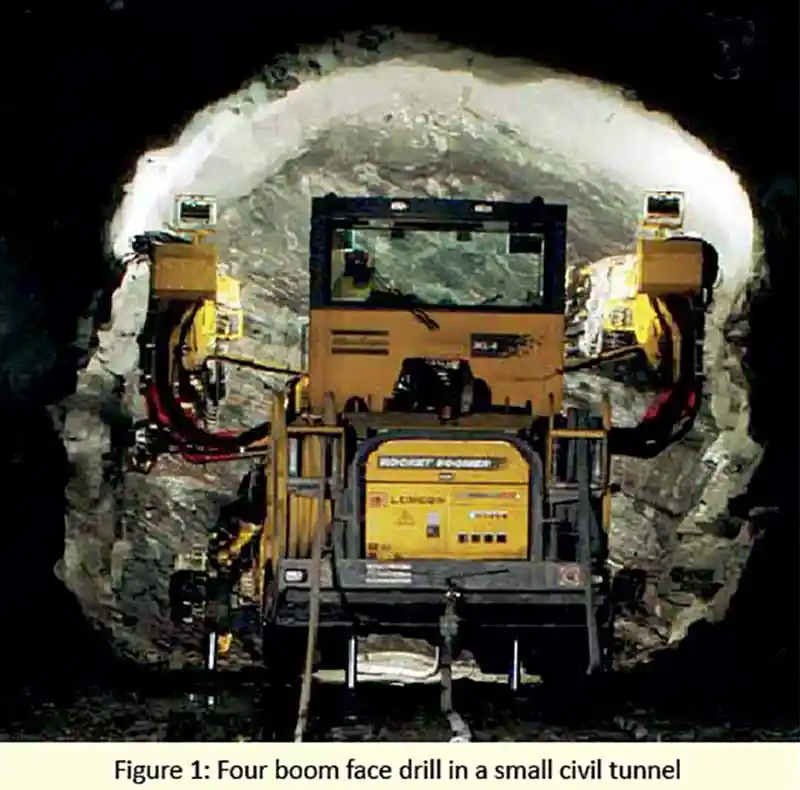

Drill & Blast Method: Civil Tunnelling vs Mine Development

Drill & blast remains a very common method of tunnel excavation in medium to hard rock situations for both civil and underground mining applications. From its early roots in the early 1900’s the method has evolved in both the drilling equipment technology and in the blasting agents used.

This is a premium article available exclusively for our subscribers.

If you are already a subscriber, please

LoginIf not, subscribe now and get access to well researched articles & reports on infrastructure construction, equipment & machinery, innovations & technology, project reports, case studies, and more. All this by simply paying just ₹200/- for a month of complete portal access, or a discounted rate of ₹1000/- for a full year of access.