Trends and Technologies in Material Handling Industry

Importance of Material Handling Industry

Tushar Mehendale,

Managing Director, ElectroMech

Managing Director, ElectroMech

For catering to the requirements of unit load handling, one typically finds equipment like forklifts, cranes, hoists, roller conveyors, walking beam conveyors, pallet trucks, scissor lifts, goods lifts, and transfer trolleys, pick and place robots.

For catering to the requirements of bulk load handling, one typically finds equipment like belt conveyors, screw conveyors, stacker reclaimers, bucket elevators, grabbing cranes, wheel loaders.

Each different type of equipment in turn has a huge variety of different specifications and as such the whole universe of MHE is quite big.

Demand and Growth

India has a few key factors in its favors that will ensure the continuing growth of the material handling sector. The election result is one of them. In addition to this, the resumption of a steady inflow of investments from foreign multinationals, increase in domestic spending on infrastructure construction and power projects, robust domestic growth rates, strong internal fundamentals and a healthy banking system make India an extremely attractive destination for companies that are facing shrinking sales in other economies. Consequently, India is emerging as one of the best global investment options. And as long as industrial investments continue to be made, the demand for capital goods such as material handling systems will grow. Hence, contrary to popular perception, the global slowdown will be good for India.

One of the most important factors that can help one to understand the development of the material handling sector is by mapping its growth over the years. The size of the Indian MHE industry is estimated around Rs 5,000 crore and is likely to grow at 20% year-on-year over the next five years, in keeping with overall economic growth (Source: Project Monitor 2009). The reason of this growth is drivers—domestic production and foreign trade. Since MHE is closely associated to the country’s imports and exports, its importance to the logistics industry cannot be denied. The report titled World Material Handling Products states that the global demand for material handling products will grow 5 percent annually by 2012 (Source: Freedonia Market Research ACM). It also predicts that growth in the nondurable goods sectors will outpace the large durable goods manufacturing market, and that advanced/ automated products will grow the fastest.

The demand for material handling equipment will continue to grow in: Manufacturing, Logistics, warehousing, General Engineering related to power plants, Metro or irrigation projects and Government sectors like the railways, ordnance factories, armed forces etc. The Indian material handling equipments industry is now poised for a healthy growth.

Trends in MH Industry

The general trend in the MHE industry is towards increasing automation, enhancing productivity and maximizing safety. A lot of innovations are also taking place to develop equipment specifically to one sub-sector of a particular industry and in turn provide a highly customized solution for a very niche requirement.Technologies have progressed rapidly in the past decade. We see superior control methodologies in terms of accuracy, repeatability and efficiency in the market today. Advanced mechanisms and use of electrical sensors, invertors help ensure safety while using these equipments.

As the production processes gets more evolved and with increased exposure of the Indian industrialists to modern manufacturing techniques and global best practices, there is a definite shift towards adoption of newer technologies for industries as well. For example, the industrial cranes industry in India was traditionally dominated by the old 1960s type Russian crane design. However, companies like ElectroMech are at the forefront in convincing people to dump the old technology and move towards the more modern and contemporary crane technology that is prevalent in Western Europe.

With the fast changing business landscapes clients today demand an MHE model that yields a quicker ROI than ever before. Even companies who are replacing or upgrading their existing range of material handling equipment are inclined towards technology that is efficient, faster, safer and cost –effective.

Technology Solutions

In the past, many considered material handling control systems simply a collection of mechanical and control devices that cause objects to be moved from one place to another within the walls of a manufacturing, warehouse or distribution facility.In days of yore, there was hardly any effort to connect material handling equipment units to the other departments or functions in the factory. This was essentially true for the manufacturing industry. Particularly in manufacturing, the material handling controls were not connected to the company’s upper-level software. Thus this entire system required to facilitate smoother flow of goods, majorly lacked consistency and organized connectivity in its approach.

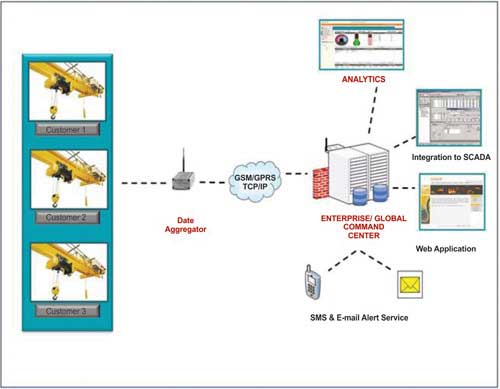

However with the advent of superior technology and introduction of high-level softwares such as warehouse management system (WMS), manufacturing execution system (MES) the isolated connectivity of MHE is being replaced by comprehensive interfaces. The more-advanced material handling control systems that provide a single point interface with upper-level software are often called warehouse control systems (WCS). Such latest equipment control softwares are making the automation of MHE a breeze.

Another trend in material handling equipment is the growing popularity of voice-recognition systems. People understand the benefits of using a hands-free communication system and being trained to use this technology for minimal error in operations thereby leading to increased productivity. The voice-recognition system aides direct communication with a computer via a headset. While receiving instructions from the computer, operators are able to keep both hands on the equipment which results in a safer working environment.

Recession was a good teacher and has surfaced the criticality of supply chain visibility. Manufacturing houses have realized that cost reduction can be completely achieved only through a holistic approach. Today companies seek technologies that connect with each other. This offers greater visibility, information sharing and performance throughout the supply chain. This is relevant to industries such as retail and pharmaceuticals where the uptime and responsiveness are critical on the shop floor and warehouses. A real-time status check of material in the shop floor also facilitates smart decision making. Adjustments to schedules, manpower and other resources can be made proactively instead of reactively. For us the best take-away is the fact that these systems can be linked into existing technology.

Apart from advances in automation and controls, a lot of development is also being made in ensuring that the products are environmentally-friendly without sacrificing the cost competitiveness. An example is the distinct shift taking place in several industries in eliminating hydraulics and moving towards purely electrical drives. Hydraulic systems by their virtue are quite inefficient in converting energy into useful work. Typically in a hydraulic system an electrical motor first drives a power pack which then compresses hydraulic fluid which in turn rotates hydraulic motors or presses hydraulic cylinders. These systems were preferred due to their inherent compactness and smooth operational features. However, with the advent of sophisticated electrical controls through various sensors and inverter drives, it is possible to achieve the same level of control and smoothness of operations using electrical drives. The basic advantage of electrical drives is the higher efficiency in converting energy into useful work by directly driving the motors or actuators and the elimination of hydraulic fluids. The environment thus benefits due to better usage of valuable energy as well as due to elimination of problems caused by ruptured hydraulic hoses and the subsequent oil spillages. An example of this trend can be effectively seen in case of Marine Deck Cranes which are definitely moving away from the age old hydraulic technology and embracing electrical drives.

Conclusion

As outlined before the trends and technological innovations are all pointing towards equipment which will enhance productivity multifold on the shop floor and in warehouses and at the same time enhance safety of the people working with it and do so in an environmentally-friendly manner. The MHE industry will soon see a lot of exciting new developments in the near future and as always will help its customers to maximize their return on the investments.

NBM&CW October 2010